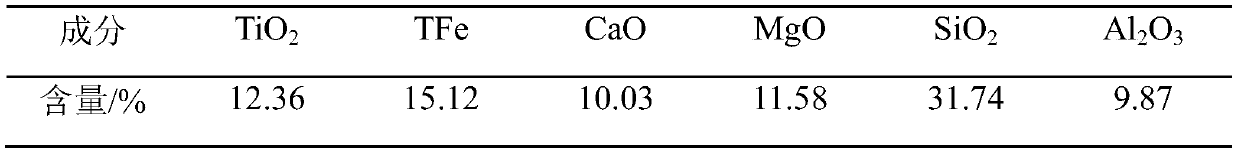

A method of microwave pretreatment to improve ilmenite flotation efficiency

A microwave treatment and pretreatment technology, applied in flotation, solid separation, etc., can solve the problems of small difference in buoyancy between ilmenite and gangue components, large amount of beneficiation agents, and increased beneficiation costs, etc., to achieve increased flotation Sex difference, lower flotation cost, high grade effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] (1) Grinding: first grind the desulfurized flotation raw ore until the particle size of -0.074mm accounts for 55%, and then dry it naturally in the air for 20 hours.

[0019] (2) Segmented microwave pretreatment: place the finely ground ilmenite in the microwave equipment, and the thickness of the material is 1 cm. Microwave pretreatment includes two stages; the first stage of microwave pretreatment conditions: intermittent microwave treatment, microwave density 2kW / kg, processing time 3min, maintaining the temperature of the microwave oven cavity at 150°C; second stage microwave pretreatment conditions: continuous Microwave treatment, microwave density 15kW / kg, treatment time 2min. After the heating is over, the ore is quickly taken out and naturally cooled to room temperature in the air.

[0020] (3) Flotation: Flotation is carried out on the ilmenite after microwave treatment. The flotation process includes a roughing and a beneficiation, the pH of the pulp is 5, an...

Embodiment 2

[0022] (1) Grinding: first grind the desulfurized flotation raw ore until the particle size of -0.074mm accounts for 65%, and then dry it naturally in the air for 30 hours.

[0023] (2) Segmented microwave pretreatment: place the finely ground ilmenite in the microwave equipment, and the thickness of the material is 2.5 cm. Microwave pretreatment includes two stages; the first stage of microwave pretreatment conditions: intermittent microwave treatment, microwave density 3kW / kg, processing time 4min, maintaining the temperature of the microwave oven cavity at 120°C; second stage microwave pretreatment conditions: continuous Microwave treatment, microwave density 20kW / kg, treatment time 2.5min. After the heating is over, the ore is quickly taken out and naturally cooled to room temperature in the air.

[0024] (3) Flotation: Flotation is carried out on the ilmenite after microwave treatment. The flotation process includes a roughing and a beneficiation. The pH of the pulp is 6...

Embodiment 3

[0026] (1) Grinding: Grind the desulfurized flotation raw ore until the particle size of -0.074mm accounts for 60%, and then dry it naturally in the air for 24 hours.

[0027] (2) Segmented microwave pretreatment: place the finely ground ilmenite in the microwave equipment, and the thickness of the material is 2cm. Microwave pretreatment includes two stages; the first microwave pretreatment conditions: use intermittent microwave treatment, microwave density 1.5kW / kg, processing time 3.5min, maintain the microwave oven cavity temperature at 180 ℃; the second microwave pretreatment conditions: Continuous microwave treatment is adopted, the microwave density is 25kW / kg, and the treatment time is 1.5min. After the heating is over, the ore is quickly taken out and naturally cooled to room temperature in the air.

[0028] (3) Flotation: Carry out flotation on ilmenite after microwave treatment. The flotation process includes a roughing and a beneficiation, the pH of the pulp is 5.5...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com