Patents

Literature

124results about "Mechanical surface treatment" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

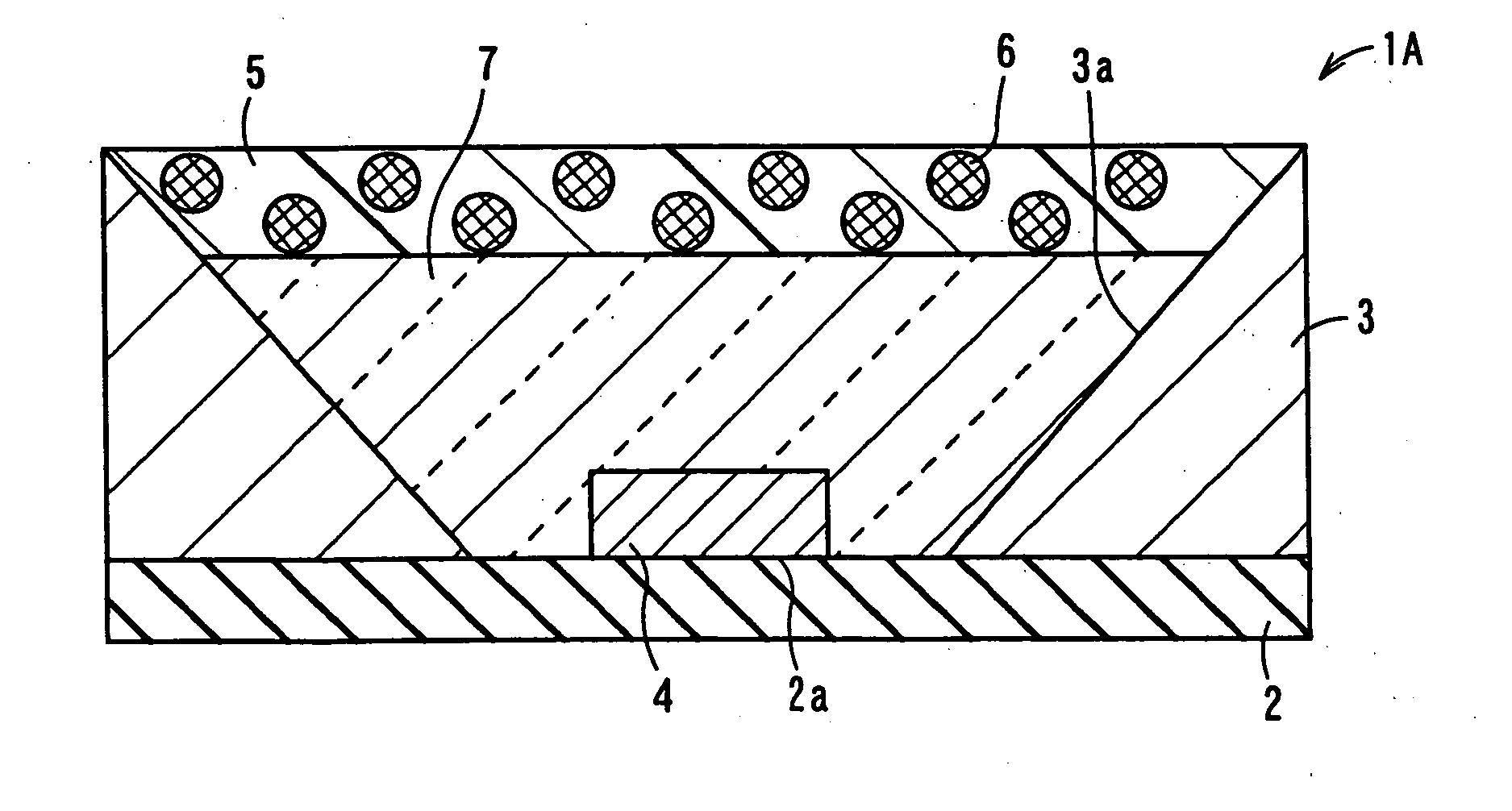

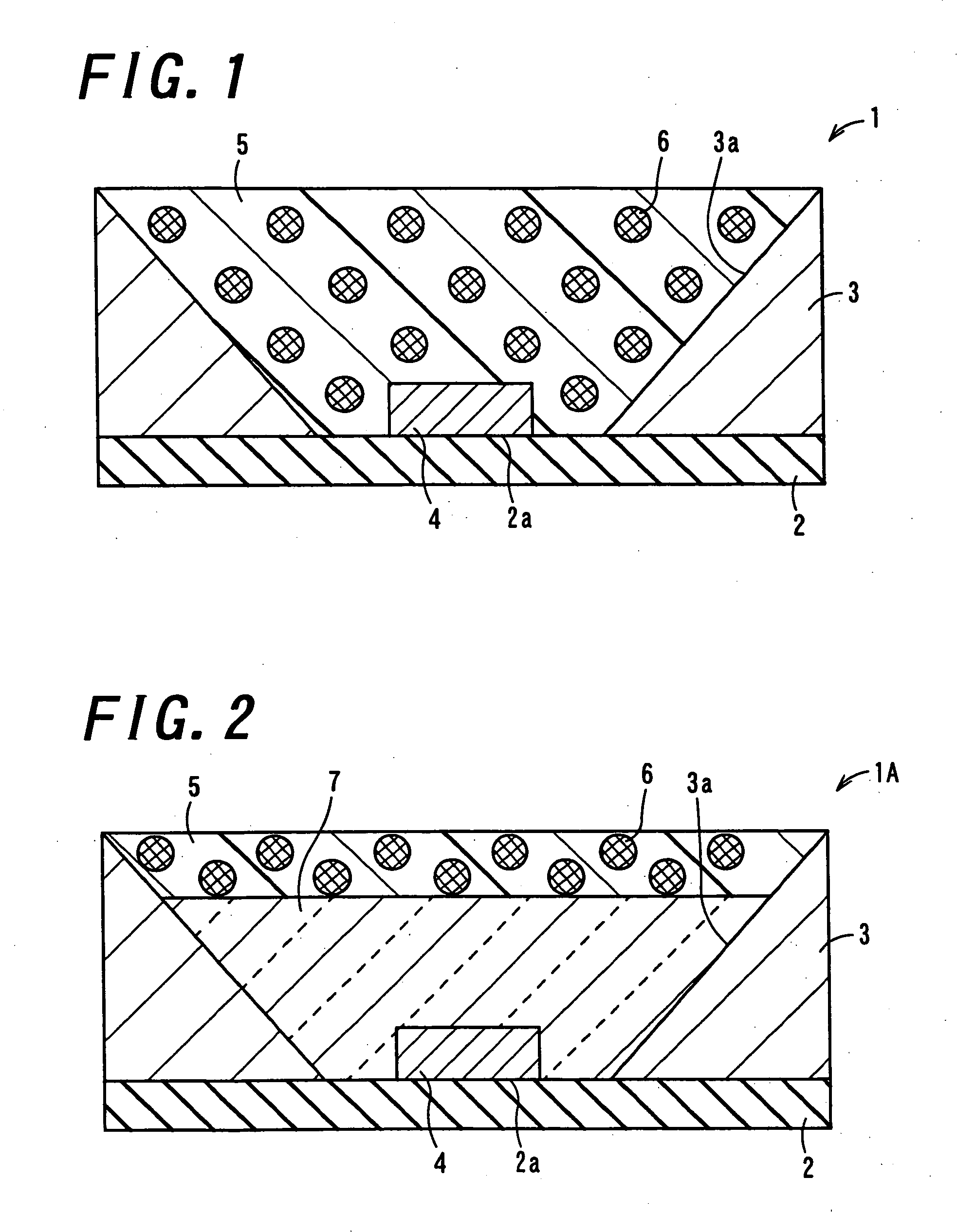

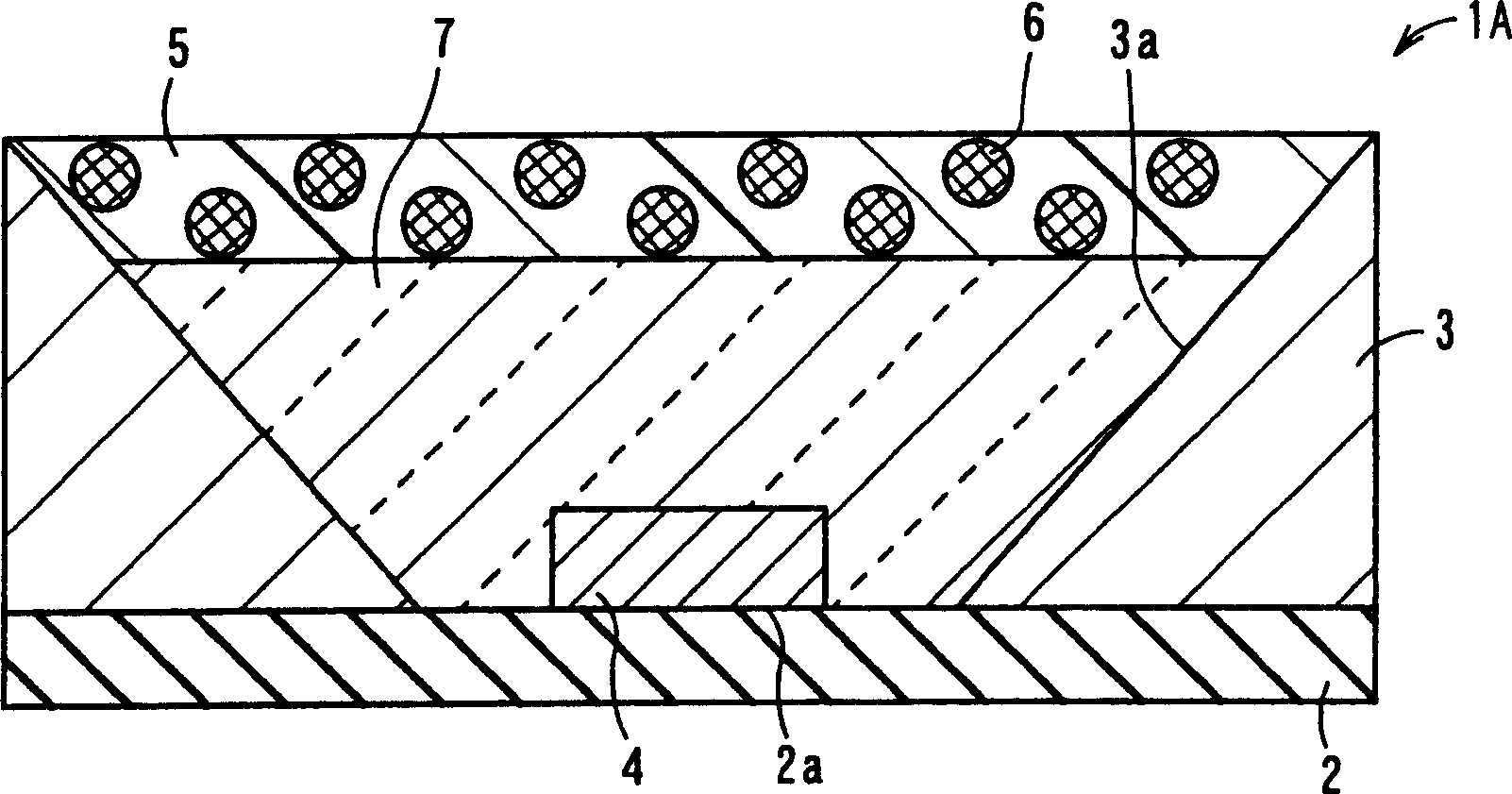

Light-emitting apparatus and illuminating apparatus

InactiveUS20050211991A1Reduce light intensitySignificant rateOther plywood/veneer working apparatusMechanical surface treatmentColor temperatureEngineering

There is provided a light-emitting apparatus with favorable radiation light intensity, which is excellent in light extraction efficiency, color temperature and color rendering property. The light-emitting apparatus includes a light-emitting element, a base body having, on its top surface, a placement portion for emplacing thereon the light-emitting element, a frame body attached to the top surface of the base body so as to surround the placement portion, a light transmitting member disposed inside the frame body so as to cover the light-emitting element, and phosphors contained in the light transmitting member, which performs wavelength conversion on the light emitted from the light-emitting element. The light transmitting member has a pre-cured viscosity ranging from 0.4 to 50 Pa.s.

