Lead zinc ore flotation depressing agent composition and lead zinc ore flotation method

A technology of inhibitor and composition, which is applied in the field of lead-zinc flotation and lead-zinc ore flotation inhibitor composition, can solve the problems that the production index cannot meet the requirements, the effect is not obvious, and the cyanide is highly toxic. No time-limited source of raw materials, good zinc suppression effect, and enhanced hydrophilicity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

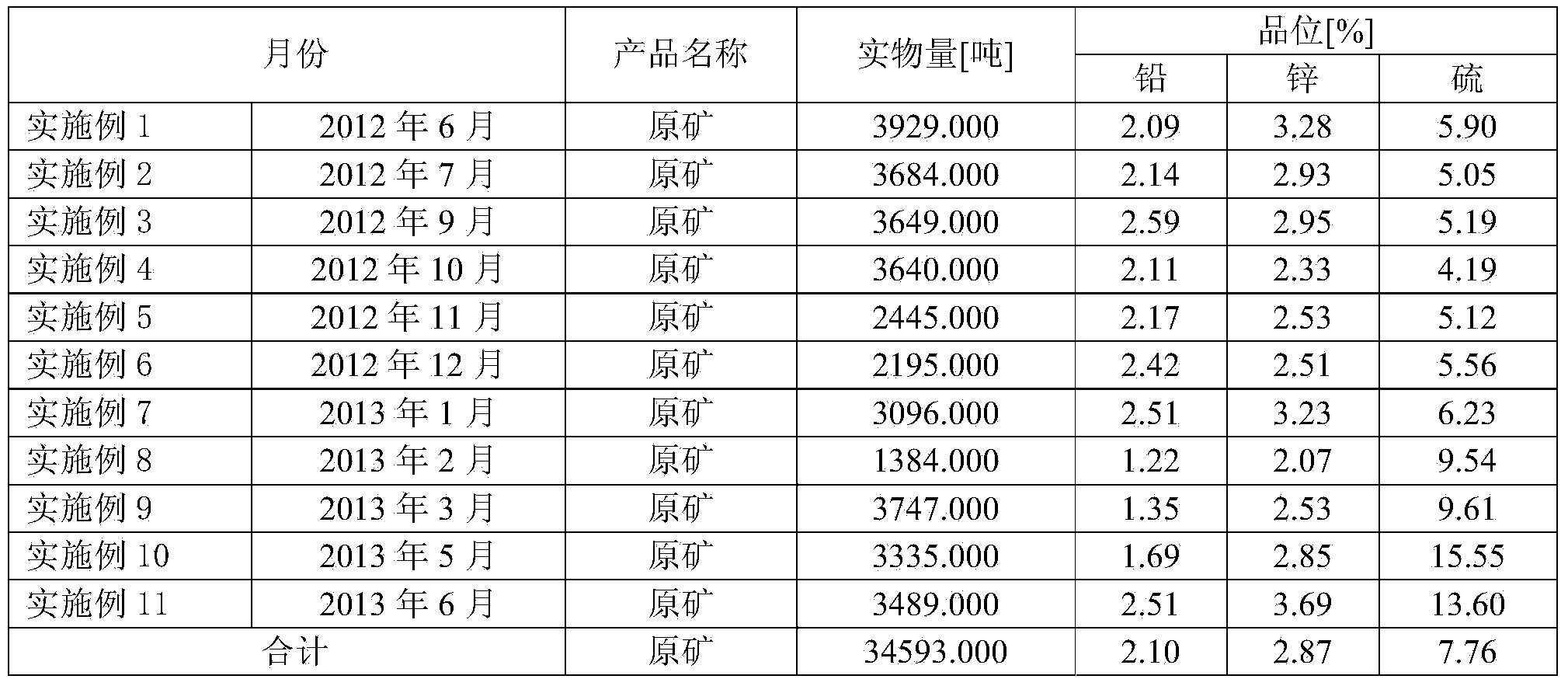

Embodiment 1~11

[0030] The technical process of lead area flotation is as follows:

[0031] Add the finely ground raw ore to the lead mixing tank, then adjust the pH to 9-12, add the lead collector 25# black medicine, dixanthate and dixanthate, and sodium sulfide, an inhibitor composition that inhibits the flotation of zinc, Zinc sulfate and sodium metabisulfite are flotation to obtain lead concentrate.

