The beneficiation method of tungsten polymetallic ore

A technology of polymetallic ore and ore dressing method, which is applied in flotation, solid separation, etc., and can solve the problem of low recovery rate of scheelite

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

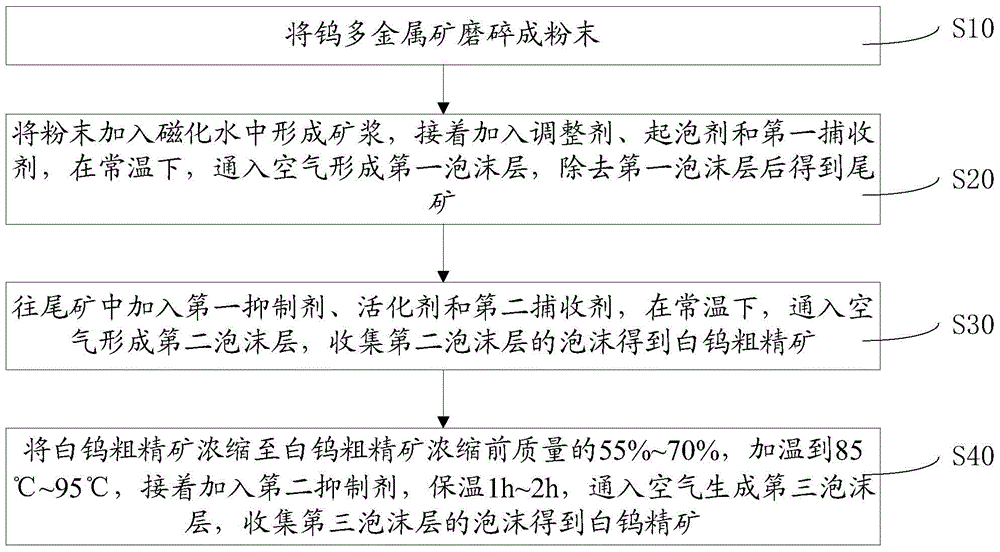

Method used

Image

Examples

Embodiment 1

[0051] The tungsten polymetallic ore with a tungsten grade of 0.15% is ground into powder. Among the powders, the weight of the powder with particle size less than 0.074mm accounts for 75% of the total weight of all powders.

[0052] Add the powder into the magnetized water to form a slurry, then add 2000g / t of sodium carbonate, 30g / t of No. 2 oil and 40g / t of xanthate, stir for 3min, and at room temperature, the flow rate is 0.6m 3 / (m 2 .min) air forms the first foam layer, and tailings are obtained after removing the first foam layer. Then collect the removed foam of the first foam layer to obtain sulfide ore. Magnetized water is water that has been magnetized for 50 minutes under the condition of a magnetic field strength of 400kA / m.

[0053] Add 4000g / t of water glass, 600g / t of lead nitrate and 300g / t of oxidized paraffin wax soap to the tailings. 3 / (m 2 .min) of air to form the second foam layer, and collect the foam in the second foam layer to obtain scheelite co...

Embodiment 2

[0056] The tungsten polymetallic ore with a tungsten grade of 0.31% is ground into powder. Among the powders, the weight of powders with particle size less than 0.074mm accounts for 85% of the total weight of all powders.

[0057] Add the powder into magnetized water to form a slurry, then add 4000g / t of sodium carbonate, 15g / t of No. 2 oil and 30g / t of ethyl disulfide, stir for 5min, and at room temperature, the flow rate of the feed is 1.2m 3 / (m 2 .min) air forms the first foam layer, and tailings are obtained after removing the first foam layer. Then the foam obtained by removing the first foam layer is collected to obtain sulfide ore. Magnetized water is water that has been magnetized for 30 minutes under the condition of a magnetic field strength of 600kA / m.

[0058] Add a mixture of 4000g / t water glass and 1000g / t aluminum sulfate, 400g / t lead nitrate and 500g / t dihydrocarbyl dithiourea to the tailings. 3 / (m 2 .min) of air to form the second foam layer, and collec...

Embodiment 3

[0061] The tungsten polymetallic ore with a tungsten grade of 0.4% is ground into powder. Among the powders, the weight of the powder with particle size less than 0.074mm accounts for 80% of the total weight of all powders.

[0062] Add the powder into magnetized water to form a slurry, then add 3000g / t of sodium carbonate, 20g / t of No. 2 oil and 20g / t of kerosene, stir for 4min, and at room temperature, the flow rate is 0.8m 3 / (m 2 .min) air forms the first foam layer, and tailings are obtained after removing the first foam layer. Then collect the removed foam of the first foam layer to obtain sulfide ore. Magnetized water is water that has been magnetized for 60 minutes under the condition of a magnetic field strength of 700kA / m.

[0063] Add 6000g / t of water glass, 500g / t of lead nitrate and 500g / t of oxidized paraffin wax soap to the tailings, and at normal temperature, the flow rate is 0.8m 3 / (m 2 .min) of air to form the second foam layer, and collect the foam in ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com