Owner:KYOCERA CORP

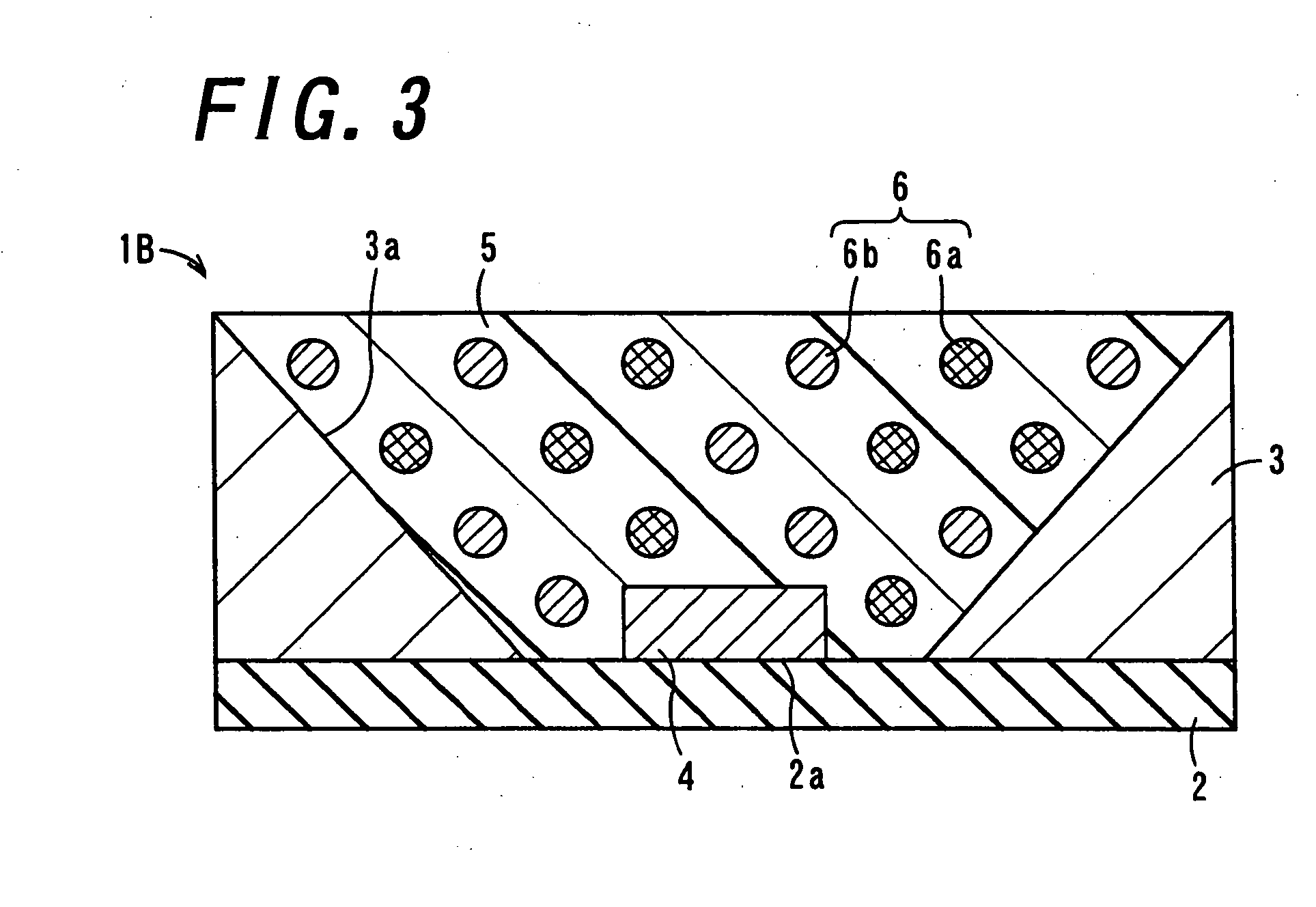

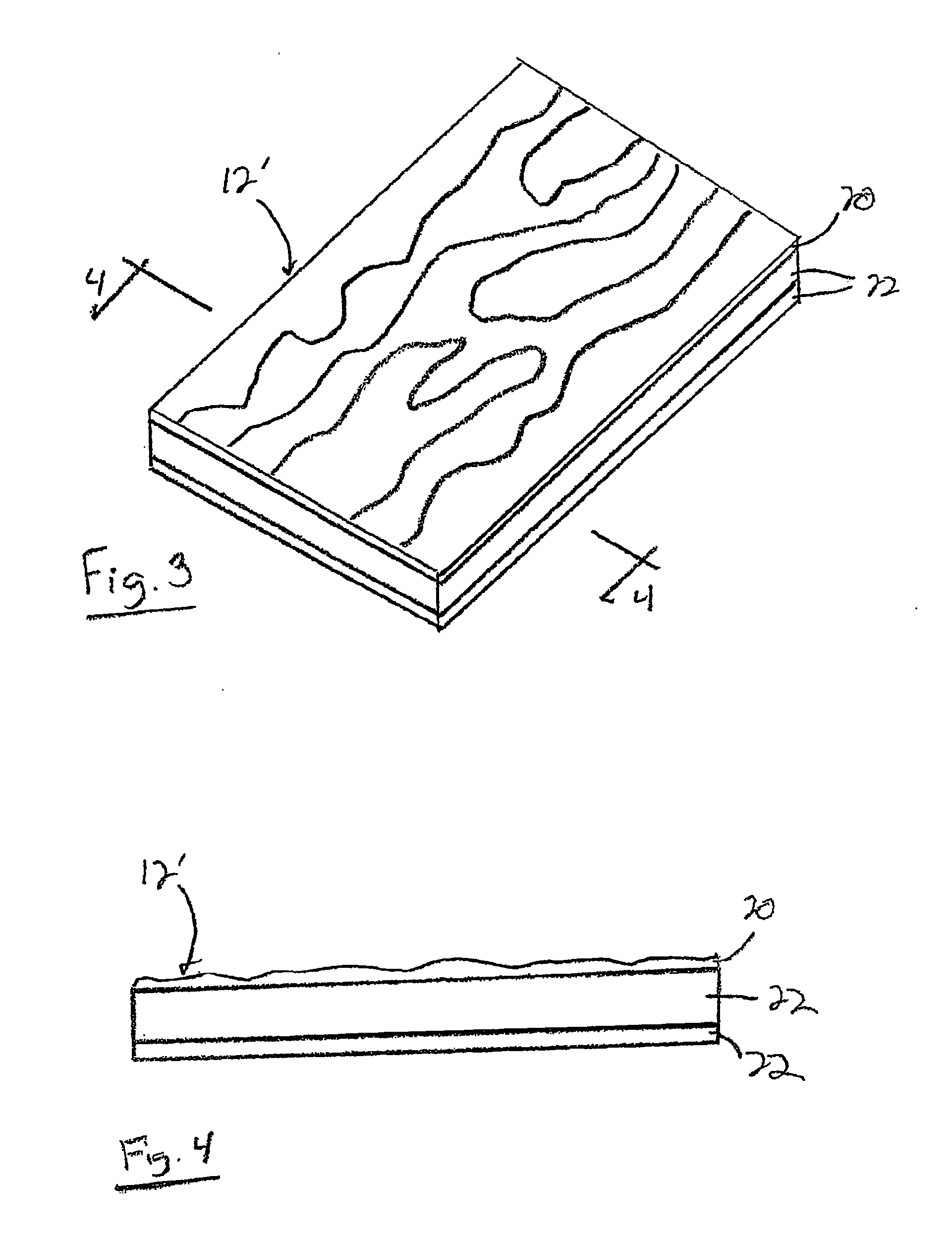

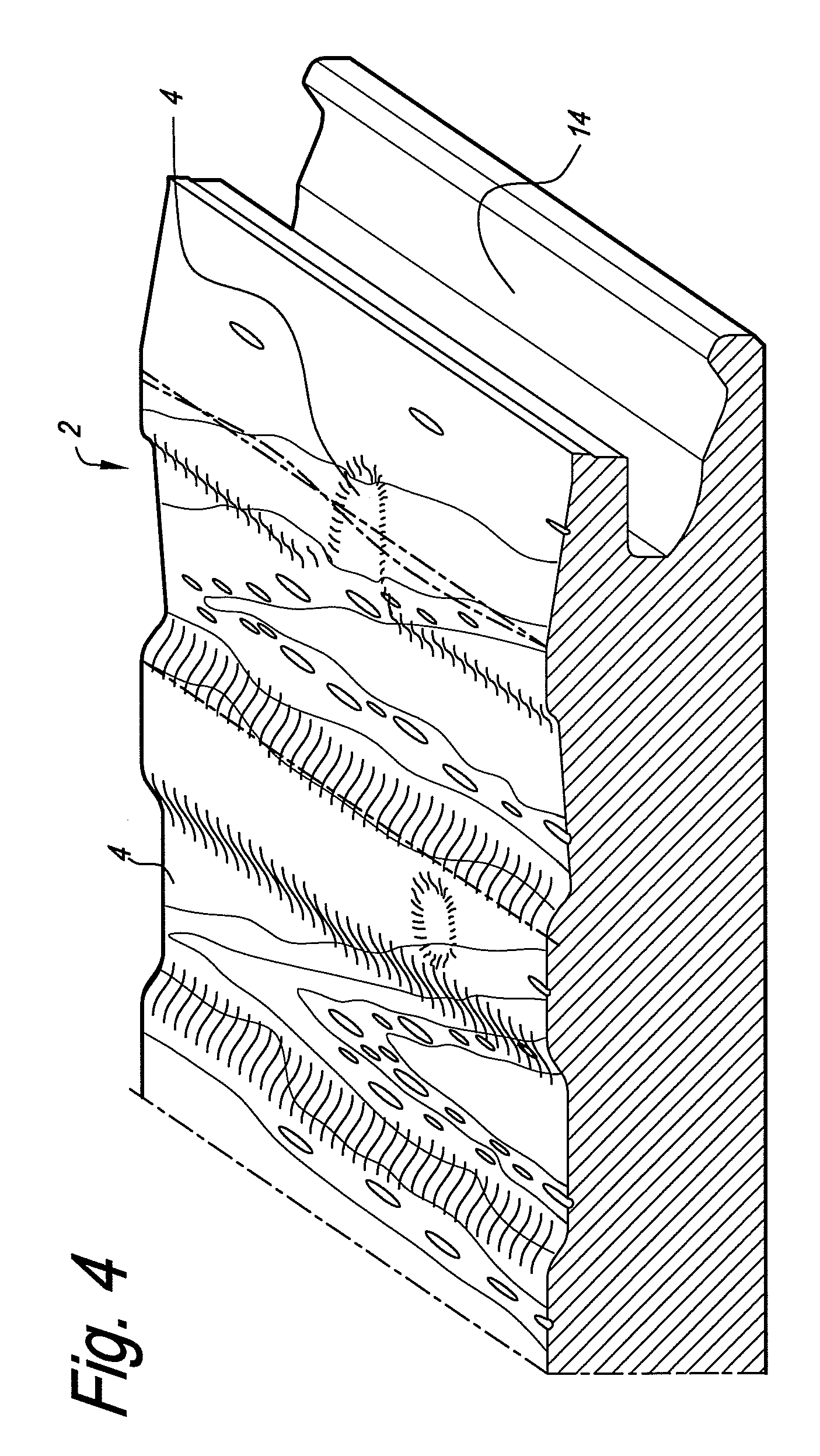

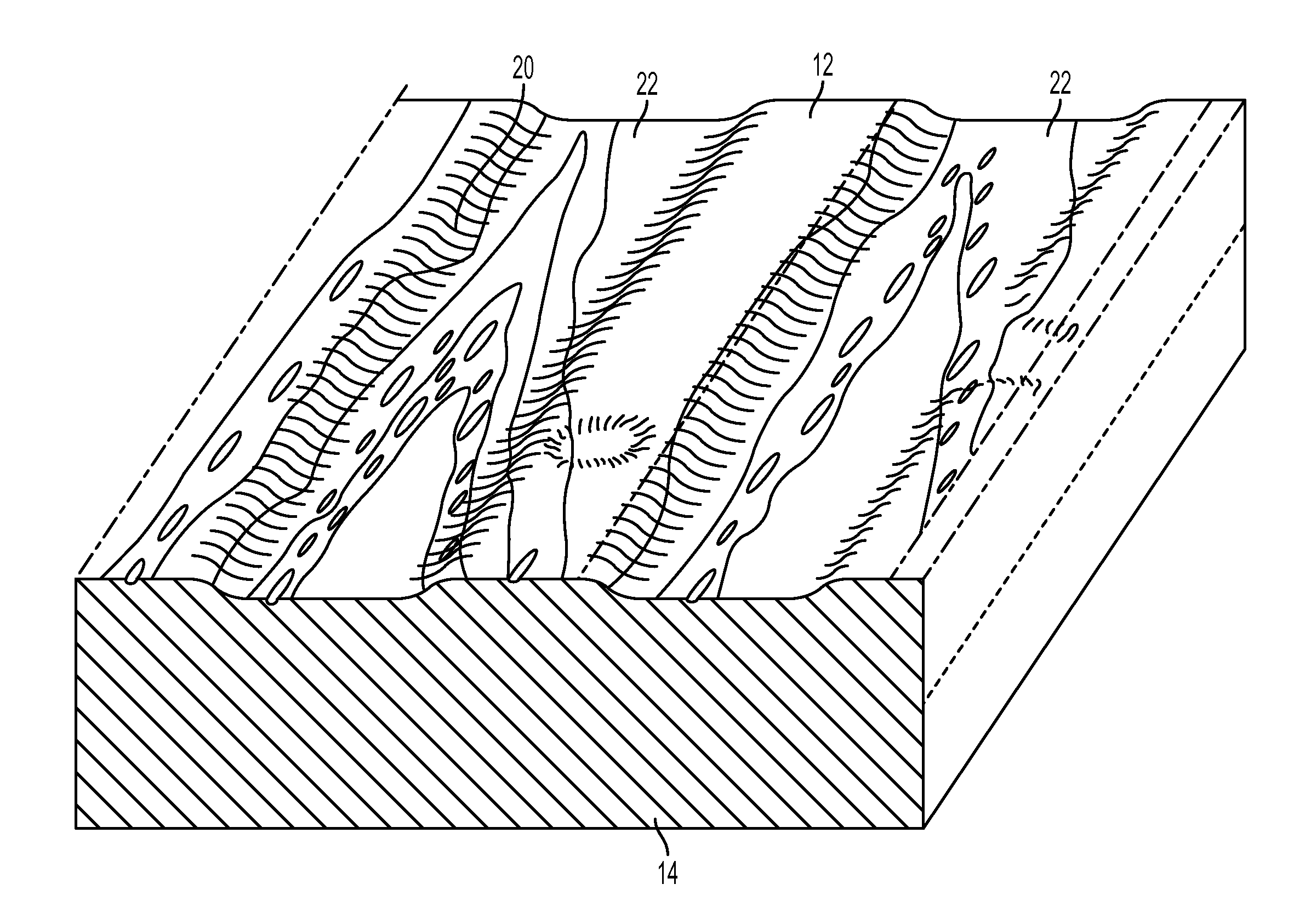

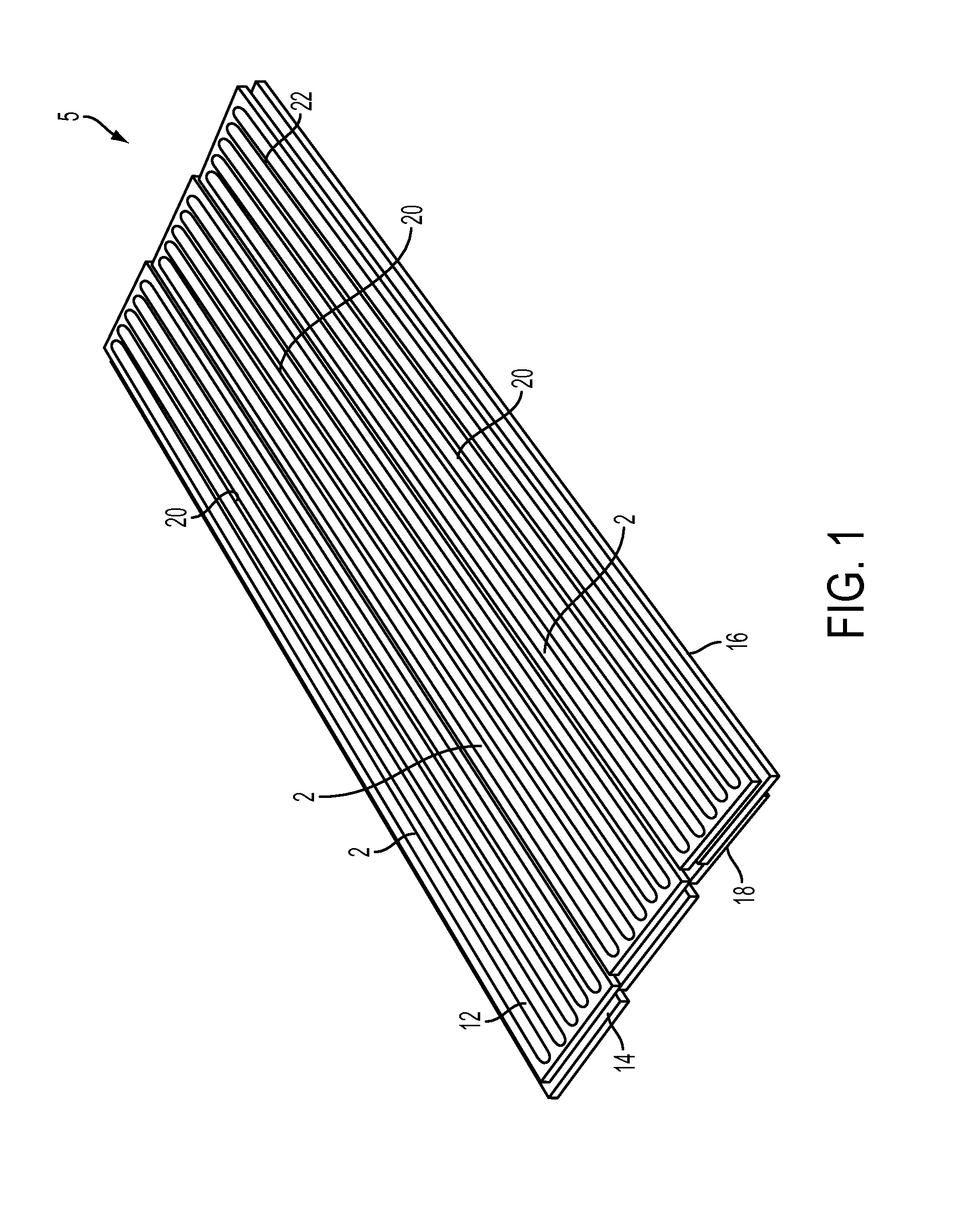

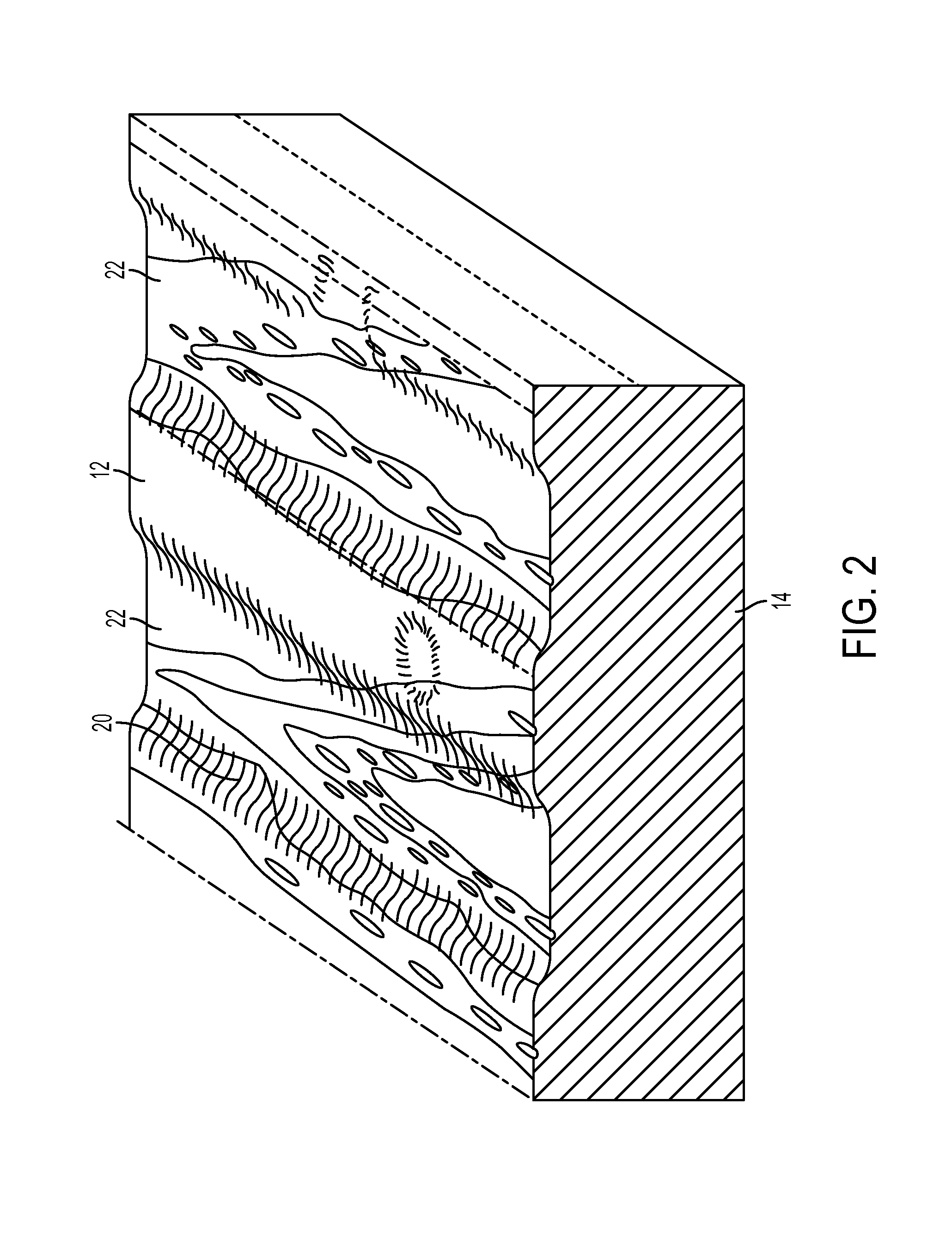

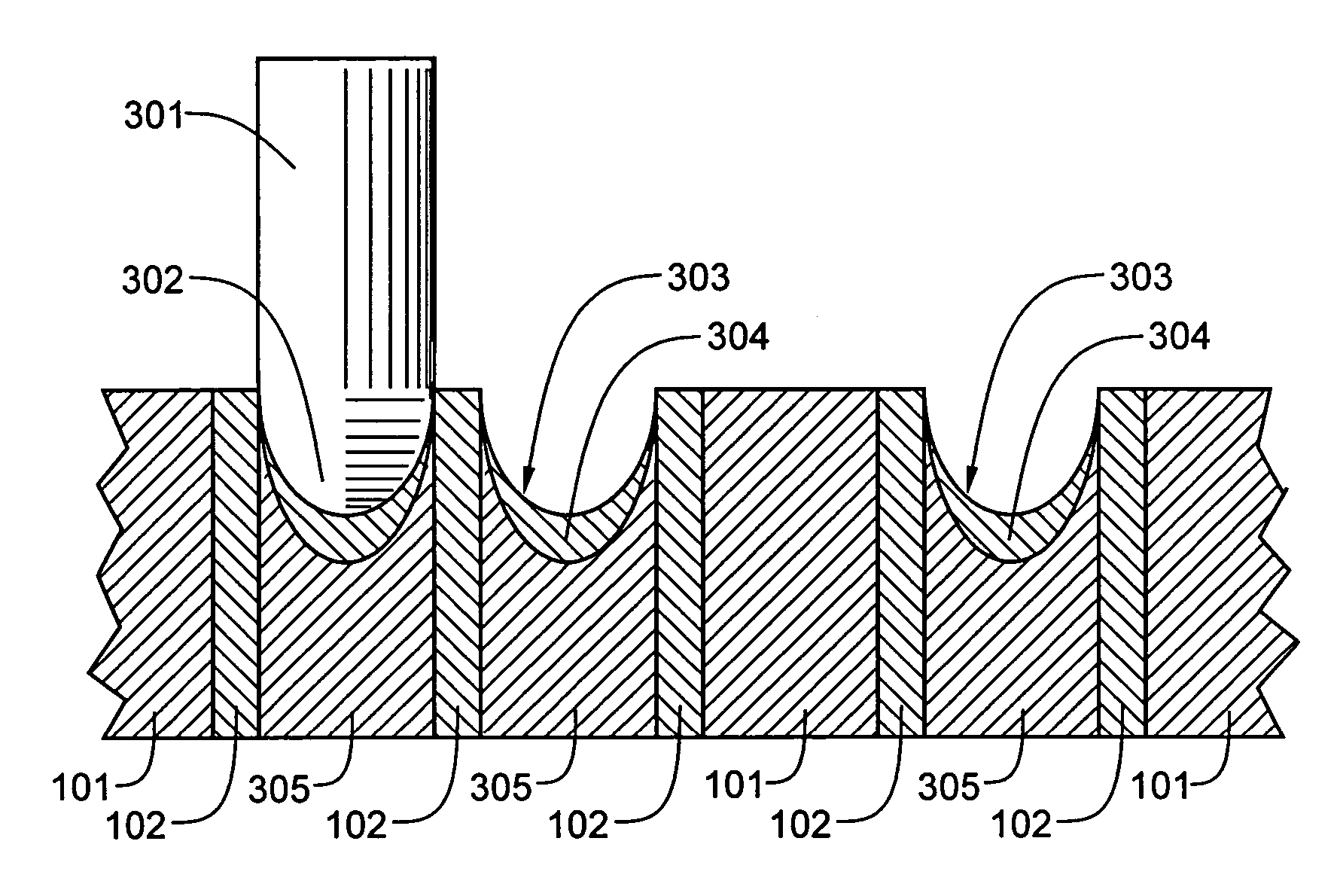

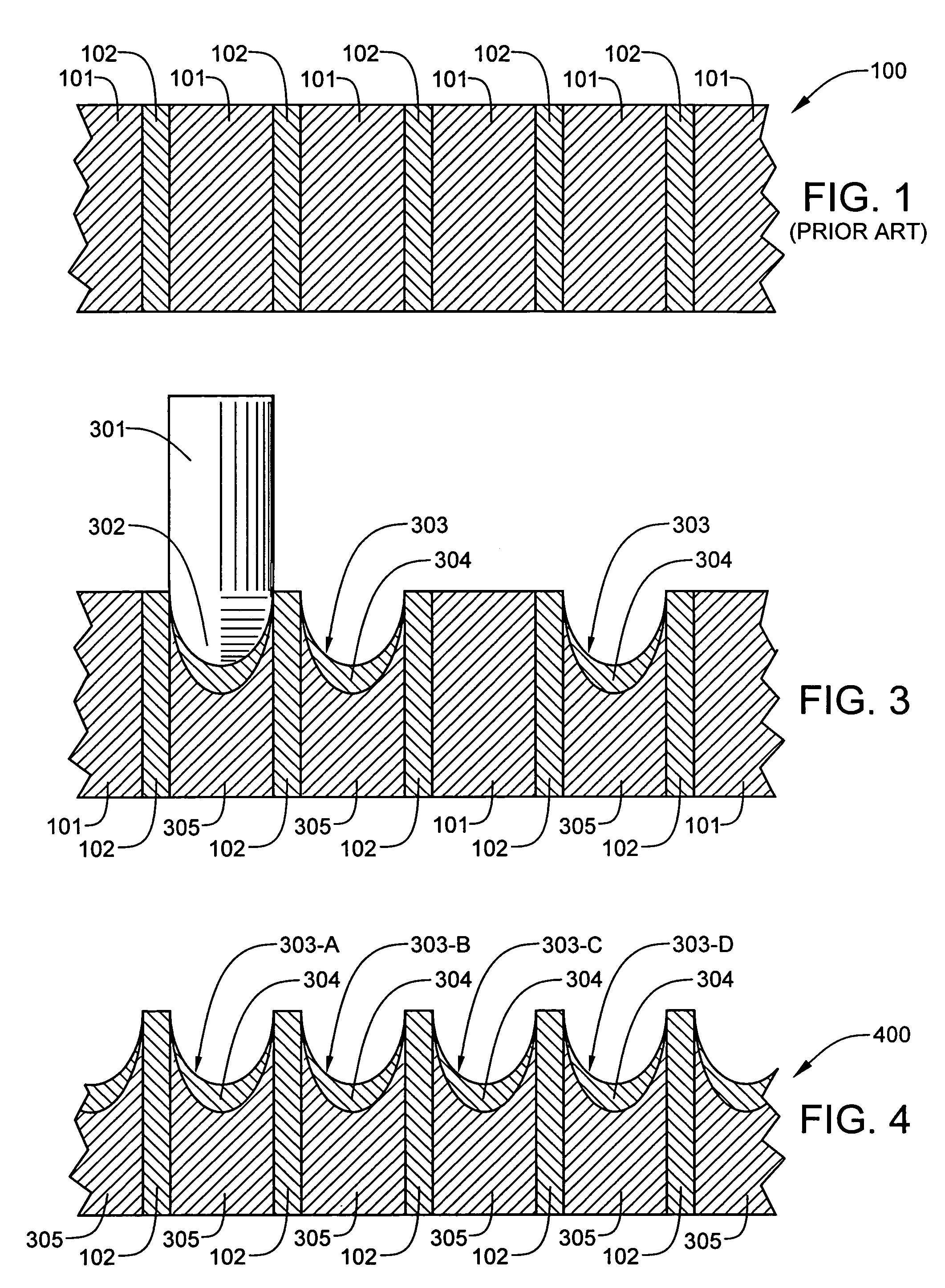

Manufactured Wood Boards Having a Distressed Appearance

InactiveUS20100304089A1Natural appearanceWood compressionMechanical surface treatmentPulp and paper industryWood plank

The present invention is a wood-based product utilized in forming various structures and other items. The product includes a piece of wood disposed on the exposed surface of the product that has been embossed with a desired pattern to give the product a desired appearance, such as a distressed or weathered appearance. The wood piece used in the product is embossed at a sufficient temperature and pressure to create the desired appearance in the wood piece. Additionally the product can be formed completely or only partially from the wood piece.

Owner:SPECTRUM TOWERS

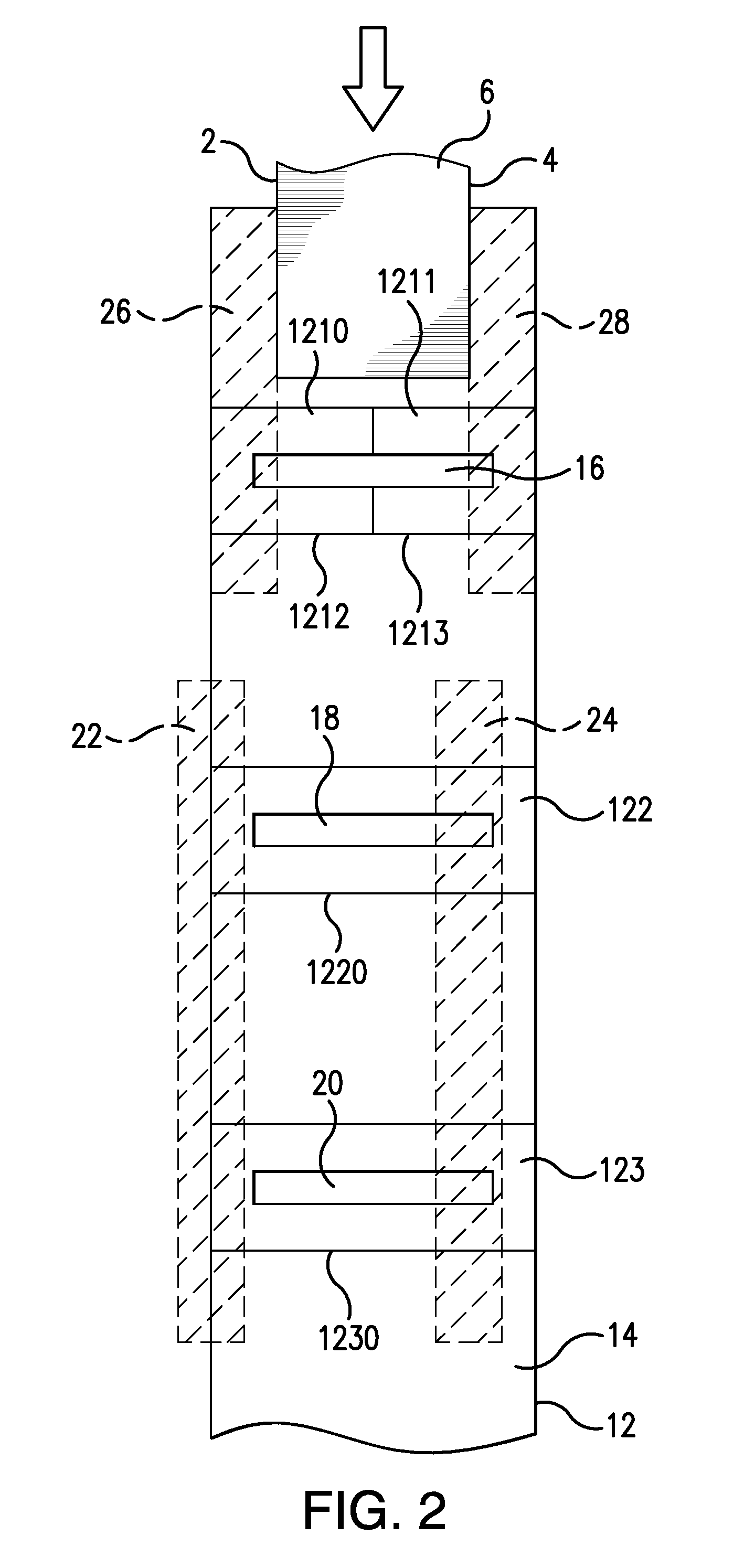

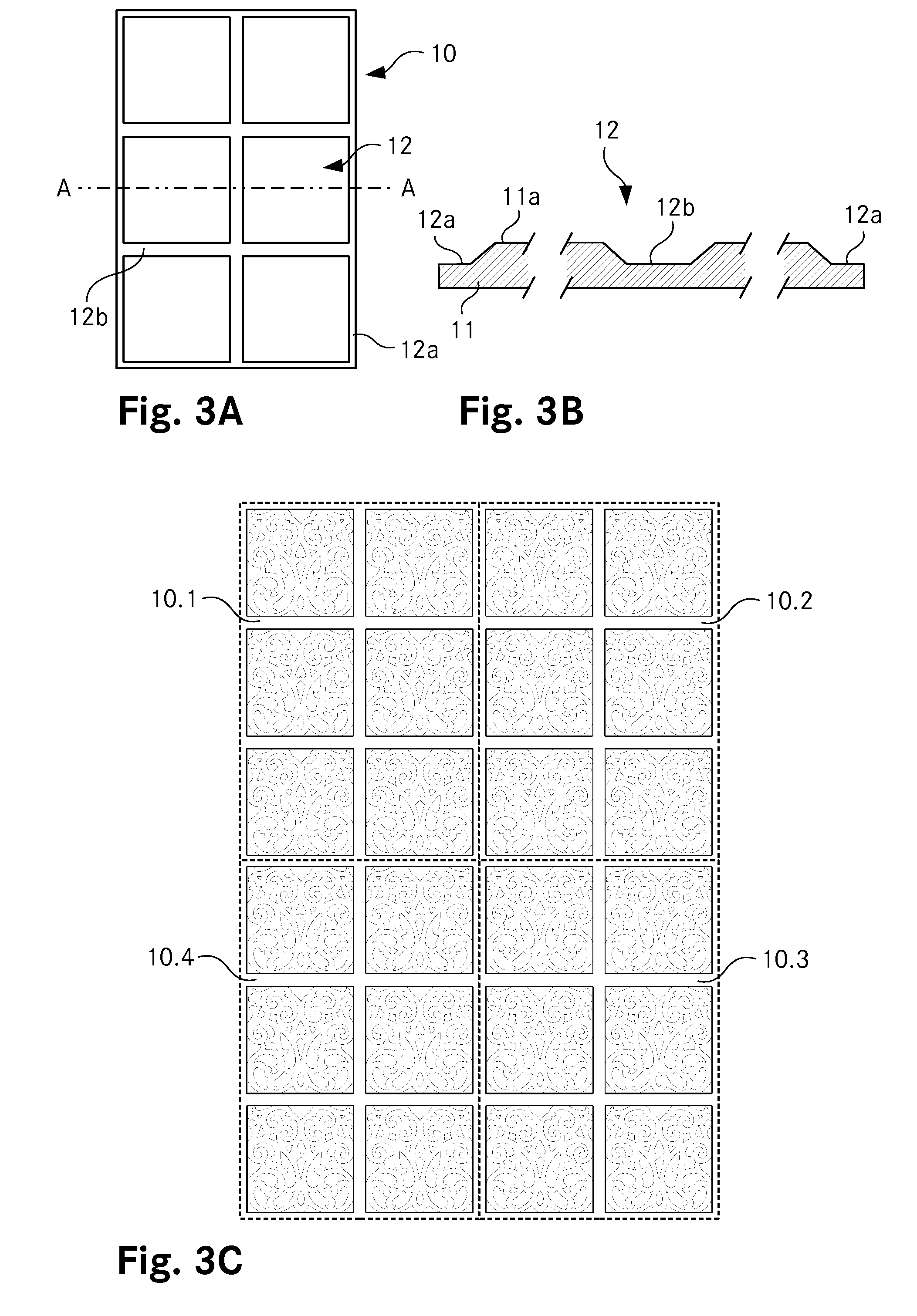

Panel and method for producing a panel

InactiveUS20070275169A1Easy to produceCovering/liningsMechanical surface treatmentEngineeringSynthetic resin

A method for producing a panel, in particular a wall panel, ceiling panel or flooring panel of split woodbased-material boards with lateral edges. The boards have a pattern on the top and / or underside. The pattern is coated with a heat-activatable synthetic resin or a radiation-curable varnish. The woodbased-material board, pattern and synthetic resin coat or varnish coat is pressed one under the other by an engraved roller and at least one counterpressure roller. The method includes heating the engraved roller to a temperature of 200-500° C., inserting the panel between the engraved roller and a counterpressure roller, and embossing a structure with a depth of up to 500 μm into the heat-activatable synthetic resin coat on the top of the panel with a pressure of 585-1475 N / cm2 (60-150 kg / cm2).

Owner:FLOORING TECH

Light-emitting apparatus and illuminating apparatus

InactiveCN1674317AIncrease the intensity of radiant lightReduced light extraction efficiencyOther plywood/veneer working apparatusMechanical surface treatmentPhosphorLight emitting device

There is provided a light-emitting apparatus with favorable radiation light intensity, which is excellent in light extraction efficiency, color temperature and color rendering property. The light-emitting apparatus includes a light-emitting element, a base body having, on its top surface, a placement portion for emplacing thereon the light-emitting element, a frame body attached to the top surface of the base body so as to surround the placement portion, a light transmitting member disposed inside the frame body so as to cover the light-emitting element, and phosphors contained in the light transmitting member, which performs wavelength conversion on the light emitted from the light-emitting element. The light transmitting member has a pre-cured viscosity ranging from 0.4 to 50 Pa.s.

Owner:KYOCERA CORP

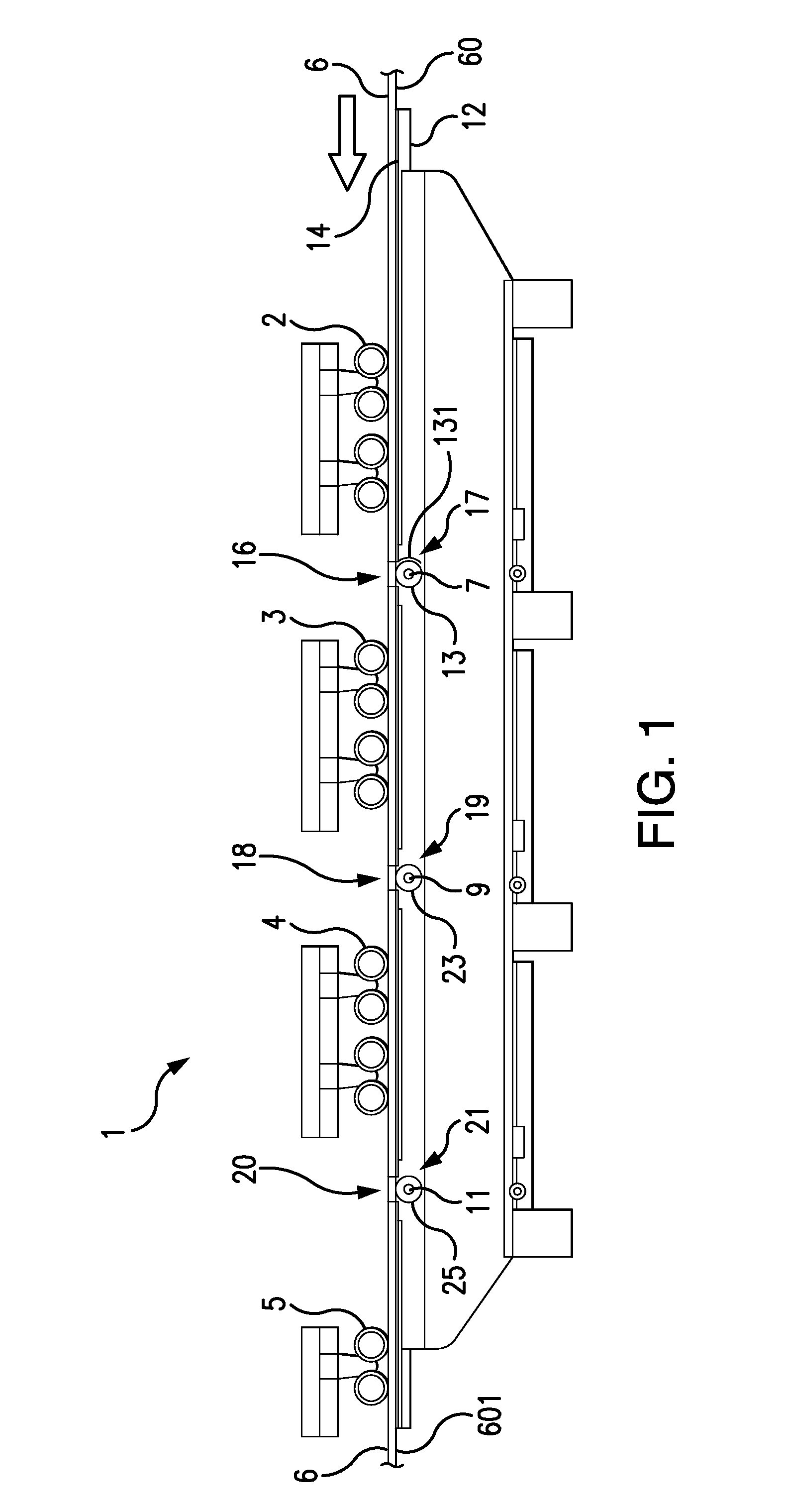

Automated floor board texturing cell and method

Owner:ALADDIN MFG CORP

Process for treating wood with a mixture of garnet particles and glass beads

Owner:LOVELAND SCREW MACHINE

Rough hew planer

Owner:JANZEN MARTIN

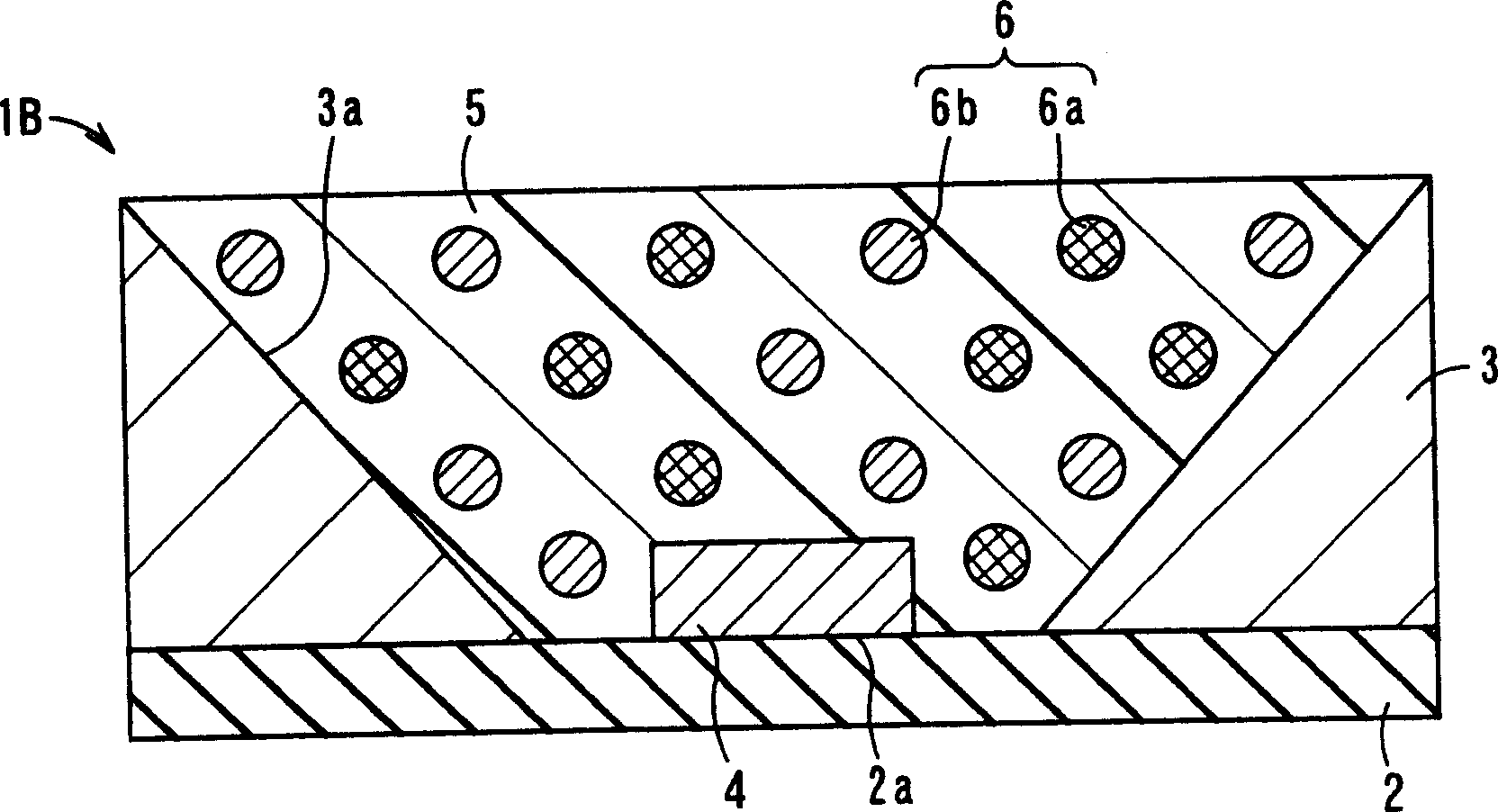

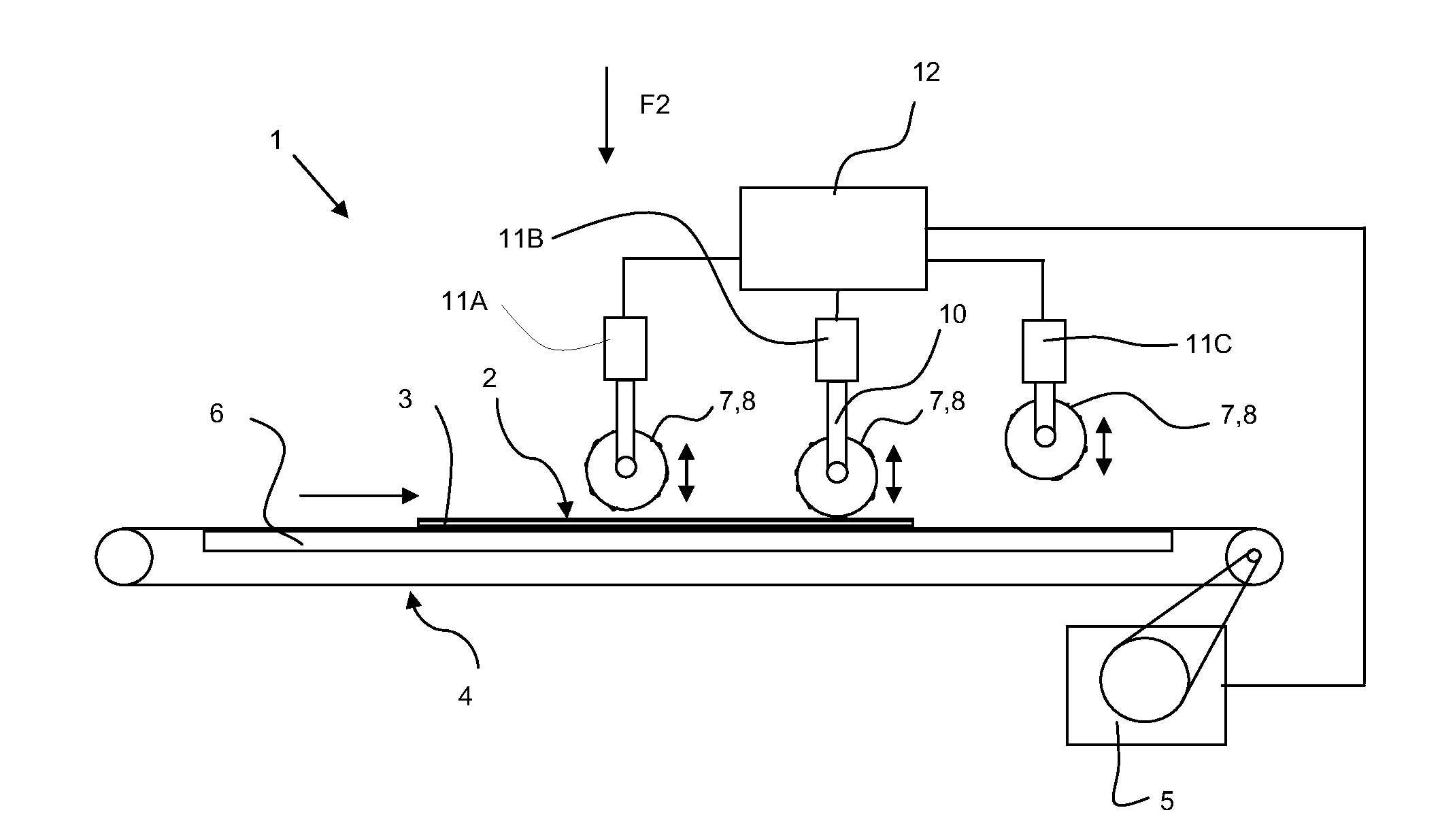

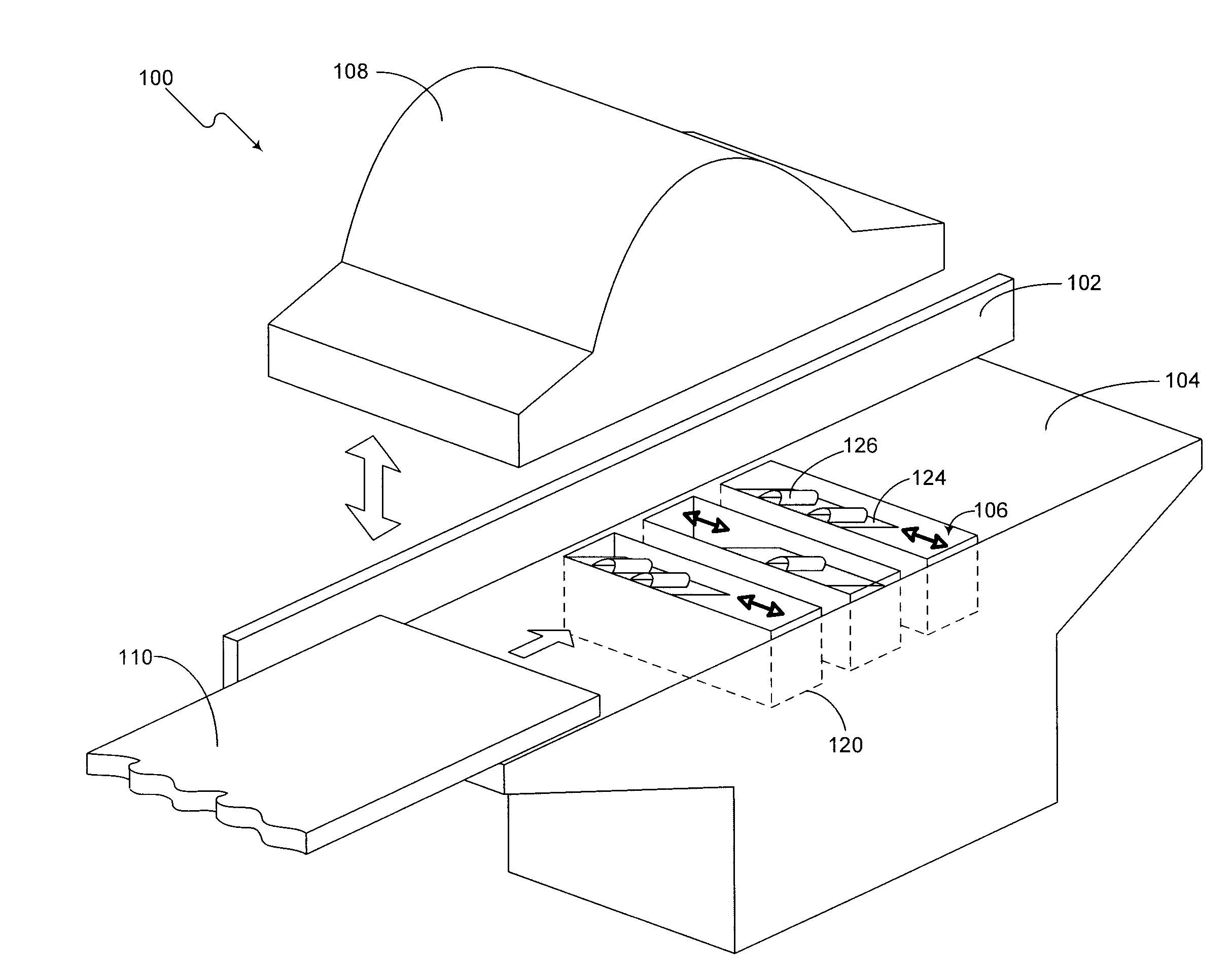

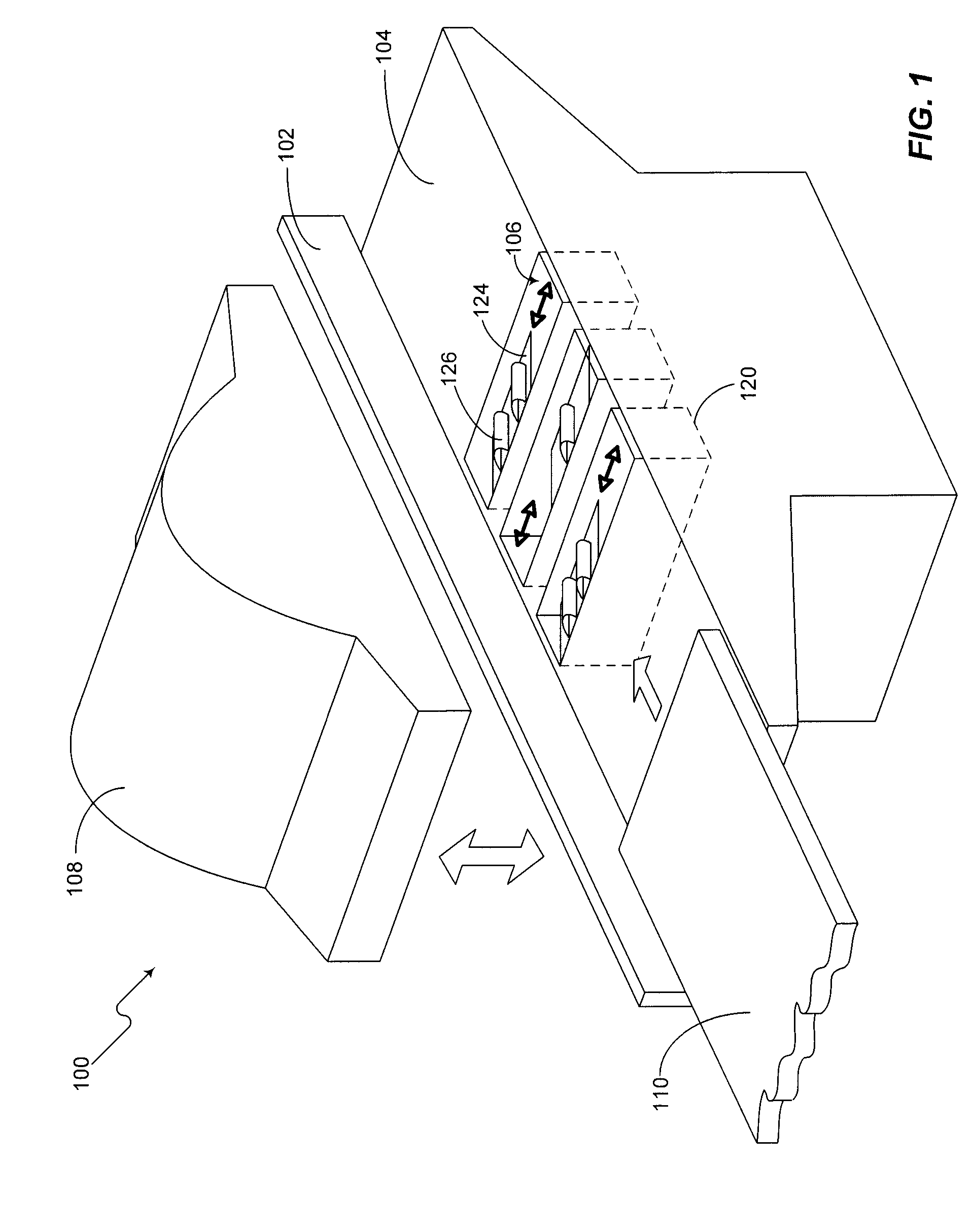

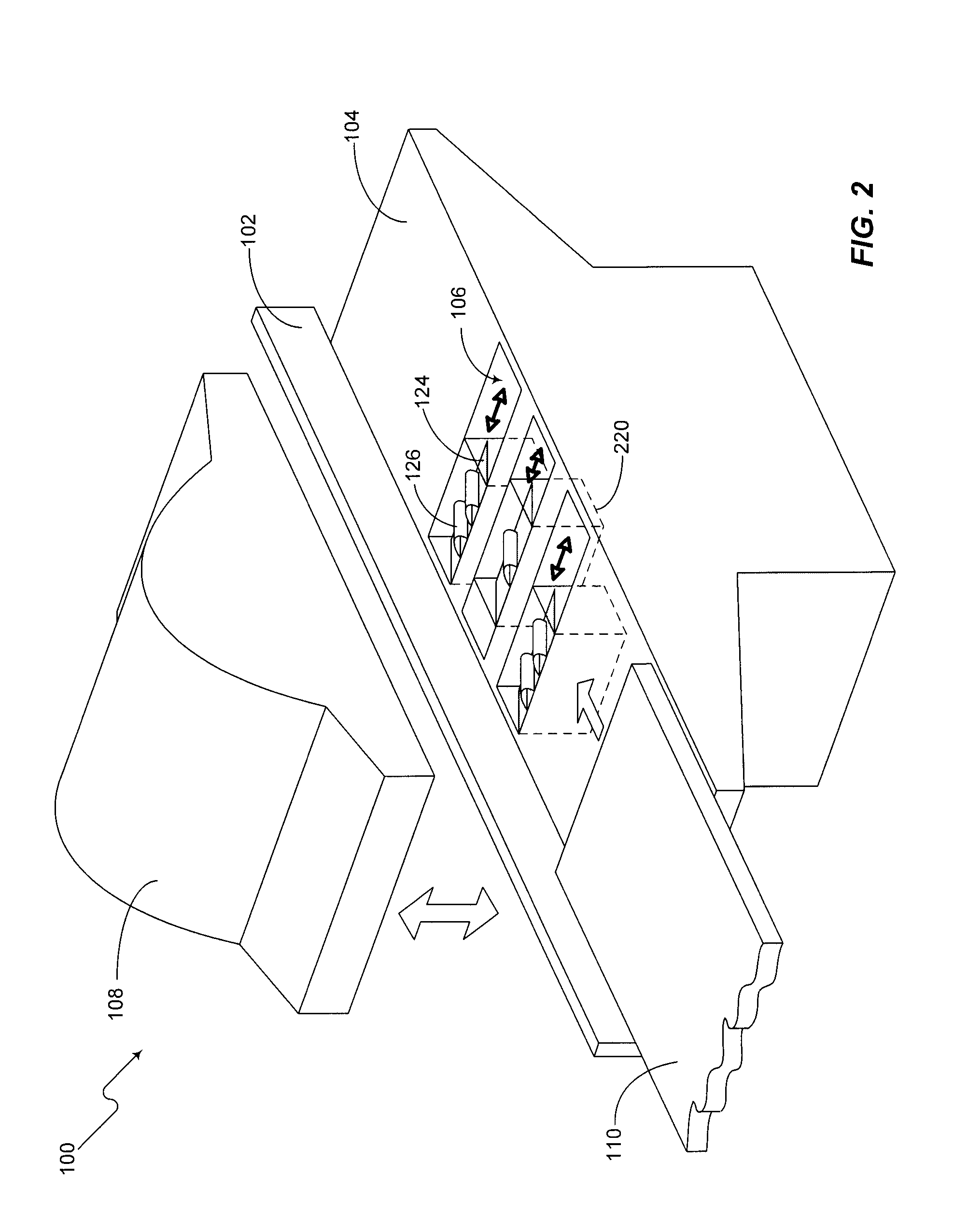

Automated hardwood texturing system and associated methods

A system and method for imparting a textured surface effect in a board. The system and method are configured to releasably secure a charge on a table; determine a random abrasion pattern for the charge with at least one programmable controller; and control at least one abrasion assembly with the at least one programmable controller in accord with the random abrasion pattern to selectively engage and remove desired portions of the upper surface of the charge with the at least one abrasion assembly to form a randomized textured surface effect thereon.

