Patents

Literature

34results about How to "To achieve the purpose of mass production" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

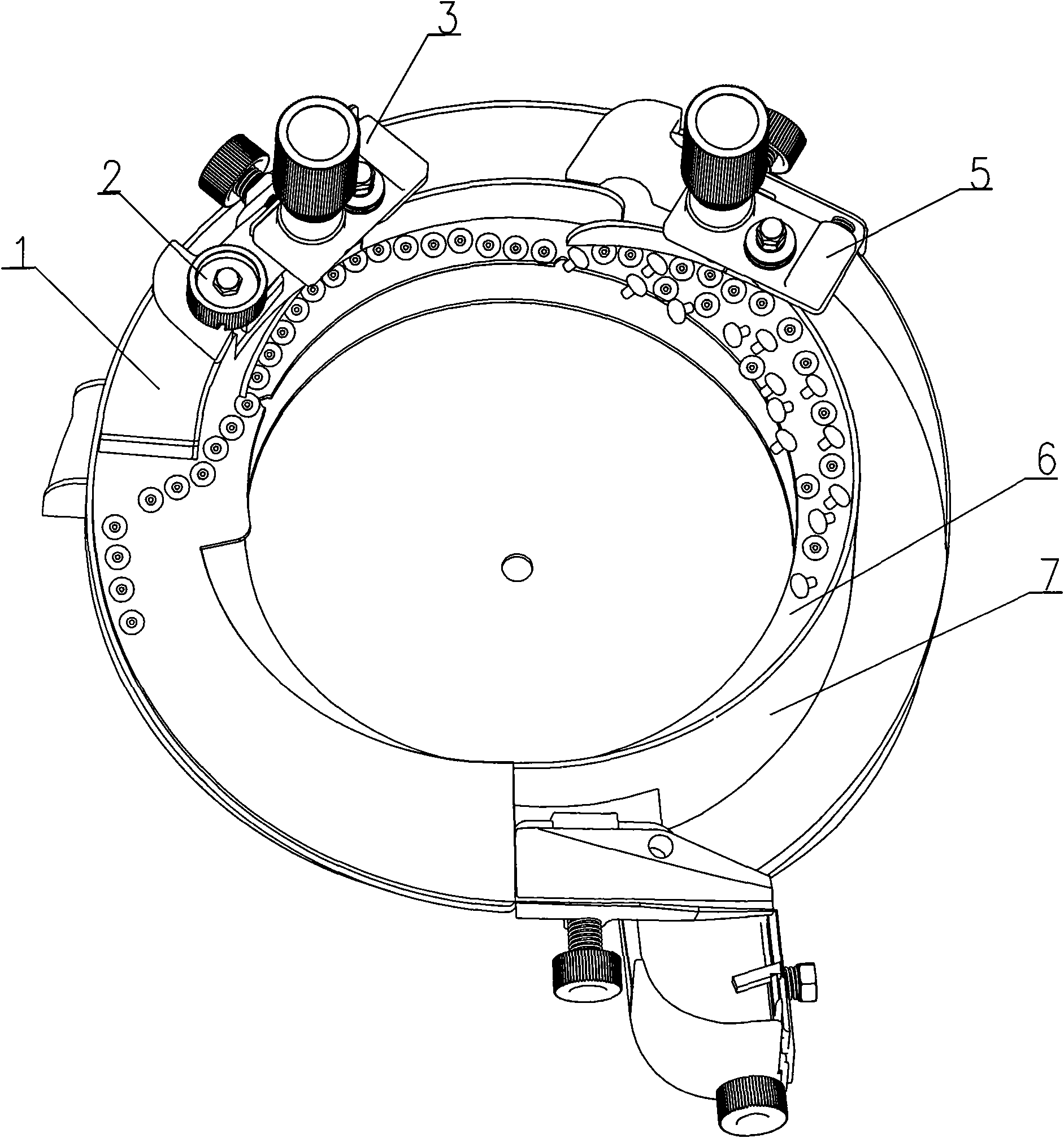

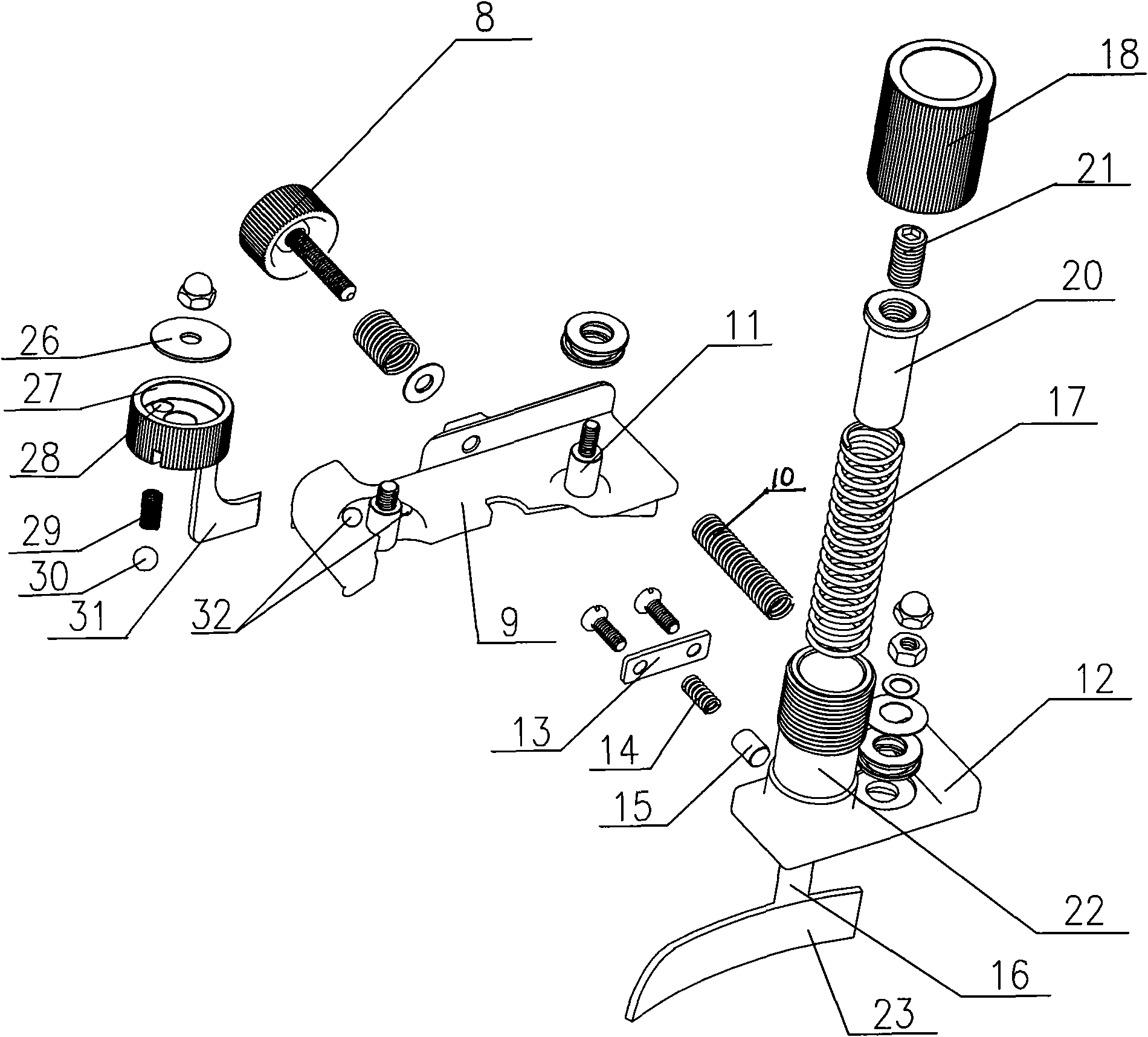

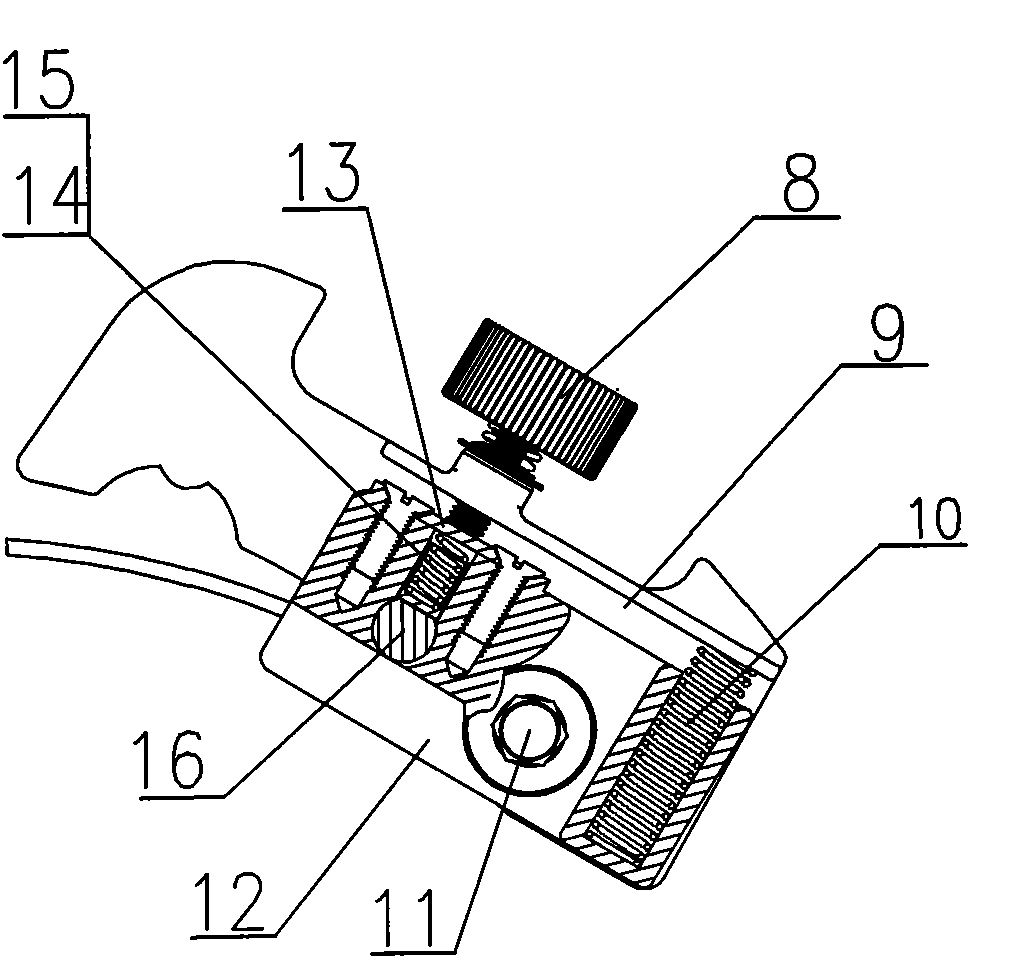

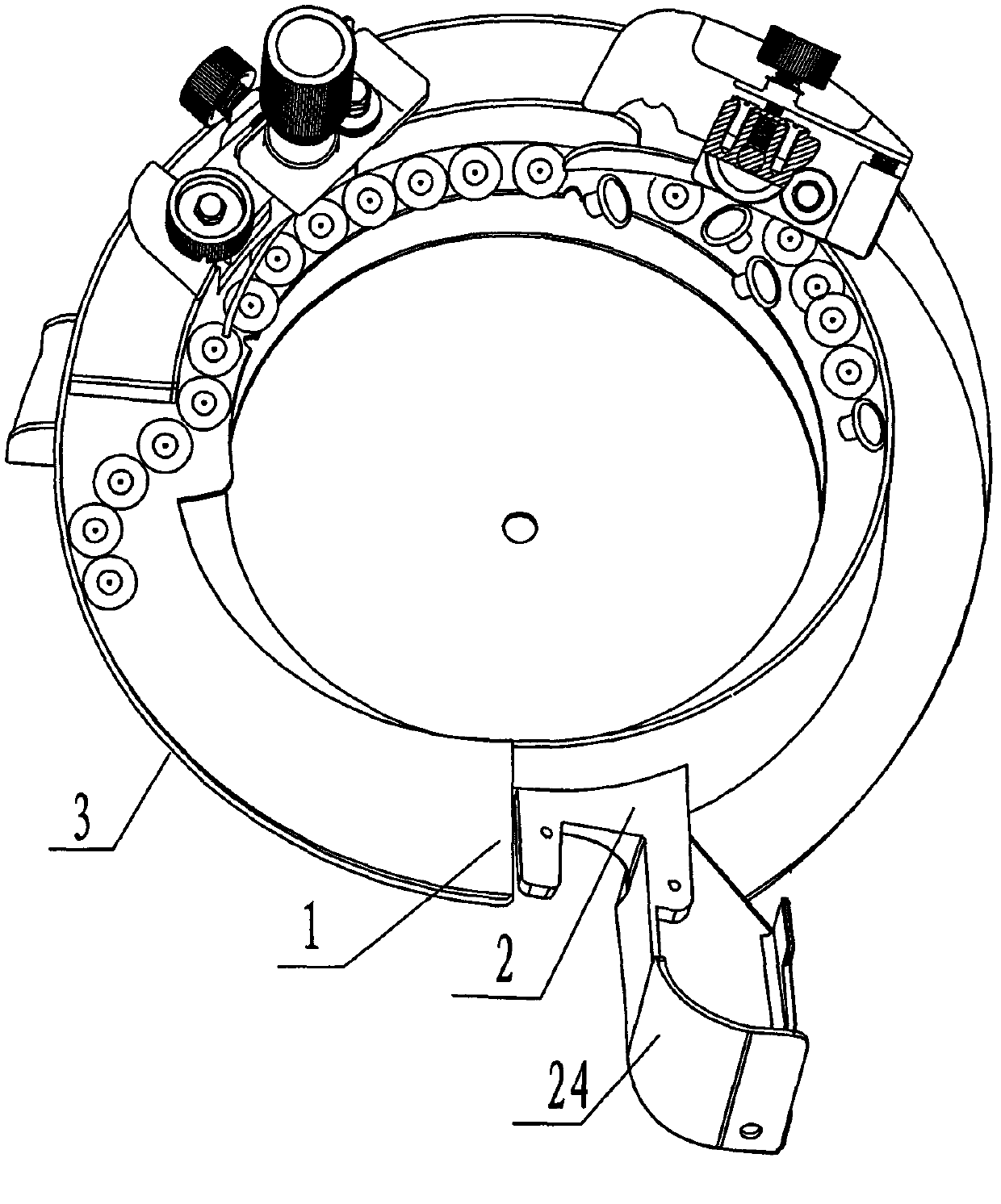

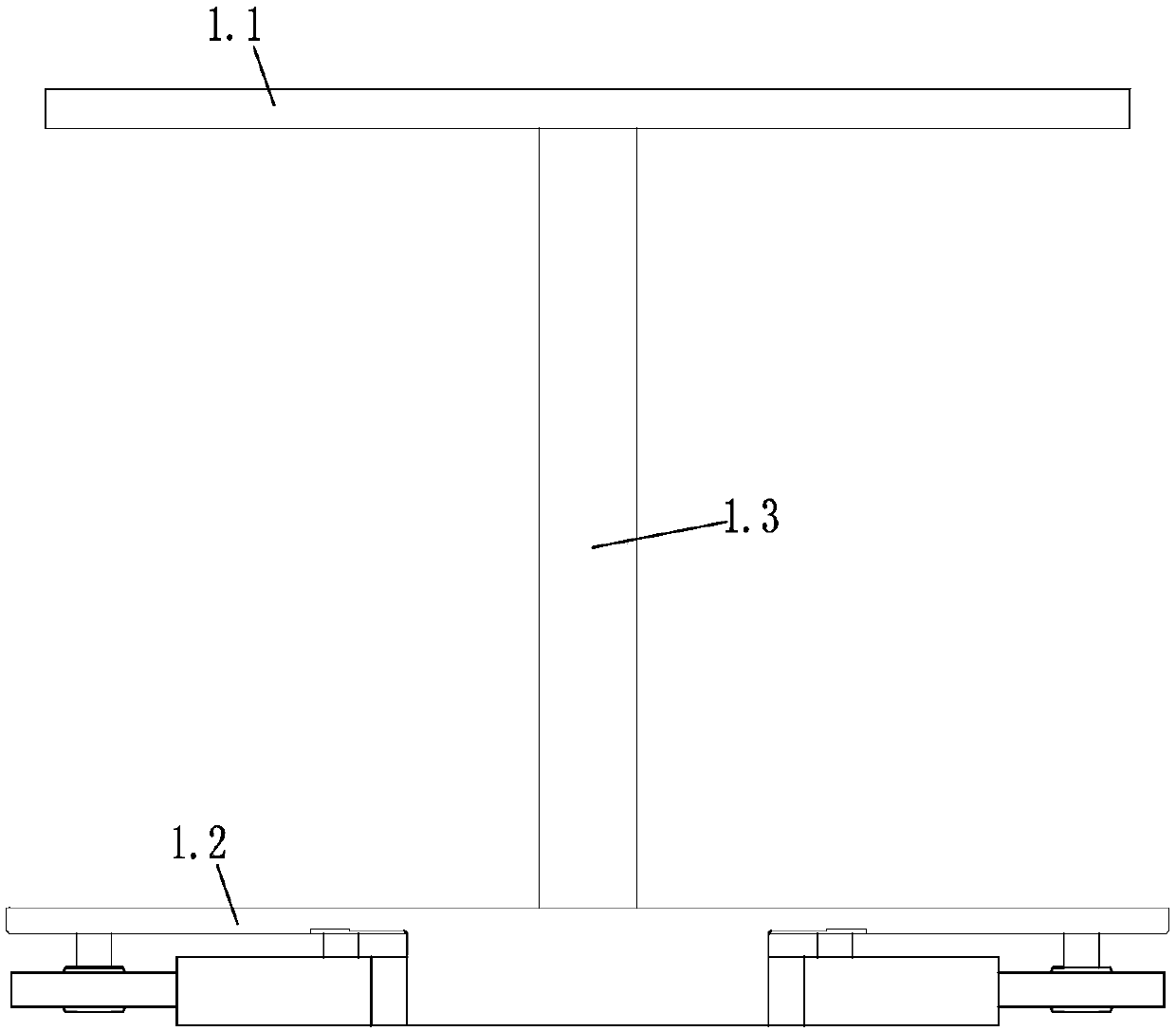

Multifunctional adjustable vibrating tray

InactiveCN102092567ATo achieve the purpose of mass productionJigging conveyorsConveyor partsManufacturing cost reductionEngineering

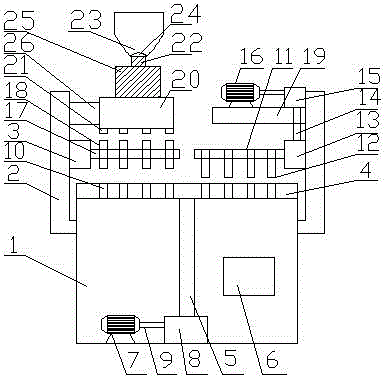

The invention relates to a vibrating tray for conveying a workpiece to be processed to automatic mechanical equipment, in particular to a multifunctional adjustable vibrating tray which comprises a top tray, wherein the top tray is mainly composed of a spiral feed channel and a spiral feed channel outer race, characterized in that a workpiece position adjusting processor is arranged on the spiral feed channel of the top tray, the workpiece position adjusting processor is fixedly installed on the spiral feed channel outer race, and the workpiece position adjusting processor comprises a radial adjusting device and a height adjusting device. The invention aims to design a multifunctional adjustable vibrating tray capable of adjusting according to the structural shapes of workpieces, screening the directions of workpieces and conveying in an array, so that one vibrating tray can be used for conveying workpieces of all sizes and various shapes. Compared with the prior art, the manufacturing cost and the automatic mechanical equipment matching cost are reduced, mass production can be realized, the workpieces to be processed are convenient to replace, the operation is convenient and the working efficiency is high.

