Novel mica inhibitor and preparation method and use method thereof

A technology of inhibitor and mica, which is applied in the direction of sulfonate preparation, solid separation, organic chemistry, etc., can solve the problem of high loss rate of mica

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] The preparation of embodiment 1 mica inhibitor

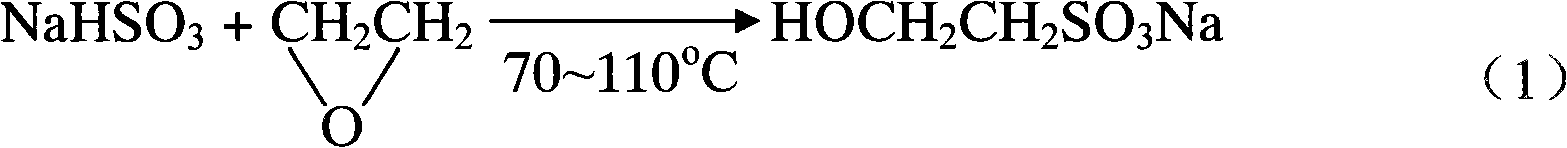

[0023] The first step: generate sodium isethionate with sodium bisulfite and ethylene oxide under heating conditions, and the chemical reaction is as follows (1);

[0024]

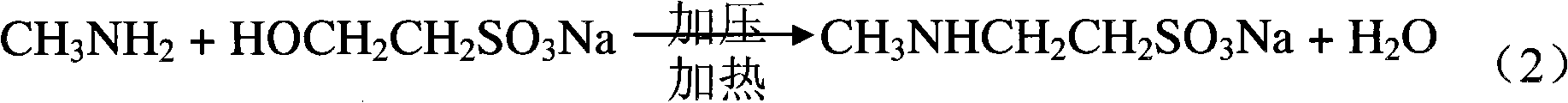

[0025] Second step: generate sodium methyl taurate with methylamine and sodium isethionate under conditions of heating and pressurization, and the chemical reaction is as follows (2);

[0026]

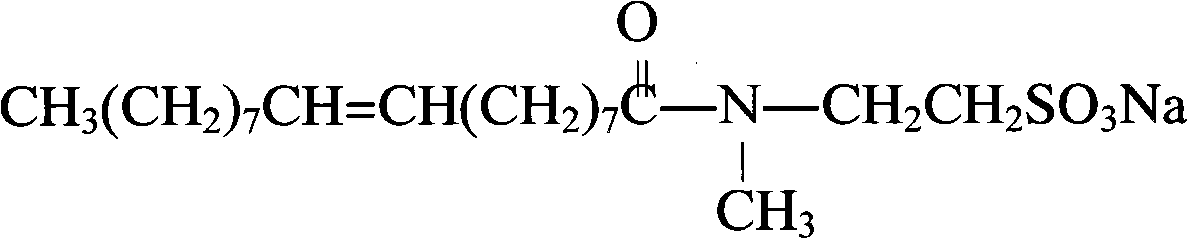

[0027] The 3rd step: carry out condensation reaction with oleoyl chloride and sodium methyl taurate to generate N methyl heptadecenyl amido ethyl sulfonate sodium, chemical reaction is as follows formula (3);

[0028]

Embodiment 2

[0029] The using method of embodiment 2 novel mica inhibitors

[0030] (1) the equipment of mica inhibitor aqueous solution: be made into the aqueous solution that weight concentration is 5% with mica inhibitor N methyl heptadecenamido ethyl sulfonate sodium;

[0031] (2) Ore treatment: crush or grind mica concentrate ore to 1mm;

[0032] (3) De-ironing operation before mica flotation: add 100g of mica inhibitor aqueous solution prepared by step (1) per ton of ore and fully stir for 10 minutes, then add 100g of carboxylic acid collectors and fully stir for 10 minutes, carry out Iron removal operation before mica flotation.

Embodiment 3

[0034] (1) the equipment of mica inhibitor aqueous solution: be made into the aqueous solution that weight concentration is 10% with mica inhibitor N methyl heptadecenamidoethyl sulfonate sodium;

[0035] (2) Ore treatment: crush or grind the raw ore containing mica to less than 2mm;

[0036] (3) Deironing operation before mica flotation: add 500g of mica inhibitor aqueous solution prepared by step (1) per ton of ore and stir for 5 minutes, then add 800g of carboxylic acid collector and stir for 5 to 10 minutes , to remove iron before mica flotation.

[0037] The invention is applicable to mines producing mica concentrates, and the mica inhibitor of the invention is added in the iron removal operation before mica flotation, so as to inhibit mica from floating up and reduce the loss rate of mica. Improve the recovery efficiency of mica.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com