Owner:COLUMBIA INSURANCE CO

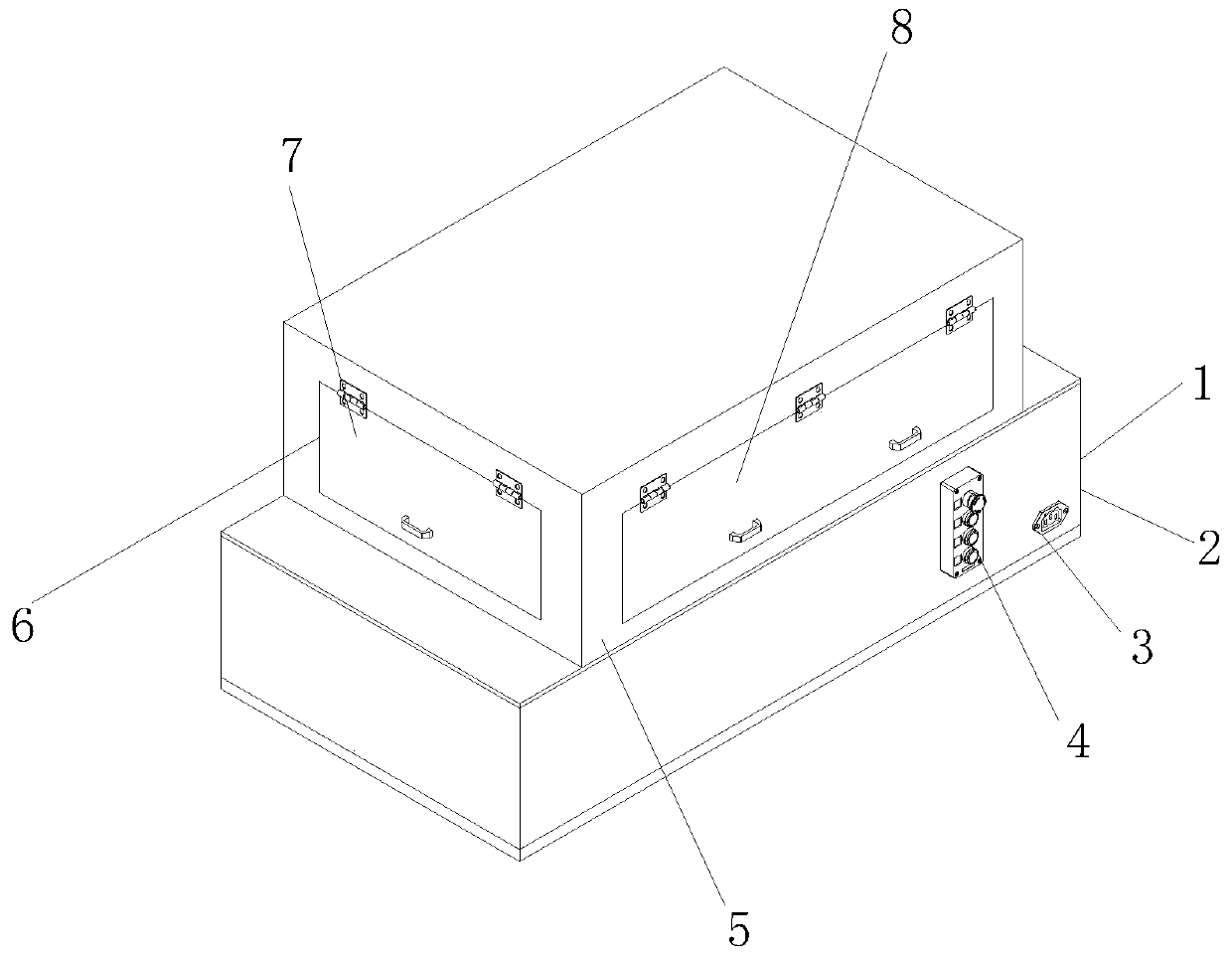

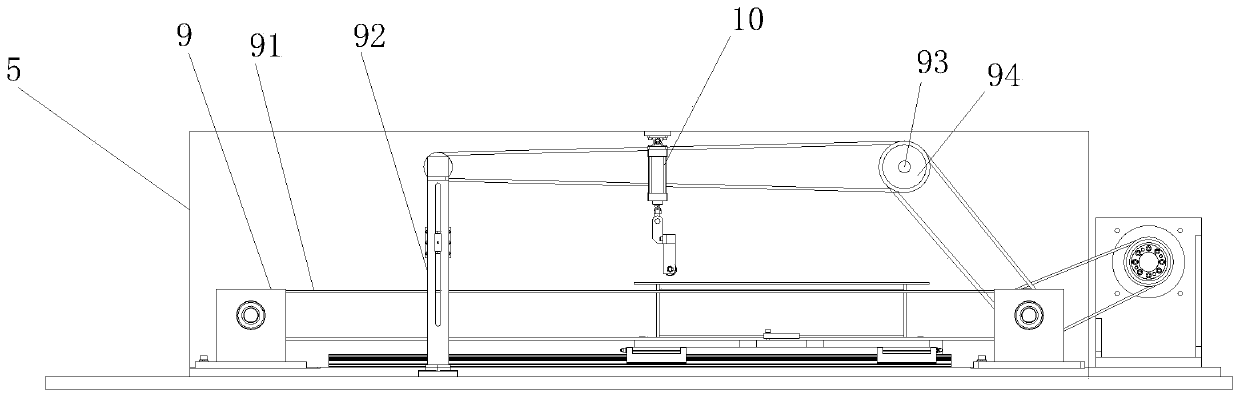

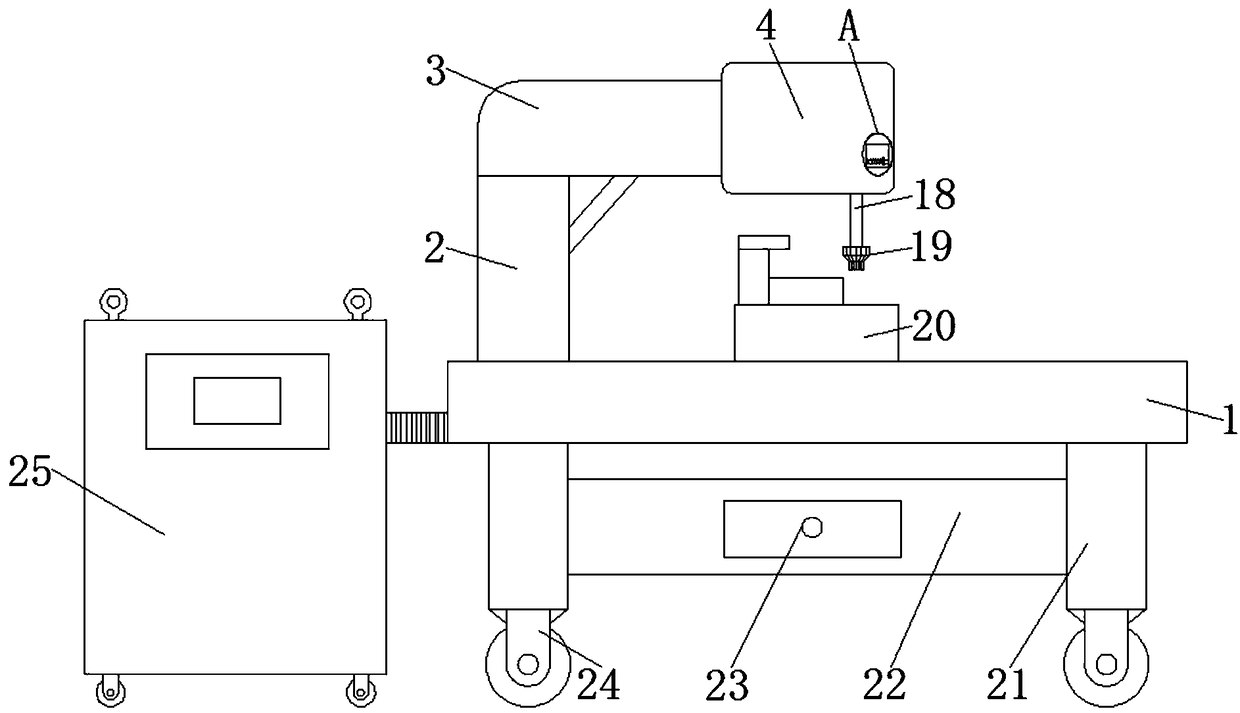

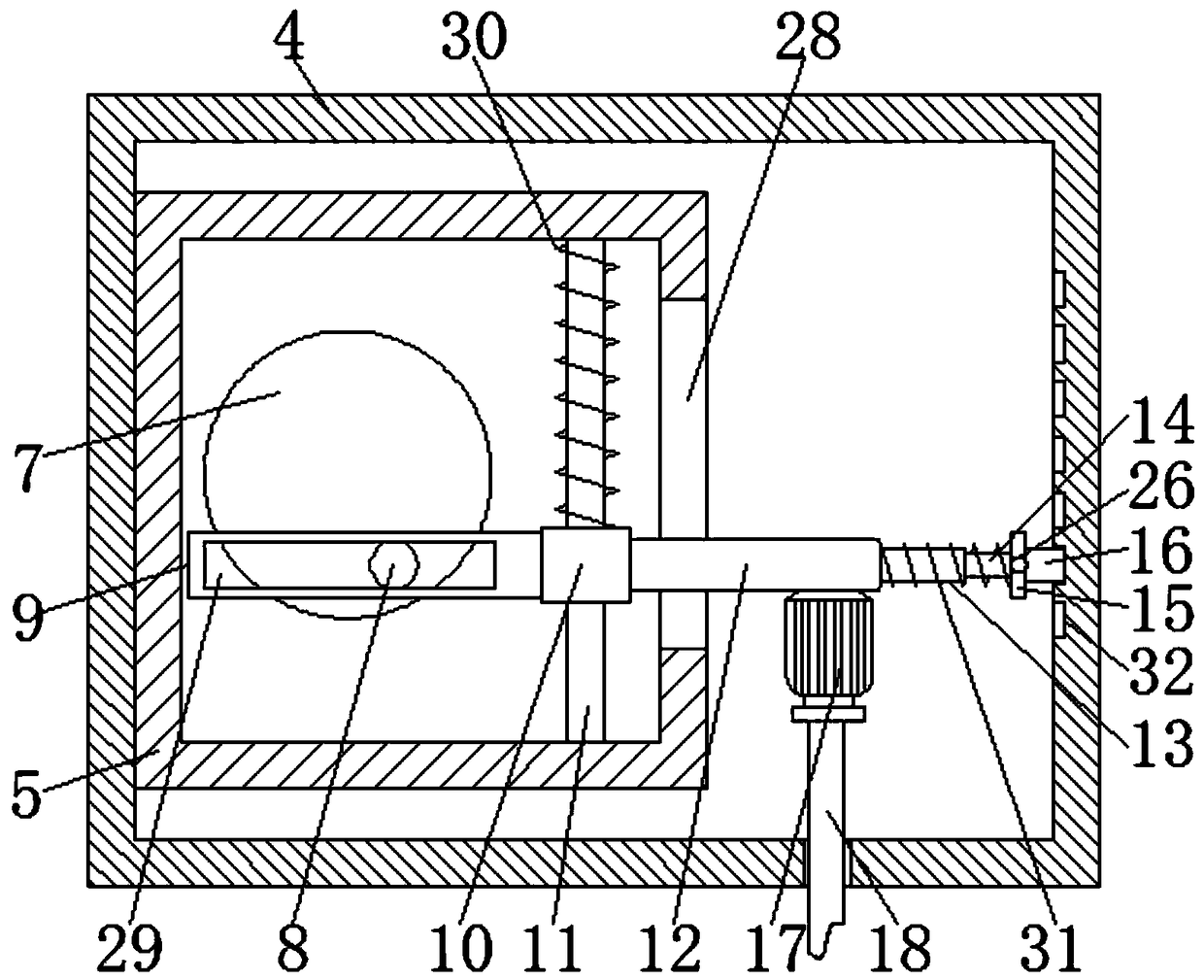

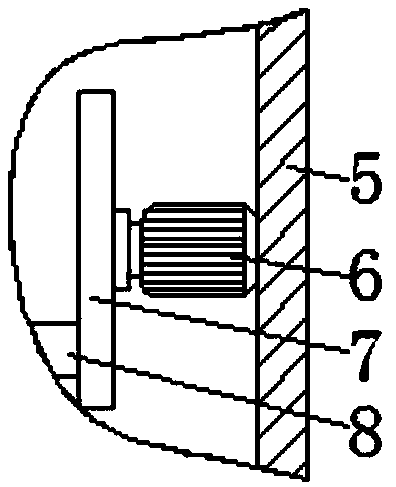

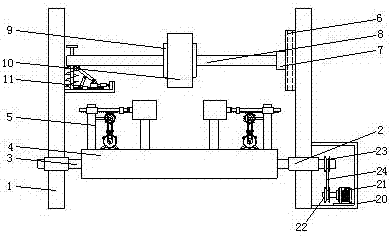

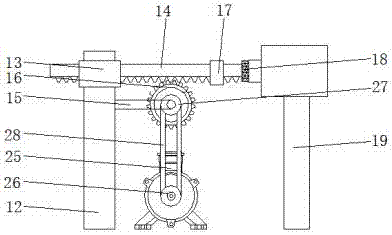

Grinding equipment for wood manufacturing

InactiveCN110421442AQuick sandingGood effectEdge grinding machinesGrinding carriagesBall bearingGear wheel

The invention discloses grinding equipment for wood manufacturing. A work bin is included and internally provided with a reciprocating deburring device. A reciprocating transmission mechanism is arranged at the bottom in the reciprocating deburring device, and a deburring mechanism is arranged at the left end of the reciprocating transmission mechanism. When a wood board is placed on a sliding base, a motor is started to drive a belt wheel for transmission, a connecting belt is made to drive a sliding block to slide on a sliding rail, the sliding base is made to slide, then, the belt wheel canbe in transmission, a rotation shaft in the deburring mechanism is driven to rotate, a bevel gear in a transmission box is in transmission so that a lead screw can rotate, and a ball bearing can drive a fixing plate so that a scraper can descend to conduct deburring on a target. The motor rotates forwards and reversely so that repeated machining can be achieved. A grinding device is arranged at the middle portion of the top end in the work bin, an inner air cylinder is connected with pneumatic equipment through an air port, a push rod at the bottom of the air cylinder drives a transverse rodso that a grinding roller at the bottom can descend, then, the wood board can be rapidly ground, the effect is good, efficiency is high, and stability and the yield are high.

Owner:山东福达木业有限公司

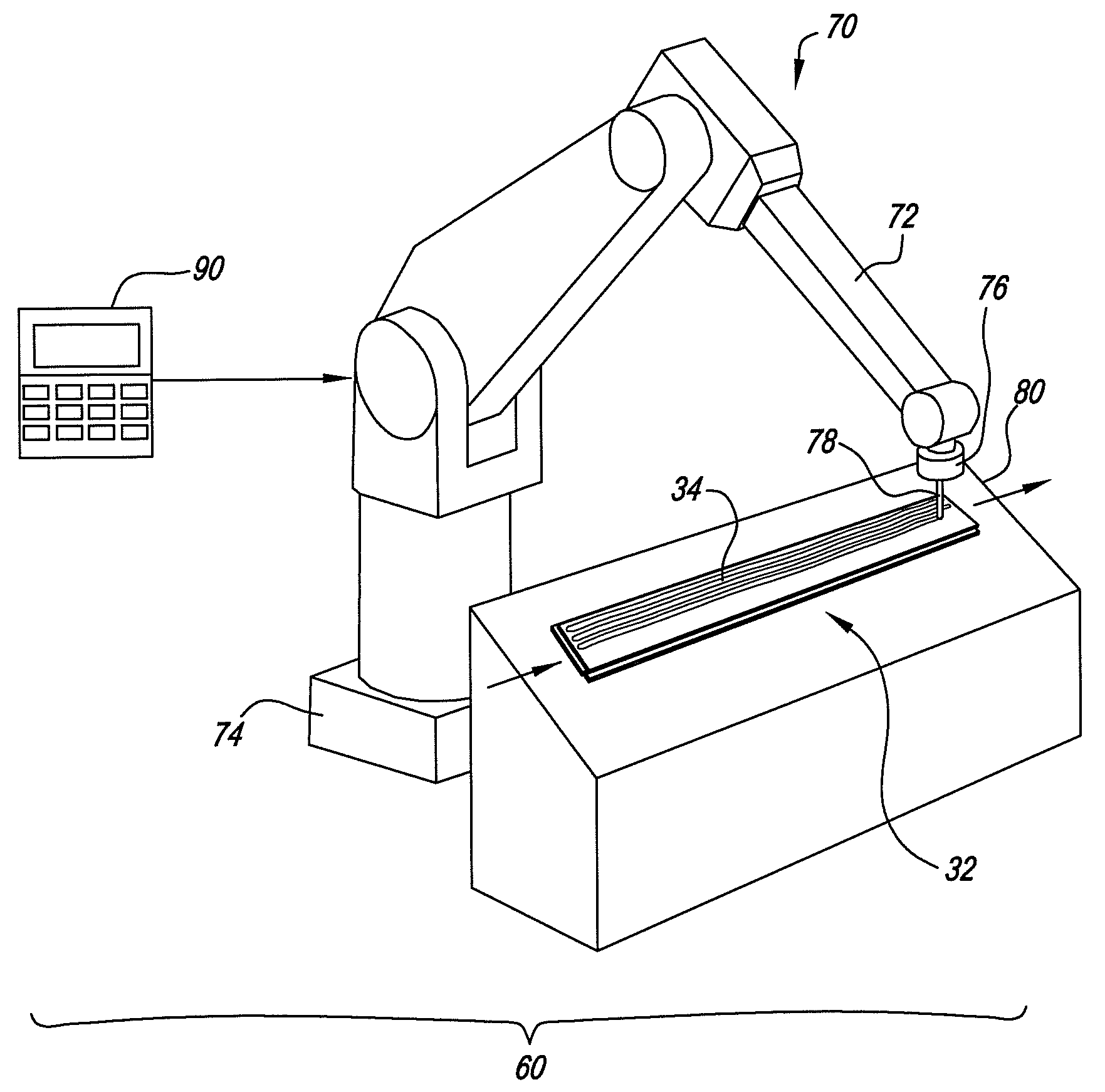

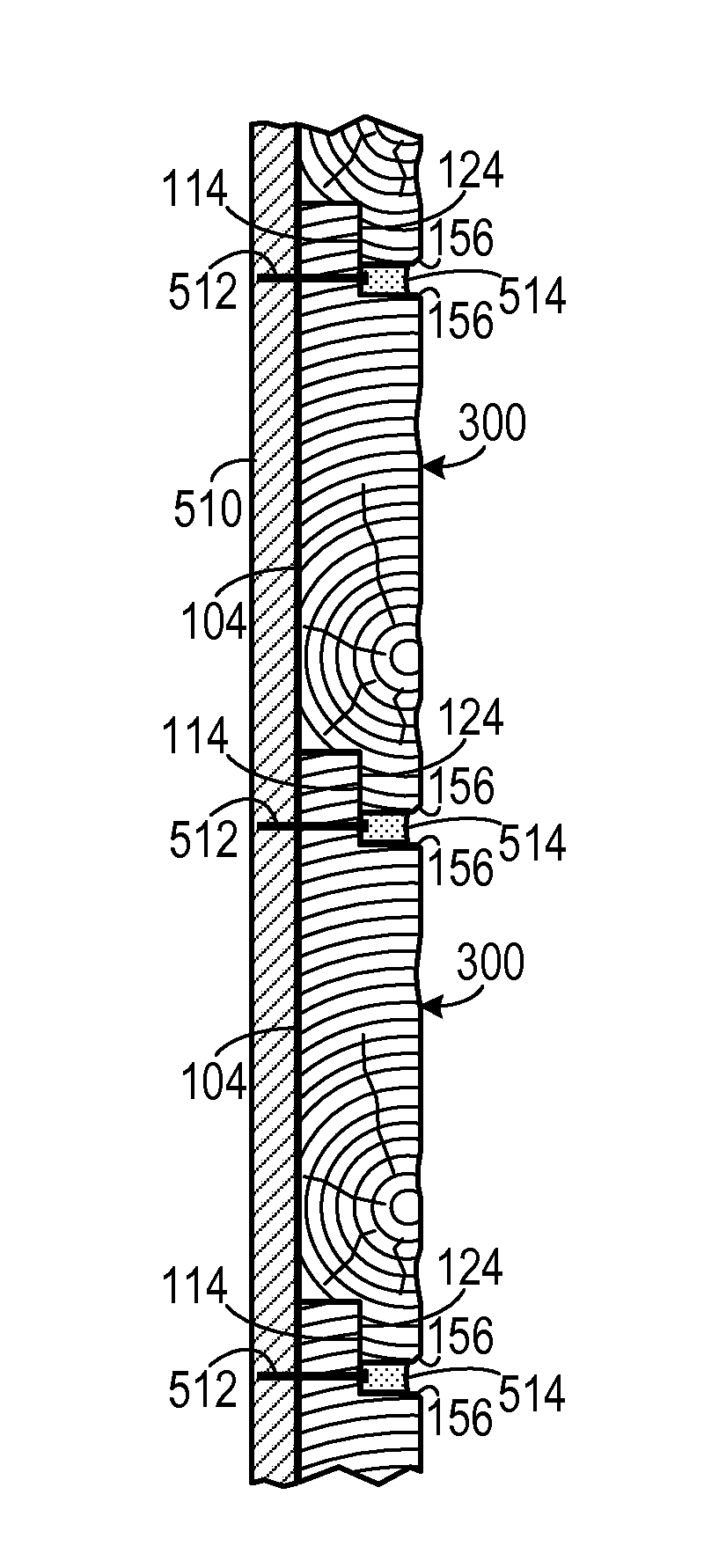

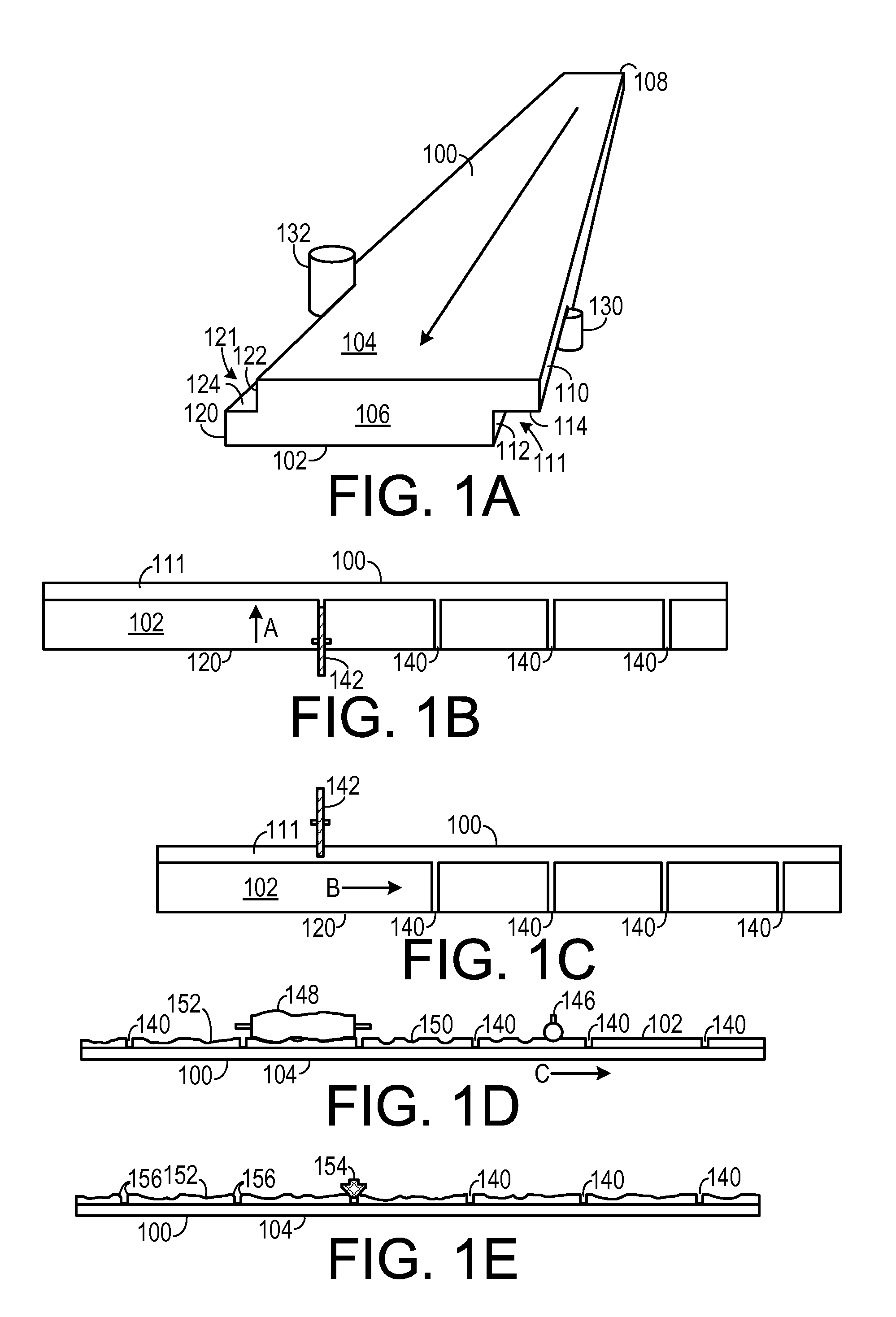

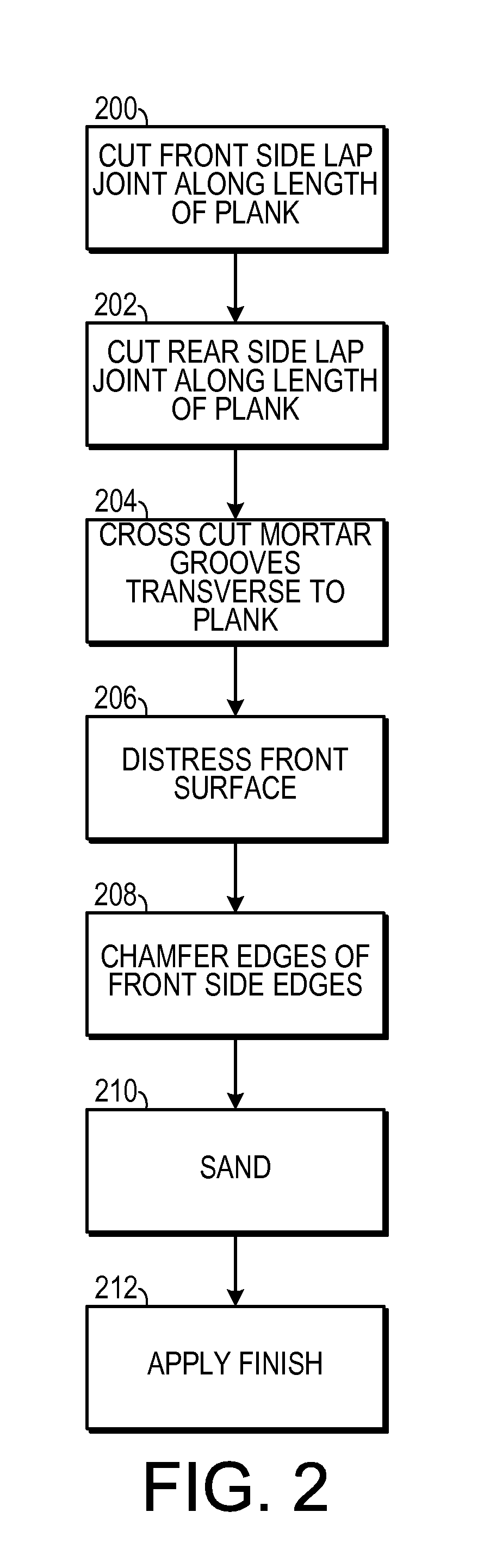

Wood planks with brick-like surface features and method of making same

InactiveUS20110277409A1Stable maintenanceOvercome disadvantagesCovering/liningsWallsTransverse grooveEngineering

A plank has a simulated brick front surface formed on a board. The board has a horizontal first lap cut into a first edge of the board defined by a first shoulder and a first cheek. The first shoulder has a first shoulder distance and the first cheek has a first cheek distance. The board has a horizontal second lap cut into the second edge of the board that is defined by a second shoulder and a second cheek. The second shoulder has a second shoulder distance and the second cheek has a second cheek distance. The second shoulder distance is substantially equal to the first shoulder distance subtracted from the thickness of the board. The second cheek distance is substantially equal to a width of a brick mortar joint subtracted from the first cheek distance. A plurality of evenly spaced vertical transverse grooves is cut into the front side.