Owner:WENZHOU ZHONGKE AUTOMATION EQUIP

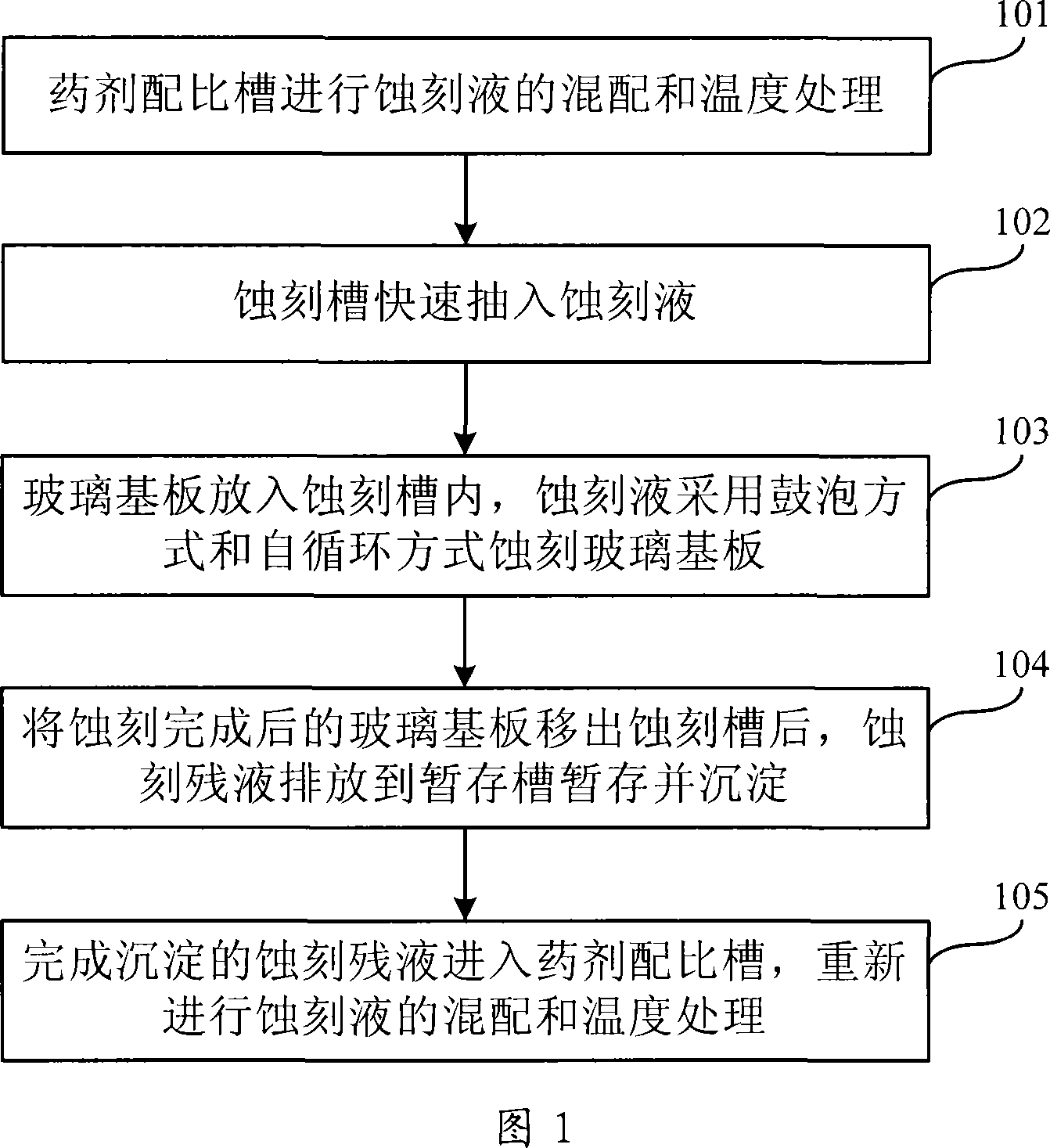

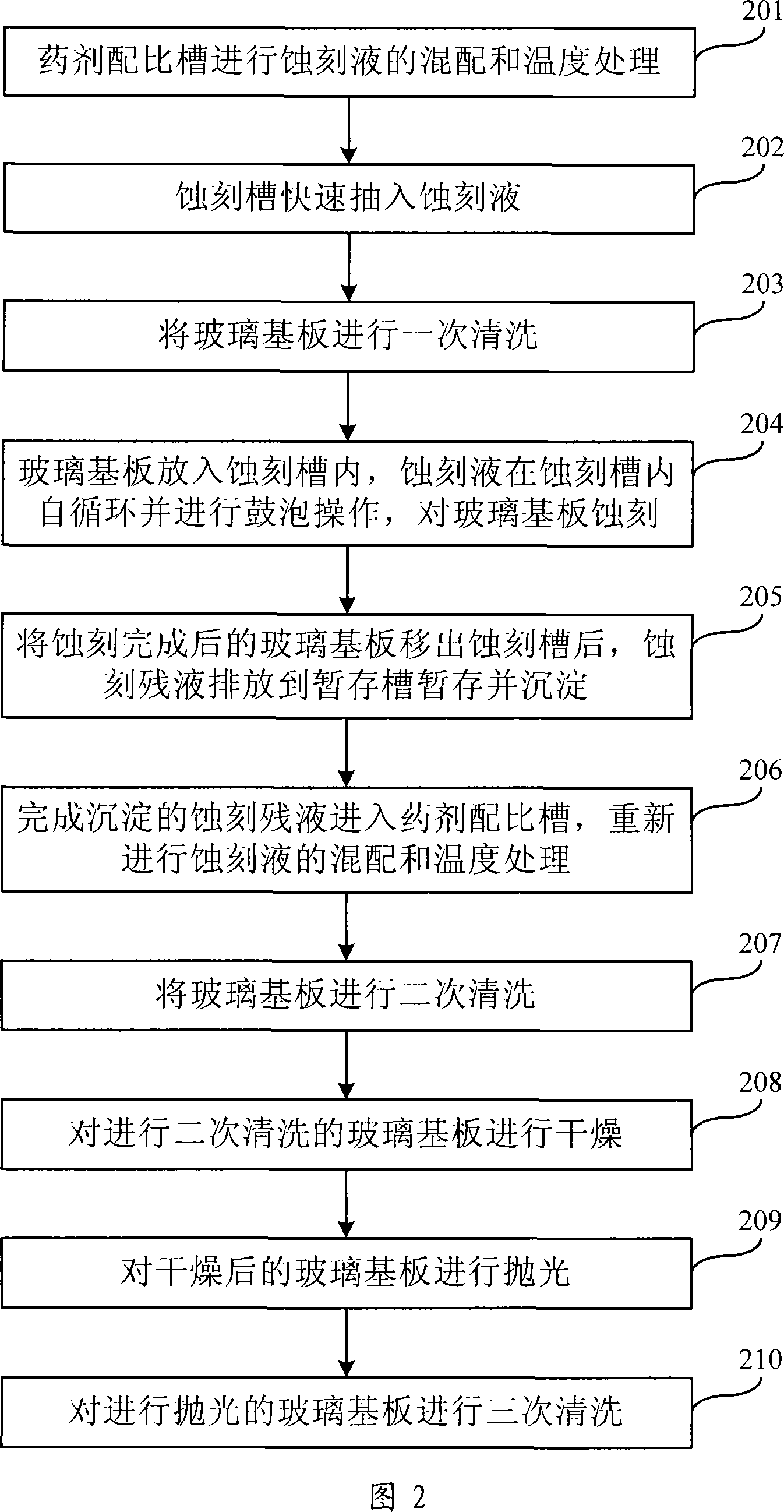

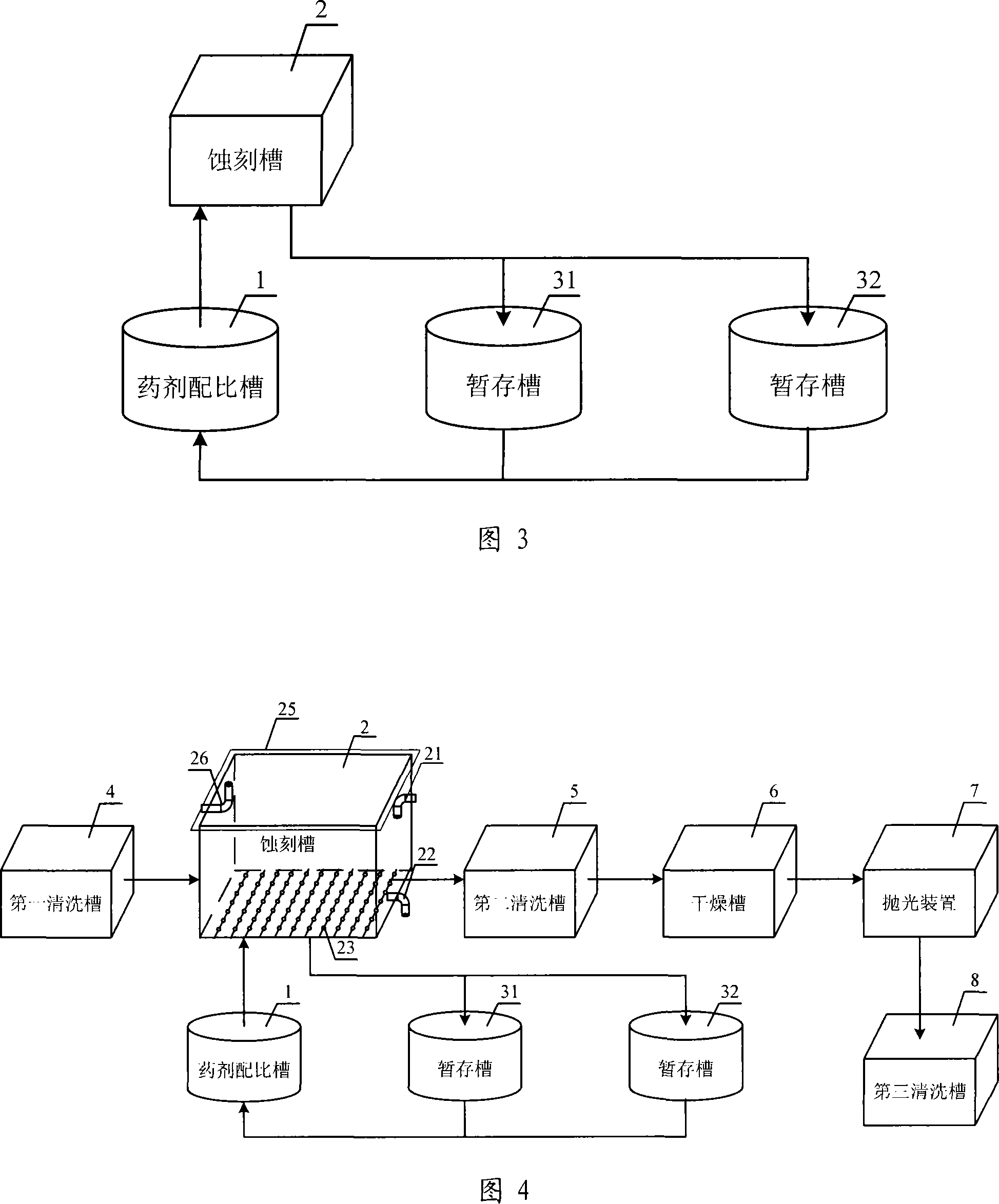

Attenuation method and device for flat glass substrate

ActiveCN101234853AUniform etchingTo achieve the purpose of mass productionFlat glassUltrasound attenuation

The invention relates to a method for thinning a flat glass substrate and a device thereof. First, etching liquor is mixed and processed of temperature treatment in a reagent preparation trough; the prepared etching liquor is quickly pumped into an etching trough. The glass substrate is placed into the etching trough and is etched by adopting a self-circulation way of bubbling and etching. After being etched, the glass substrate is taken out and the etching liquor is quickly poured into a temporary storage trough for a temporary storage and a precipitation. The etching liquor can be re-prepared and reused when the glass substrate is etched next time. The etched and thinned glass substrate is cleaned, dried and polished. The invention provides the method for thinning the flat glass substrate and a device thereof. By adopting the etching method of reagent circulation and bubbling, the aim of batch production can be received, thus supplying a thin glass substrate product and improving the good product rate and production quantity.

Owner:BOE TECH GRP CO LTD +2

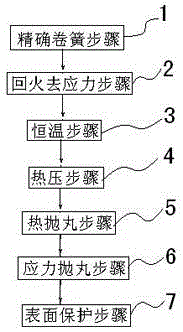

Manufacturing process of high-stress suspension spring

InactiveCN104690495AAvoid stress concentrationImprove stabilityFurnace typesHeat treatment furnacesStress distributionEngineering

The invention discloses a manufacturing process of a high-stress suspension spring. The manufacturing process performs the following steps in sequence: a precise spring coiling step: a primary finished product of the high-stress suspension spring is formed; a tempering destressing step: the tempering destressing annealing is performed for the primary finished product produced by precise spring coiling equipment; a constant temperature step: the constant temperature treatment is performed for the destressed primary finished product; a thermal pressing step: the primary finished product is thermally compressed after the constant temperature treatment under a heating condition; a thermal shot blasting step: the shot blasting is performed for the thermally pressed primary finished product; a stress shot blasting step: the stress shot blasting is performed for the primary finished product after the thermal shot blasting at a normal temperature to form a semi-finished product; and a surface treatment step is performed for the semi-finished product after the stress shot blasting to form a spring finished product. The process controls the whole shape of the spring in the spring coiling to guarantee the uniformity of the spring stress distribution, and adopts such steps as the thermal pressing, the thermal shot blasting and the stress shot blasting to largely improve the spring fatigue strength and the load stability under high stress so as to achieve the purpose of large-batch production of the high-stress suspension spring.