[0032] Add water to the lead concentrate to adjust the slurry, then adjust the pH to 9-12, add zinc inhibitor zinc sulfate and lime to carry out flotation, and obtain the selected lead concentrate.

[0033] Adding water to the selected lead concentrate to adjust the slurry, then adjusting the pH to 9-12, adding zinc sulfate, sodium metabisulfite and sodium sulfide as an inhibitor composition for inhibiting the flotation of zinc, and mixing them for flotation to obtain re-selected lead concentrate.

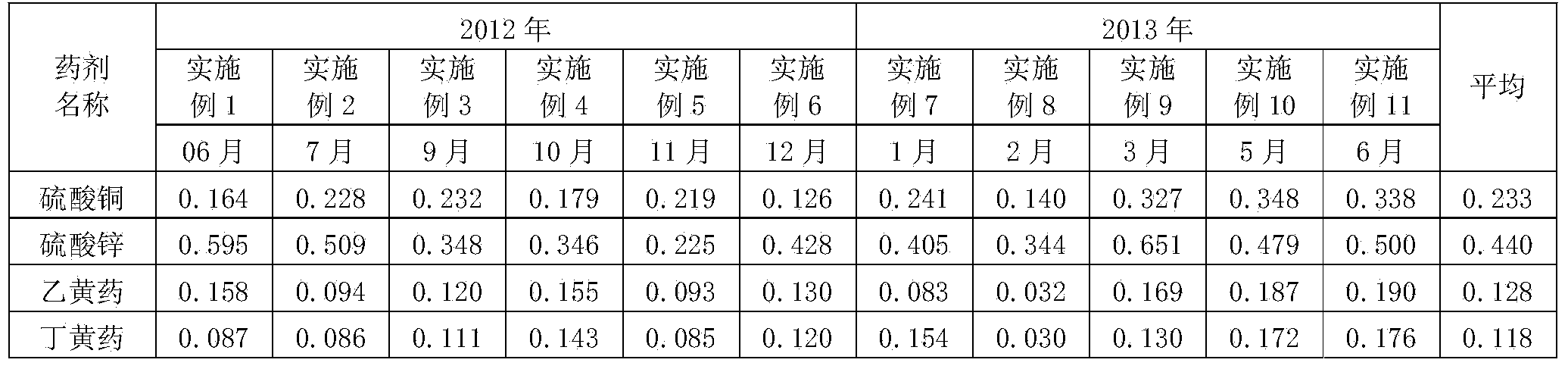

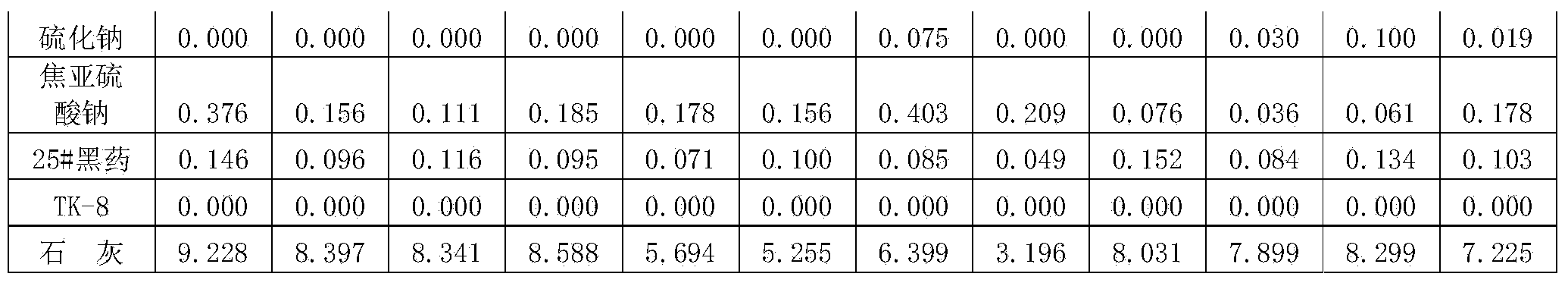

[0034] The consumption of each medicament required for flotation of the present invention is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com