Owner:ATKINSON DAVID J

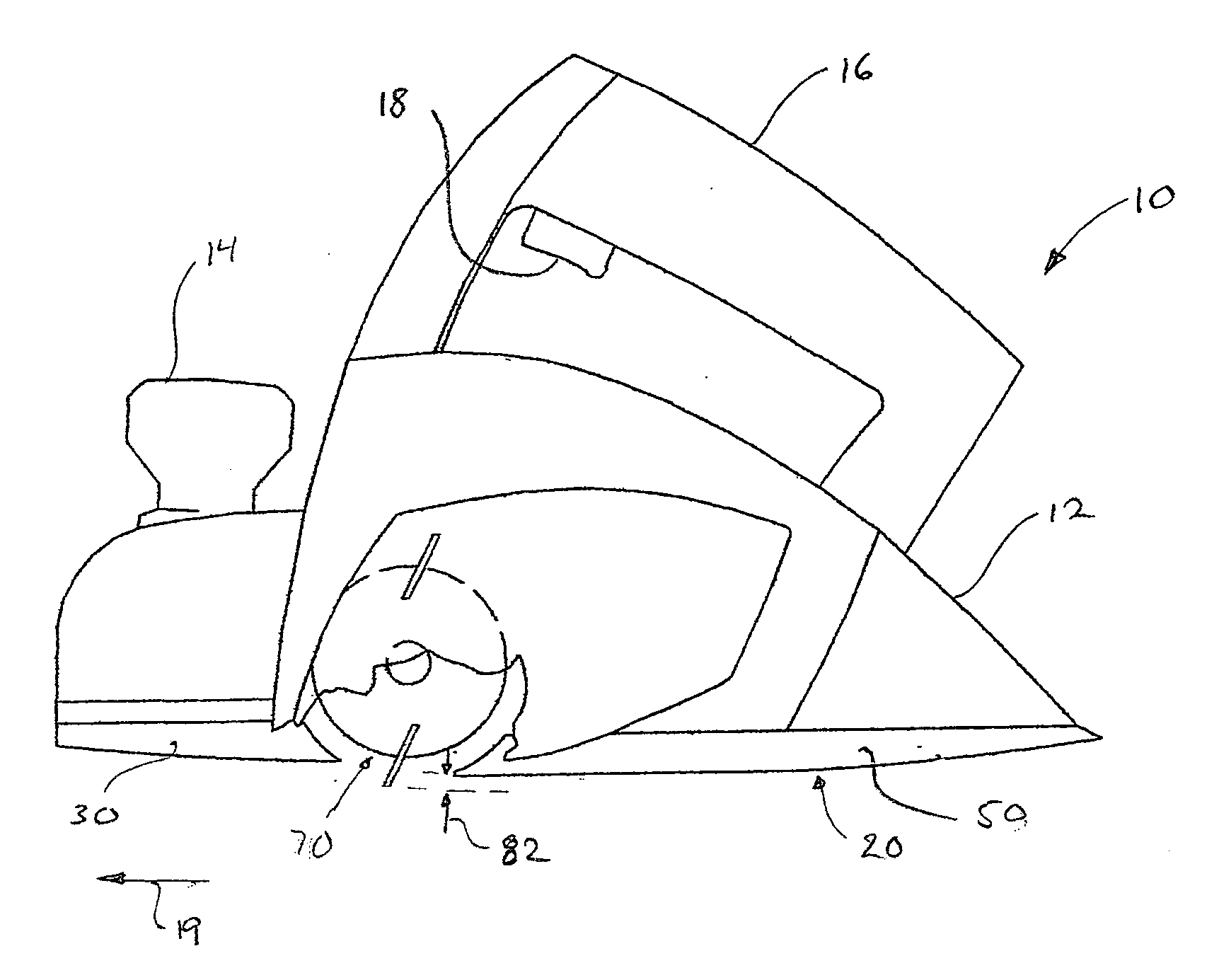

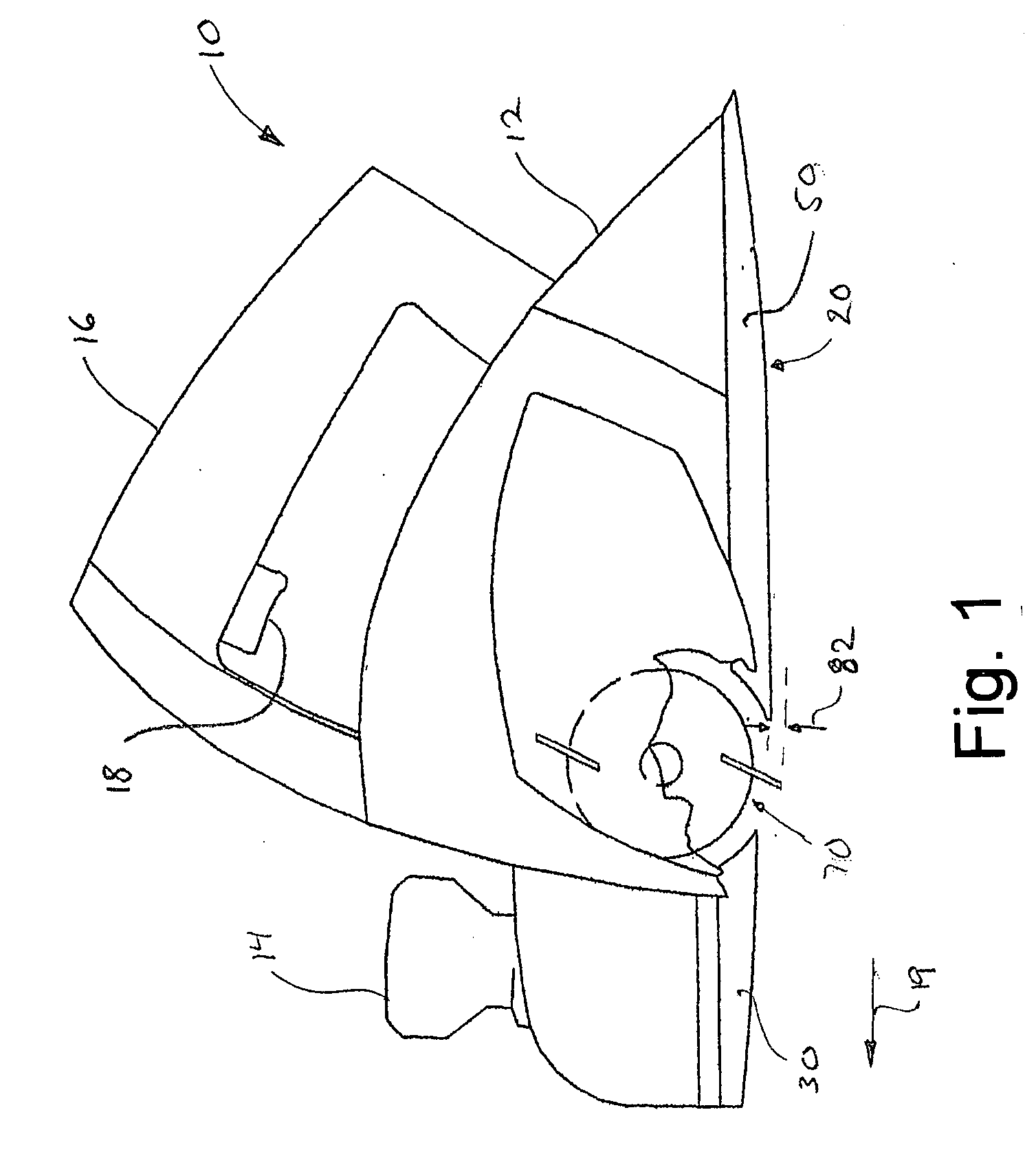

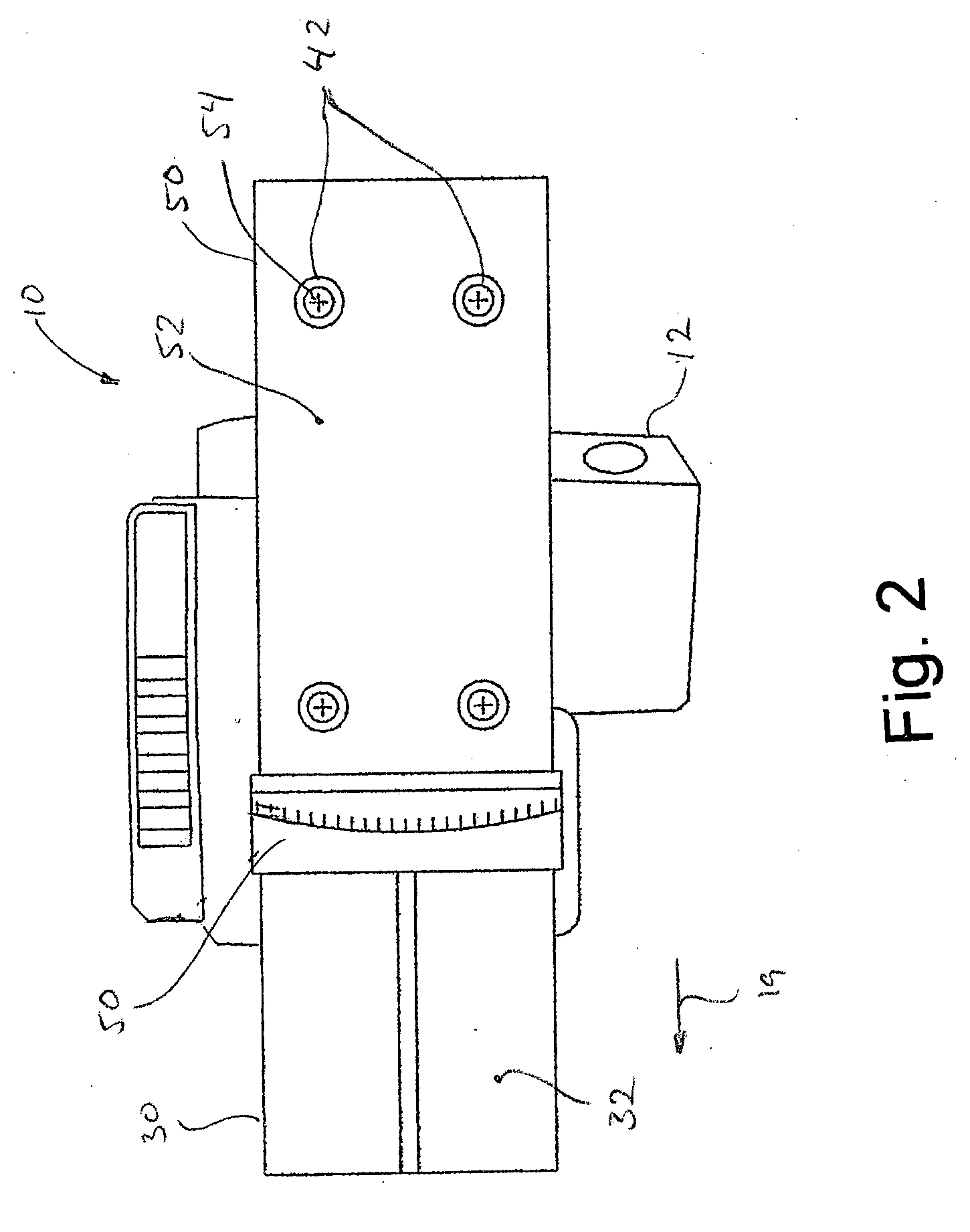

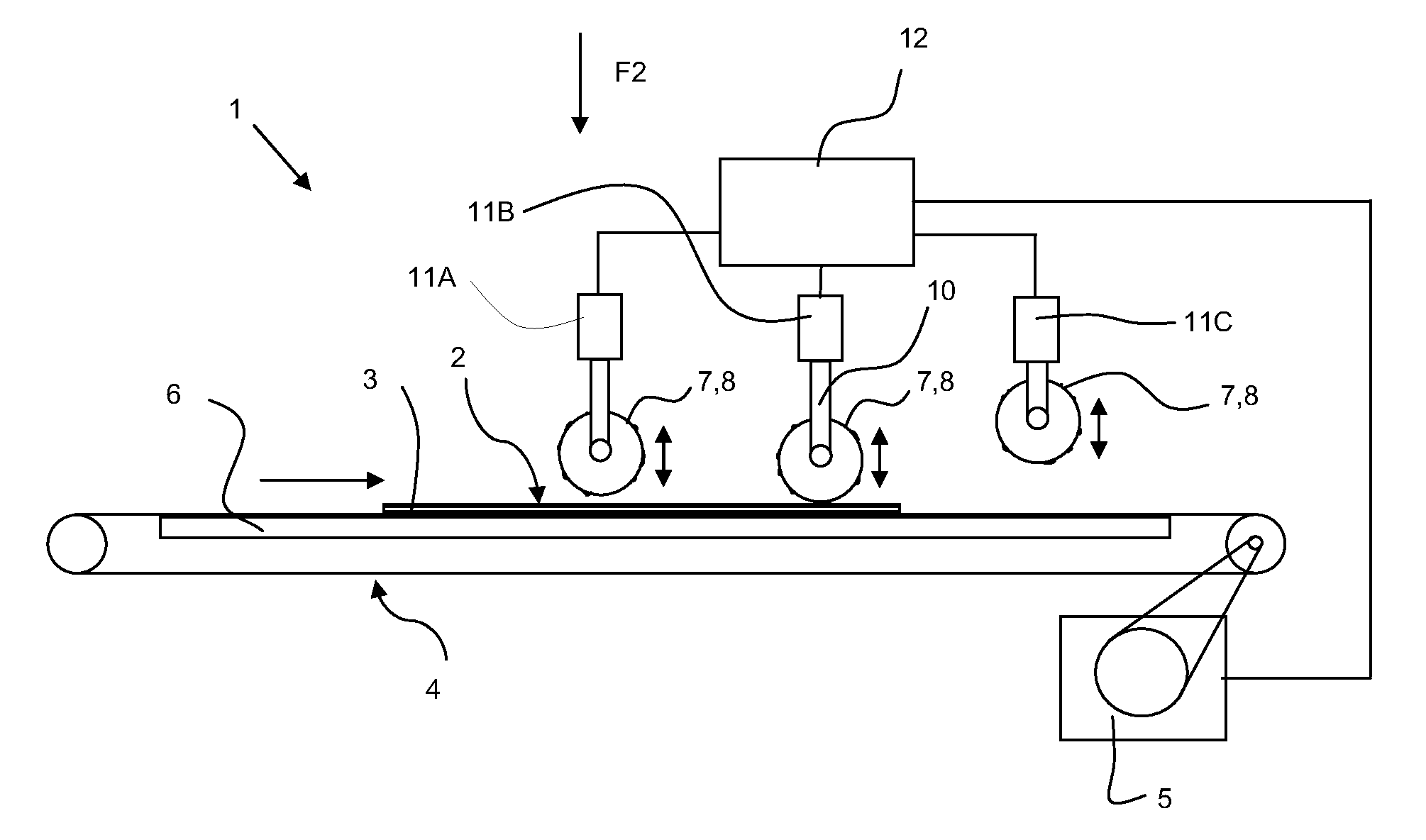

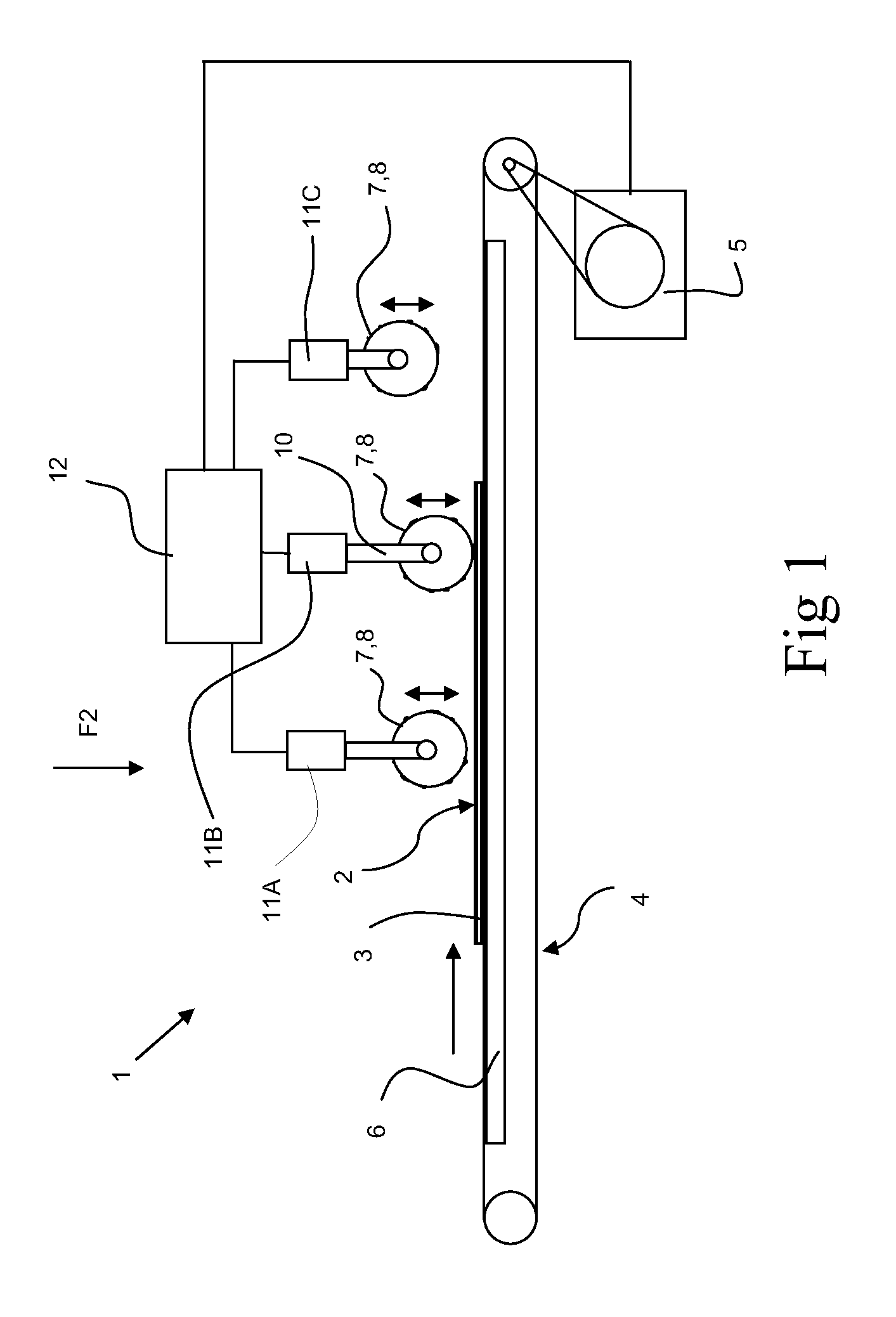

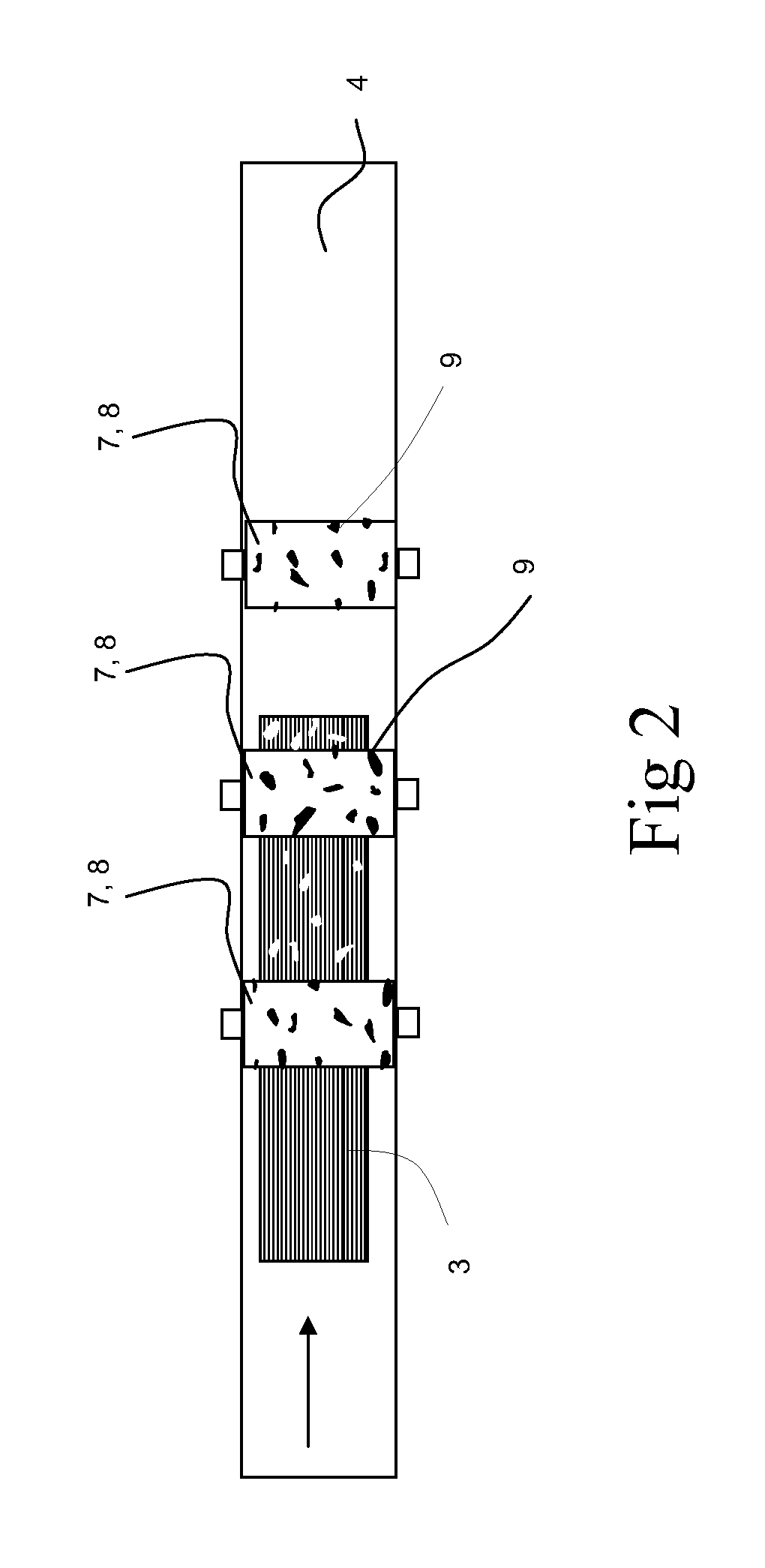

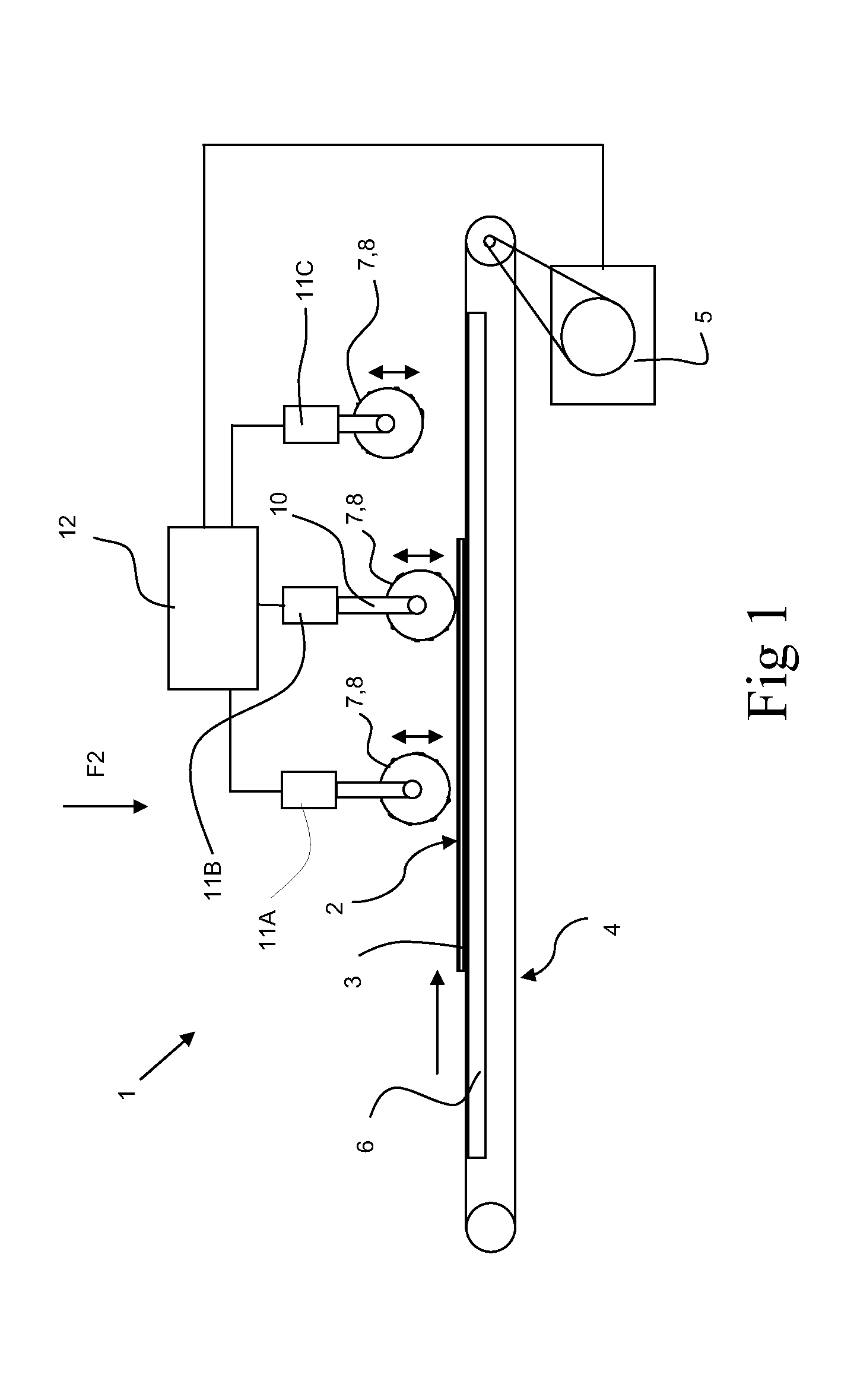

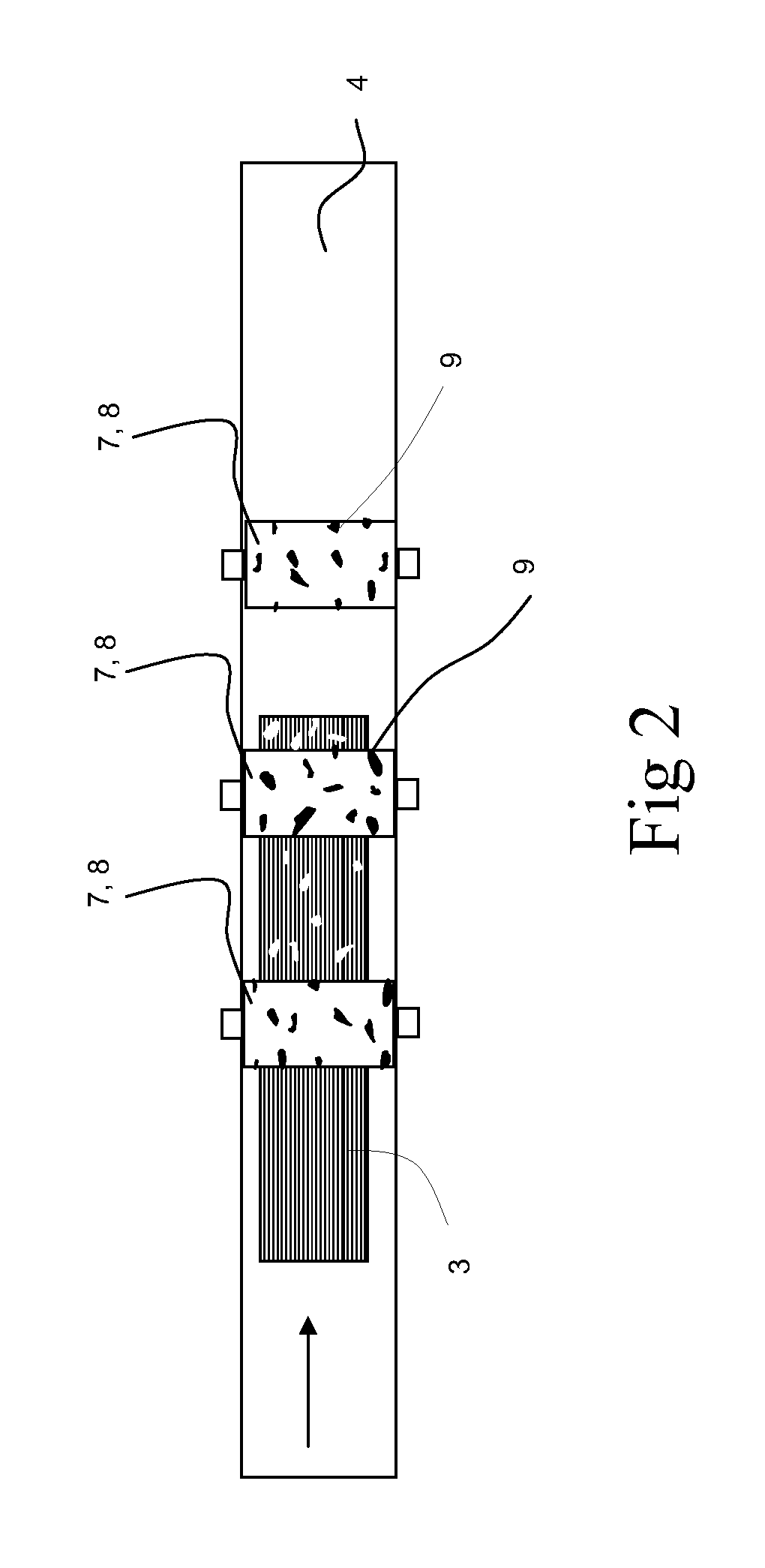

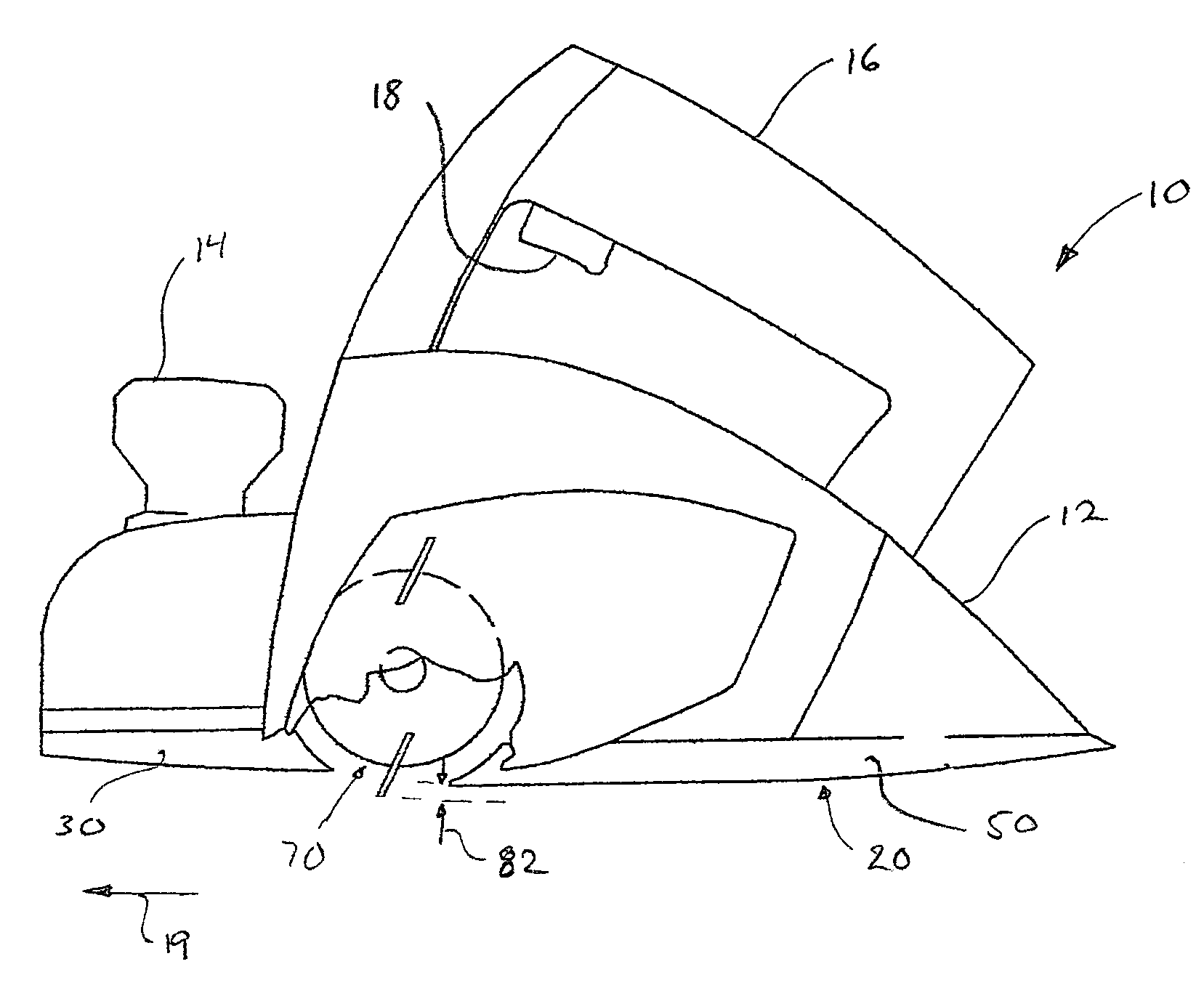

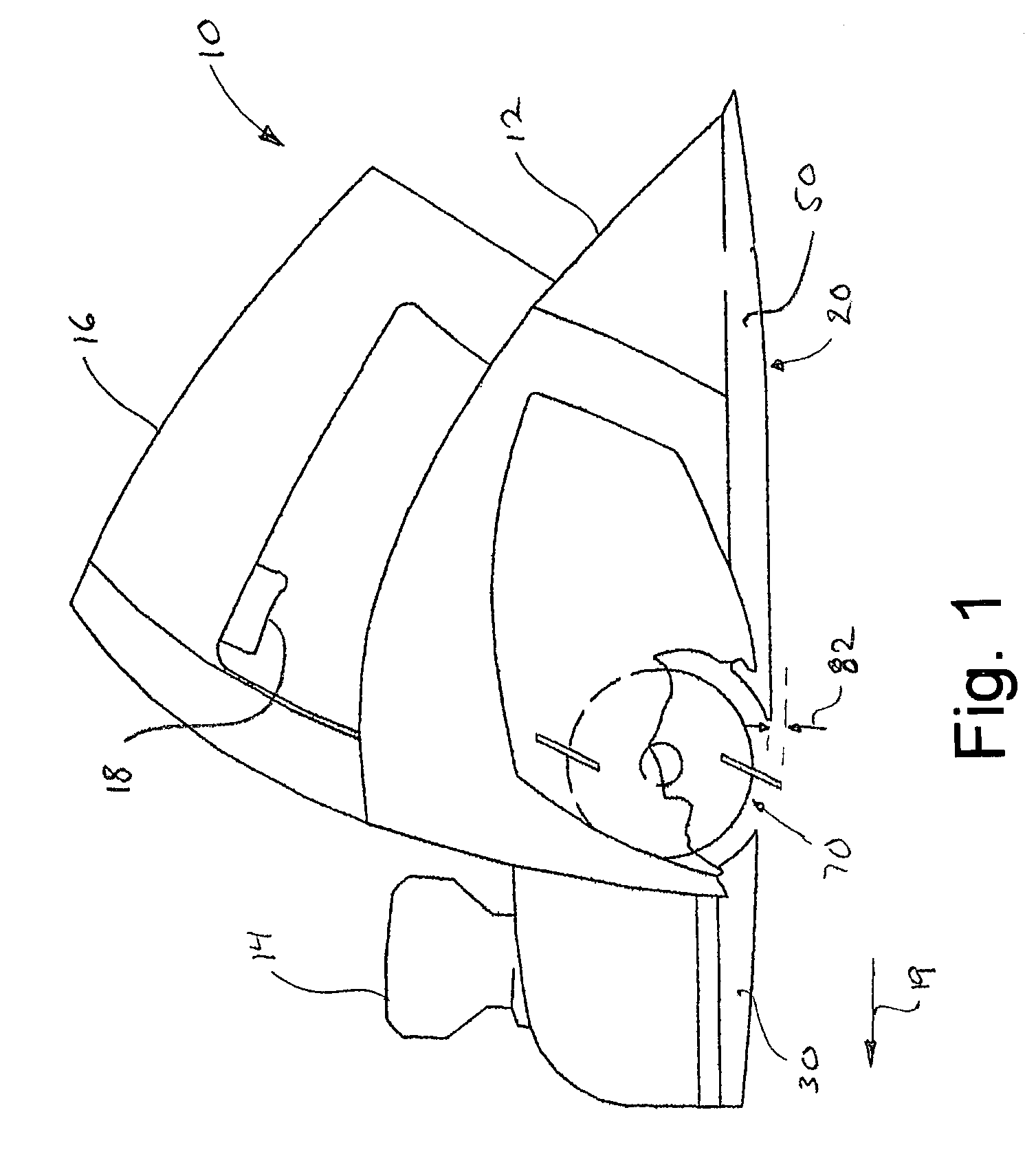

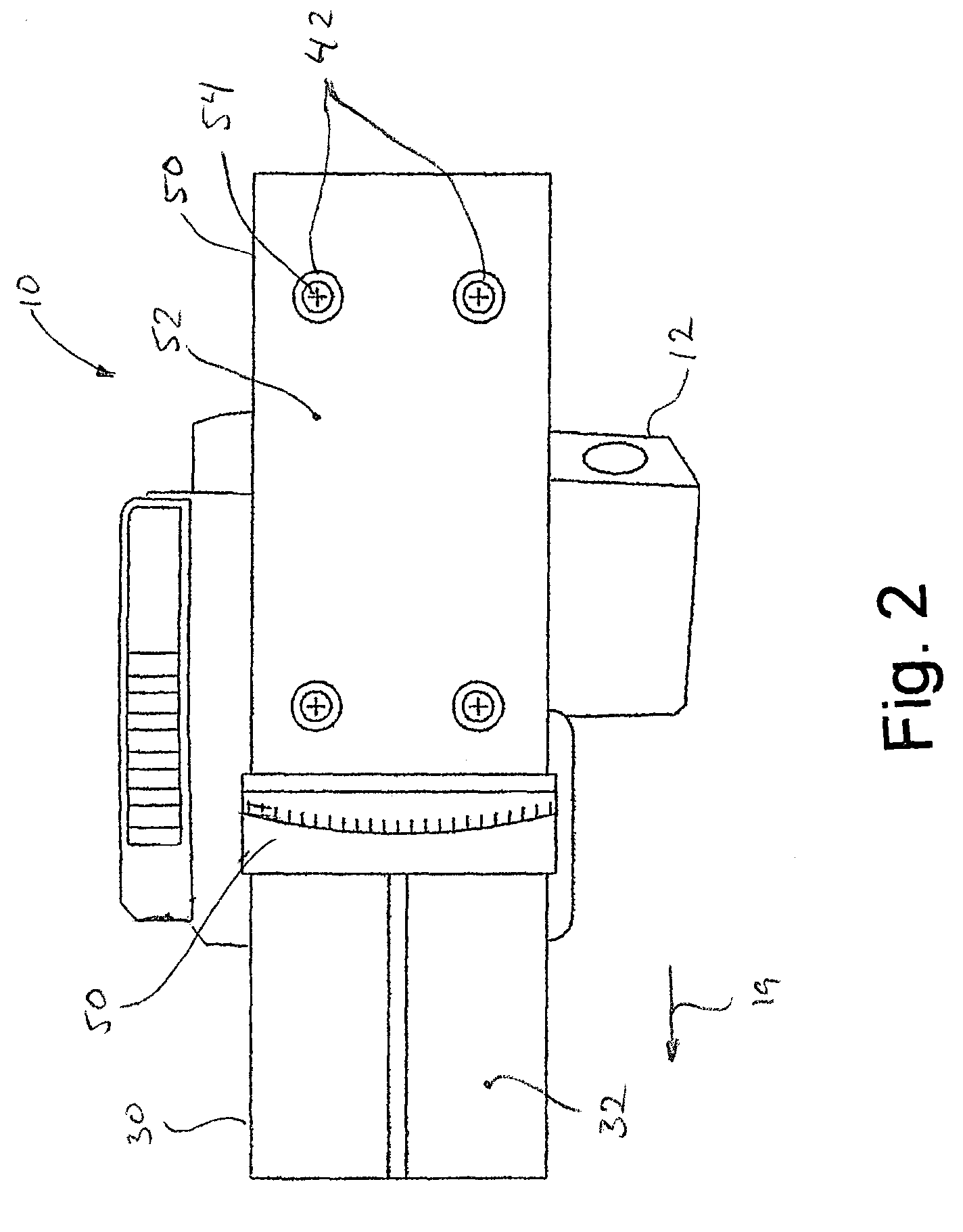

Distressing process and apparatus for applying such process

InactiveUS8051886B2Simple resultWooden sticks manufactureAutomatic control devicesDistressingEngineering