Owner:SHANGHAI SPRING CORP

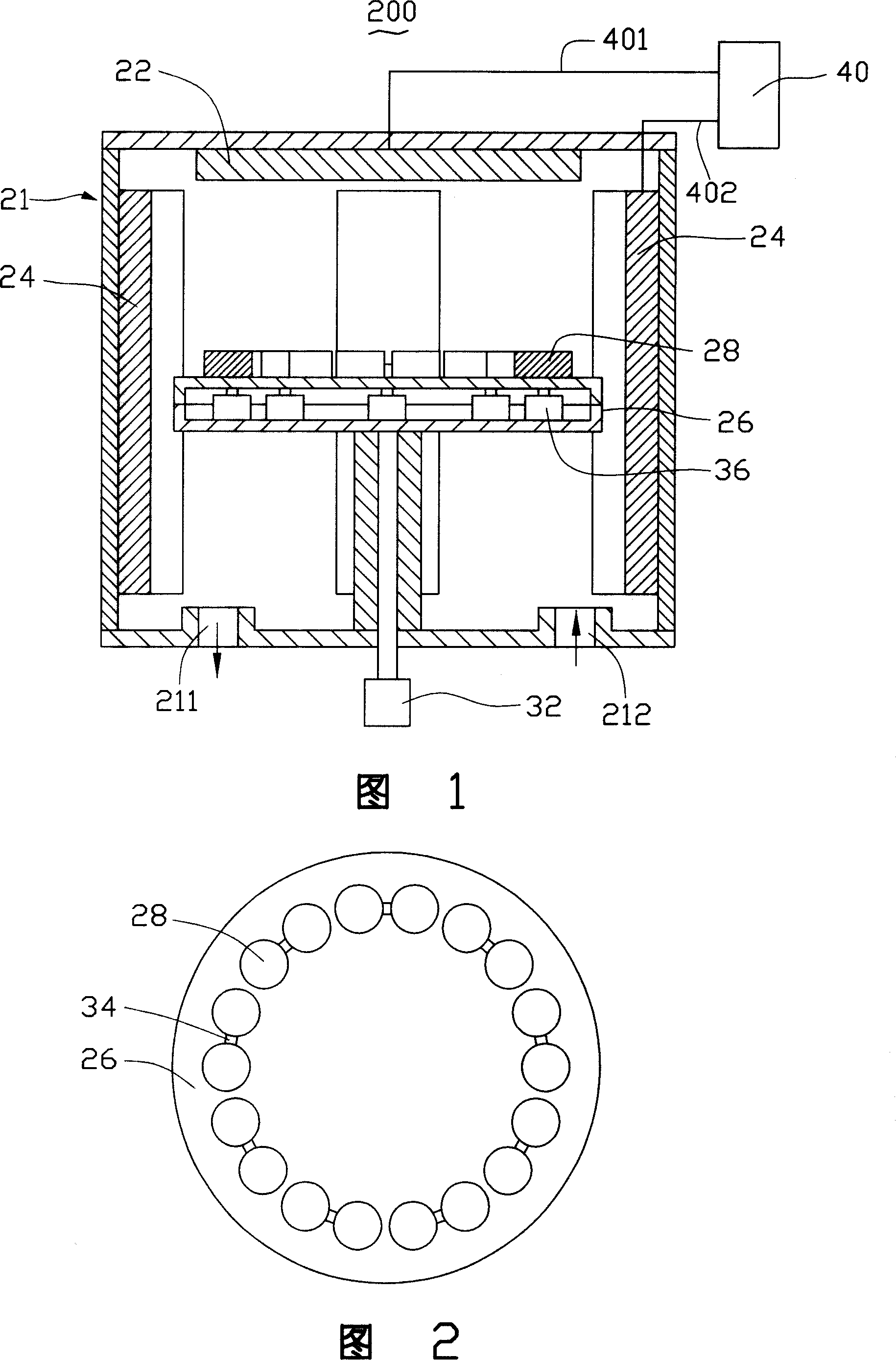

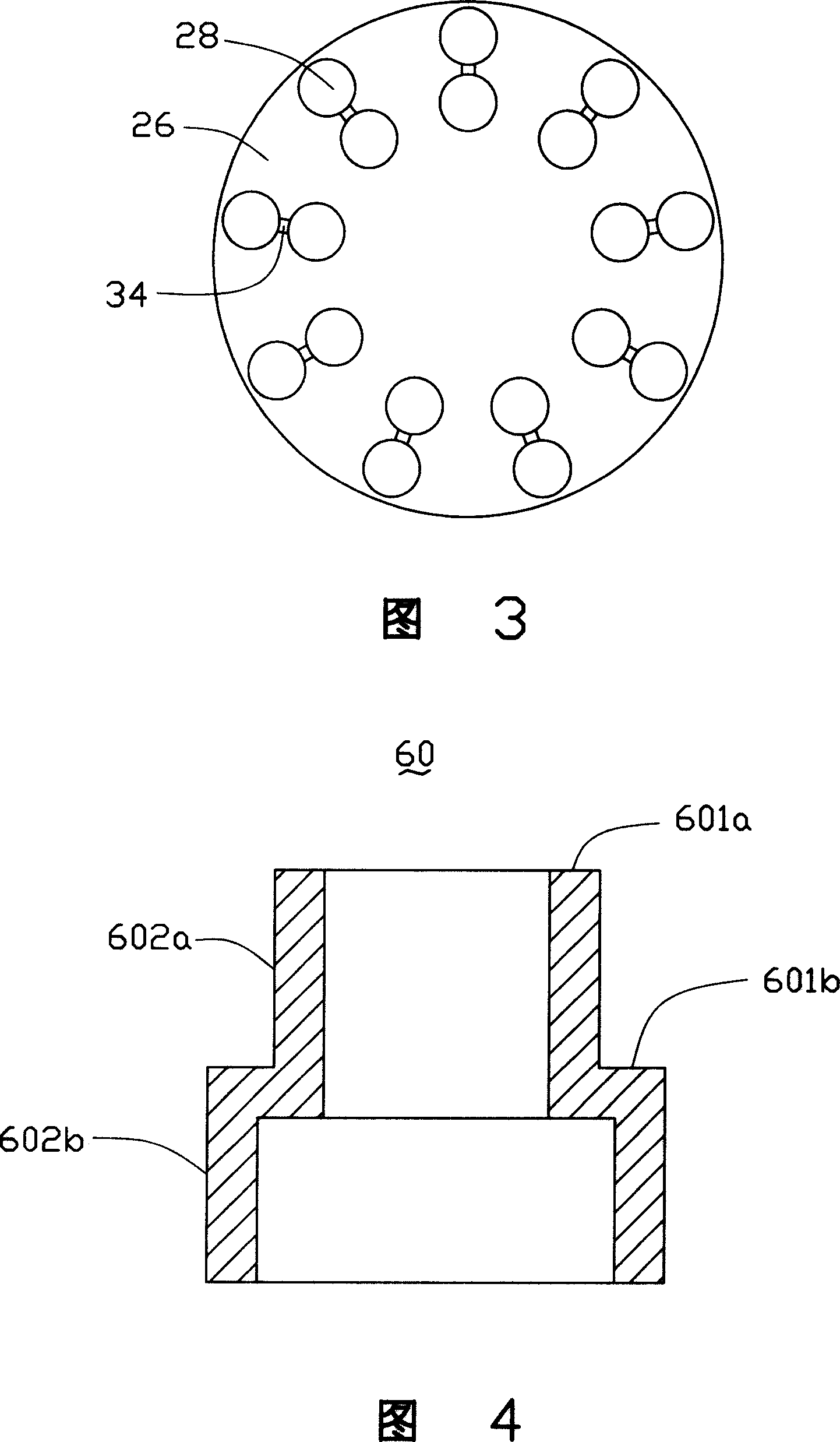

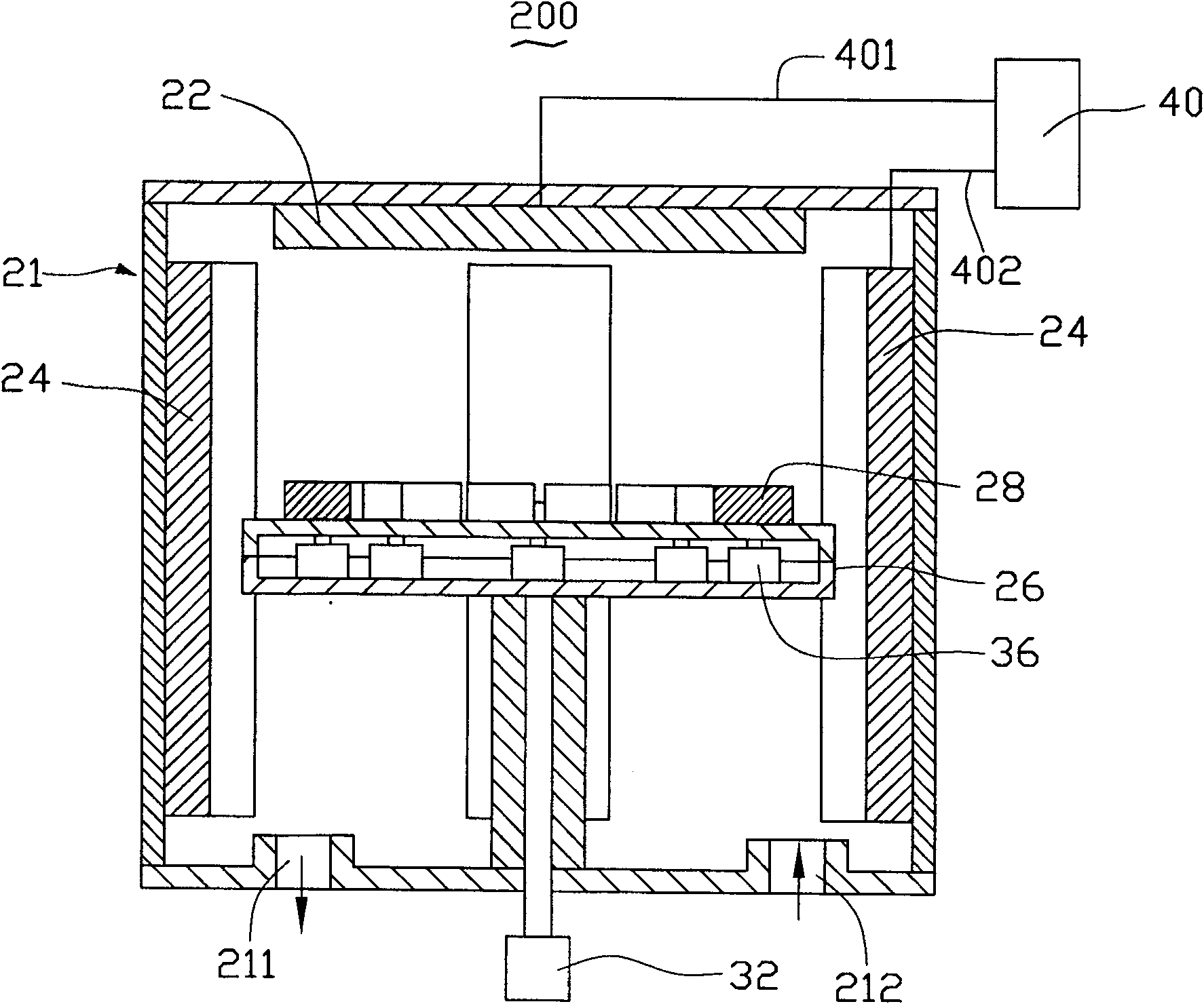

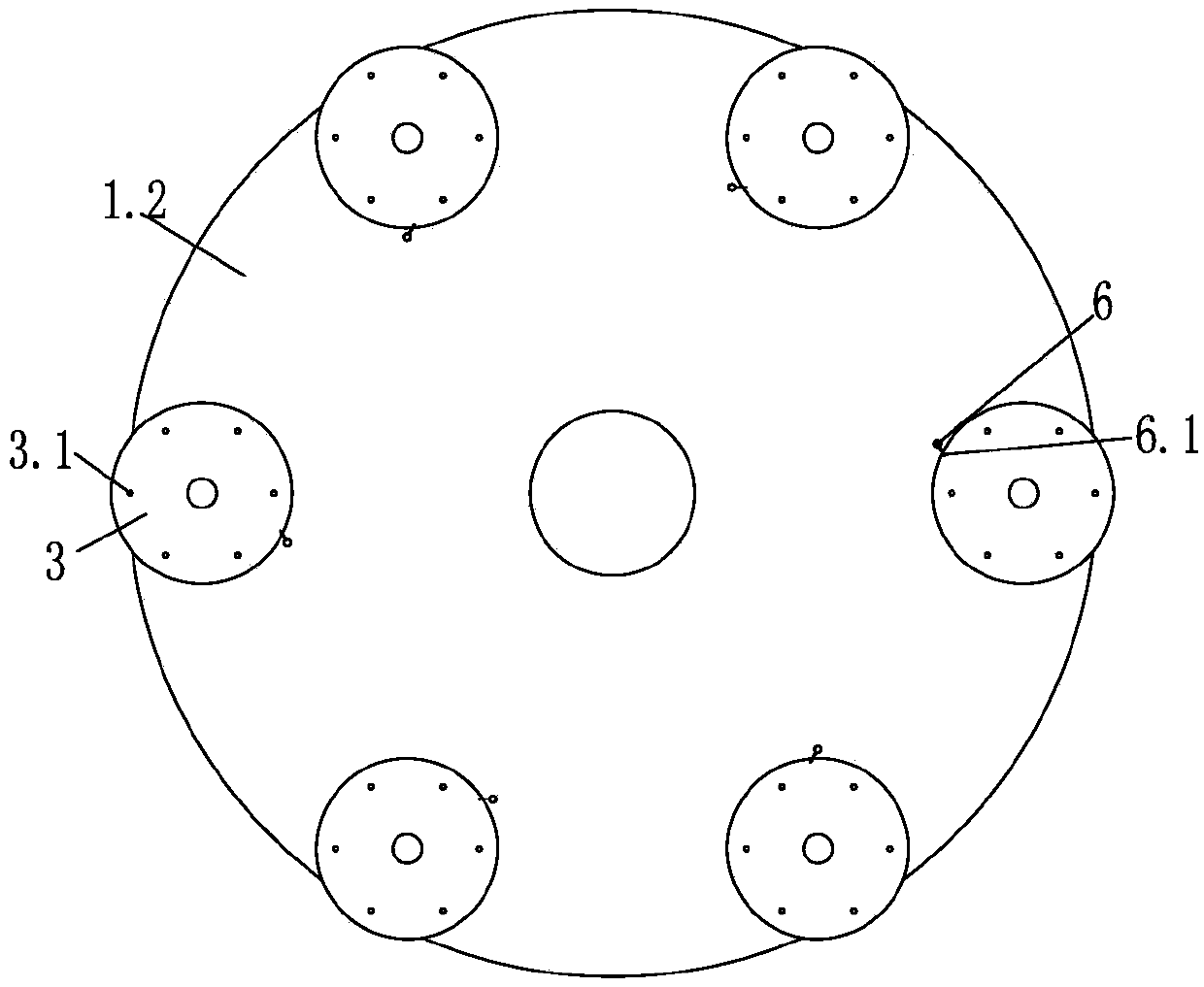

Sputtering device and method

InactiveCN101082123AIncrease productivityEasy to operateVacuum evaporation coatingSputtering coatingMaterials scienceIrregular shape

The present invention relates to one kind of sputtering apparatus, which includes one sputtering cavity, one first sputtering target, one second sputtering target, one bottom turntable and several pairs of bearing stages. The first sputtering target is set oppositely to the upper surface of the bottom turntable, the second sputtering target is set around the bottom turntable, the bottom turntable is connected to one rotating unit for rotating, and the bearing stage pairs on the upper surface are connected to connecting rods and a drive unit for rotating. The present invention also relates to the sputtering process with the sputtering apparatus. The present invention can sputter several irregular workpieces in high production efficiency.

Owner:HONG FU JIN PRECISION IND (SHENZHEN) CO LTD +1

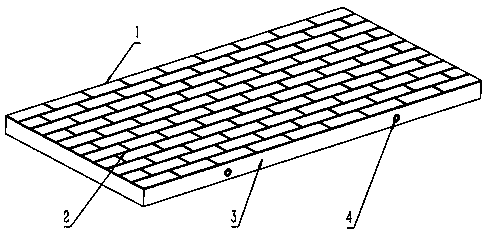

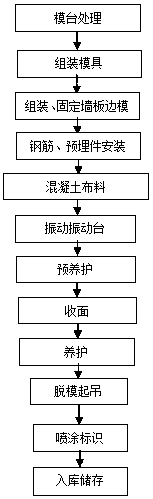

Prefabricated facing bare concrete wallboard and manufacturing process

InactiveCN110091414ATo achieve the purpose of mass productionImprove product qualityConstruction materialMouldsAssembly lineEngineering

The invention discloses a prefabricated facing bare concrete wallboard. The prefabricated facing bare concrete wallboard comprises a wallboard body, and is characterized in that a decoration face is arranged on the outer surface of the wallboard body, the wallboard body is made of bare concrete, and a sleeve is pre-arranged in the wallboard body. An assembly line production process is adopted, thebare concrete wallboard with a decoration effect can be manufactured, the aim of batched production can be achieved, and product quality is stable.

Owner:河南清水建设科技有限公司 +1

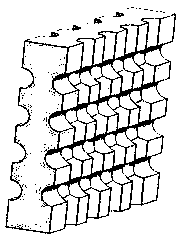

Radiating unit and broadband high-intermodulation omni-directional ceiling antenna

InactiveCN103066377AEasy to processLow costRadiating elements structural formsAntennas earthing switches associationHigh volume manufacturingDirectional antenna

The invention provides a radiating unit which is used for overcoming the defects that a common radiating body is low in intermodulation and high in cost and further provides a broadband high-intermodulation omni-directional ceiling antenna with the radiating unit, and the high-intermodulation performance of the omni-directional ceiling antenna is achieved. The radiating unit is a rotary shell body which is formed by metal materials in an integrated mode. The rotary shell body is sequentially composed of an arc part, a cylinder part and a cone part. The conical degree of the cone part is 4:1-2:1, the diameter of the bottom face is 80mm-130mm, the height of the cylinder part is 25mm-75mm, and the radius of curvature of the arc part is 15mm-35mm. The radiating unit has the advantages of being easy to process, low in cost and capable of achieving the high-intermodulation requirement and the like. The broadband high-intermodulation omni-directional ceiling antenna has the advantages of being wide in a frequency band, low in a standing wave, large in half radiation lobe width, high in gain and the like. The requirement for the long term evolution (LTE) by indoor broadband covering is met, and the purpose of mass production is achieved.

Owner:FOSHAN CITY EAHISON COMM

Automobile instrument board leather hot-pressing composite technology

InactiveCN105774186ASimple and fast operationEasy to implementLaminationLamination apparatusEngineeringCompositing

The invention discloses an automobile instrument board leather hot-pressing composite technology. The technology comprises the following steps of 1, skeleton glue spraying; 2, foam attaching; 3, skeleton glue spraying after foam attaching; 4, leather attaching; 5, prepositioning; 6, hot-pressing compositing; 7, edge covering. The automobile instrument board leather hot-pressing composite technology is easy and convenient to implement and easy to achieve, the obtained automobile instrument board is flat in surface and free of bubbles and pressing marks, the product consistency is ensured, manual covering uncertainty is eliminated, the requirement for surface attractiveness and comfortableness is met, the preparation time is effectively shortened, and the production working efficiency is greatly improved, so that the purpose of batch production is achieved, and the domestic industrial gap is filled.

