Color resist composition and a color filter using the same

A technology for resists and compositions, applied in the field of color resist compositions, can solve the problems of undisclosed special effects of dialkylamides, color resist floating, peeling defects, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

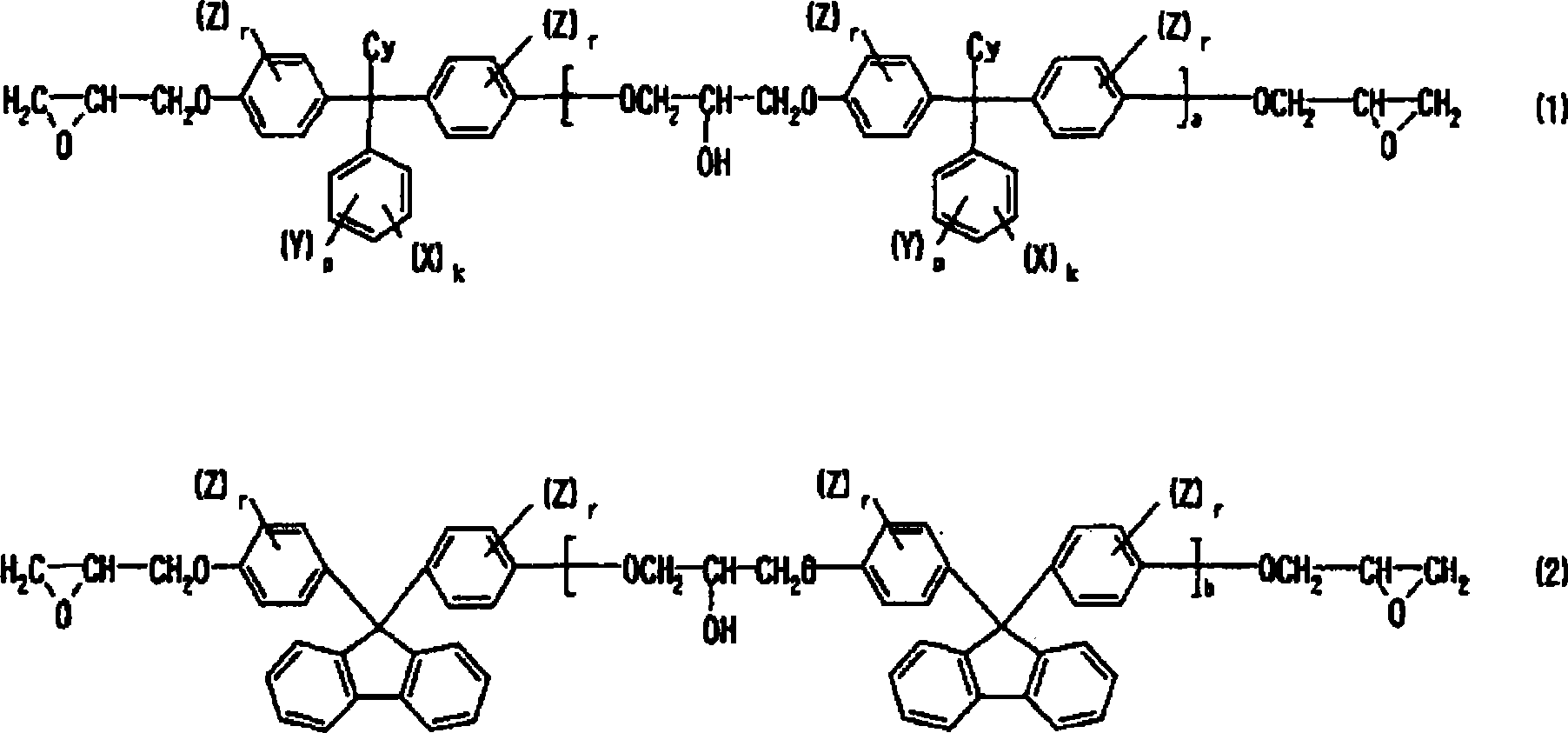

Method used

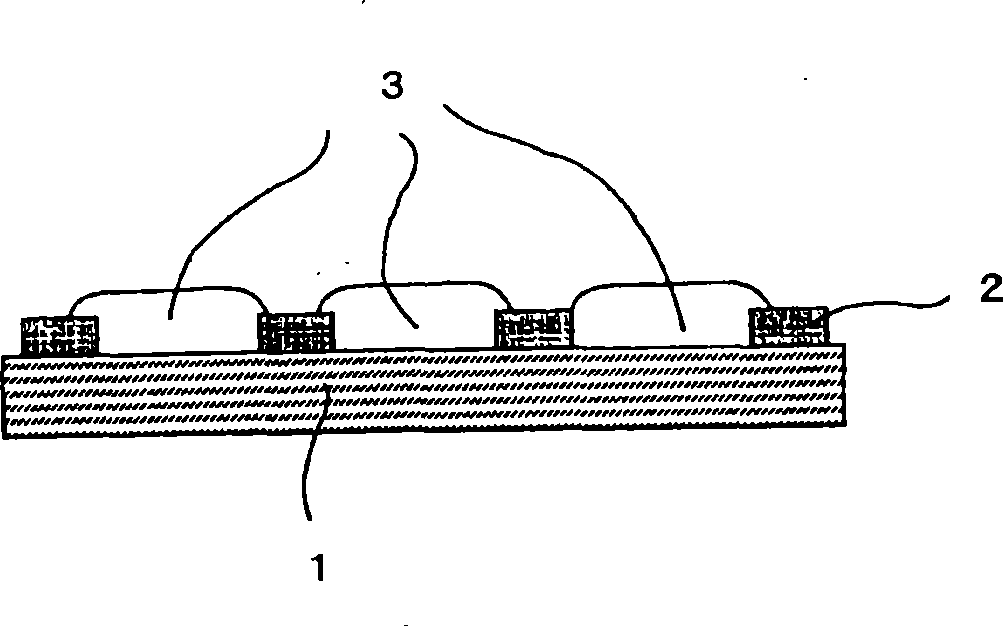

Image

Examples

manufacture example 1

[0100] [Production Example 1] Production of Alkali Developable Resin Composition 1

[0101] Production of 1,1-bis(4'-hydroxyphenyl)-1-(1"-biphenyl)-1-cyclohexylmethane

[0102] 70.5 g of biphenylcyclohexyl ketone, 200.7 g of phenol, and 10.15 g of thioacetic acid were charged, and 40.0 g of trifluoromethanesulfonic acid was added dropwise at 18° C. over 20 minutes. After reacting at 17-19° C. for 18 hours, 500 g of water was added to stop the reaction, 500 g of toluene was added, and the organic layer was washed with water until the pH was 3-4 to extract the organic layer. Toluene, water and excess phenol were distilled off. Toluene was added to the residue, and the precipitated solid was collected by filtration and dispersed and washed with toluene to obtain 59.2 g of pale yellow crystals (51% yield). The melting point of the pale yellow crystals was 239.5°C, and it was confirmed that the pale yellow crystals were the target substance.