Owner:UNILIN FLOORING NC

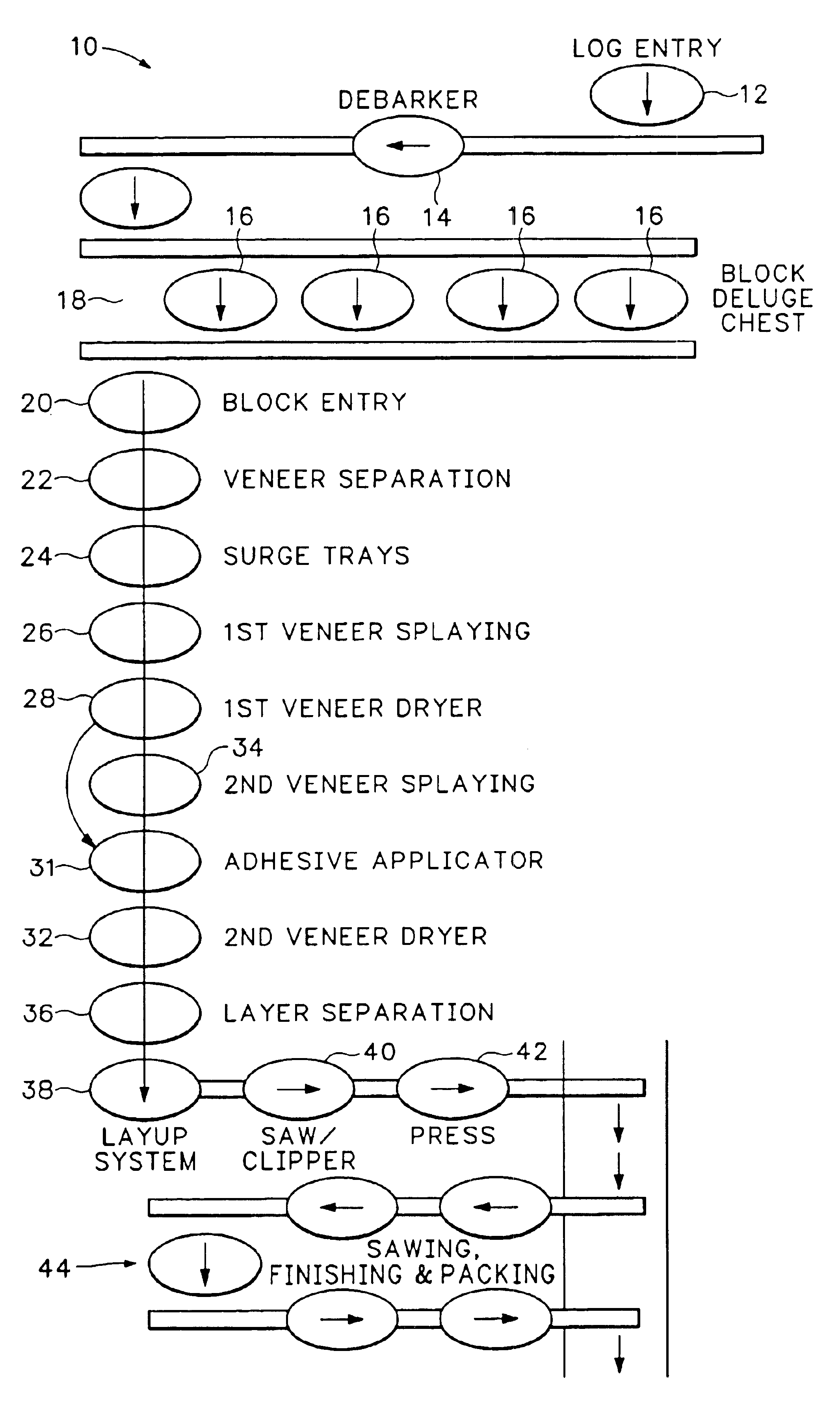

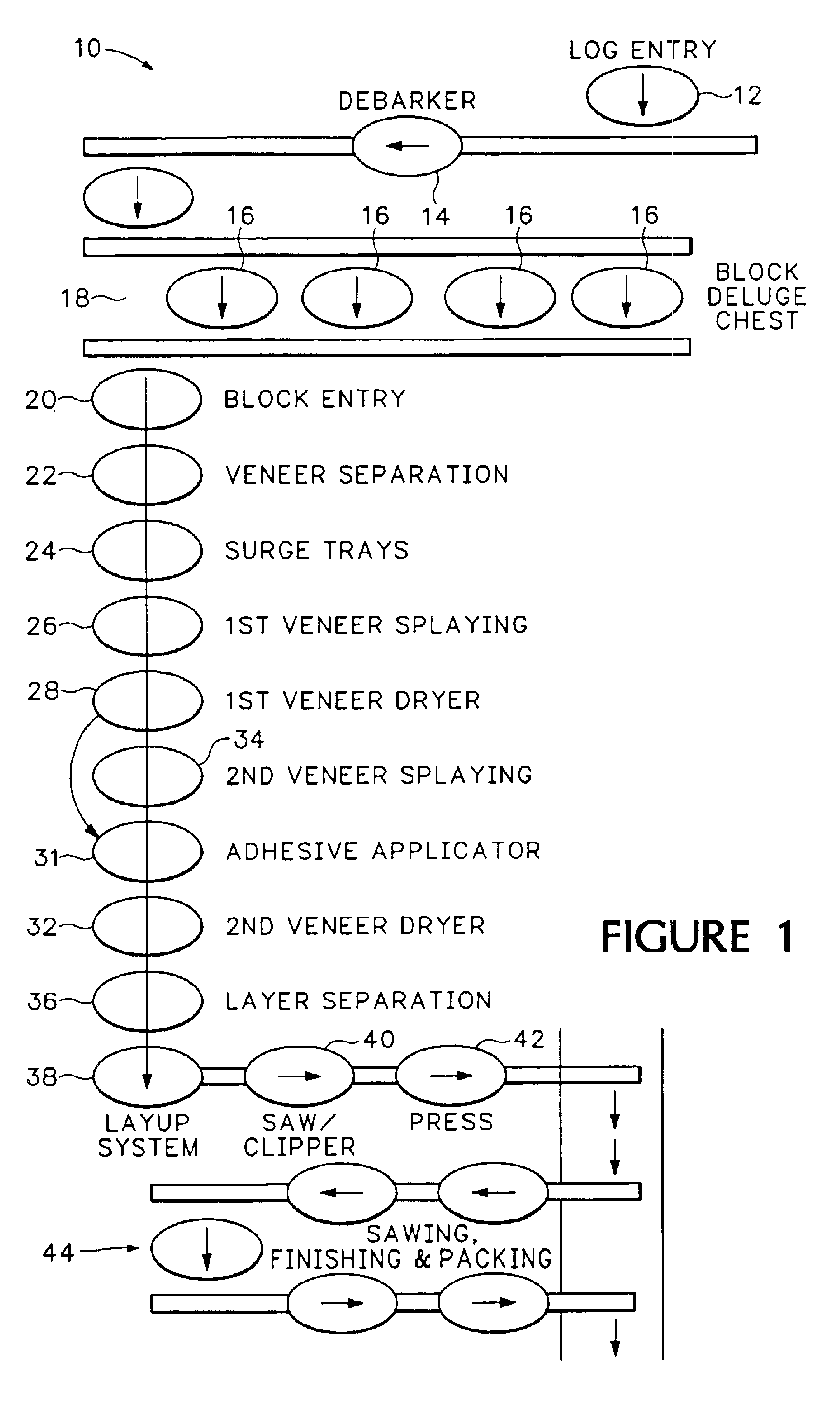

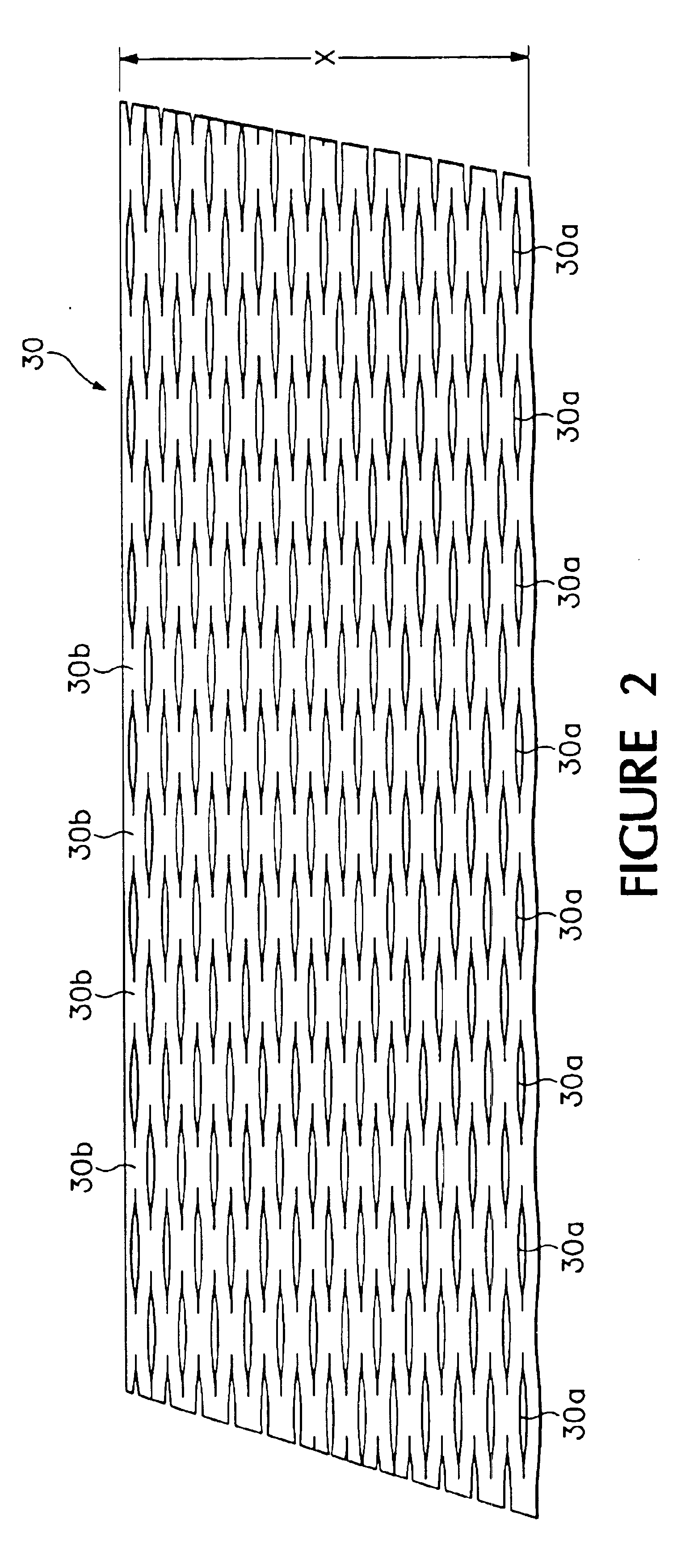

Method for producing a processed continuous veneer ribbon and consolidated processed veneer strand product therefrom

InactiveUS6868877B2Reduce manufacturing costReduce the amount requiredOther plywood/veneer working apparatusStapling toolsProcess systemsEngineering

A method for producing a processed substantially continuous veneer ribbon is provided. The method comprises providing a plurality of debarked wood logs. A substantially continuous veneer ribbon is separated from each of said plurality of debarked wood logs. The substantially continuous veneer ribbons is conveyed to a plurality of storage locations. A system is provided for processing the substantially continuous veneer ribbons introducing a plurality of the substantially continuous veneer ribbons from the storage location to the continuous veneer ribbon process system. A processed continuous veneer ribbon is formed from the plurality of the substantially continuous veneer ribbons in the continuous veneer ribbon process system.

Owner:GANG NAIL SYST

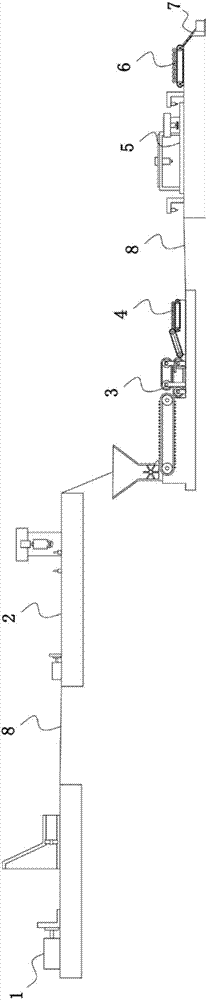

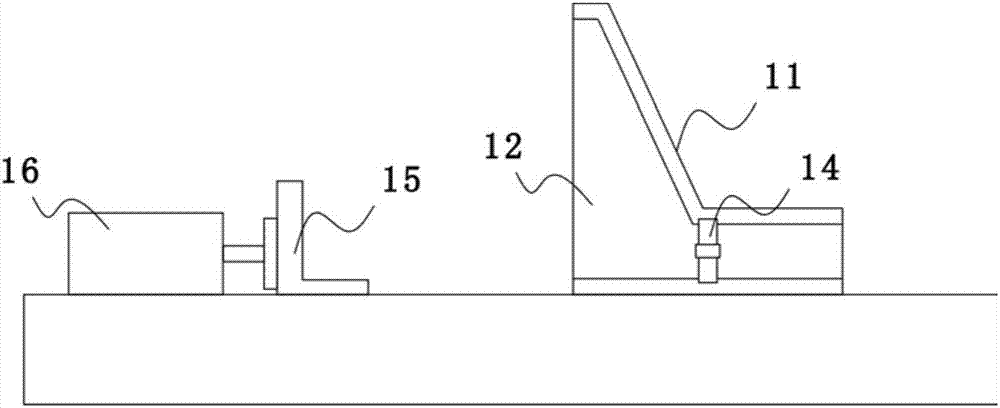

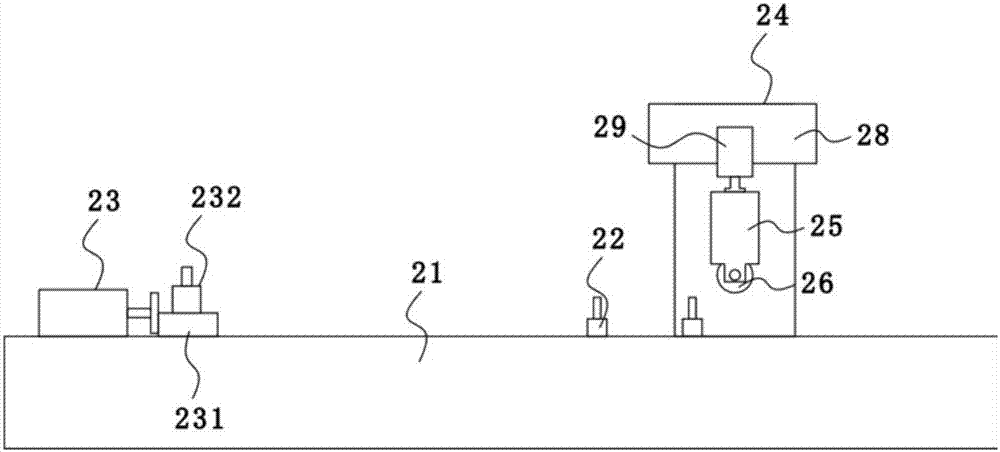

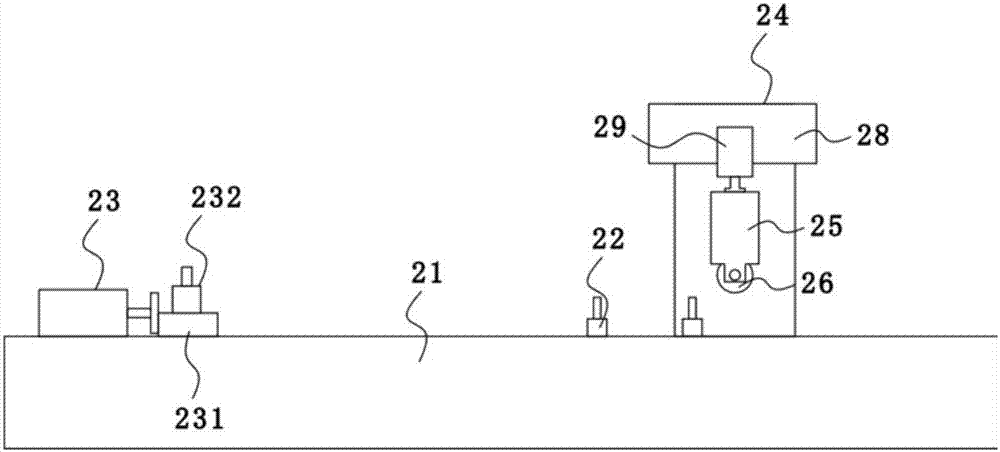

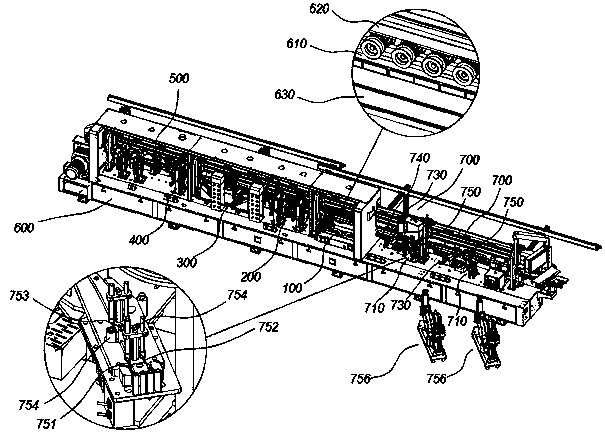

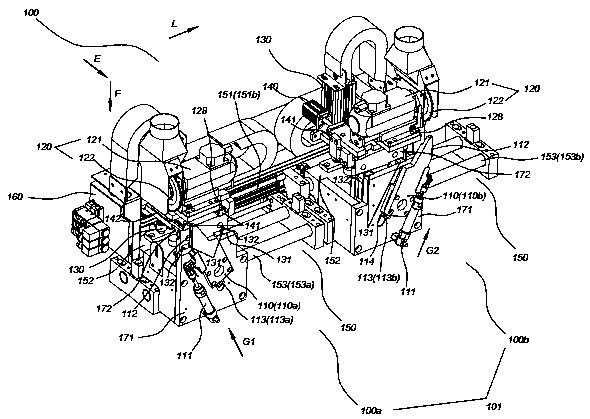

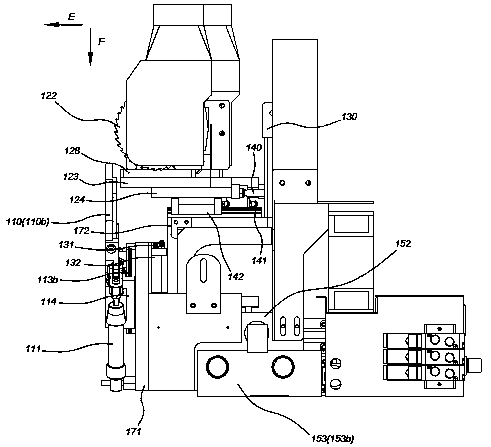

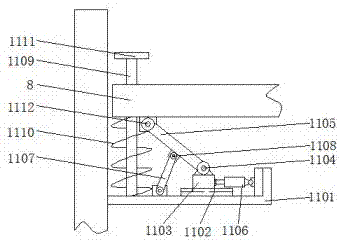

Carved bamboo chopstick production system

ActiveCN106985254ARealize automated productionIncrease productivityMechanical surface treatmentCane mechanical workingEngineeringCarving

The invention discloses a carved bamboo chopstick production system. The production system comprises a bamboo splitting mechanism, a sawing-off mechanism, an automatic head cutting mechanism, a first polishing mechanism, a chopstick body carving mechanism, a second polishing mechanism and a discharging mechanism which are connected in sequence. The adjacent mechanisms are connected through a conveying belt. The bamboo splitting mechanism comprises a rack, a feeding bin arranged on the rack, feeding inlets formed in the two ends of the feeding bin, bamboo splitting cutter knives arranged at the feeding inlets, and material pushing parts arranged on the rack. The material pushing parts are opposite to the feeding inlets. Each material pushing part comprises an L-shaped pushing plate and a first driving part used for driving the pushing plate to reciprocally act front and back. The equipment can achieve full-automatic production of chopsticks, large batches of the chopsticks with the carving process can be produced and manufactured in a short time, the production efficiency is high, the labor cost is low, and the product industrialization demands are met.

Owner:ZHEJIANG IND POLYTECHNIC COLLEGE

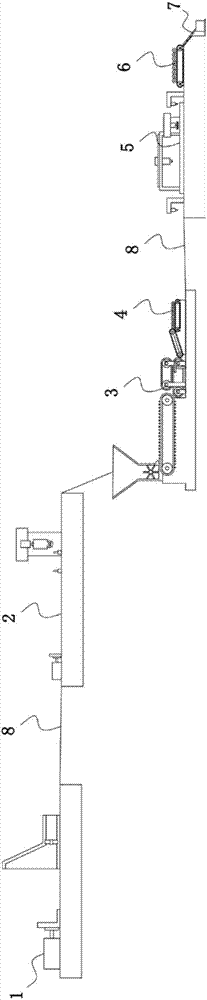

Automatic processing equipment for bamboo products

ActiveCN106985252ARealize automated productionIncrease productivityMechanical surface treatmentCane mechanical workingEngineeringAutomatic processing

The invention discloses an automatic processing equipment for bamboo products. The automatic processing equipment comprises a bamboo splitting mechanism, a sawing-off mechanism, an automatic head cutting mechanism, a first polishing mechanism, a chopstick body carving mechanism, a second polishing mechanism and a discharging mechanism which are connected in sequence. The adjacent mechanisms are connected through a conveying belt. The bamboo splitting mechanism comprises a rack, a feeding bin arranged on the rack, feeding inlets formed in the two ends of the feeding bin, bamboo splitting cutter knives arranged at the feeding inlets, and material pushing parts arranged on the rack. The material pushing parts are opposite to the feeding inlets. Each material pushing part comprises an L-shaped pushing plate and a first driving part used for driving the pushing plate to reciprocally act front and back. The automatic processing equipment can achieve full-automatic production of chopsticks, large batches of the chopsticks with the carving process can be produced and manufactured in a short time, the production efficiency is high, the labor cost is low, and the product industrialization demands are met.

Owner:ZHEJIANG IND POLYTECHNIC COLLEGE

Textured sound generating panels having increased efficiency in converting vibrational energy to sound waves

InactiveUS7507884B2Increase volumeImprove sound qualityStringed musical instrumentsMechanical surface treatmentAcoustic energyEngineering

I have discovered a way to improve the sound of musical instruments that utilize a soundboard or sound generating surface such as found in stringed musical instruments. I accomplished this by establishing a pronounced textured acoustical diffusing surface to one or more of the overall surfaces of the vibrating sound generating surface or soundboard of a stringed musical instrument creating greater surface area from which to generate greater acoustic energy. The result-compared to existing methods of improving the performance of soundboards of stringed musical instruments-is improved volume, timbre, projection, and tonality and sustain of the acoustical sounds produced by the stringed musical instrument.