Owner:常熟安通林汽车饰件有限公司

Rapid forming method of thermoplastic fiber-reinforced composite material plate

InactiveCN107214980AResolutionResolution cycleLaminationLamination apparatusTemperature controlSheet film

The invention relates to a rapid forming method of a thermoplastic fiber-reinforced composite material plate. The rapid forming method is characterized by comprising the following steps that (1) forming equipment and materials are prepared, specifically, the special equipment with presoaking, laying, superimposing, temperature control and pressure control, vacuum lamination forming, cutting, heating and mould pressing forming structures is arranged, a resin solution with a thermoplastic-forming function and the fiber-reinforced materials are prepared; (2) the fiber-reinforced materials are soaked into the resin solution with the thermoplastic-forming function, and fiber glue pieces are prepared; (3) the fiber glue pieces obtained in the step (2) are superimposed by 1-5 layers, the superimposed fiber glue pieces are placed in a vacuum press with a programmable temperature control and pressure control function, and a thermoplastic fiber-reinforced laminated composite material is prepared; (4) a mould plate is cut; (5) the mould plate is heated and softened; (6) mould pressing forming is conducted; and (7) the finished product is prepared. The rapid forming method of the thermoplastic fiber-reinforced composite material plate has the characteristics and beneficial effects of high mechanization degree, short processing period, high efficiency, low product cost and the like.

Owner:东莞市海旭新材料技术有限公司

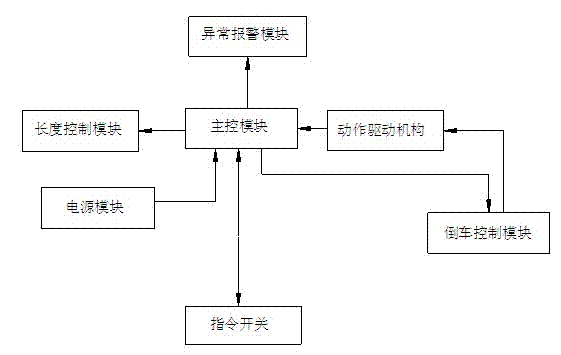

Batched code printing device for plastic products

InactiveCN107901601ATo achieve the purpose of mass productionTo achieve the purpose of height adjustmentTypewritersSpray nozzleBatch production

The invention discloses a batched code printing device for plastic products. The batched code printing device comprises a support frame. A clamp plate push device is fixedly connected to the top of aconveyor belt. A height adjustment device is fixedly connected to one inner side of the support frame; a moving chute is fixedly connected to the position, symmetric to the position of the height adjustment device, of one side of the support frame; a sliding block is in sliding connection to the moving chute; a support rod is fixedly connected to the sliding block; and the height adjustment deviceis fixedly connected to one end, far away from the sliding block, of the support rod. An ink storage box is fixedly connected to the middle position of the support rod; a high-pressure pump is communicated to the bottom of the ink storage box; and a spraying nozzle is communicated to the bottom of the high-pressure pump. The invention relates to the technical field of the plastic product machine.With the batched code printing device for plastic products, problems that the existing code printing working efficiency is low, batched code printing can not be realized, the code printing precisionis low, and the production quality is low can be solved; and objectives of clamping plastics during code printing and carrying out batched production are achieved.

Owner:湖州骏马包装材料有限公司

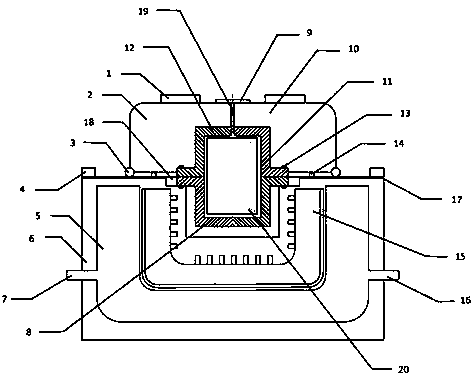

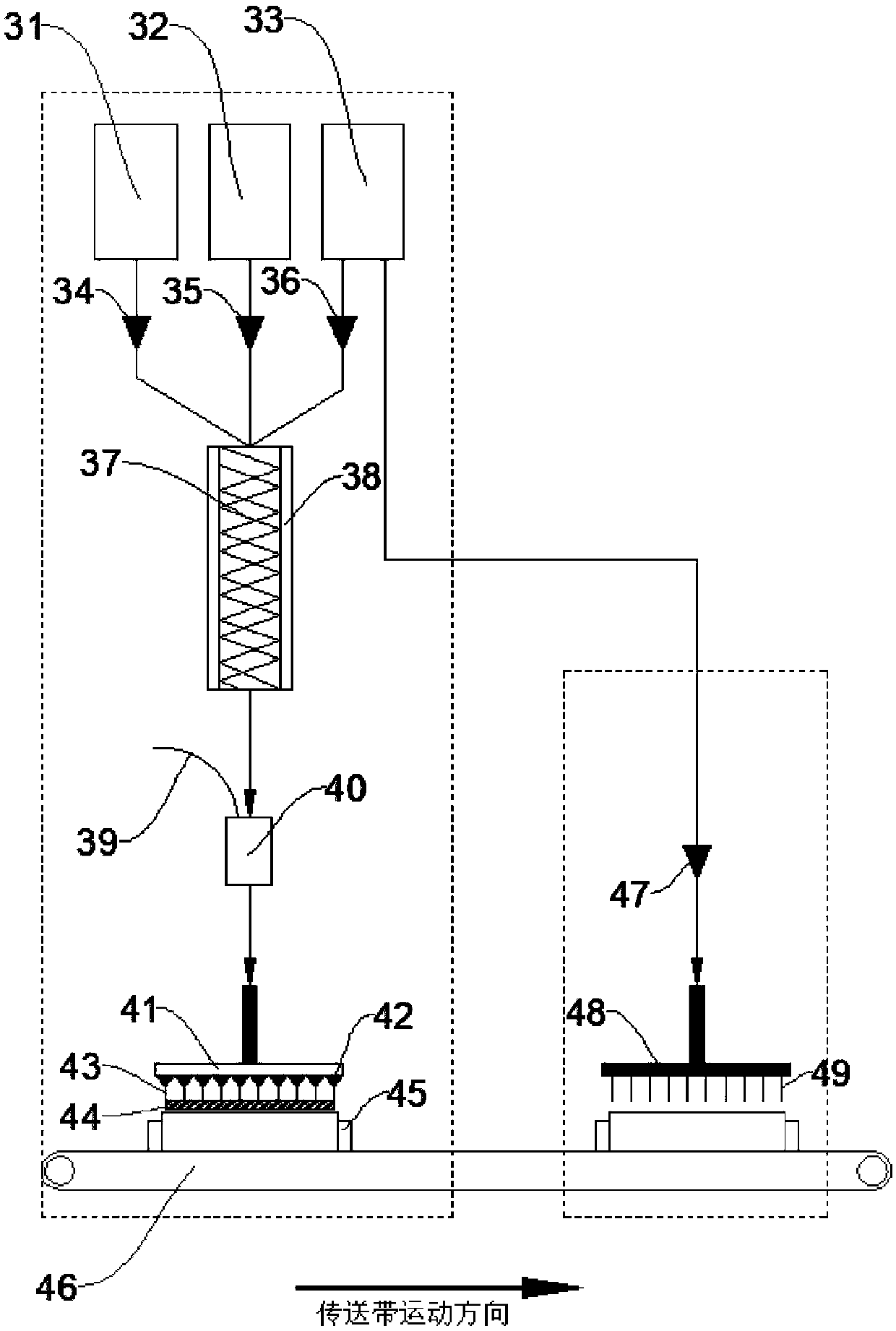

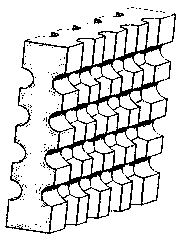

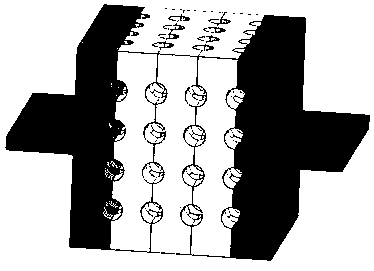

Production equipment for space structure prefabricated bodies and application method

ActiveCN109049280ATo achieve the purpose of mass productionWith strengthCeramic shaping plantsMicrowaveSpatial structure

The invention discloses production equipment for space structure prefabricated bodies. The production equipment comprises a cylinder block, a circular water cooling device, a microwave heating device,a mold, a molding core, a pressing plate and a pulley; the mold comprises an upper mold and a lower mold; the upper mold consists of a left upper mold and a right upper mold; the pressing plate comprises a left pressing plate and a right pressing plate; and the pulley comprises a large pulley and a small pulley. An application method comprises the following steps: the molding core is put in a mold cavity; meanwhile, prefabricated body powder is added for extrusion molding, and is heated through the microwave device; after the molding core is burnt, the heating formation is performed; and themold is taken after cooling to obtain a finished product. The device is simple in structure; and the processes of pressing, molding and drying of various prefabricated bodies with different space structures can be finished at the same time through the whole set of devices, so that the production efficiency of space structure composite materials is effectively improved, the product quality is improved, and the production cost is reduced.

Owner:KUNMING UNIV OF SCI & TECH

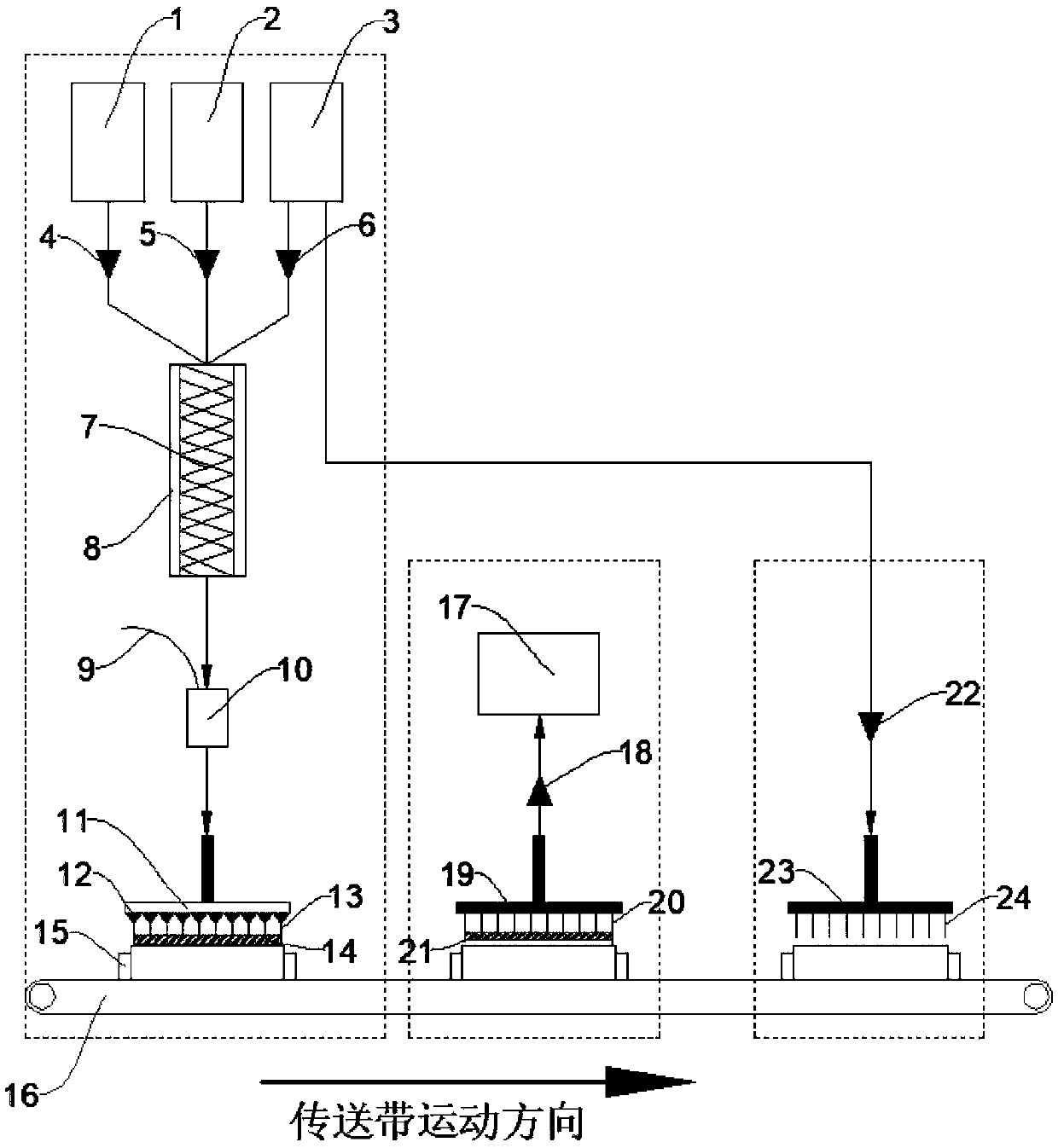

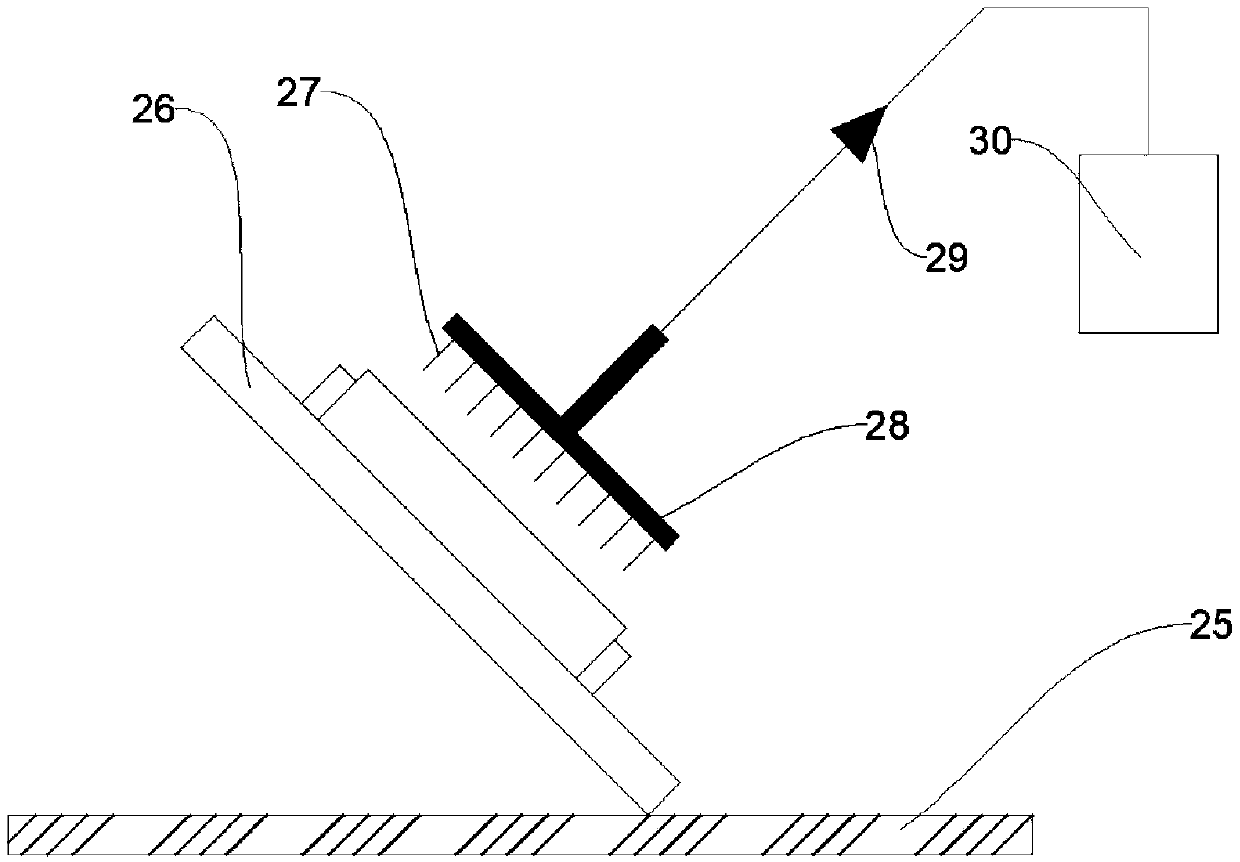

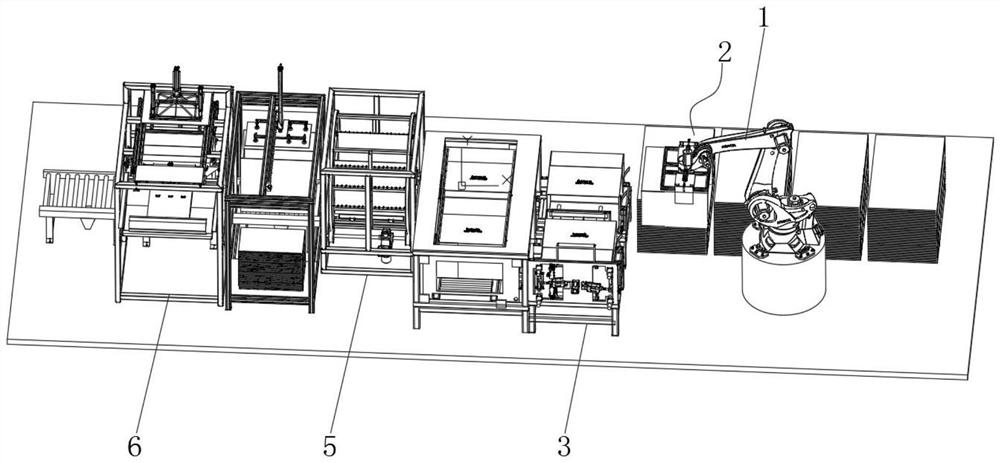

Automatic glue pouring production line and glue pouring method for preparing electrophoresis gel column and application