[0103] Production of 1,1-bis(4'-ep...

Embodiment 1

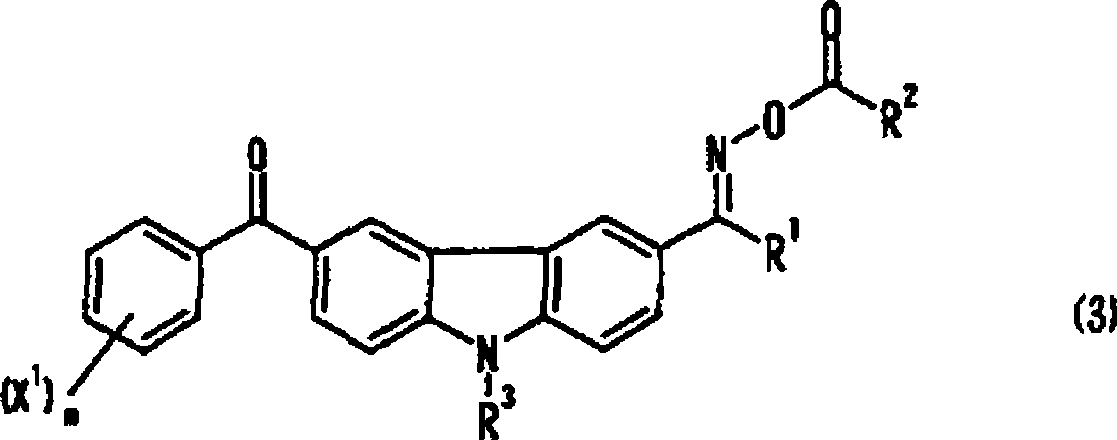

[0107] [Example 1] Preparation of color resist composition

[0108] Carbon black paste ABK-81C (manufactured by Mikuni Color Co., Ltd.) with a carbon black content of 20% by mass, a dispersant content of 5.7% by mass, and PGMAC as a dispersion medium, and PGMAC of the alkali-developable resin composition 1 obtained in Production Example 1 above Solution, 1-[9-ethyl-6-(2-methylbenzoyl)-9H-carbazol-3-yl]-1-(O-acetyloxime) ethyl ketone and organic solvent according to the following [formulation Ratio] mixed to obtain color resist compositions No.1 to No.14 of the present invention.

[0109] [matching ratio]

[0110] (A) Pigment: 7 parts by mass of carbon black

[0111] (B) Alkali-developable resin composition (solid content conversion) 3.5 mass parts

[0112] (C) 1.5 parts by mass of photopolymerization initiator

[0113] (D) Organic solvent Composition described in the following [Table 1] 86 mass

[0114] [Table 1]

[0115] The composition of (D) organic solvent of embodim...

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com