Owner:CARLSON JOSEPH W

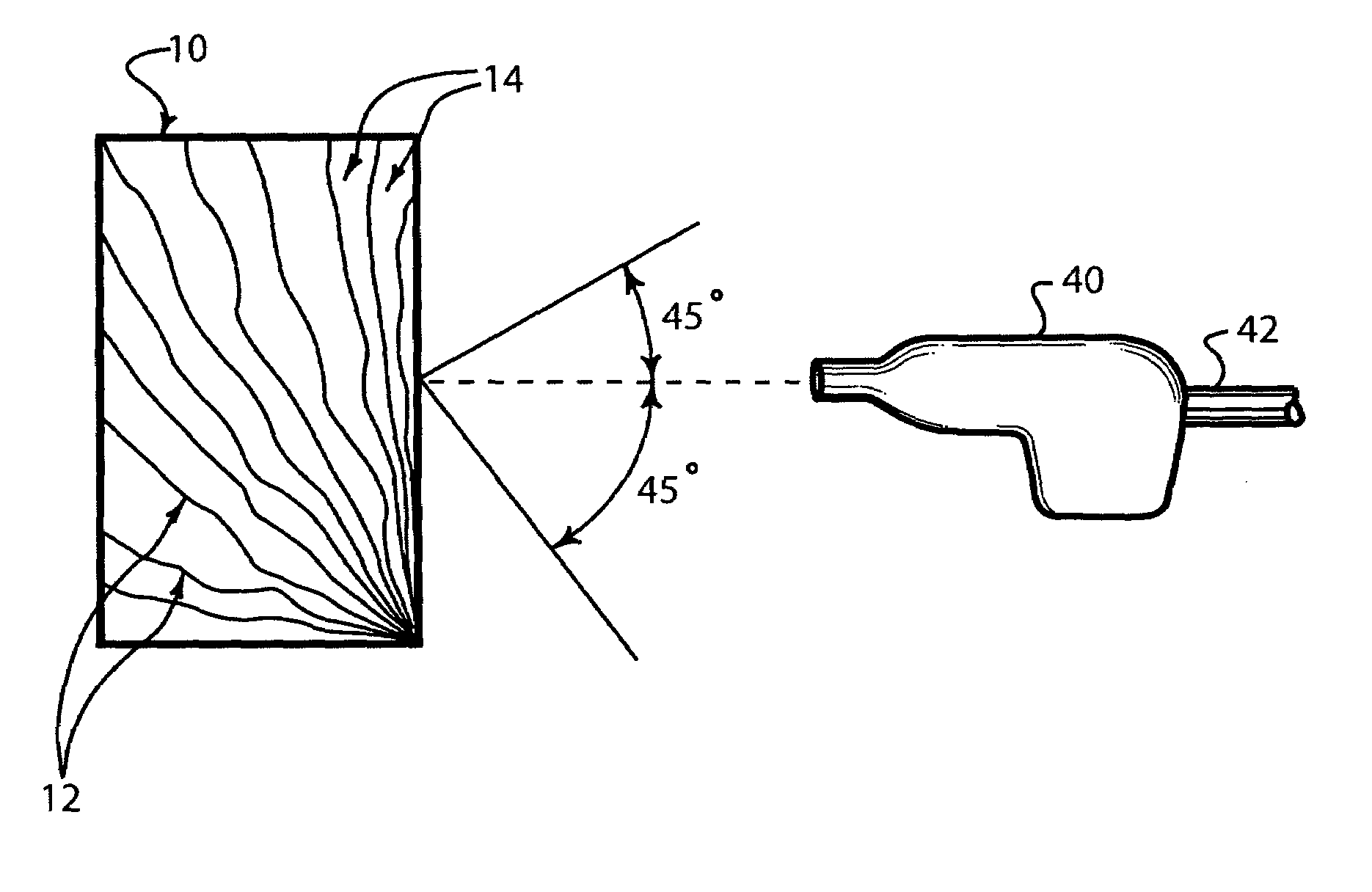

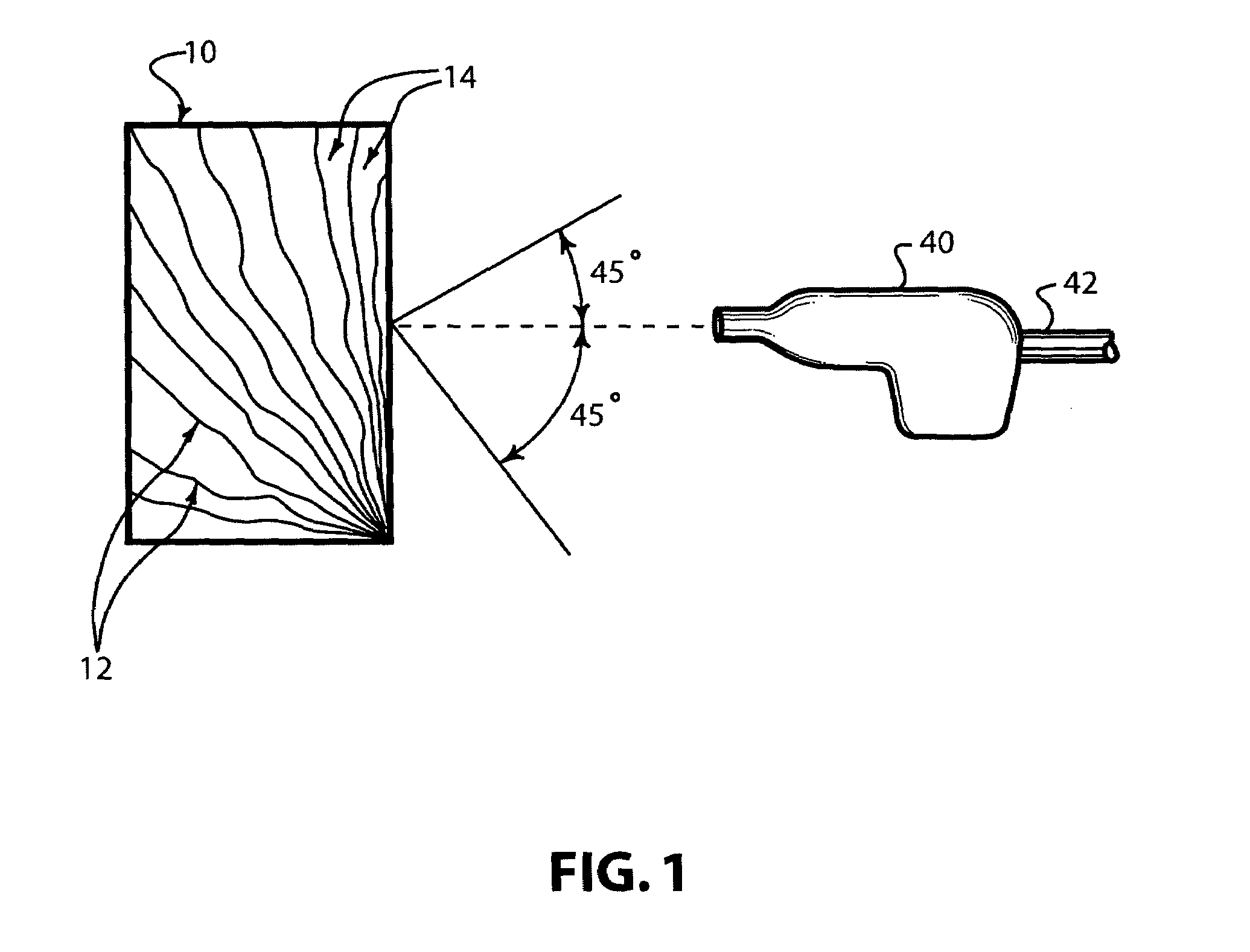

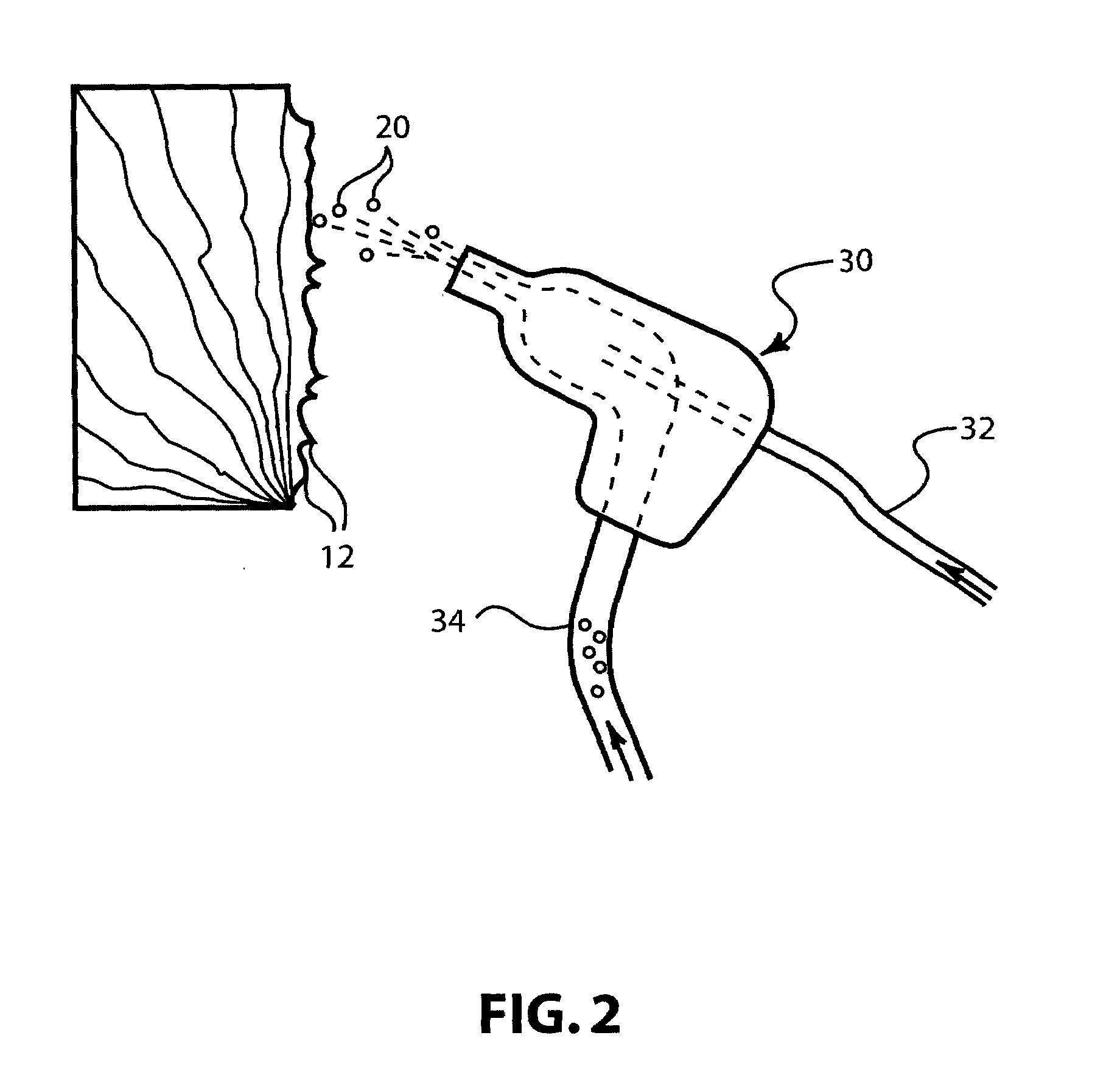

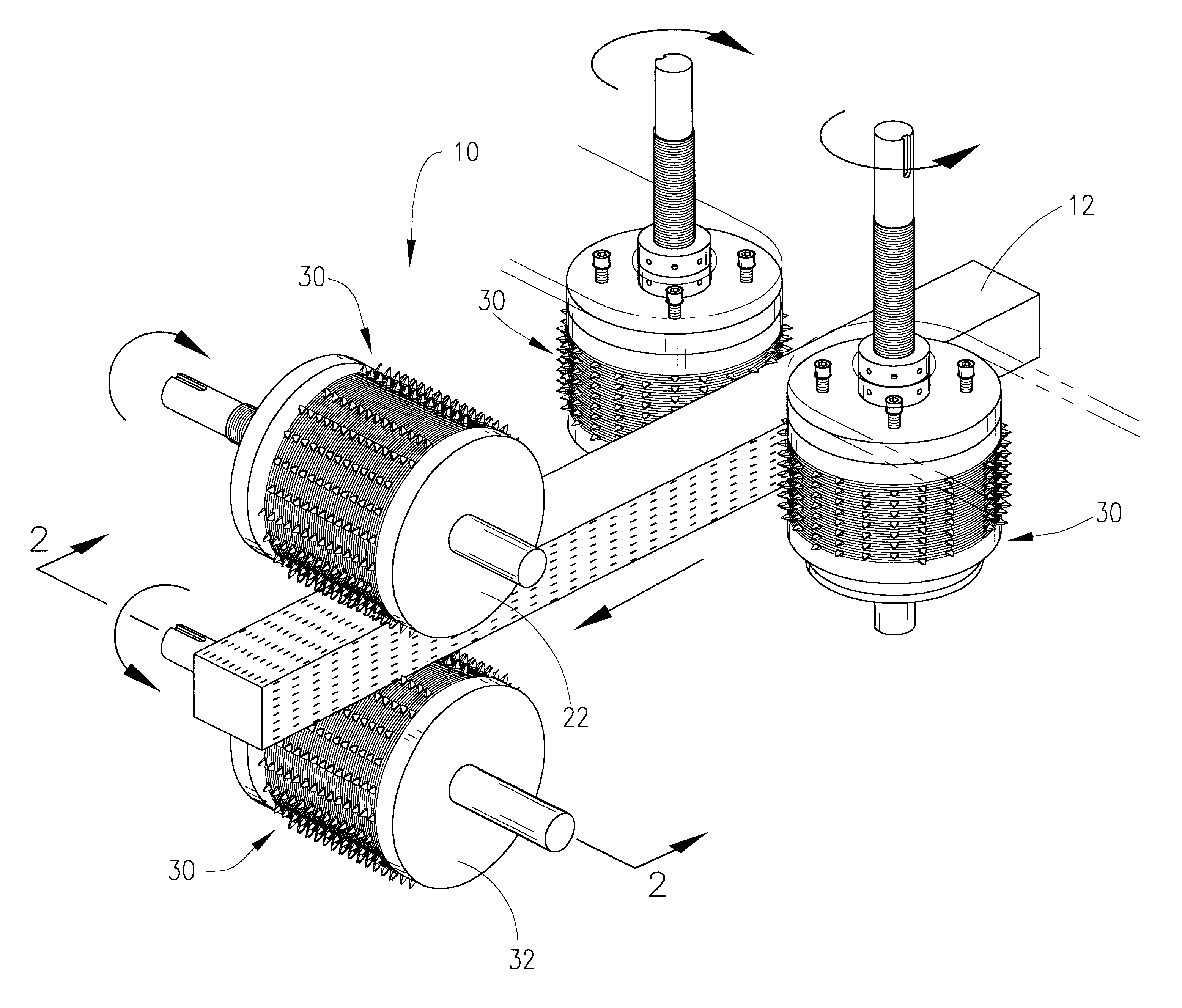

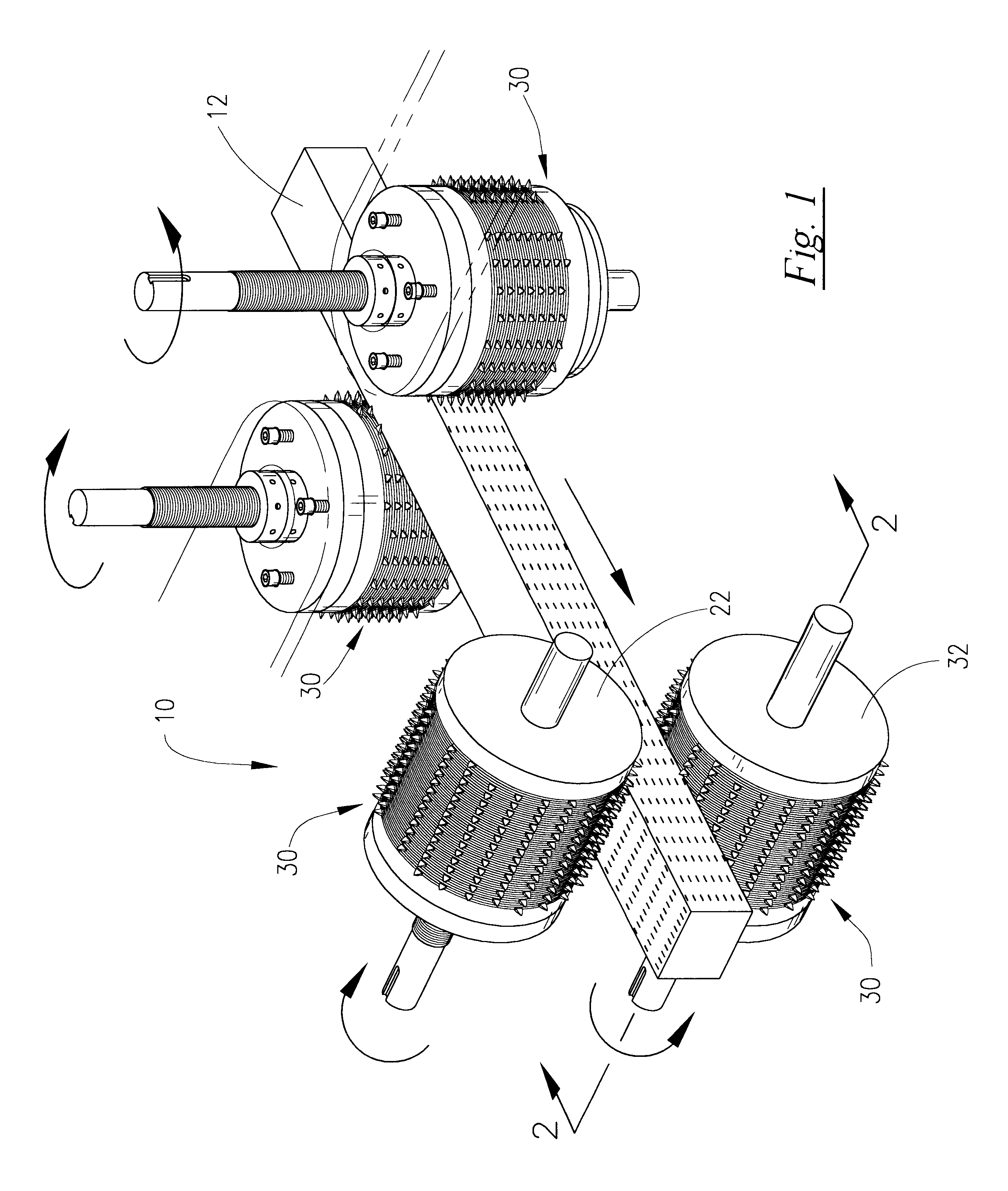

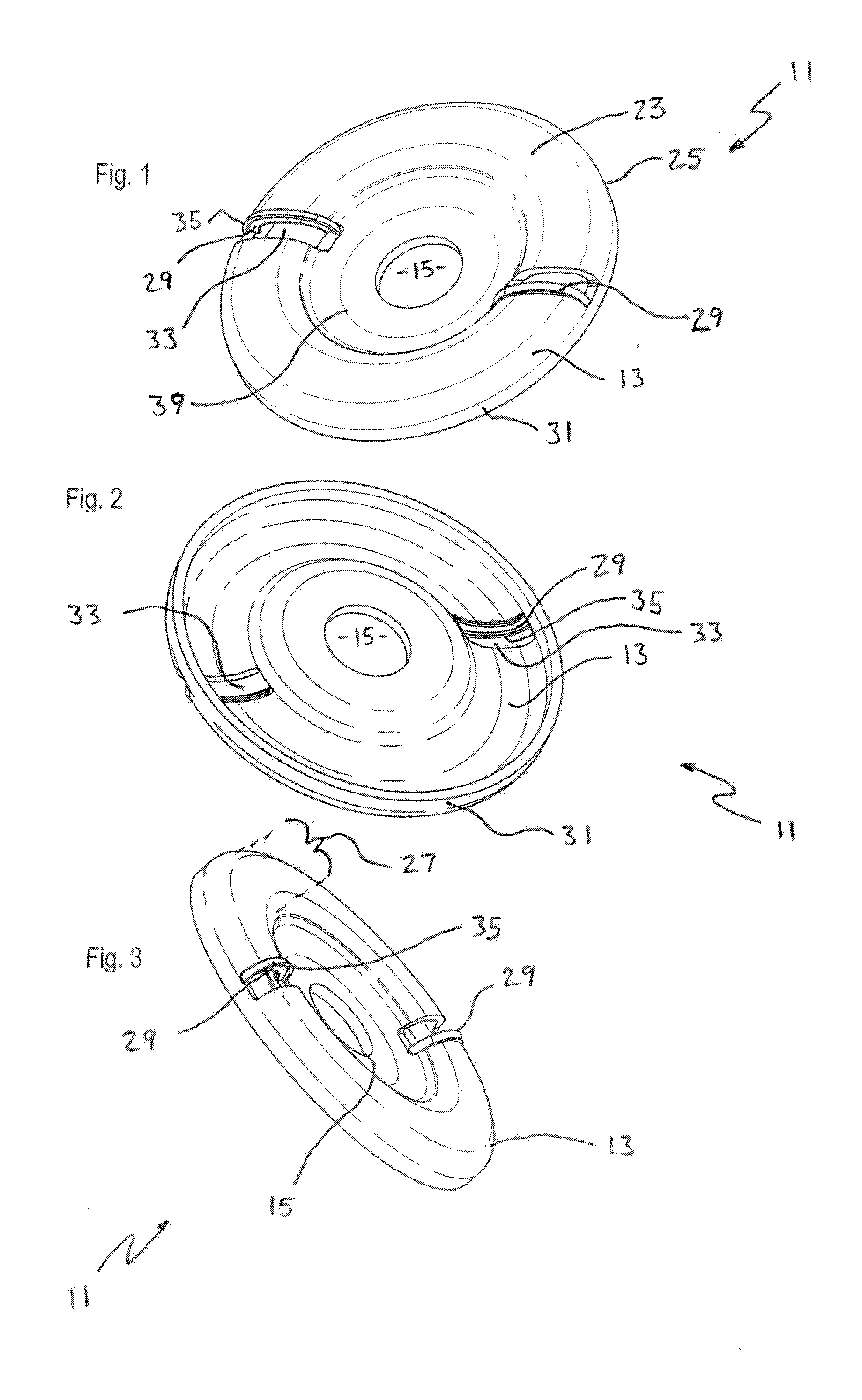

Distressing process and apparatus for applying such process

InactiveUS20110139307A1Easy desired irregular resultSimple resultWooden sticks manufactureAutomatic control devicesDistressingEngineering

A method is provided for treating the decorative face of a panel to simulate the visual effect of a distressed panel. The decorative face may include at least a layer of wood or the like. The method may involve passing the panel with respect to two or more distressing tools. The passing may be performed in an automated way by first driving means. The method may also involve advancing the distressing tools intermittently toward the moving panel to apply distress marks. The intermittently advancing may be performed in an automated way by second, third and optional further driving means. At least one of the passing of the panel and the advancing of the distressing tools toward the moving panel may be performed according to an irregular rhythm in order to obtain irregularly spaced distress marks. At least one of the first driving means, the second driving means, the third driving means, and the optional further driving means is steered by and therefore coupled to program means.

Owner:UNILIN FLOORING NC

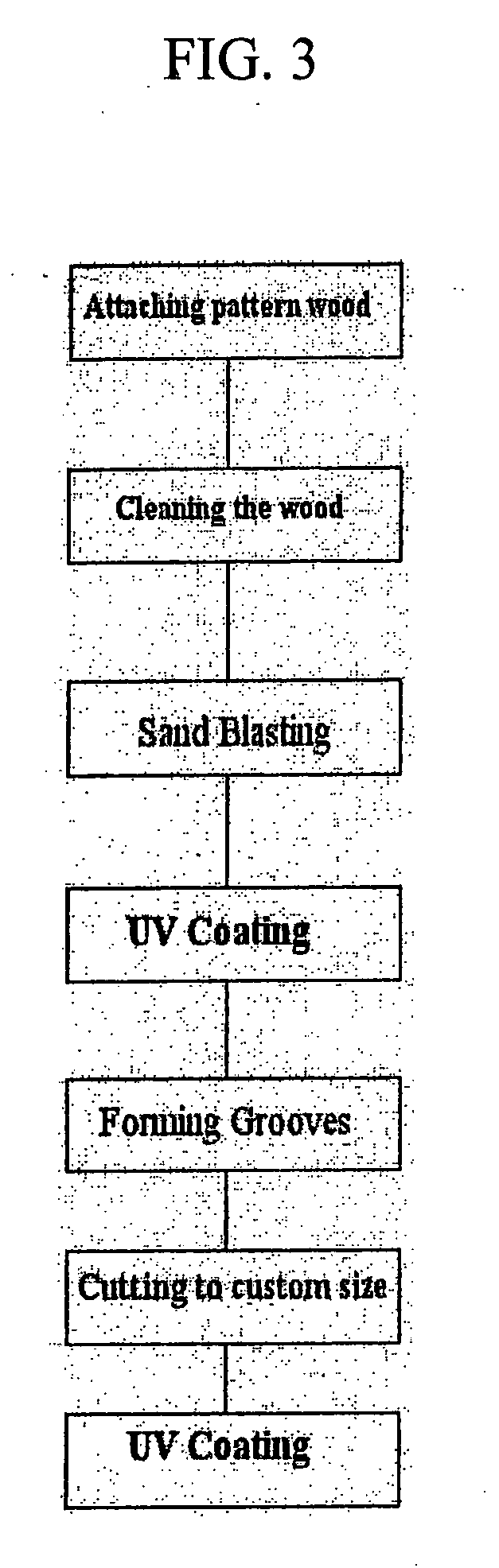

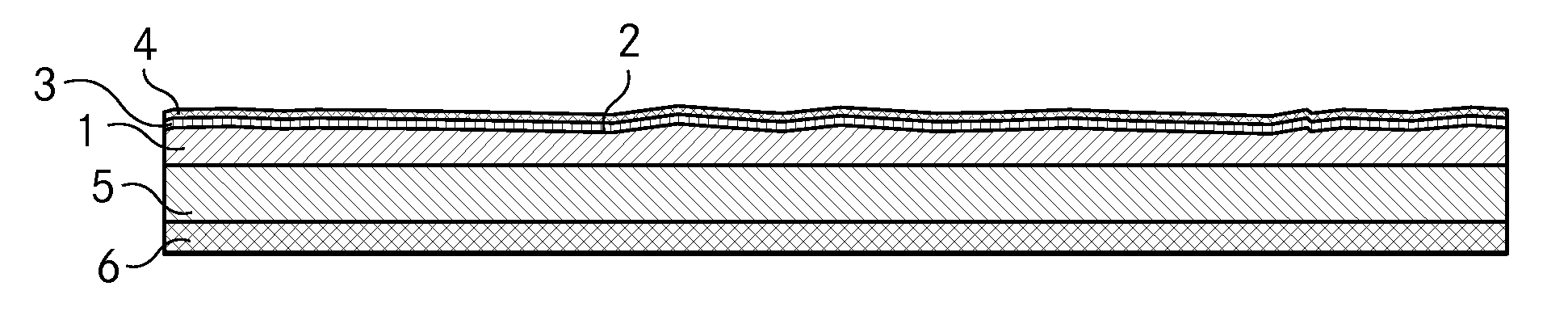

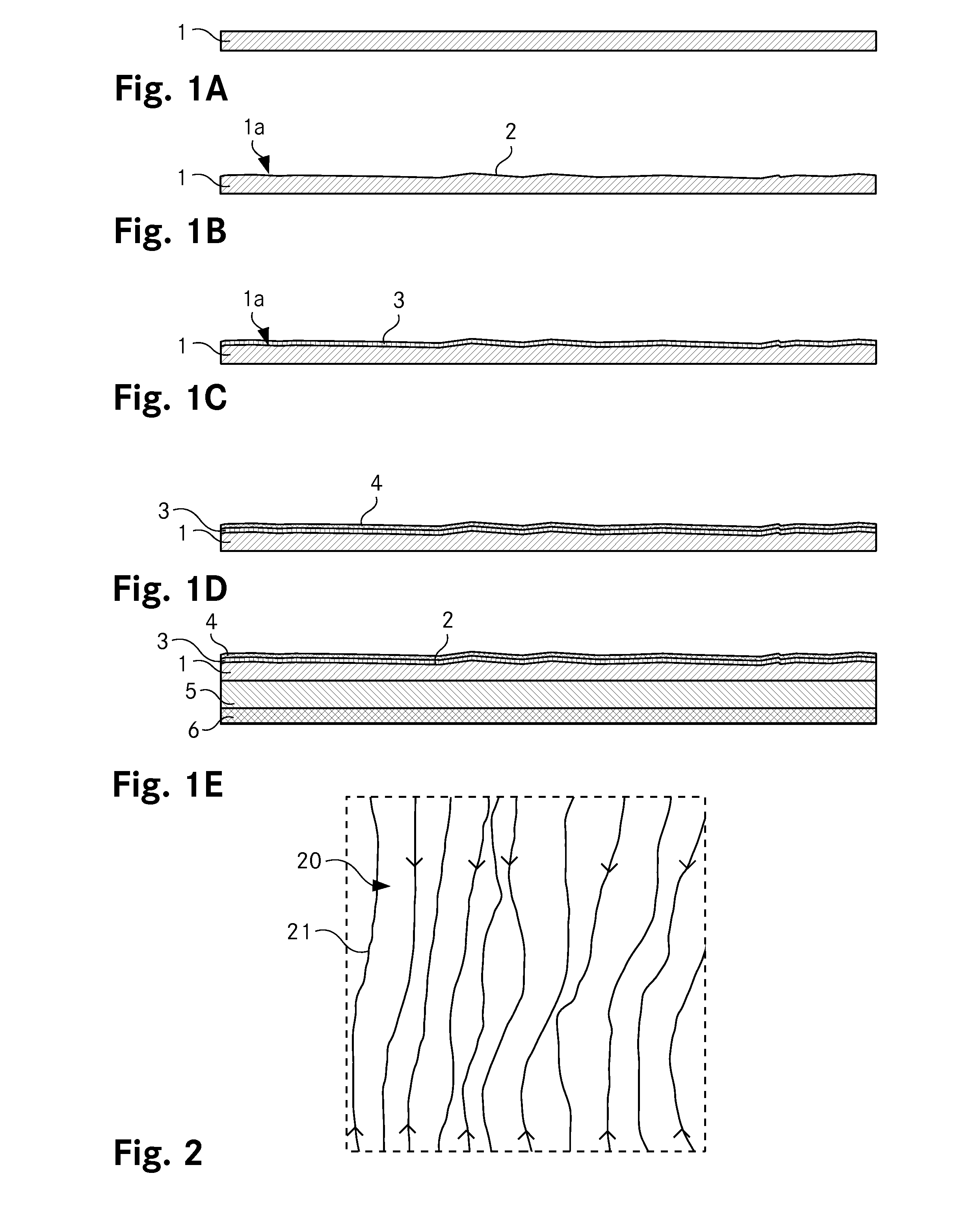

Method for enhancing texture of wood panel

A method for enhancing the texture of a wood panel. A pattern wood is attached to a surface of a plywood structure to form a wood panel. The surface of the pattern wood is then sanded followed by cleaning of the sanded surface. Thereafter, the surface of the pattern wood which has been sanded and cleaned is subjected to sand blasting. The sand blasted surface of the pattern wood is then coated with a first ultraviolet (UV) coating which is allowed to harden. Grooves are then formed on a lower surface of the wood panel. The wood panel is then cut to a preselected size. The surface of the pattern wood is then coated with a second UV coating which is allowed to harden.

Owner:PARK YOUNG WON

Manufacturing method for antique floor

InactiveCN106985249AImprove product qualityAntique effect is goodMechanical surface treatmentWood treatment detailsWood veneerEngineering

The invention discloses a manufacturing method for antique floor. The manufacturing method comprises the following steps of: performing raw wood cross-cutting, forming square-columns, and performing drying to manufacture wood veneer; then, mixing the wood veneer with a base material, performing cold-pressing, hot-pressing and enzymatic treatment, performing strip cutting, applying putty, performing sanding and grooving, thereby completing blank production; scraping a floor surface for blank through a circular scraping knife, coating chemical-change liquid medicine, scraping the surface again by the circular scraping knife, smoking, and polishing, thereby completing antiquing treatment; and finally, performing treatment of multi-time painting, drying and the like, thereby completing manufacturing for the antique floor. The antique floor manufactured by the manufacturing method is stable in quality, is good in antiquing effect and is attractive and beautiful in floor surface.

Owner:SINO MAPLE JIANGSU CO LTD

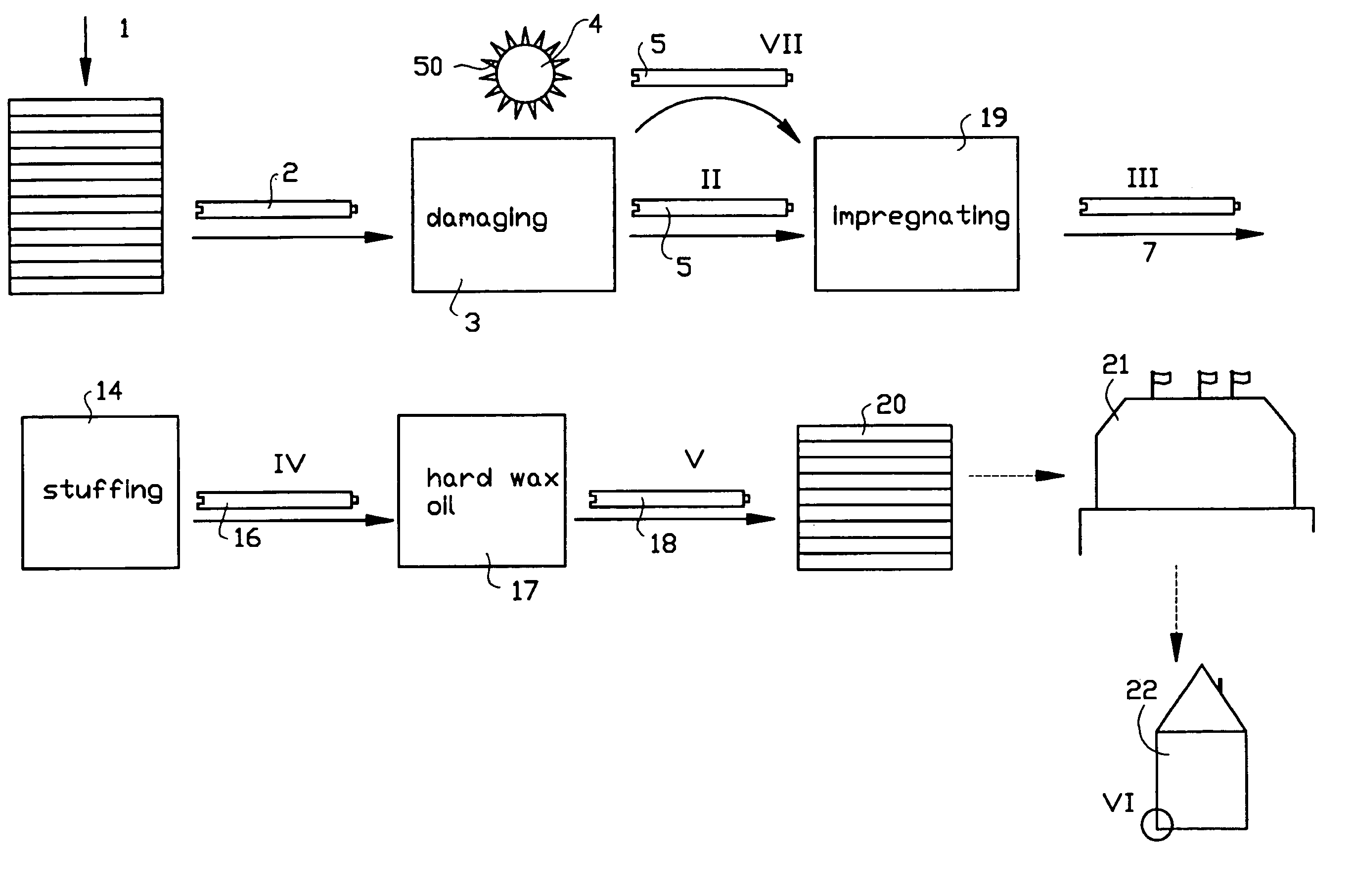

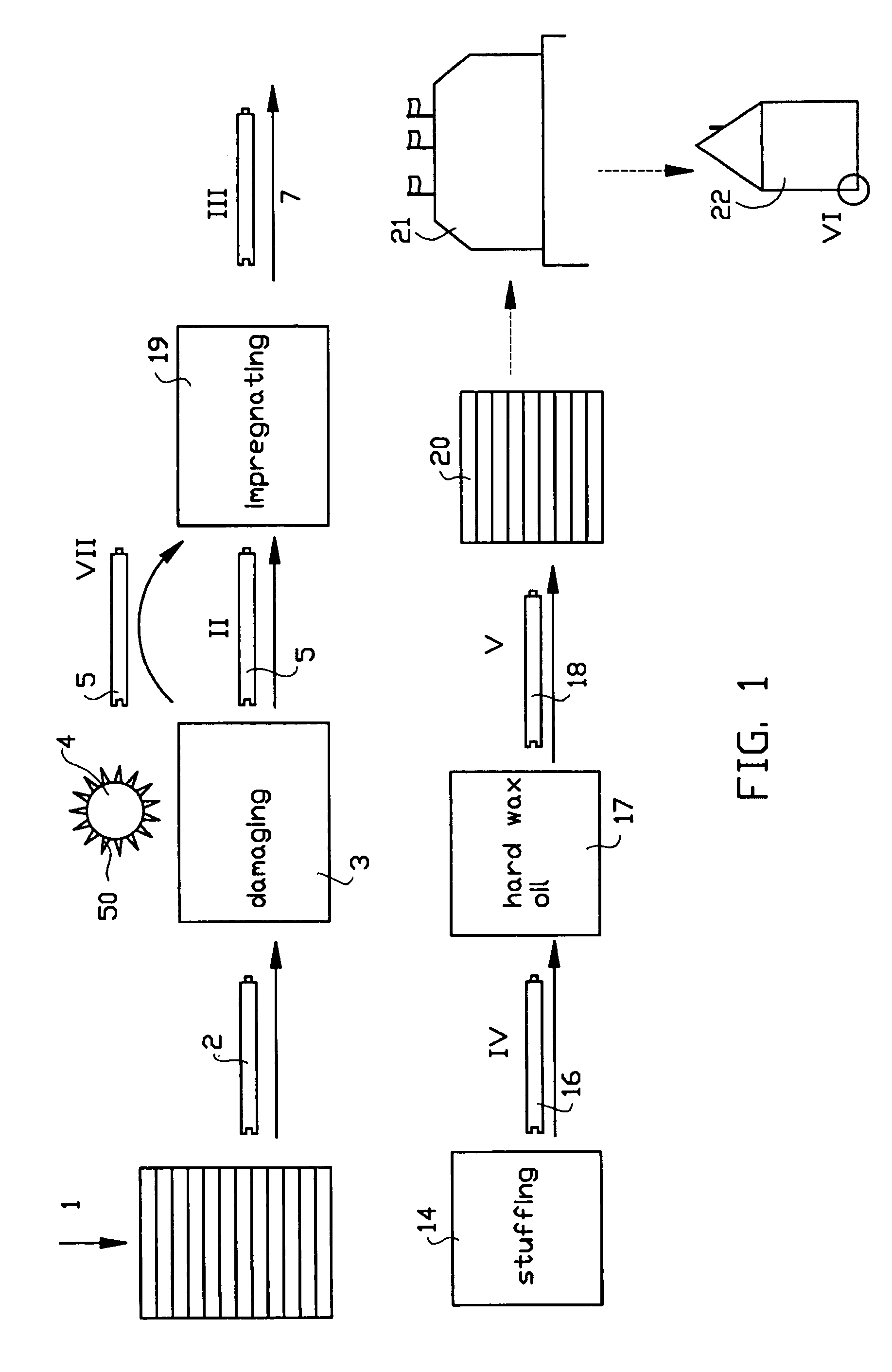

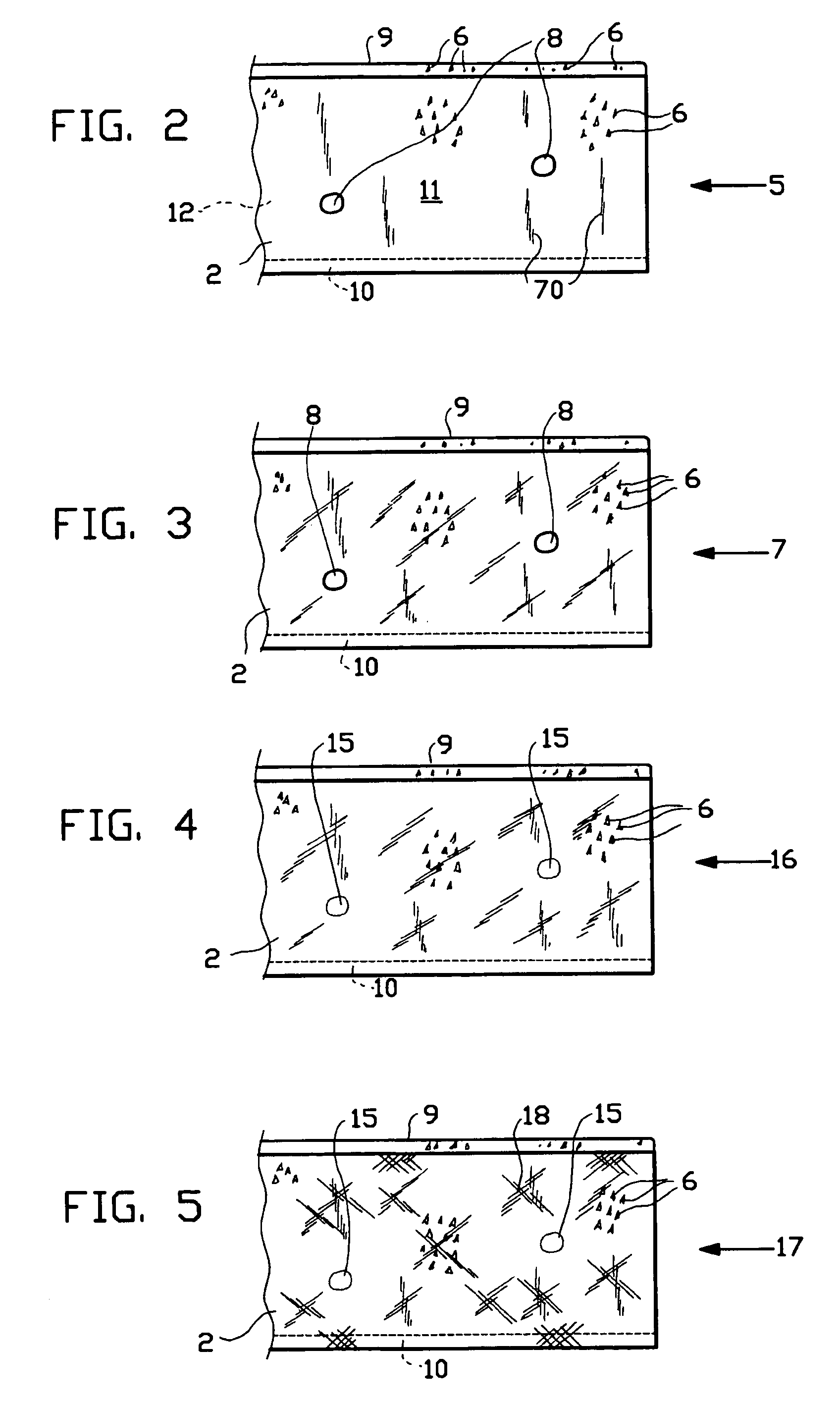

Method for manufacturing floor boards

InactiveUS6978814B2Good effectMaximal diversityMechanical surface treatmentSpecial ornamental structuresChemical treatmentWax

Method for manufacturing wooden floor boards having an antique and used look, the boards of planed new wood being subjected to a mechanical treatment for making damages in its circumferential surface, and after that to a chemical treatment of at least the entire top surface. The chemical treatment comprises the impregnation of at least the entire top surface and applying a hard wax oil after that.