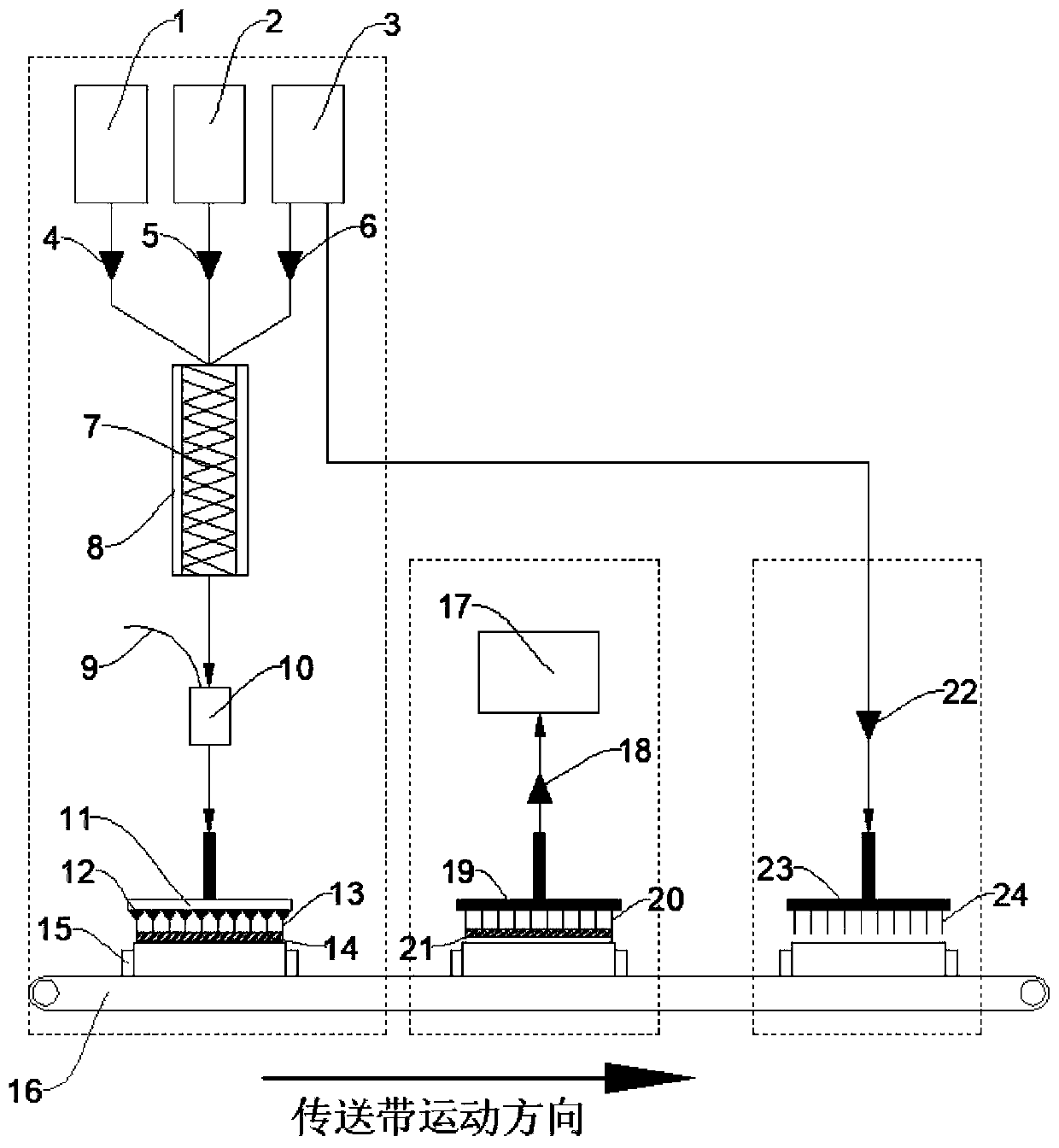

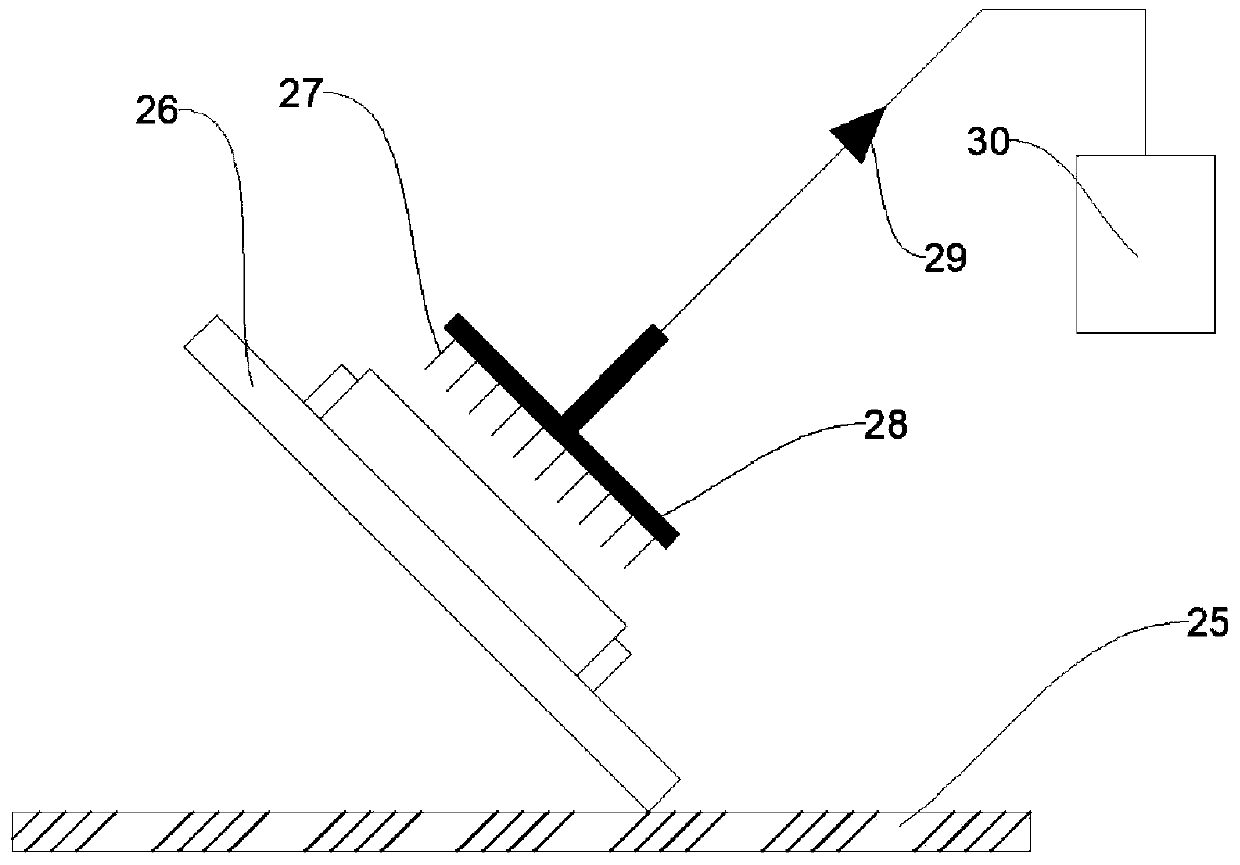

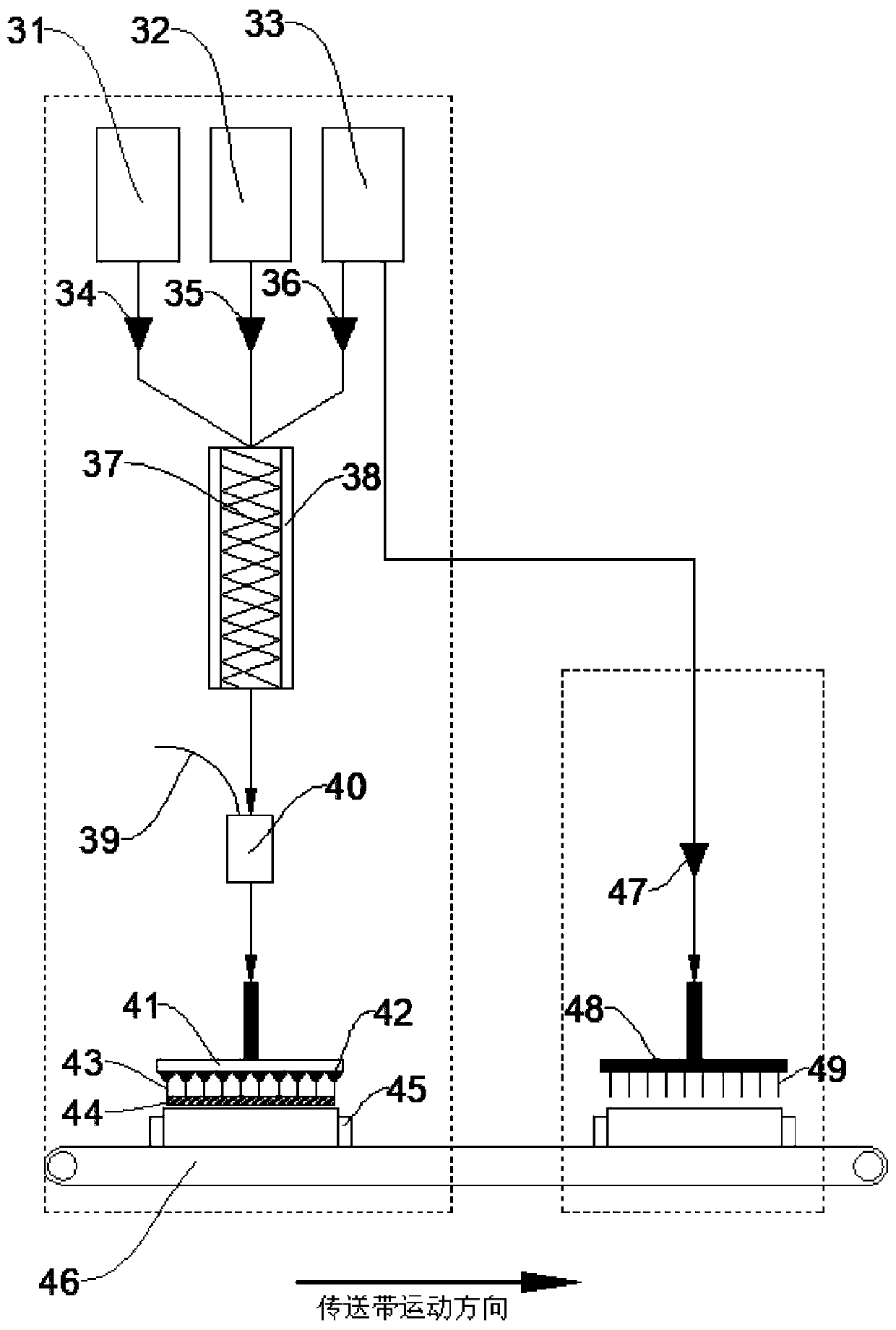

ActiveCN109590170AImprove product qualityReduce scrap rateLiquid surface applicatorsSpraying apparatusProduction lineElectrophoresis

The invention provides an automatic glue pouring production line and glue pouring method for preparing an electrophoresis gel column and application. According to the glue pouring process route, the production line comprises a first layer glue pouring module, a water absorption module and a second layer glue pouring module. The method comprises the steps that a glue pouring holed plate fixedly provided with gel glass tubes is arranged onto a clamping groove of a conveying belt; the automatic glue pouring production line is started to implement operation of first layer glue pouring; after firstlayer glue is solidified, pressure glue on the gel surface is absorbed; operation of second layer glue pouring is conducted; and after second layer glue is solidified, pressure glue on the gel surface is absorbed, so that the electrophoresis gel column is obtained. By means of the automatic glue pouring production line and glue pouring method for preparing the electrophoresis gel column and the application, two types of solutions are pumped therein quantitatively through a plunger pump, and on-line mixing is conducted; and high-throughput glue pouring operation is conducted, the glue surfaceis treated subsequently, and the problems that in the manual operation process, products are poor in performance and low in qualification rate are solved.

Owner:SHANGHAI BIOTECAN PHARMA +1

Preparing method for pizza bottom

InactiveCN106857755ATo achieve the purpose of mass productionImprove production efficiencyBakery productsRaw materialQuick freezing

The invention relates to a food preparing method, and specifically relates to a preparing method for a pizza bottom. The method comprises: preparing raw materials in proportion, stirring, kneading dough, fermenting for the first time, cutting, fermenting for the second time, rolling cakes, trimming, baking, quick freezing, to obtain a pizza bottom. Beneficial effects are that the pizza bottom is good in mouthfeel, convenient in storage, long in edible period, high in preparing efficiency, and can be prepared in batch in a streamlined manner.