Owner:HOUTIND SCHIJNDEL

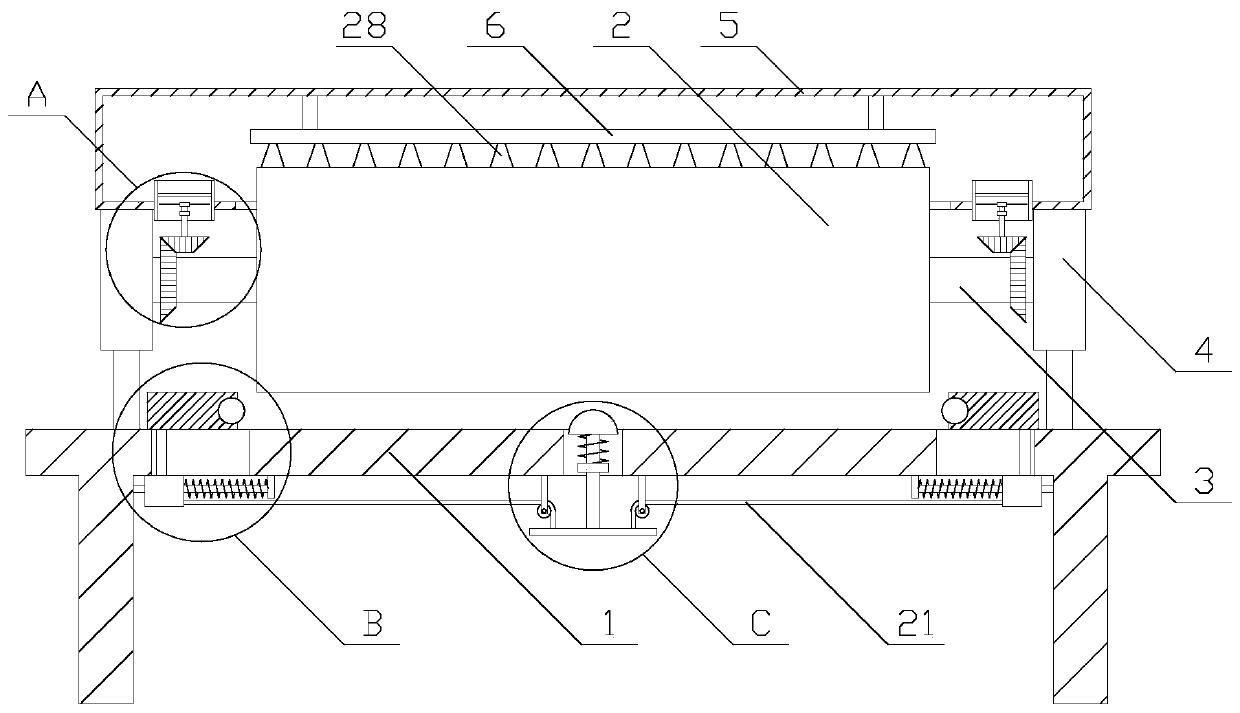

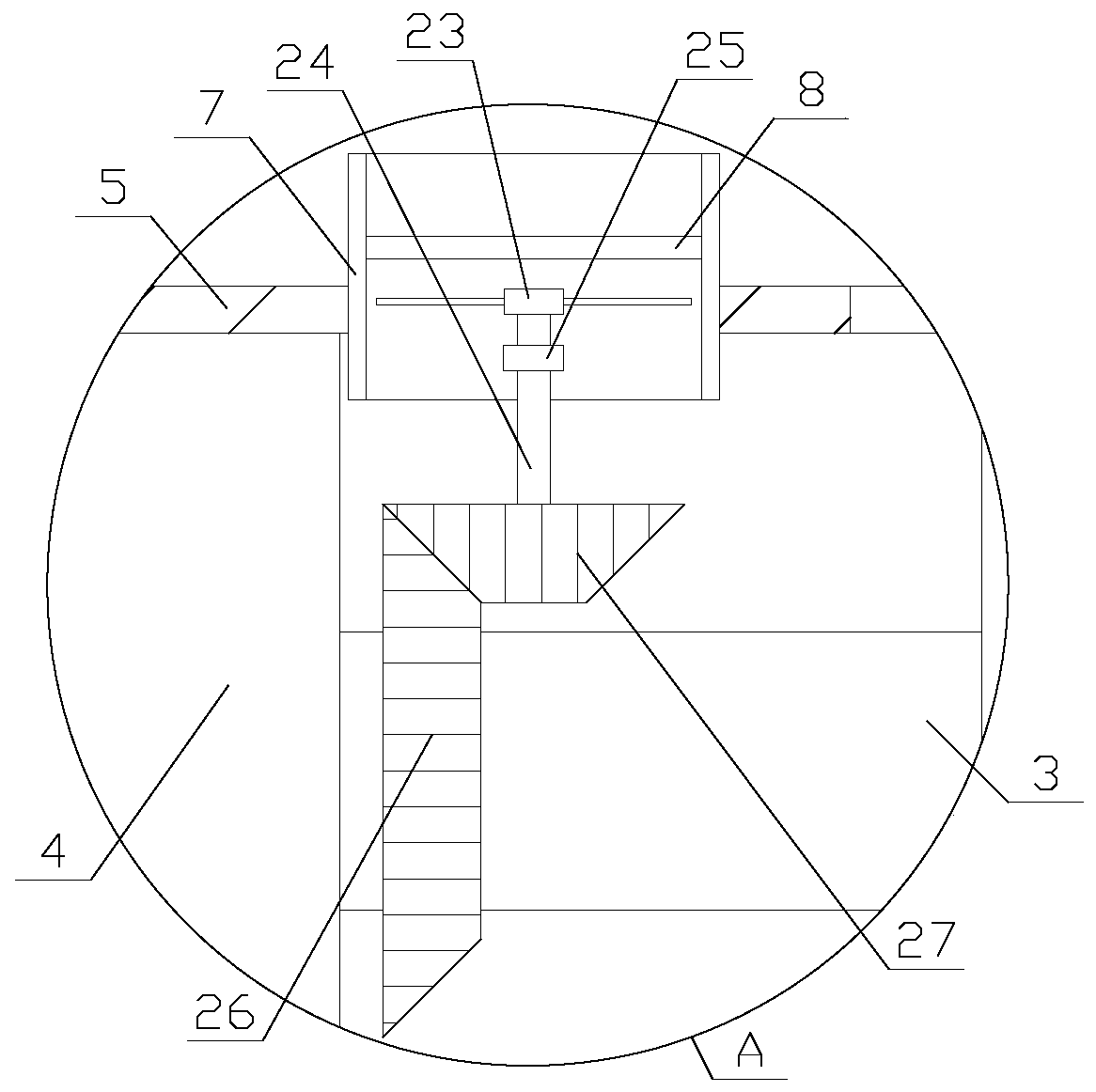

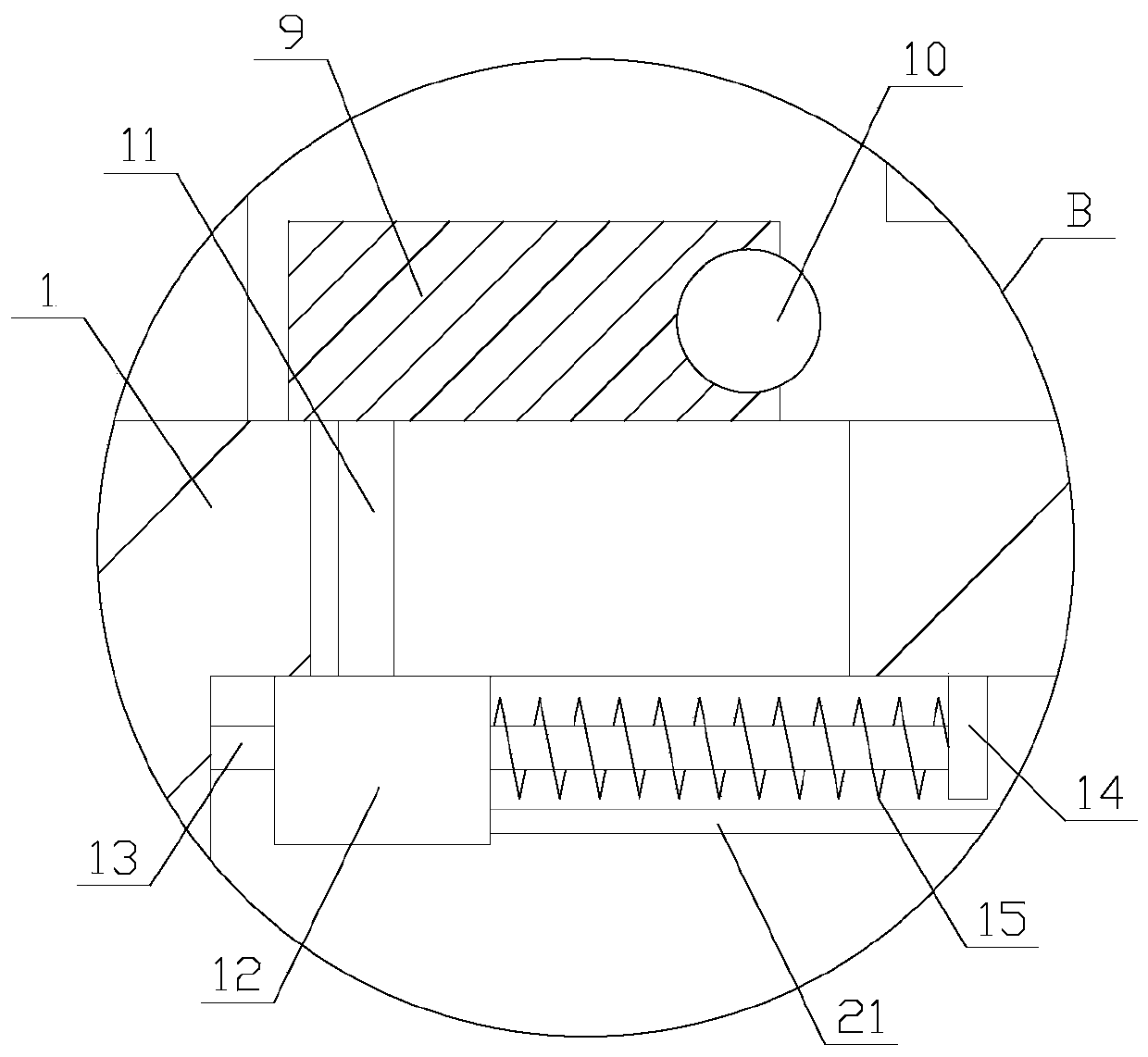

Embossing equipment used for wooden board processing and having cleaning function

ActiveCN111332054AHigh precisionAvoid stickingMechanical surface treatmentDirt cleaningWorkbenchEquipment use

The invention relates to embossing equipment used for wooden board processing and having a cleaning function. The embossing equipment comprises a working table, a pressing cylinder, a rotating shaft and two first bearings, wherein the working table is horizontally arranged; the rotating shaft is parallel with the working table and is arranged above the working table; the pressing cylinder is installed on the rotating shaft; lines are arranged on the periphery of the pressing cylinder; the inner rings of the two first bearings are installed at the two ends of the rotating shaft respectively, and the outer rings of the first bearings are fixedly connected with the top of the working table; the rotating shaft is provided with a driving device; the driving device is in transmission connectionwith the rotating shaft; the pressing cylinder is provided with a heating device; the pressing cylinder is provided with a cleaning mechanism; and the working table is provided with an auxiliary mechanism. According to the embossing equipment used for wooden board processing and having the cleaning function, the function of impurity cleaning is realized through the cleaning mechanism, so that influence of impurities to the embossing effect is prevented, and moreover, the board embossing accuracy is improved through the auxiliary mechanism, and influence to the embossing effect caused by boardoffset is prevented.

Owner:NANJING ZUNHAO FURNITURE CO LTD

Method For Mechanically Scraping Boards, Apparatus For Same, and Products Made Therewith

Owner:MANNINGTON MILLS

Method for working a useful surface of a floor covering

InactiveUS20150275528A1Desired visual appealHarmful influenceDecorative surface effectsSpecial ornamental structuresMaterial removalEngineering

A method for working a useful surface of a floor covering comprises the following steps: introducing structures into a planar cork material by way of a material-removing method, printing the structured cork material by way of a digital printing method, and applying a protective layer onto the printed structured cork material. On account of the method according to the invention, the visual appeal of the product may be influenced in a variety of ways. The visual impact may be significantly different from that of a smooth printed surface. On account of the combination of structuring and digital printing, in particular surfaces which display the impression of a non-sanded natural material (e.g. wood, slate, or similar) may be achieved.

Owner:PROVERUM

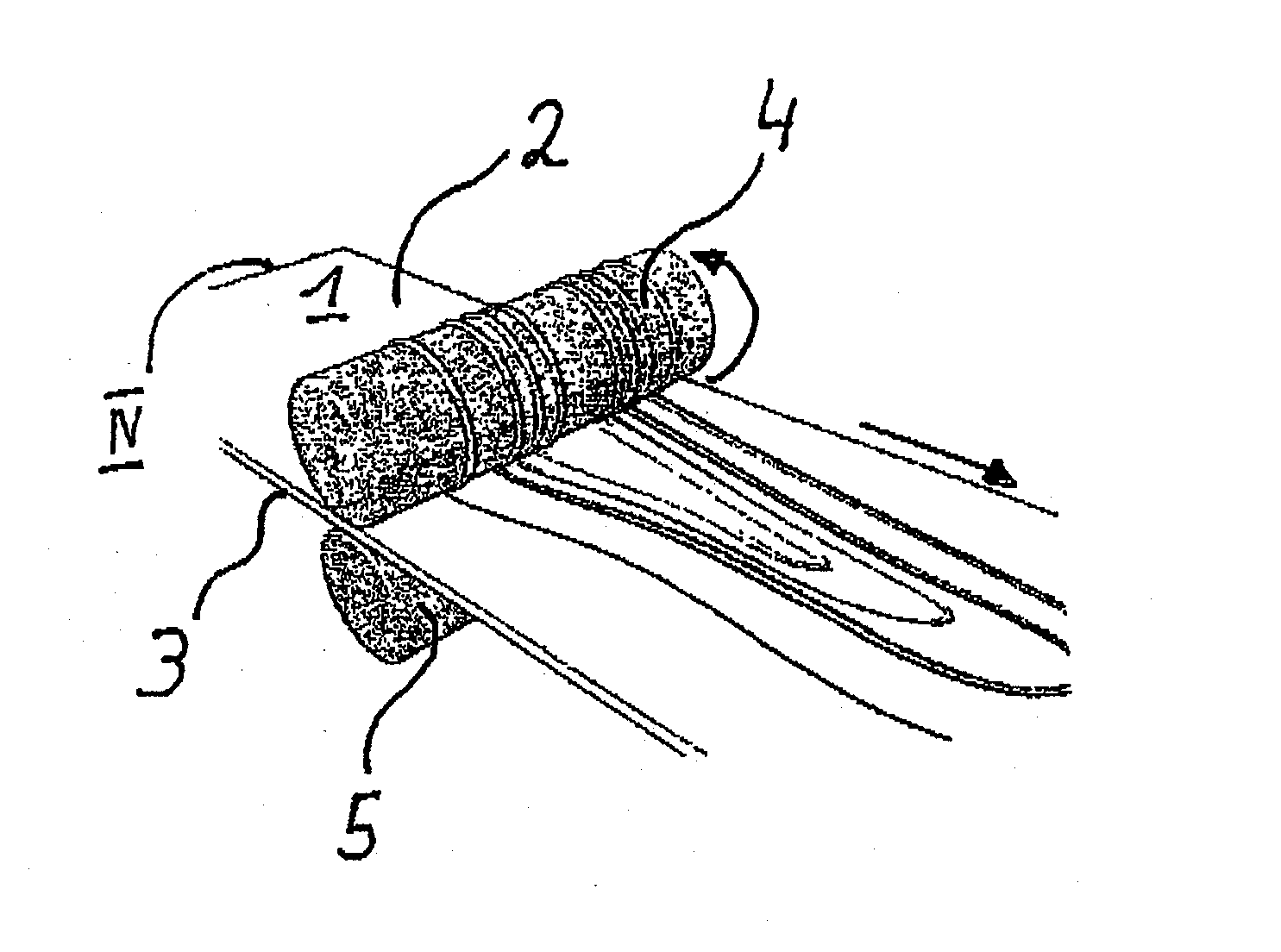

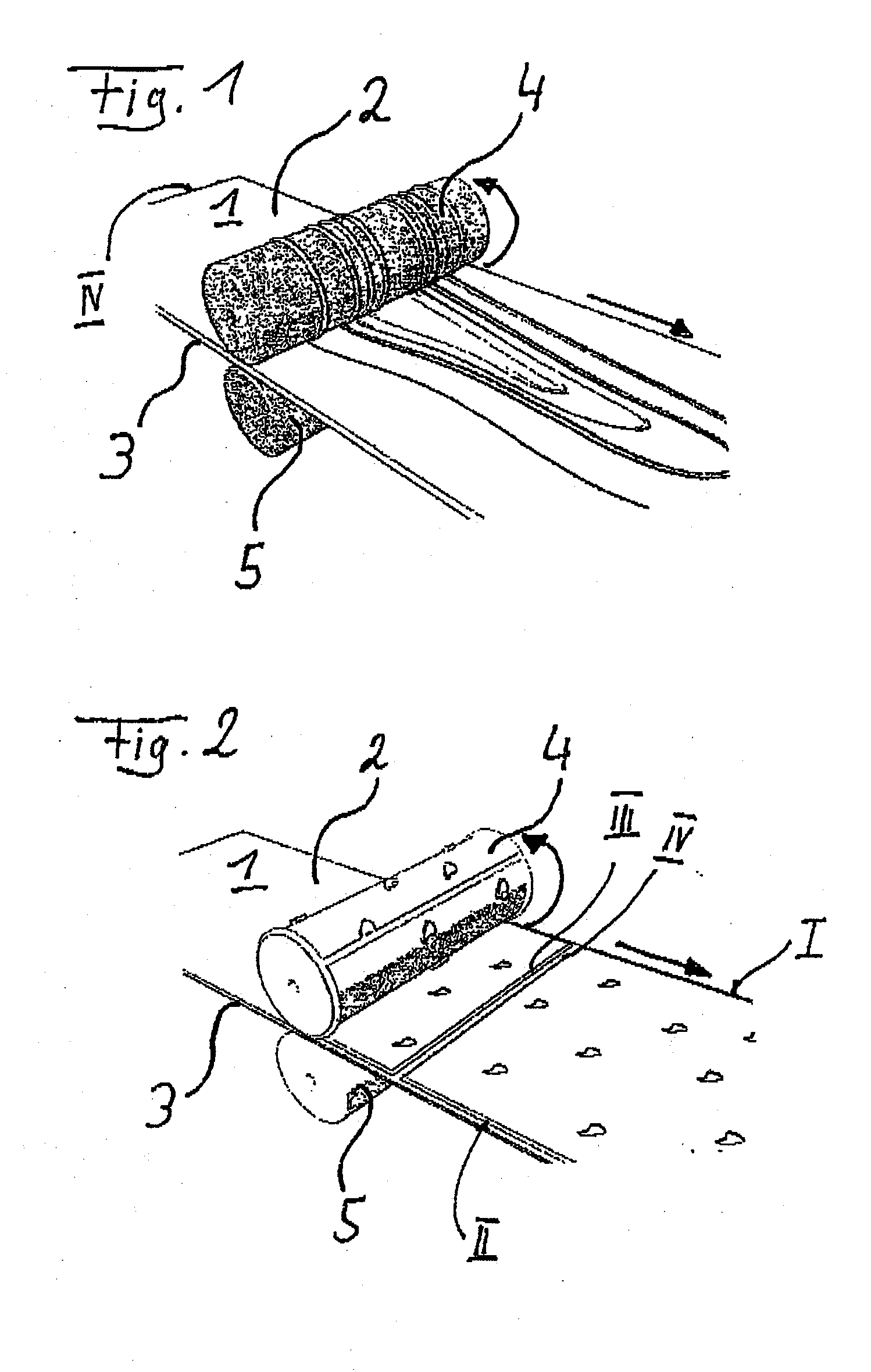

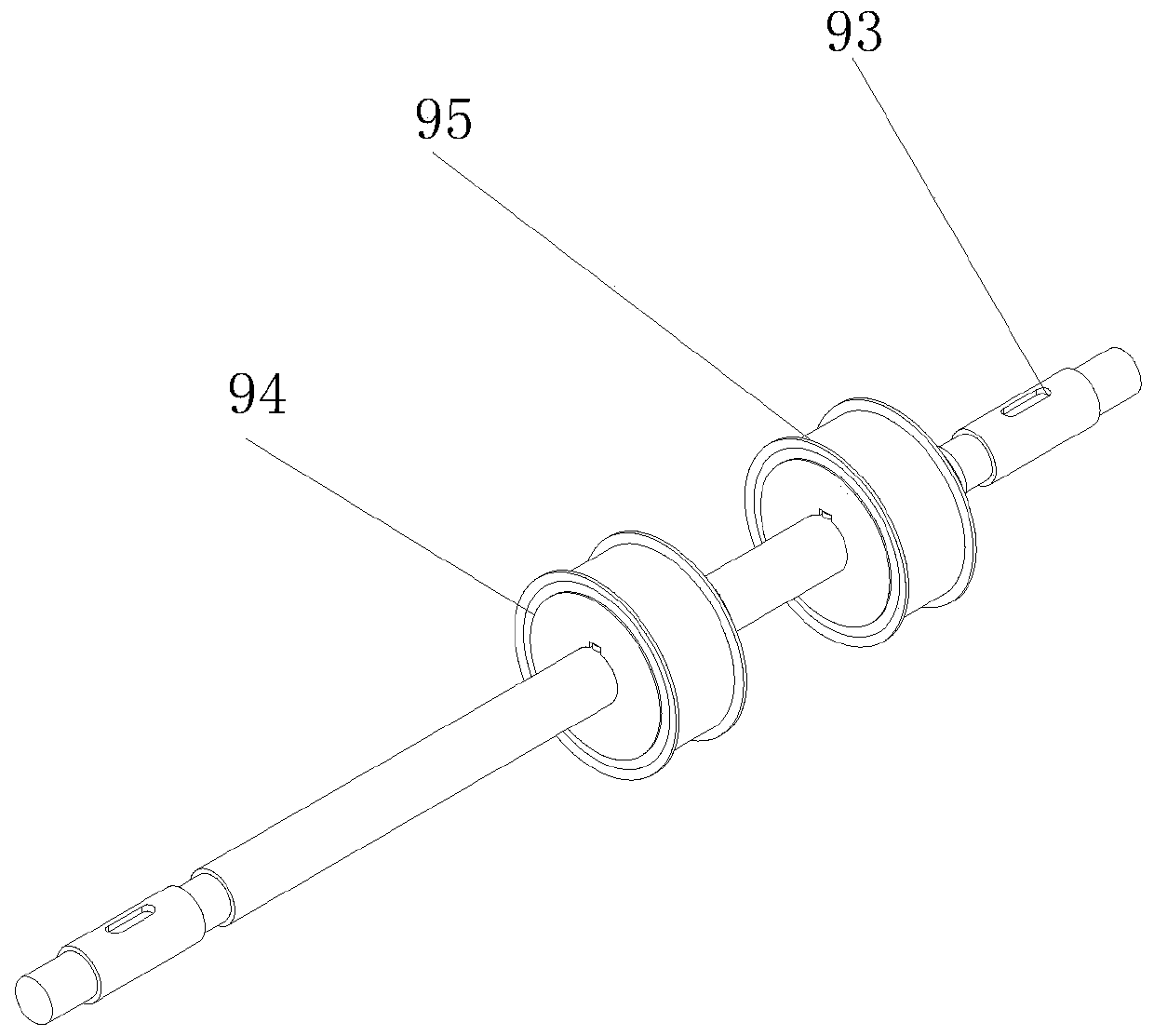

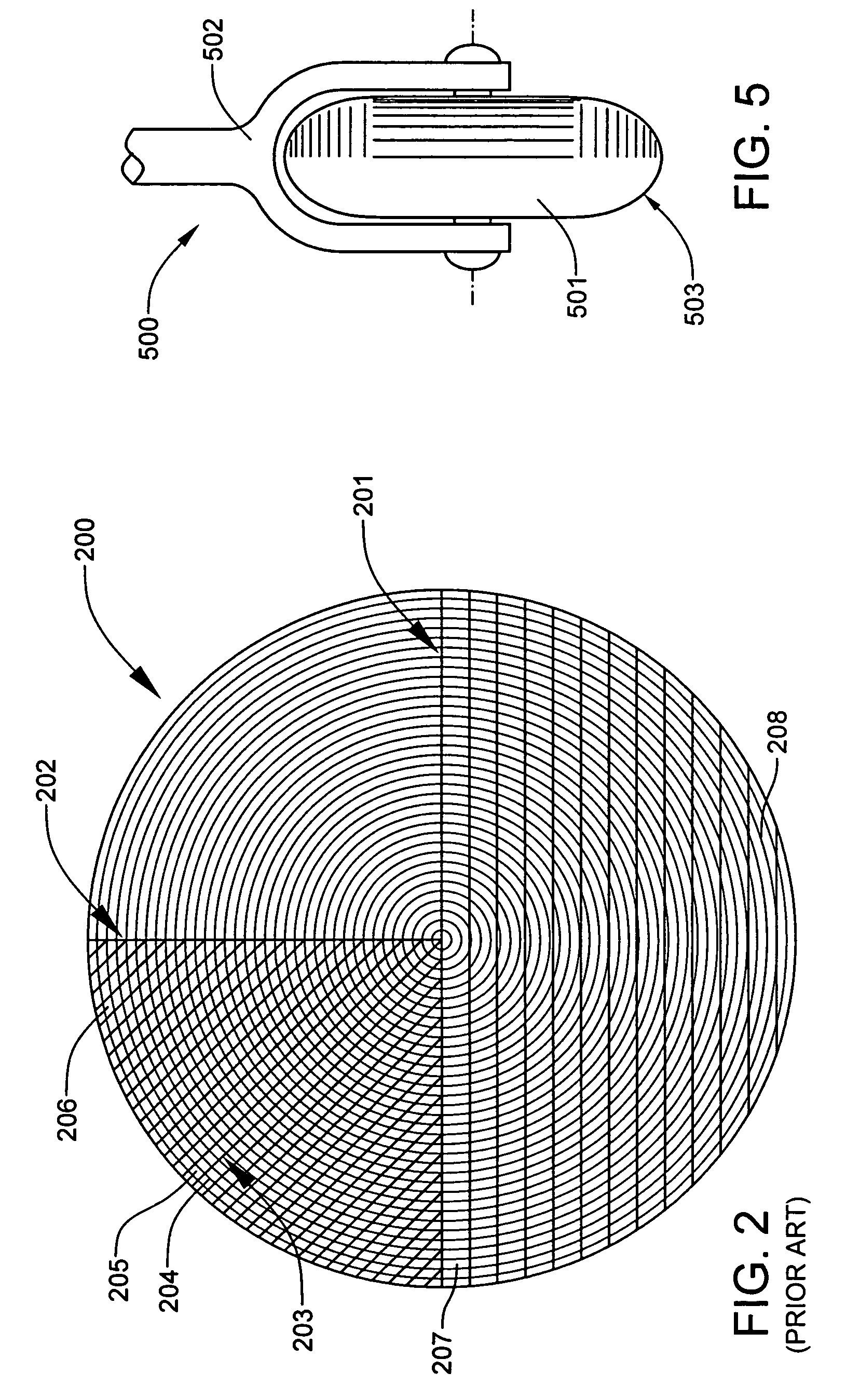

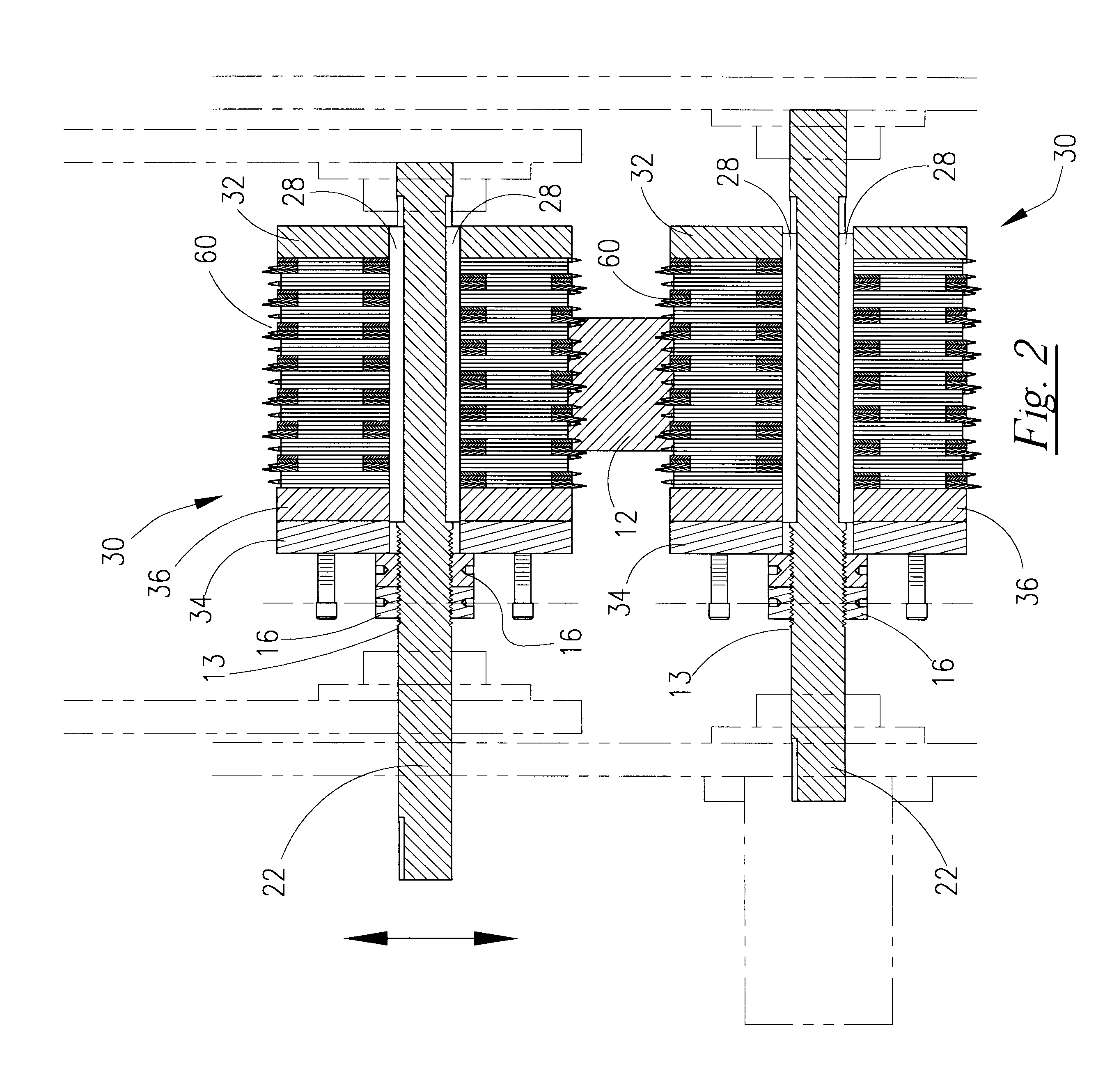

Timber incisor

InactiveUS6276412B1Less likely to bendLess likely to breakWooden sticks manufactureWood compressionEngineeringWood cutting

In a timber incising machine incorporating a shaft mounted rotating incisor drum, an improved incising drum comprising a shaft configured for rotation by the incising machine; a plurality of circular incisor plates, each of the incisor plates having a plurality of equally spaced incisor teeth extending radially from the radial edge of the circular incisor plates at a desired location. A plurality of incisor plates are stacked in a desired quantity and positioned to place the incisor teeth in a desired pattern and fixed together to form a plate array as a single unit. A plurality of the plate arrays are mounted on the shaft so as to form a rotatable drum having a plurality of radially extending incisor teeth positioned in a desired pattern.

Owner:RITA JOHNSTON & THE ESTATE OF JAMES JOHNSTON

Plastic wood floor deburring equipment convenient to use

InactiveCN108638272ASolve the cumbersome productionEasy to produceMechanical surface treatmentArchitectural engineeringTransverse plane

The invention discloses plastic wood floor deburring equipment convenient to use. The plastic wood floor deburring equipment convenient to use comprises a first transverse plate, and the left side ofthe top of the first transverse plate is fixedly connected with a bracket; the top of the bracket is fixedly connected with a second transverse plate; the right side of the second transverse plate isfixedly connected with a shell; and the left side of the inner wall of the shell is fixedly connected with a transmission box. According to the plastic wood floor deburring equipment convenient to use, through cooperation of the first transverse plate, the bracket, the second transverse plate, the shell, the transmission box, a first motor, a rotation disc, a first fixed column, a first transmission rod, a first fixed block, a slide rod, a second transmission rod, a first telescopic pipe, a second telescopic pipe, a second fixed block, a clamping block, a second motor, a movable column and a rose reamer, the problem that production is complex due to the fact that existing deburring equipment cannot adapt to floors with different thicknesses is solved; and the plastic wood floor deburring equipment convenient to use has the advantage that production is easy, a user can use the equipment conveniently, and the practicality of the deburring equipment is improved.

Owner:安吉柏森塑木材料有限公司

Edge banding machine

PendingCN111438790AAvoid displacementGuaranteed stabilityMechanical surface treatmentMulti-purpose machinesReciprocating motionFeed drive

The invention discloses an edge bonding machine. The edge bonding machine comprises an flushing device, the flushing device comprises a flushing support and a flushing assembly, the flushing assemblyis connected with the flushing support; the flushing assembly comprises a cutting assembly, a moving assembly, a flush feed driving part, a saw blade reset part and a backup plate; the cutting assembly is used for carrying out cutting on the end of a edge banding belt; the moving assembly is used for driving the flushing head assembly to do reciprocating motion in the conveying direction L of theplates; the flush feed driving part is connected with the cutting assembly to drive the cutting assembly to move to a cutting position; the saw blade reset part is connected with the moving assembly and the flush feed driving part so as to drive the cutting assembly to move so that cutting the end of the edge banding belt can be carried out; and the backup plate is movably connected with the moving assembly so as to abut against the plates during cutting and avoid the plates after cutting is completed. According to the edge banding machine of the embodiment, scratches are prevented from beingleft on the side faces of the plates when edge banding strips are cut, and the technical problem that the quality of the plates is affected due to 45-degree oblique cutting of an existing flushing device is solved.

Owner:广东龙德创展科技有限公司

Rough hew planer

Owner:JANZEN MARTIN

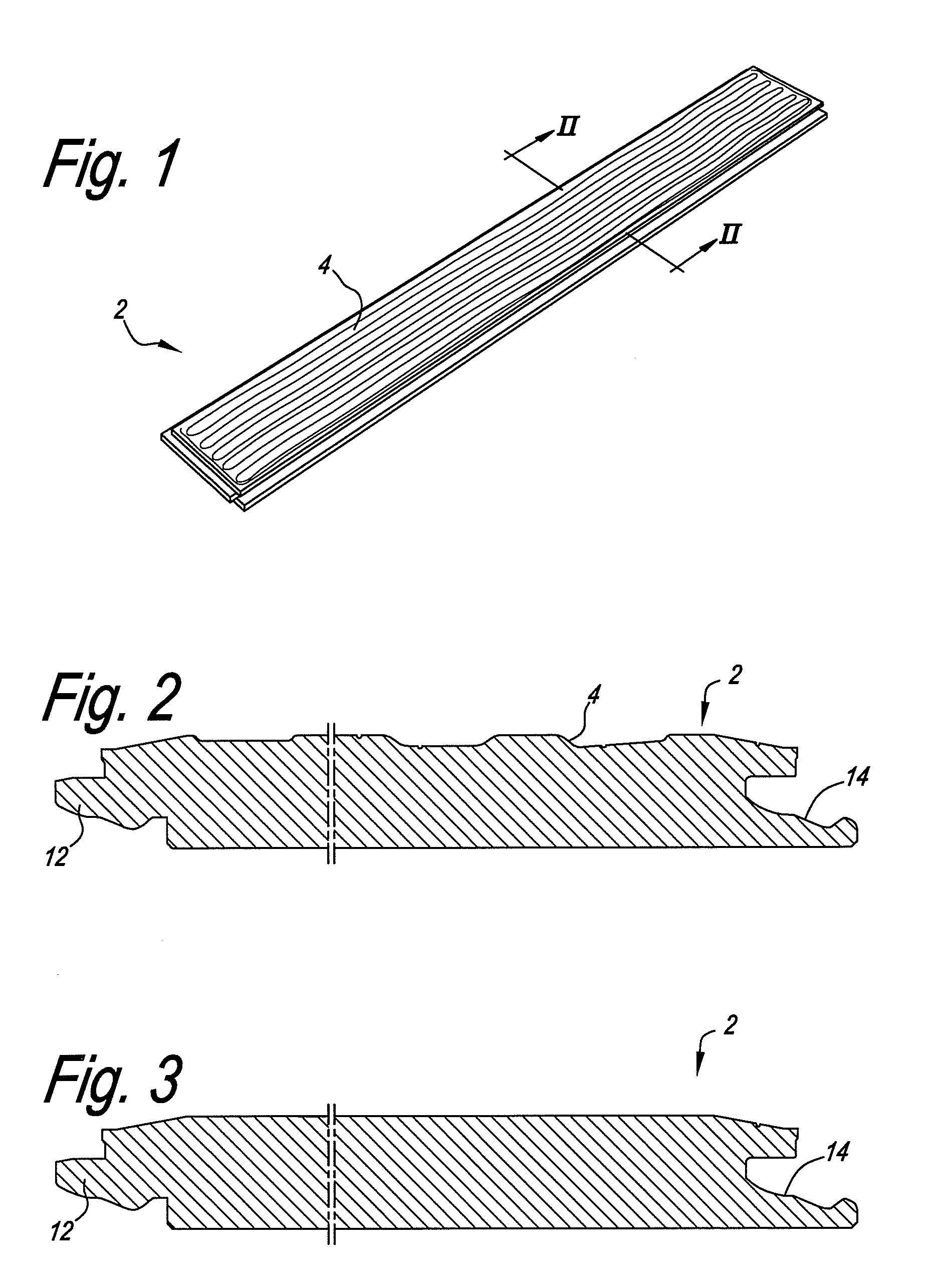

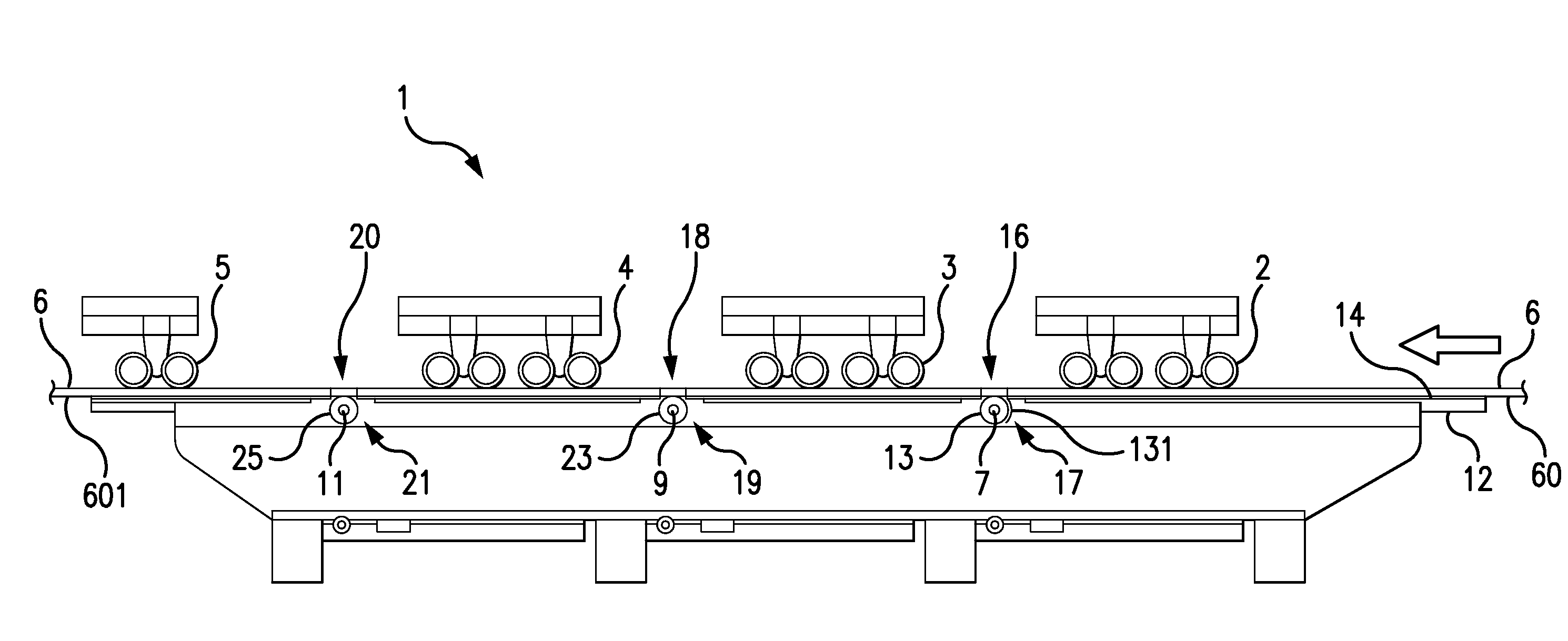

Hardwood texturing apparatus and methods for using same

Texturing apparatuses and methods are provided for forming a textured surface on a panel. An exemplary texturing apparatus has a bed and a mount having at least one cutting blade that can be configured to impart a cut to a top structural surface of the panel as the panel is moved along the bed. The bed is configured to receive the panel and can define one or more openings. The mount is operably positioned in the opening and can be articulated in one or more directions with respect to the plane of the bed.