Owner:孙盛

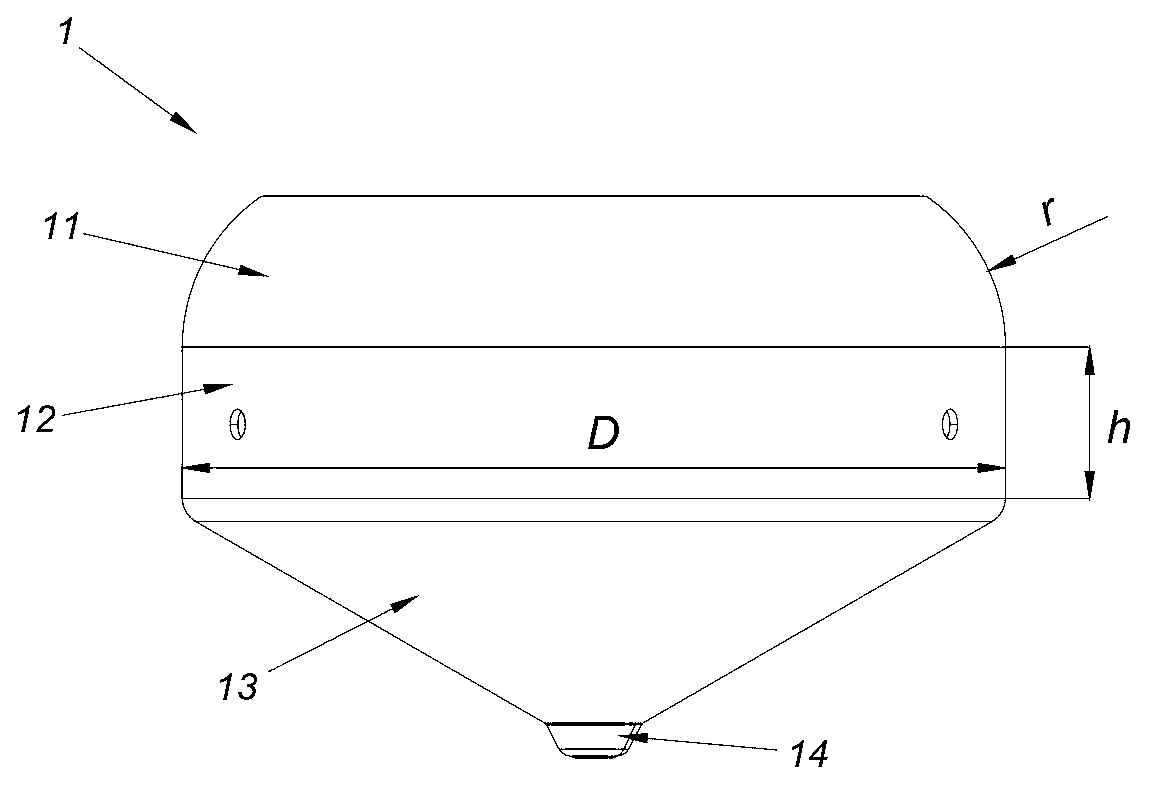

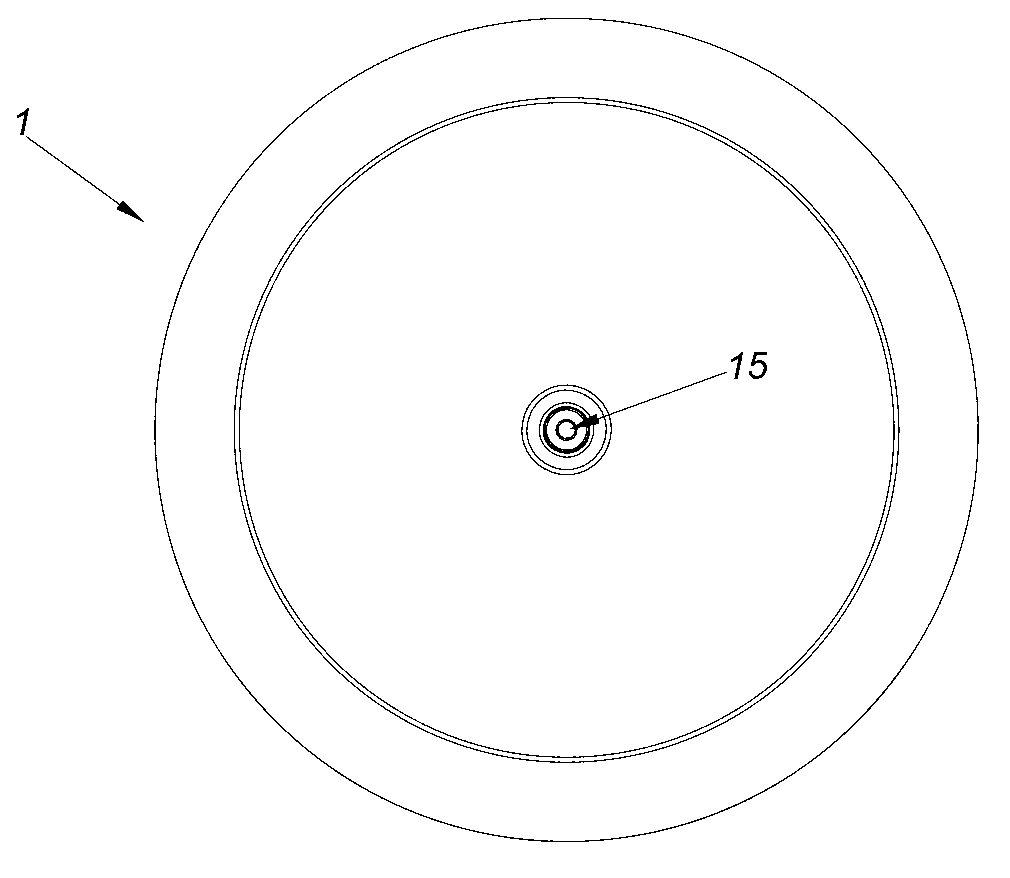

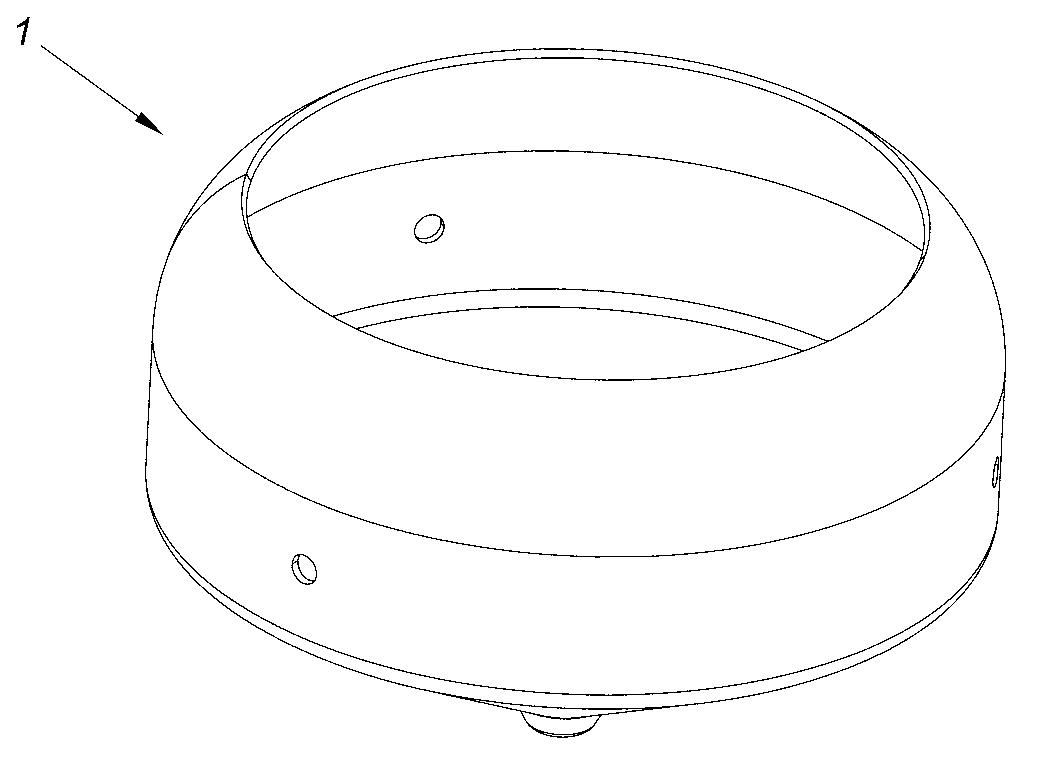

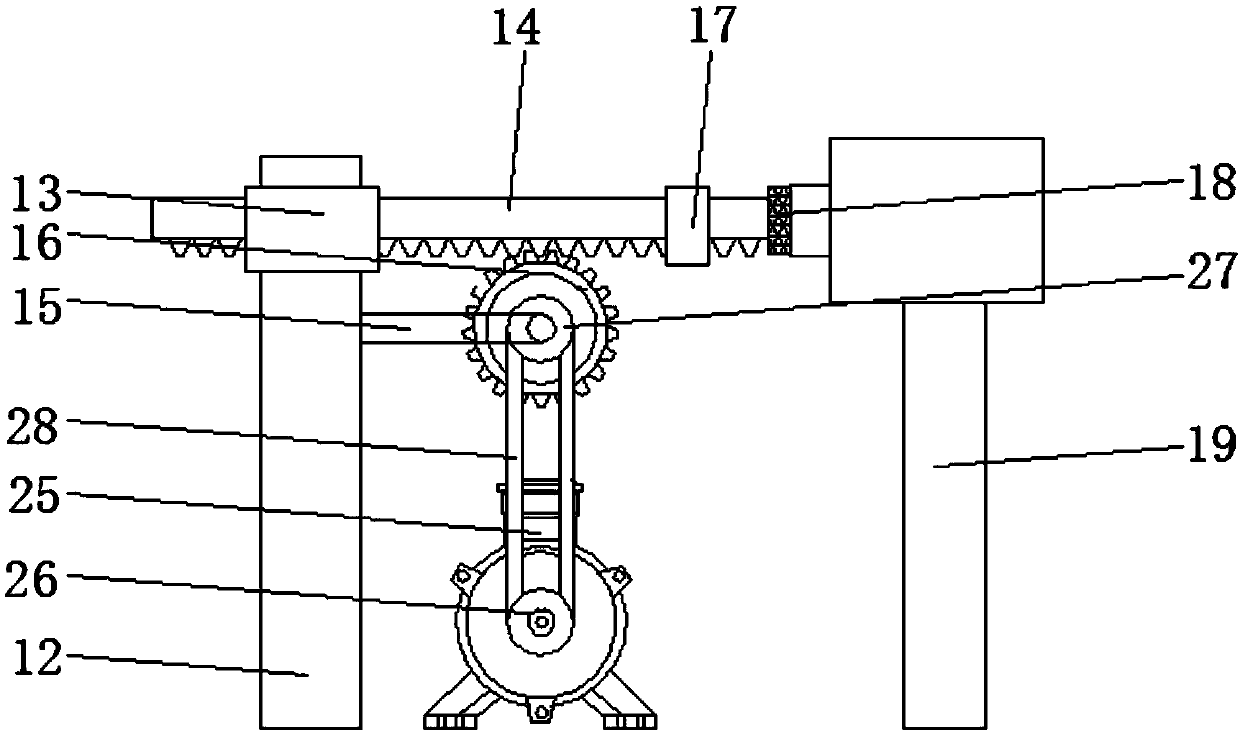

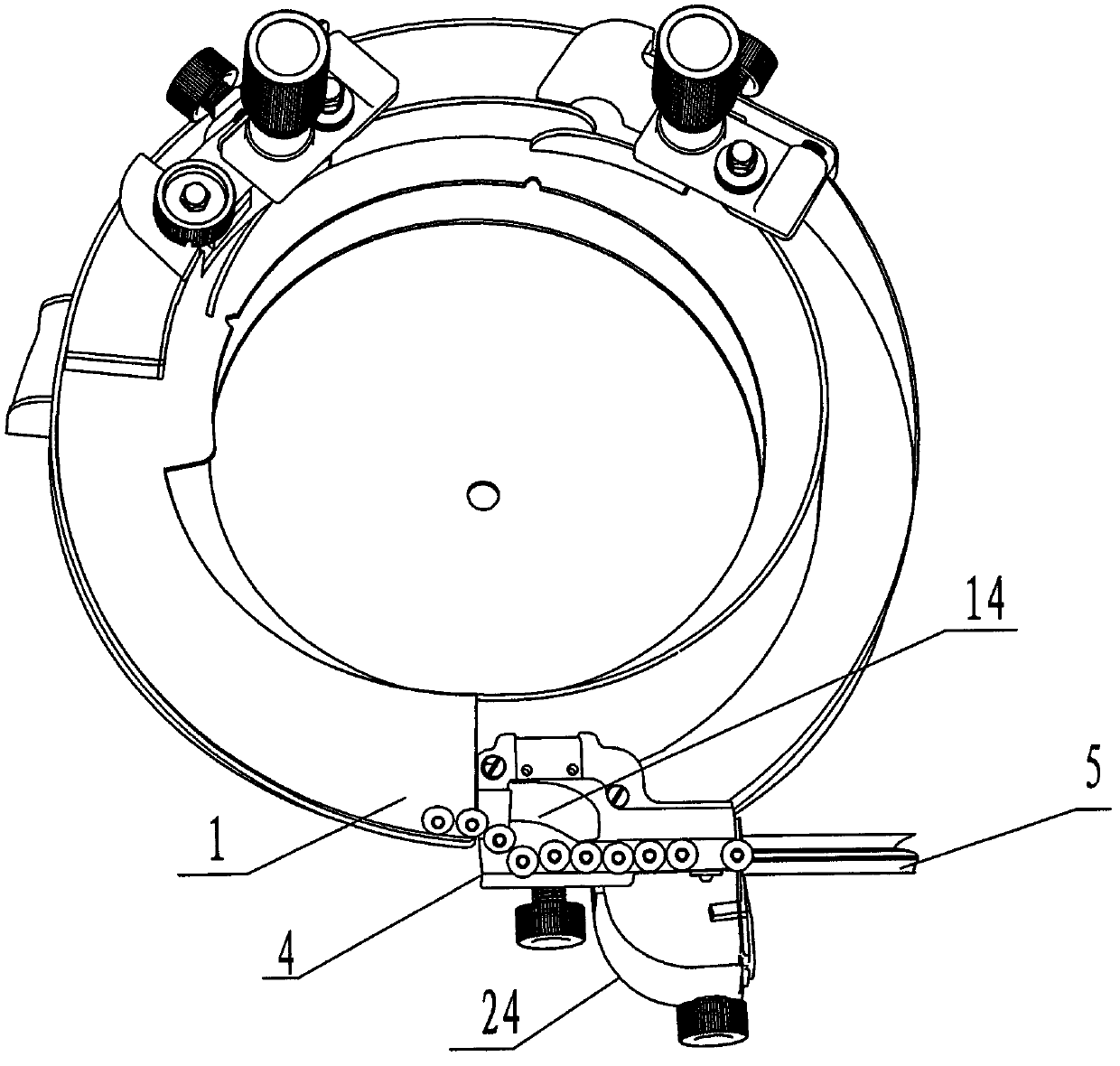

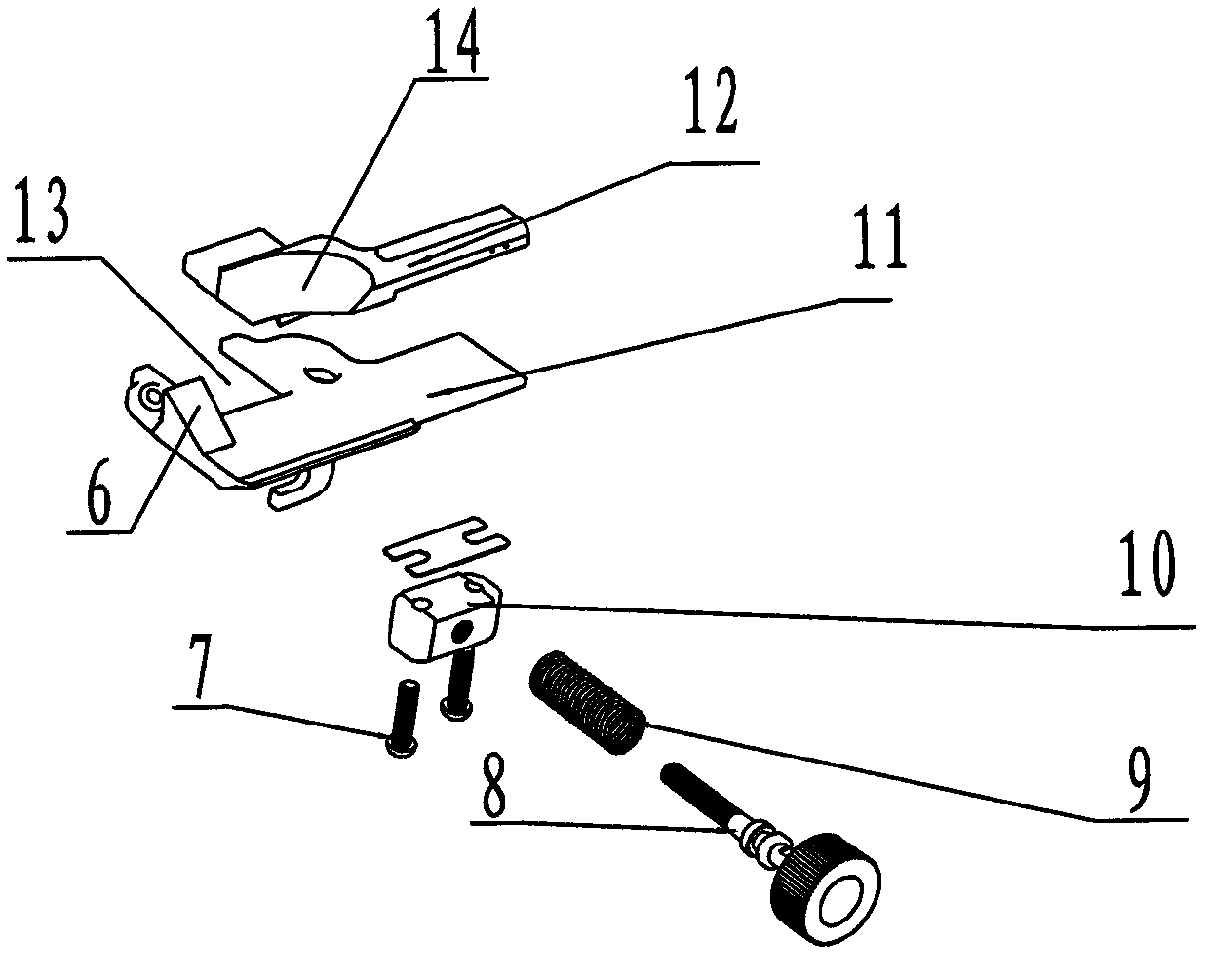

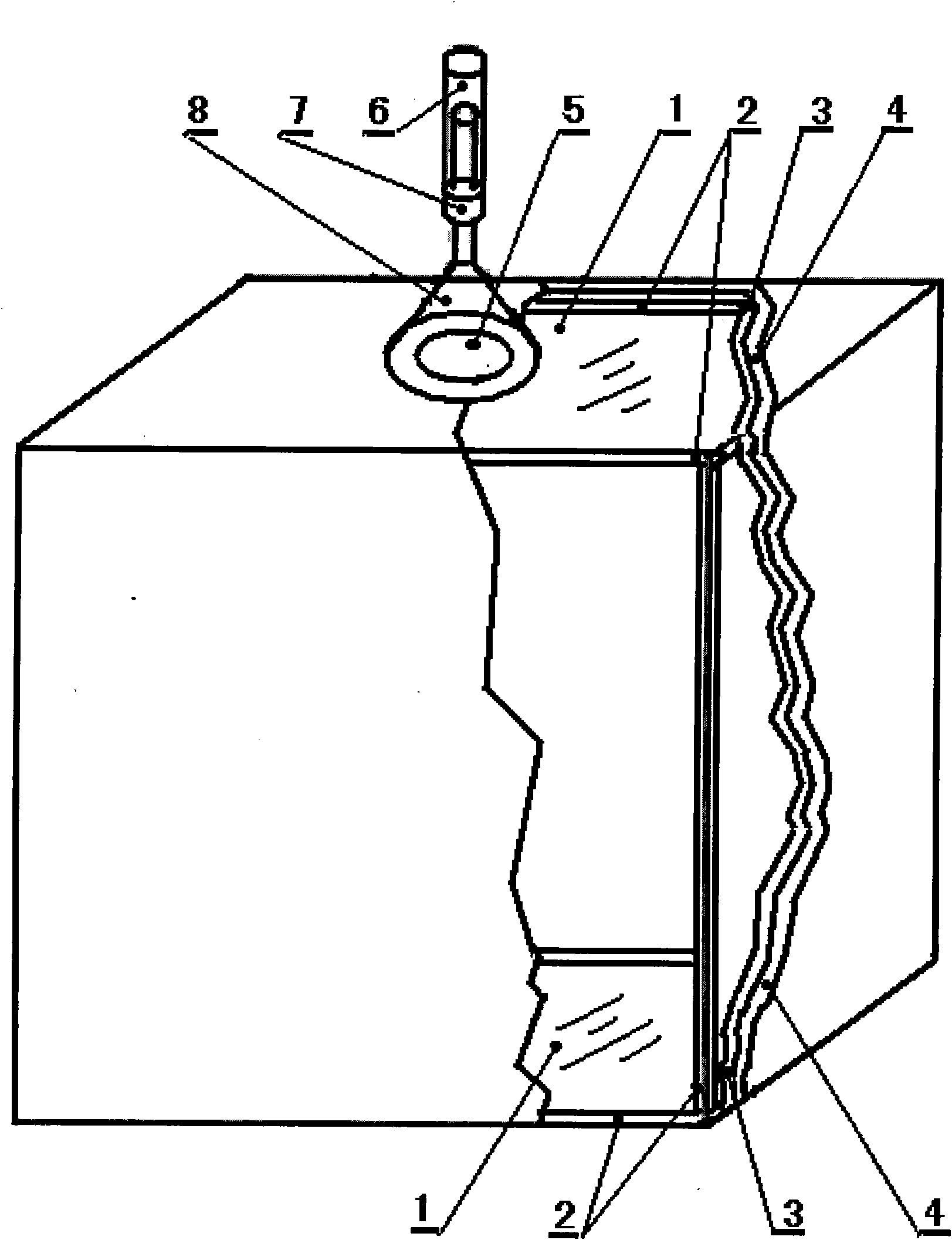

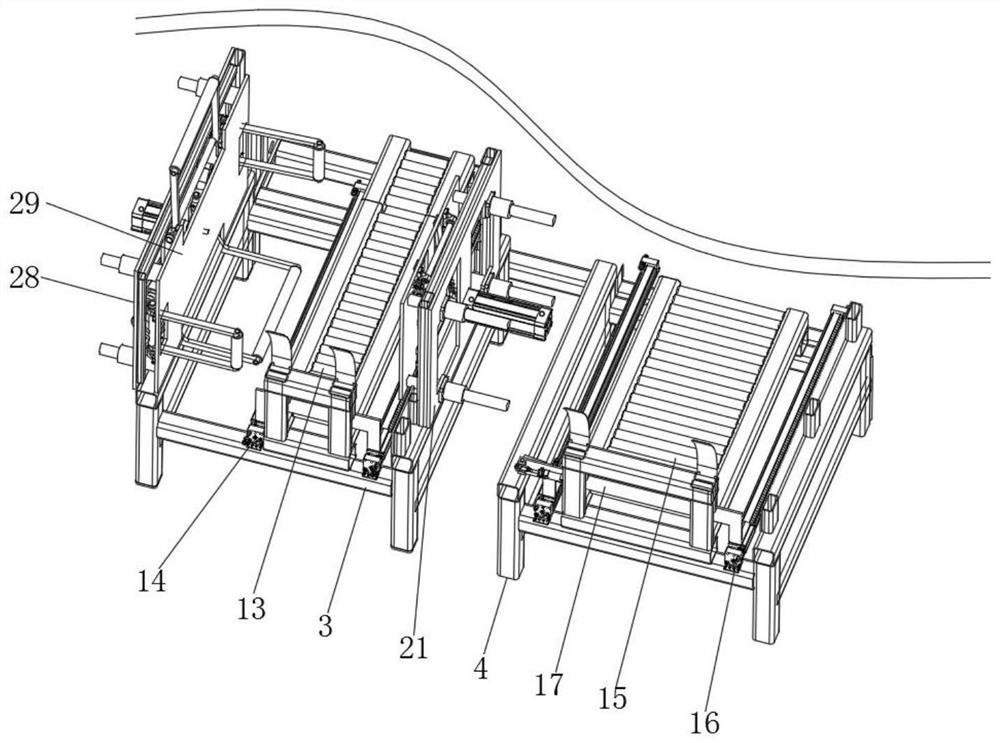

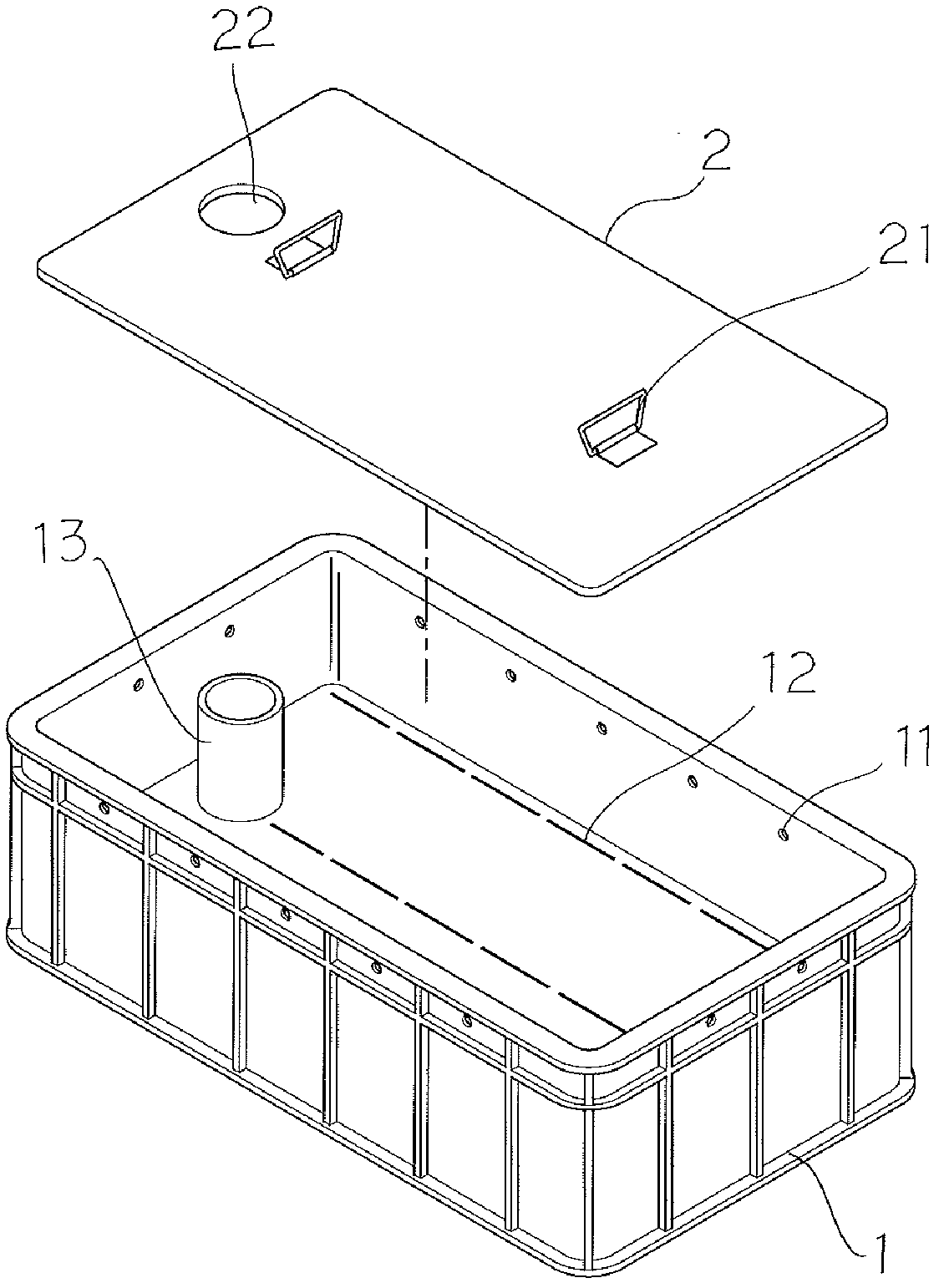

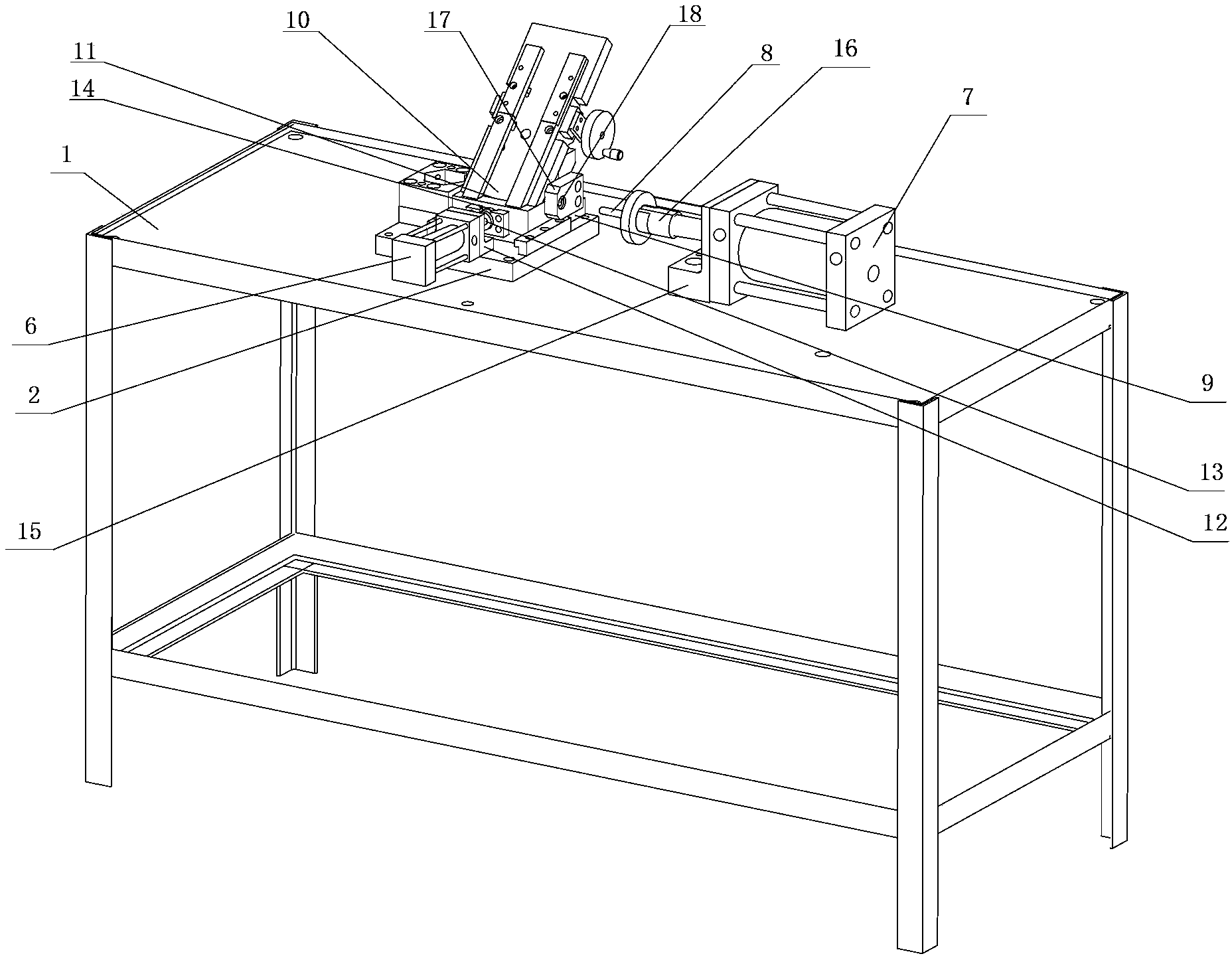

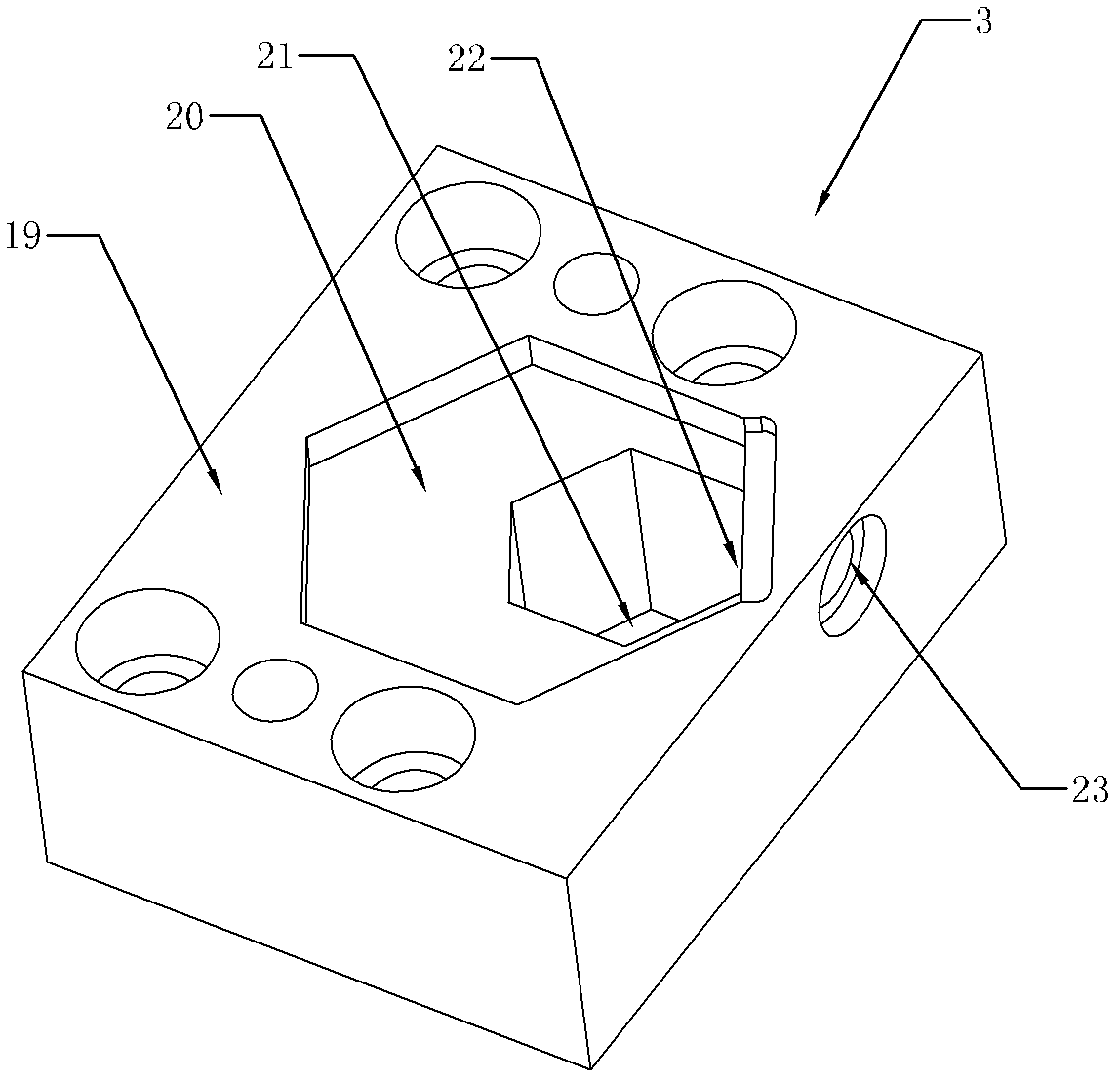

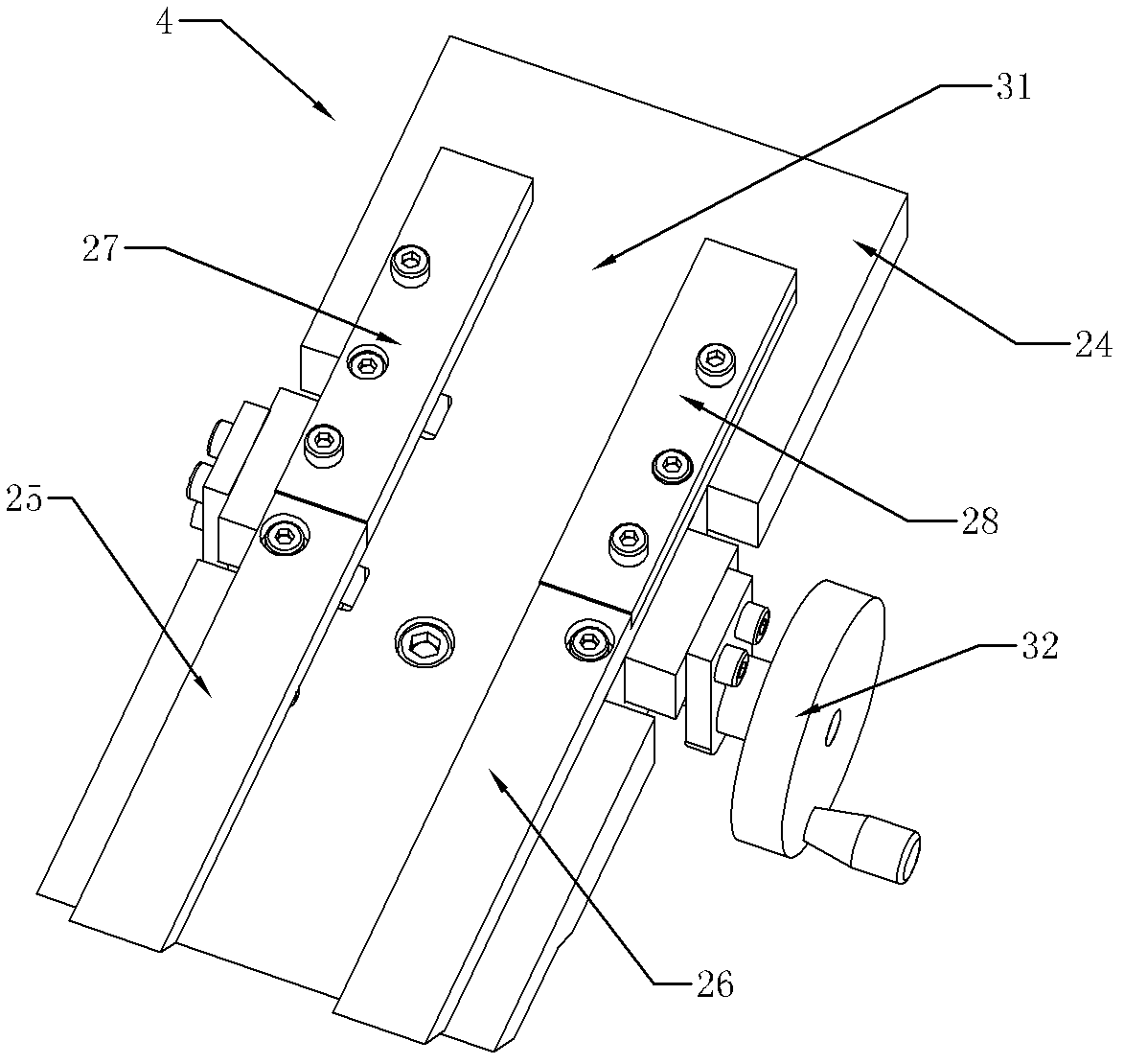

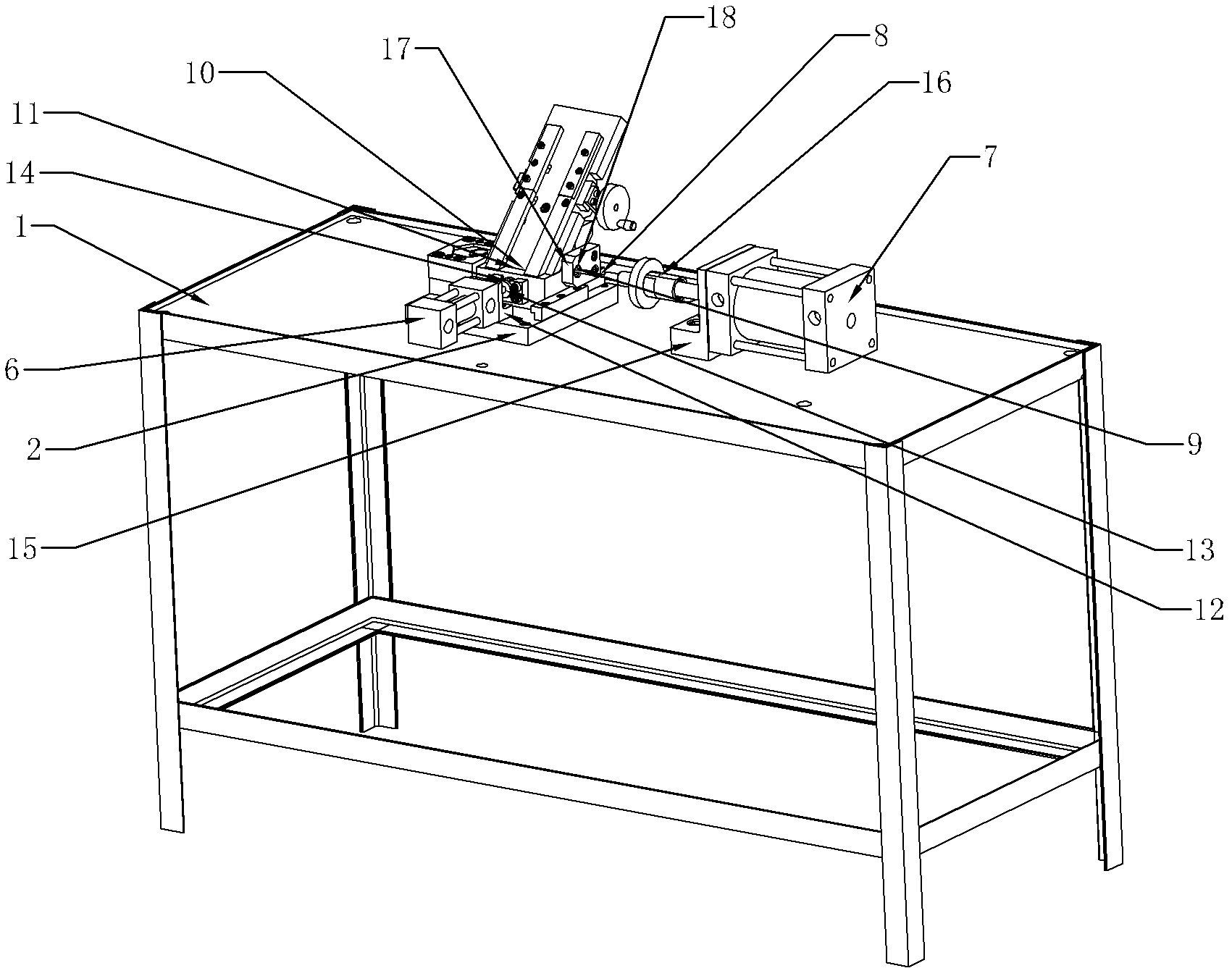

Vibrating tray with adjustable feeding output

InactiveCN102431776BReduce recycling workloadQuality improvementJigging conveyorsConveyor partsManufacturing cost reductionMechanical equipment

The invention relates to a vibrating tray for conveying and feeding workpieces to automatic mechanical equipment, in particular to a vibrating tray with adjustable feeding output. The vibrating tray comprises a top tray, a spiral slideway of the top tray, a feeding output transition connecting slideway and a slideway support and is characterized in that the feeding output transition connecting slideway comprises a slideway bottom plate fixed with an slideway outer side plate, an inner side moving plate of the slideway and an adjusting device of the inner side moving plate of the sideway; and the inner side moving plate of the slideway is connected with the adjusting device of the inner side moving plate of the slideway. The invention aims to design a vibrating tray with adjustable feeding output for adjusting the transition connecting slideway according the sizes and shapes of the workpieces and realizing conveying of different workpieces by a vibrating top tray. Compared with the prior art, the vibrating tray has the advantages that the manufacturing cost is lowered, the mass production is realized, the matching cost of the automatic mechanical equipment is reduced, the feeding output adjustment is convenient, and the working efficiency is high, etc.

Owner:WENZHOU ZHONGKE AUTOMATION EQUIP

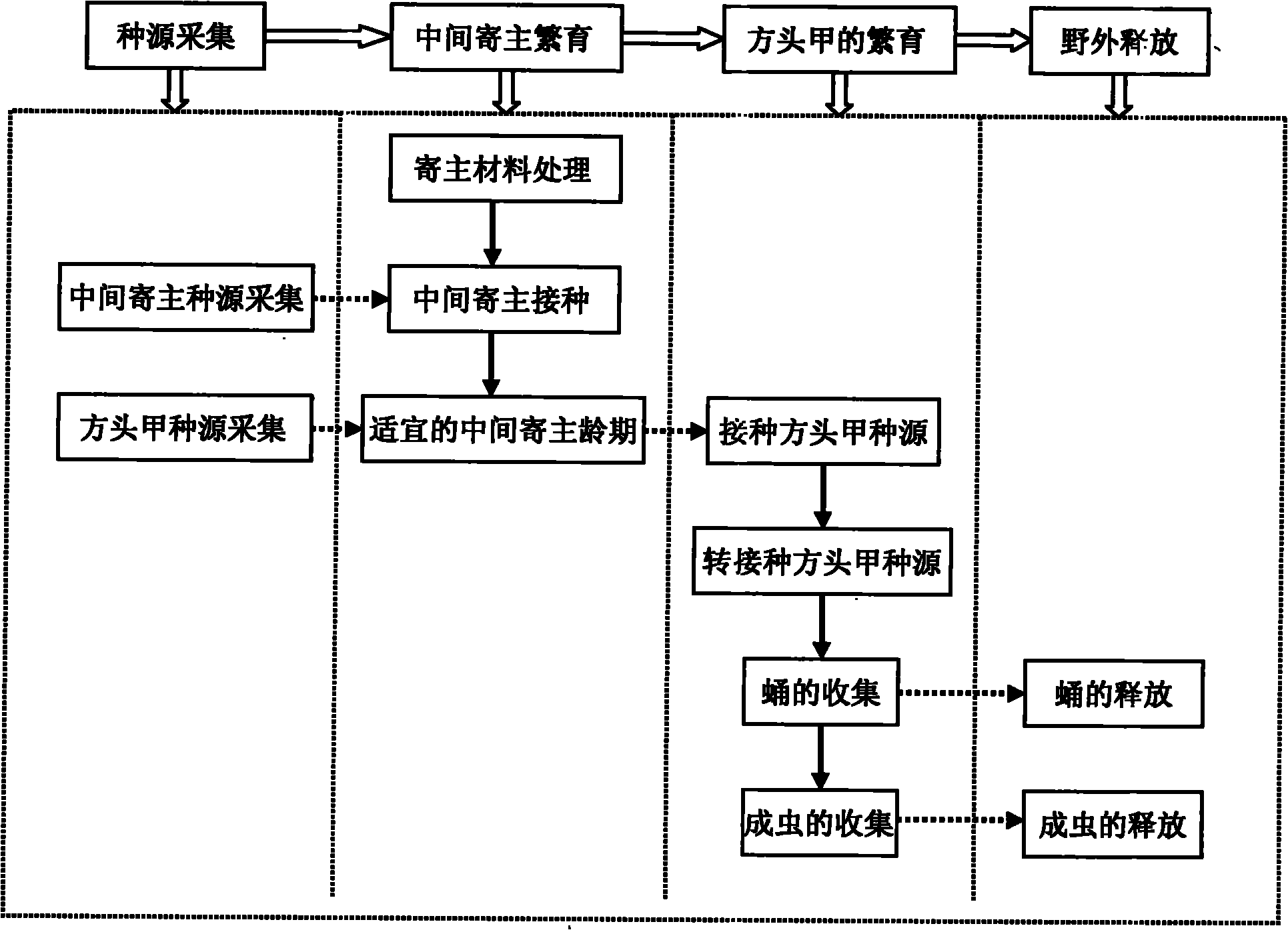

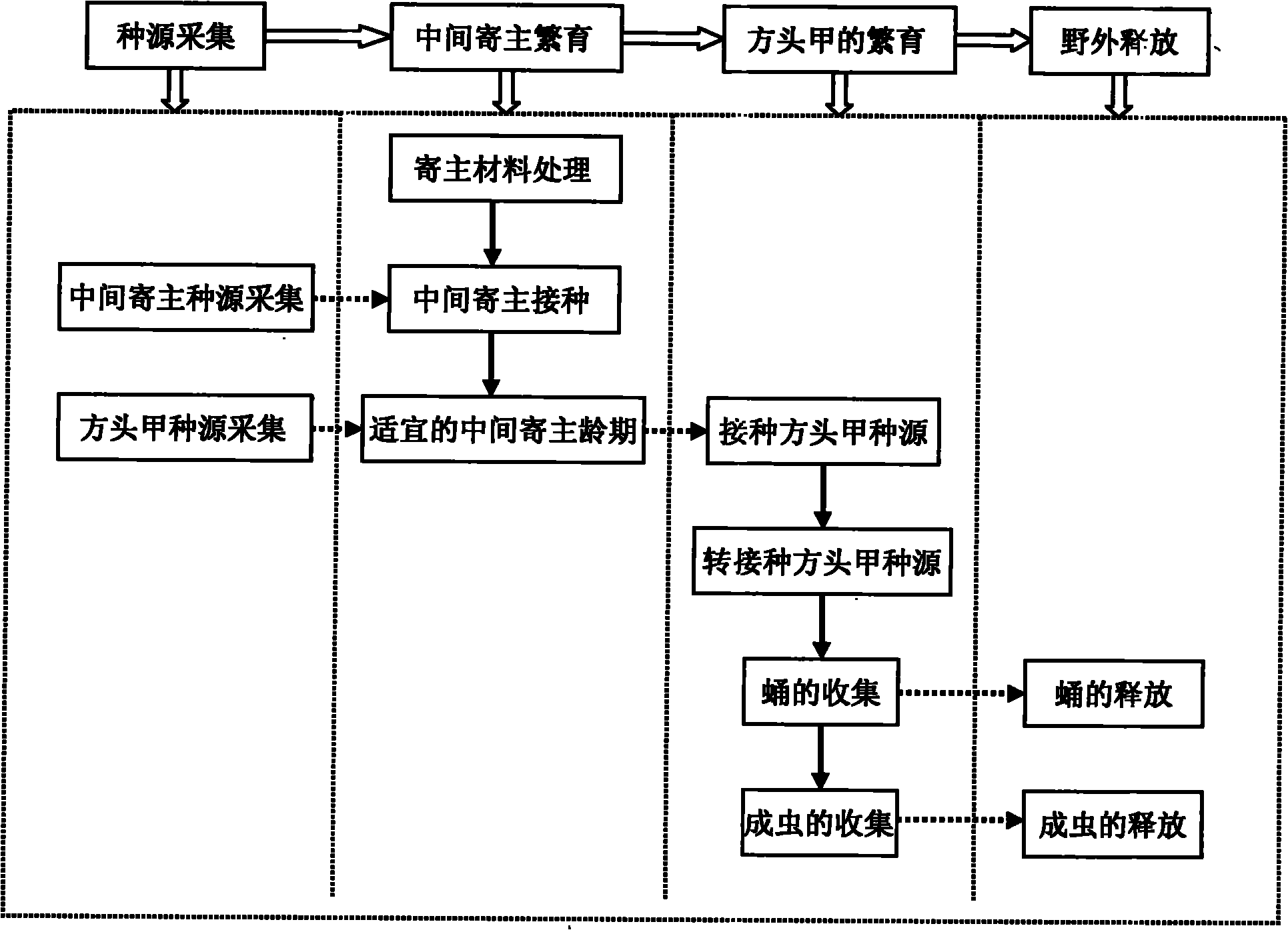

Method for indoor propagation and outdoor release of cybocephalus

InactiveCN101940193AShort generationsWide host adaptabilityAnimal husbandryNatural enemiesSeeds source

The invention belongs to the technical field of biologically controlling agricultural and forestry pests, and in particular relates to a method for the indoor propagation and the outdoor release of natural enemy insects. The method comprises the following steps of: using potatoes as a propagation material of an intermediate host; using oriental kidney armored scales which are easy to mass propagation indoors and have wide humiture adaptation range as the intermediate host, putting the intermediate host cultured for about 20-30 days in a disposable cup with a lid, inoculating and propagating a cybocephalus seed source in a sex ratio of 1 to 1, taking out the cybocephalus seed source after 10-15 days and transferring to another cup until the seed source is dead; putting the rest potatoes in rows in a plastic box with bilayer gauze on the bottom layer to collect pupas; and putting the collected pupas in an adult insect collecting cage or releasing the pupas in the field so as to prevent armored scale pests or releasing the collected adult insects in the field. The invention can carry out the mass production on the cybocephalus and solve the problems of low propagation efficiency and annual productivity incapability of the cybocephalus.