Owner:COLUMBIA INSURANCE CO

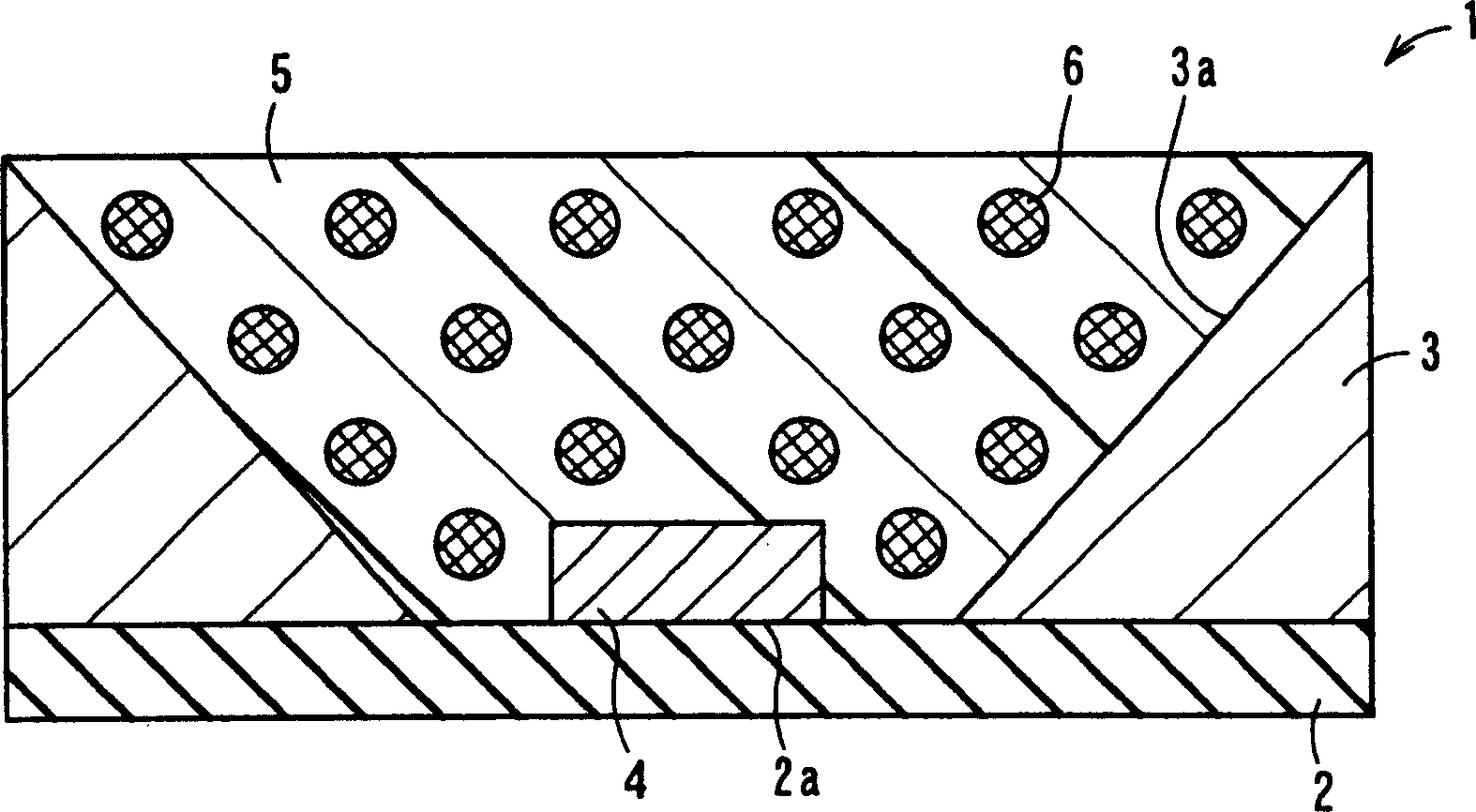

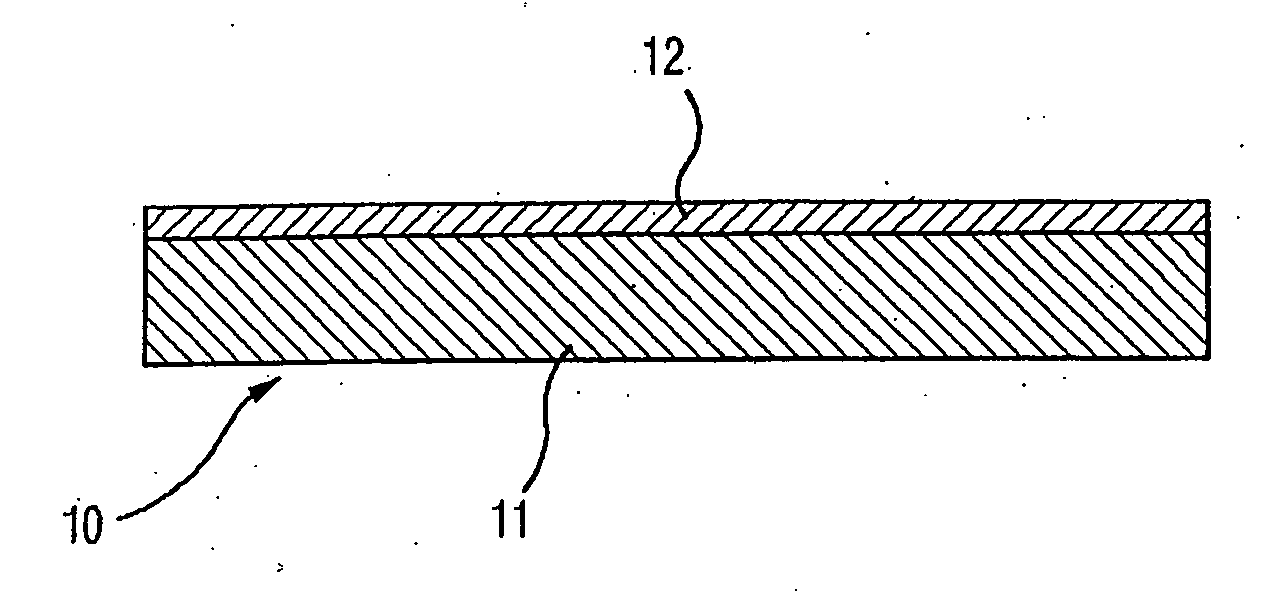

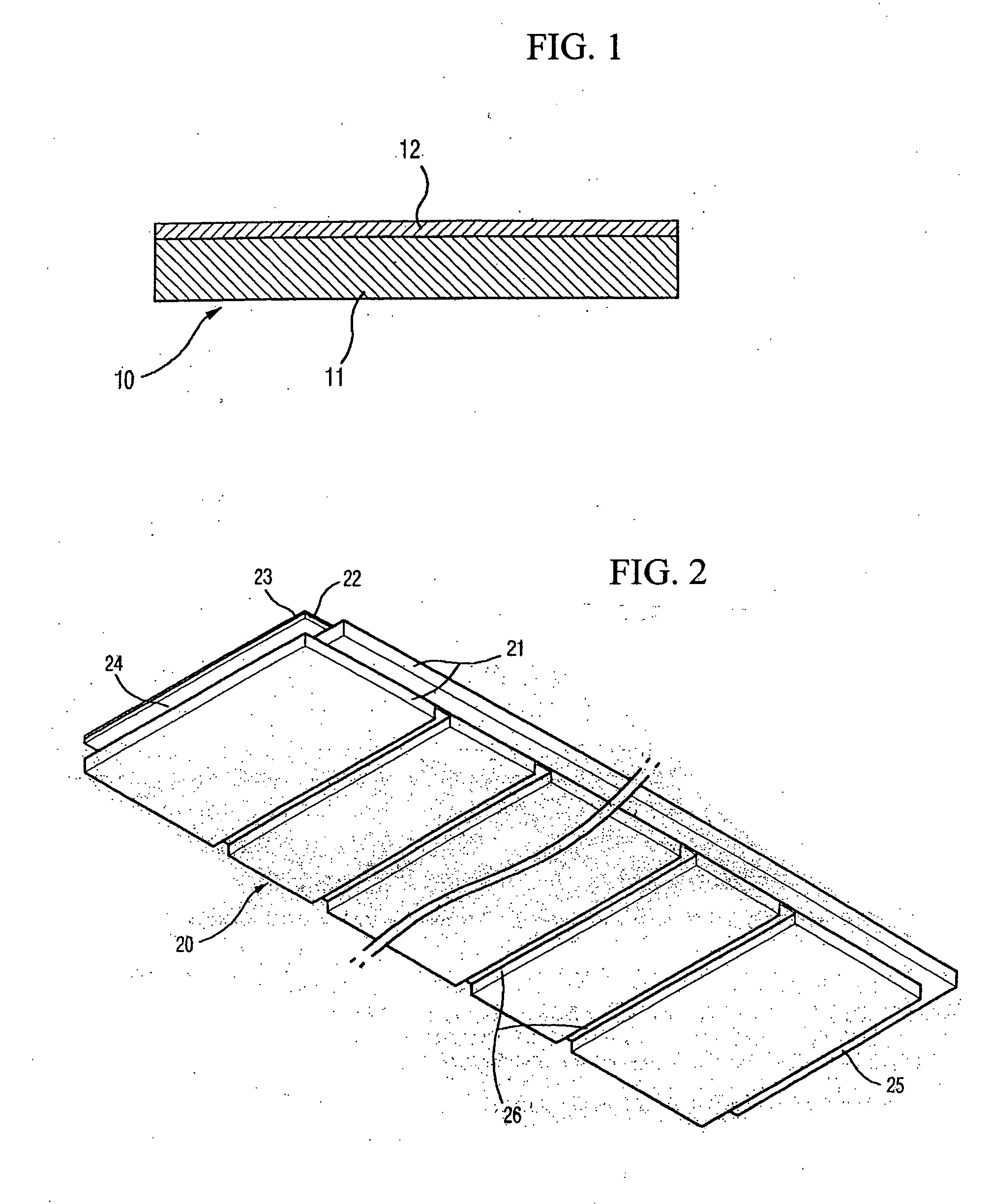

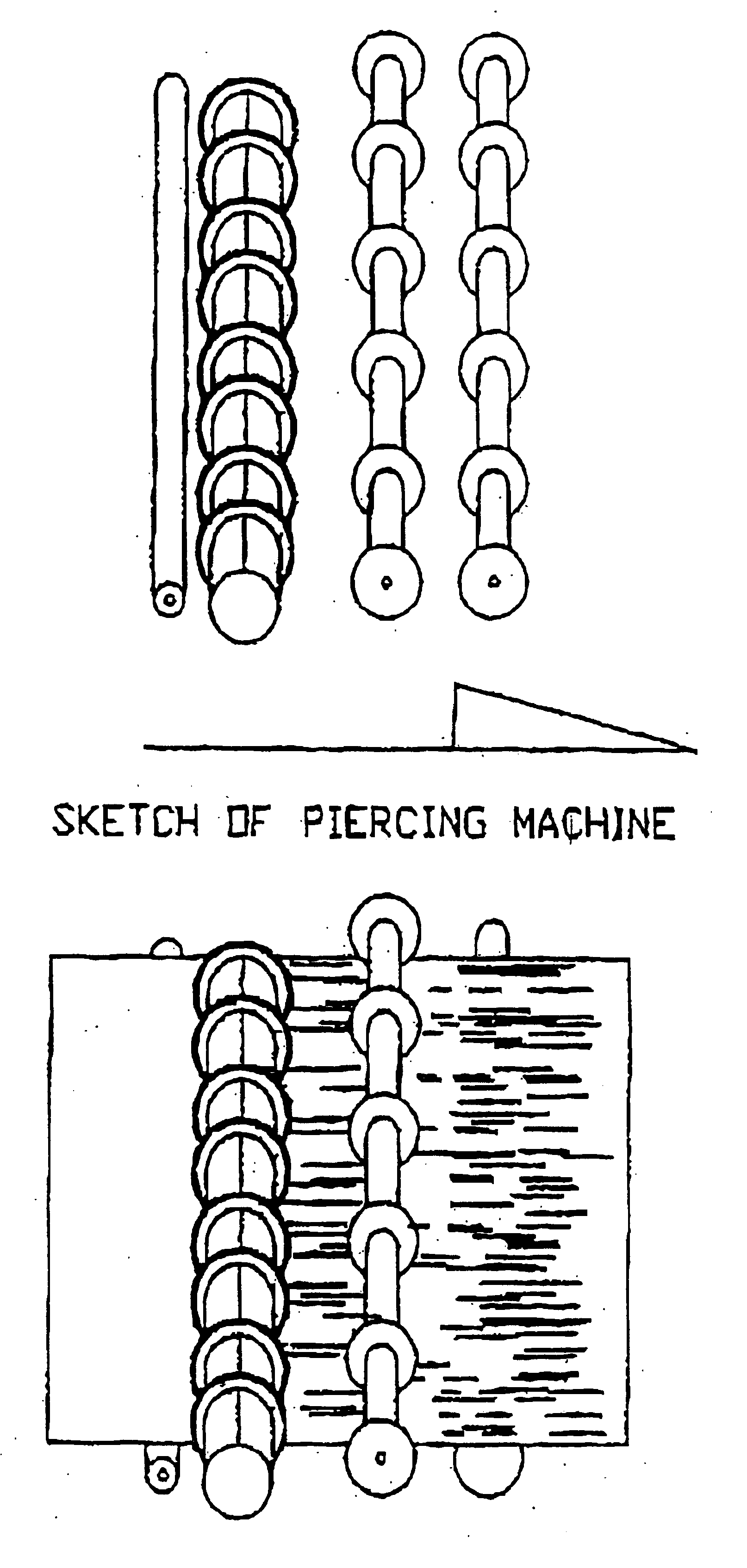

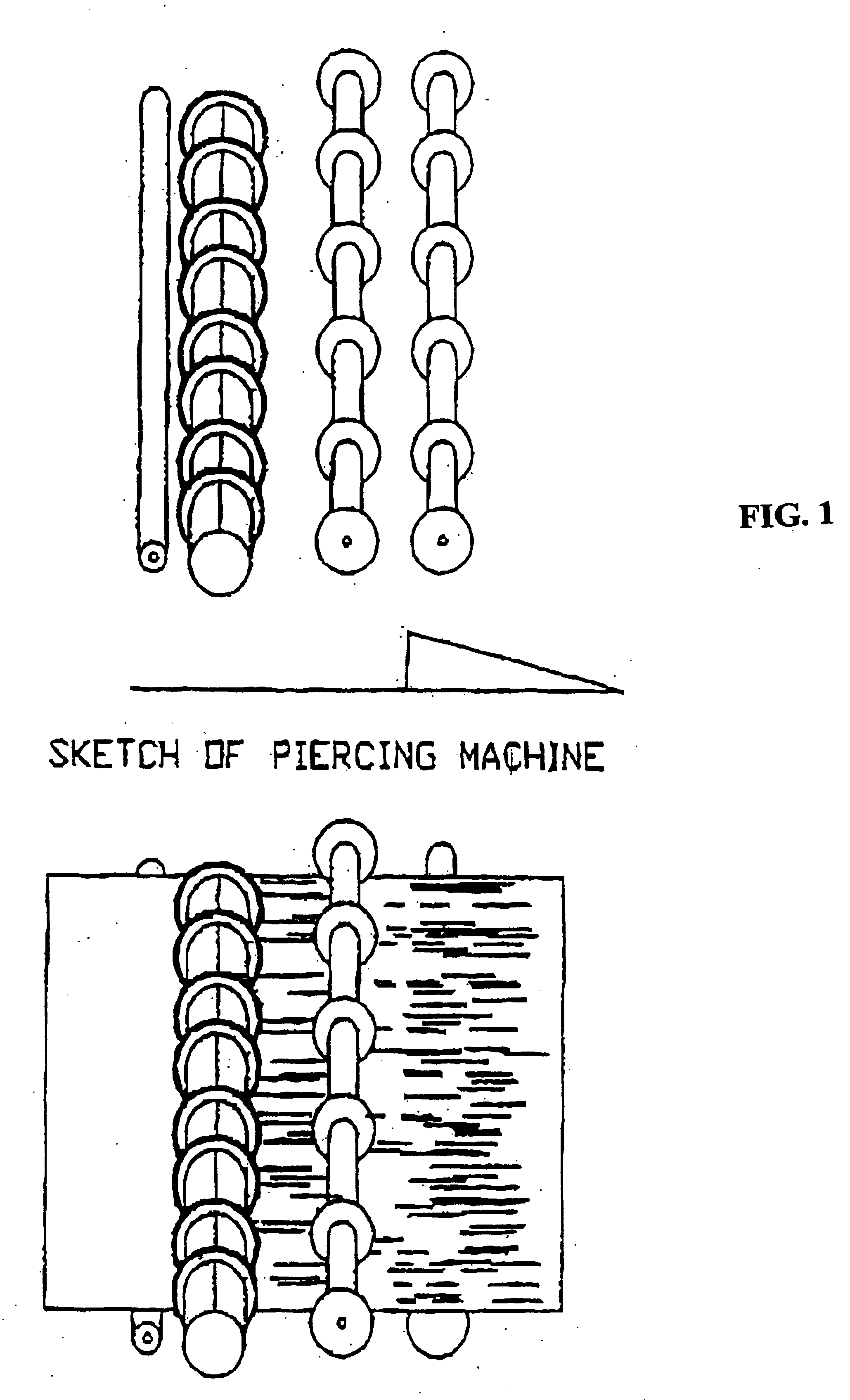

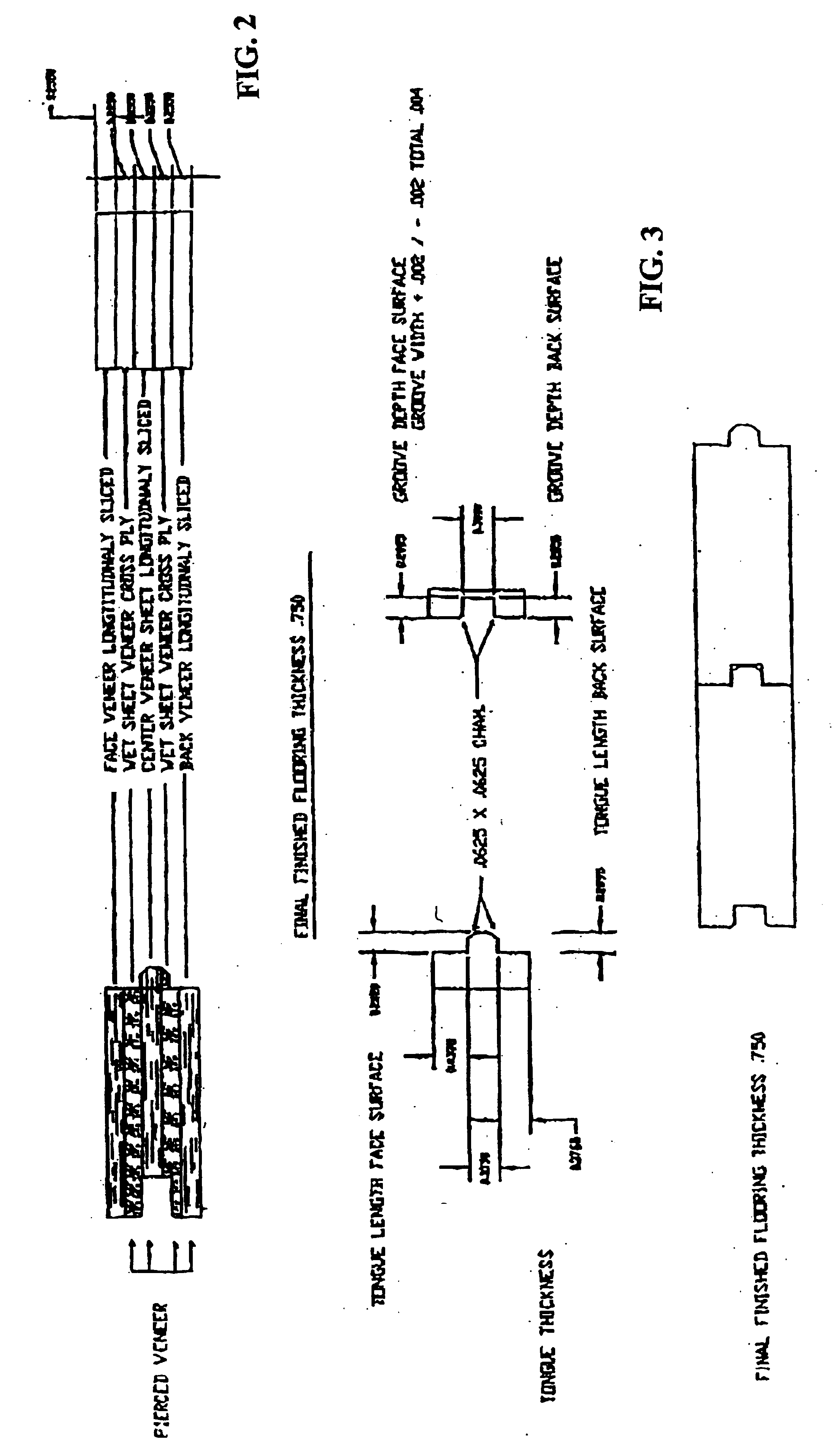

Veneer face plywood flooring and method of making the same

InactiveUS6878228B2Quality improvementLamination ancillary operationsMechanical surface treatmentSurface finishPanelling

The present invention provides a wood board for use as flooring panels and a method of making the wood board. The wood board has the strength and outer surface finish of hardwood boards, increased flexibility, and a lower cost than hardwood boards. The wood board of the present invention comprises a core layer having plural veneer layers oriented such that longitudinal grain structures of adjacent layers are perpendicular with respect to each other, and each veneer having longitudinal pierced slots placed therein oriented in parallel with their respective longitudinal grain structures; and a longitudinally sliced face layer placed upon the inner core layer. This wood board and flooring panel of the present invention have high strength, high flexibility and superior surface smoothness. Further, the present invention provides lower manufacturing costs and thus lower costs for the consumer.

Owner:CAPELLA ENGINEERED WOOD

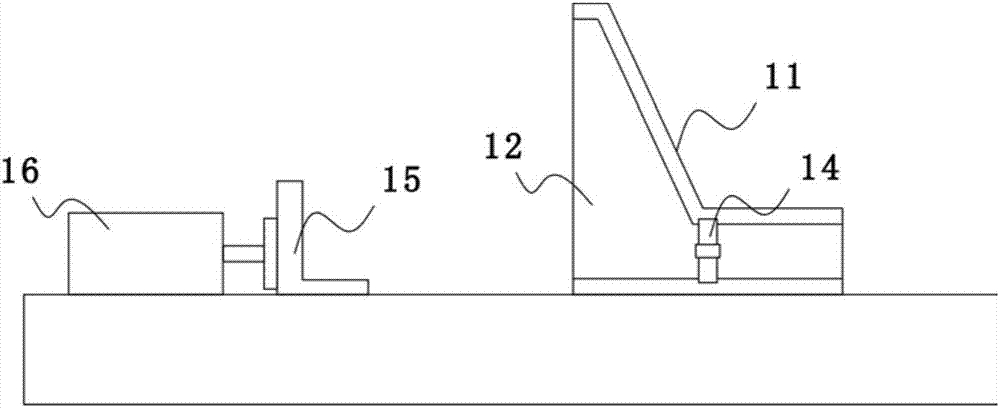

Furniture wood board surface knurling device

InactiveCN108000663ATo achieve the purpose of mass productionTo achieve the purpose of height adjustmentMechanical surface treatmentEmbossing decorationsKnurlingEngineering

The invention discloses a furniture wood board surface knurling device and relates to the technical field of furniture wood board producing and machining. The furniture wood board surface knurling device comprises supporting frames. The top end of a conveying belt is fixedly connected with clamping plate pushing devices, a height adjusting device is fixedly connected with one side between the supporting frames, a movable sliding chute is fixedly connected to one side of the supporting frames and located in the position symmetrical to the height adjusting device, a sliding block is in sliding connection with the movable sliding chute, and a supporting rod is fixedly connected with the sliding block. The end, away from the sliding block, of the supporting rod is fixedly connected with the height adjusting device, a rotary sleeve is fixedly connected with the middle of the supporting rod, and a rolling wheel is arranged on the outer side of the rotary sleeve. By means of the wood board finished product batch knurling device, the problems that in the existing knurling process, working efficiency is low, batch knurling cannot be achieved, knurling precision is low and production qualityis low are solved, and the purposes of clamping wood boards during knurling and conducting batch production are realized.

Owner:湖州雍客整木家居有限公司

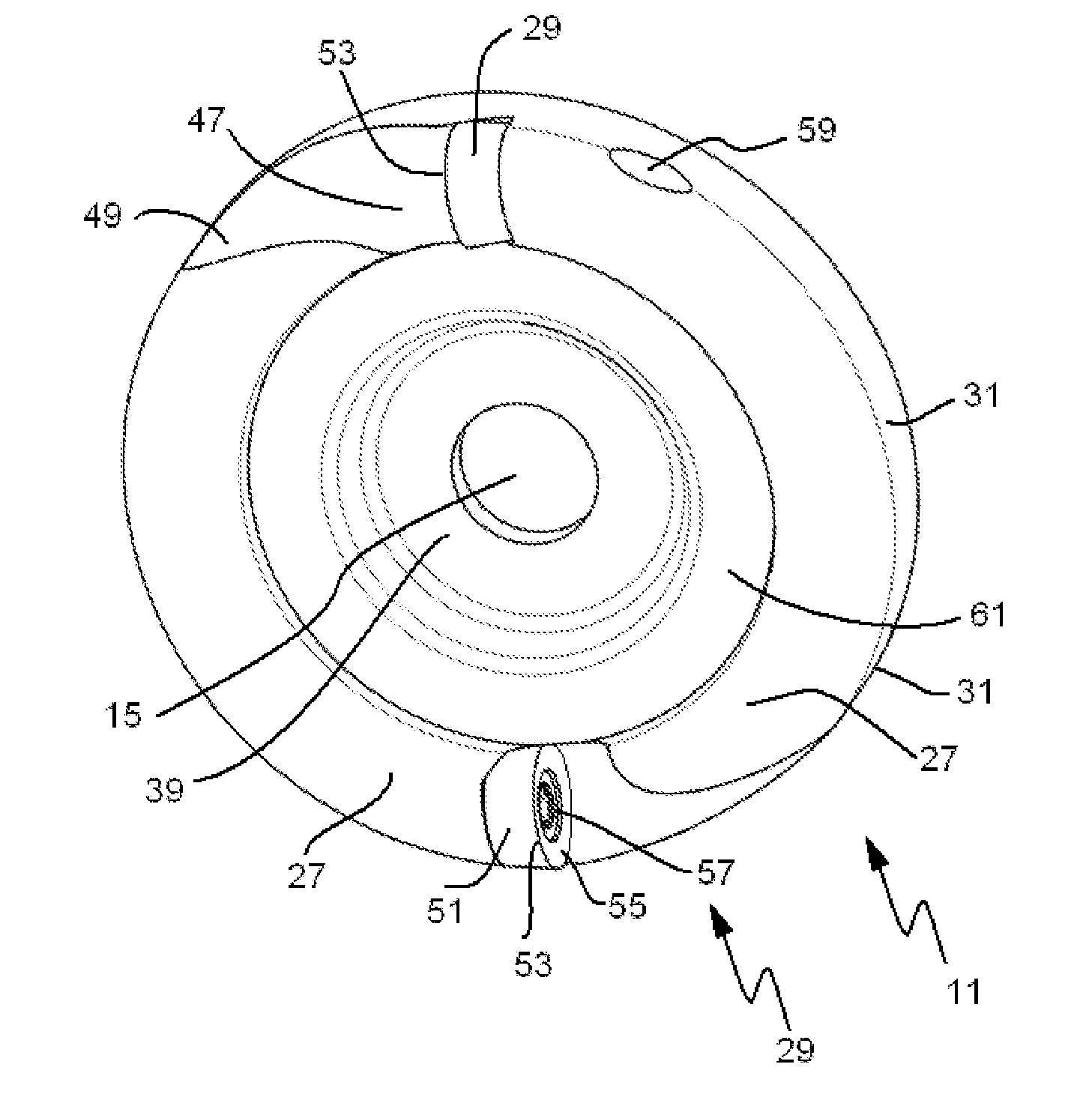

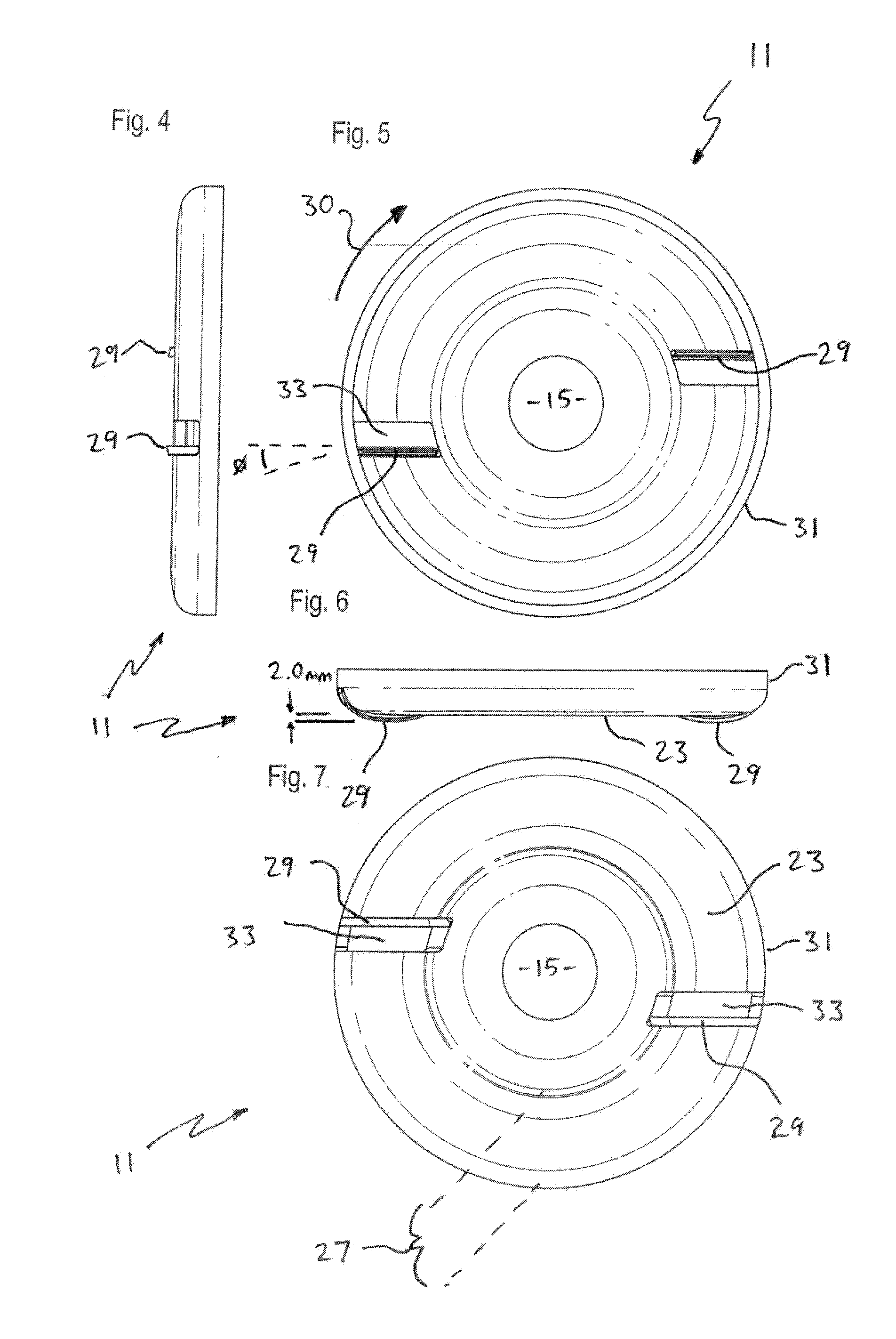

Rotary planing tool

InactiveUS20130118642A1Smooth transitionImprove biteMechanical surface treatmentMilling cuttersLeading edgeAngle grinder

A rotary planing tool comprising a disk having a central mount for mounting on an angle grinder. The rotary planing tool has a working radial surface in which substantially radially extending blades are attached. The working radial surface has radial voids extending before a leading edge of each blade. The blades extend proud of the working radial surface, and each have a curvature tending away from the working radial surface into the circumference of the disk, and are arranged to not extend past the outer circumference of the disk.

Owner:ARBORTECH IND

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com