Owner:GUANGXI FORESTRY RES INST

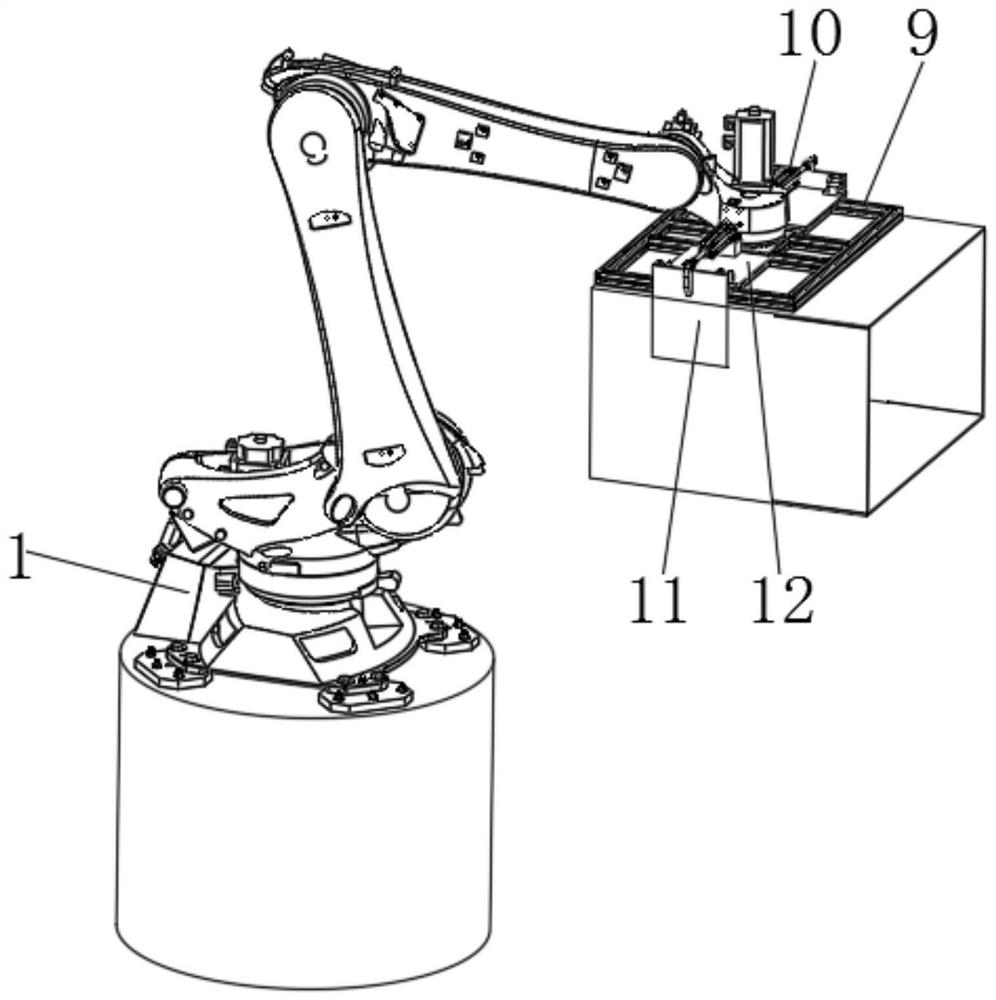

Full-automatic inner and outer box sleeving system

ActiveCN113199809ATo achieve the purpose of mass productionSolve the problem of low initial molding efficiencyEnvelopes/bags making machineryBox making operationsCartonEngineering

The invention discloses a full-automatic inner and outer box sleeving system. The system comprises a feeding unit, a box body forming unit, a box sleeving unit, an overturning unit, a bottom plate adding unit and a film sleeving unit which are sequentially arranged, wherein the box body forming unit is used for receiving an inner box and an outer box supplied by the feeding unit, positioning and forming the inner box and the outer box and then feeding the inner box and the outer box into the box sleeving unit, the box sleeving unit can feed the inner box into the outer box in a horizontal mode to form a primary box sleeving body and feed the primary box sleeving body into the overturning unit, the overturning unit can rotate the primary casing body so that the primary casing body can enter the bottom plate adding unit in the mode that the opening faces upwards. In short, according to the technical scheme, through the coherent and compact structure, the problem that a complete carton processing device for systematic assembly line processing of cartons is lacked in the field at present is solved, the processing efficiency of the cartons is improved to the maximum extent, and batch production of the cartons is facilitated.

Owner:重庆衍裕机电科技有限公司

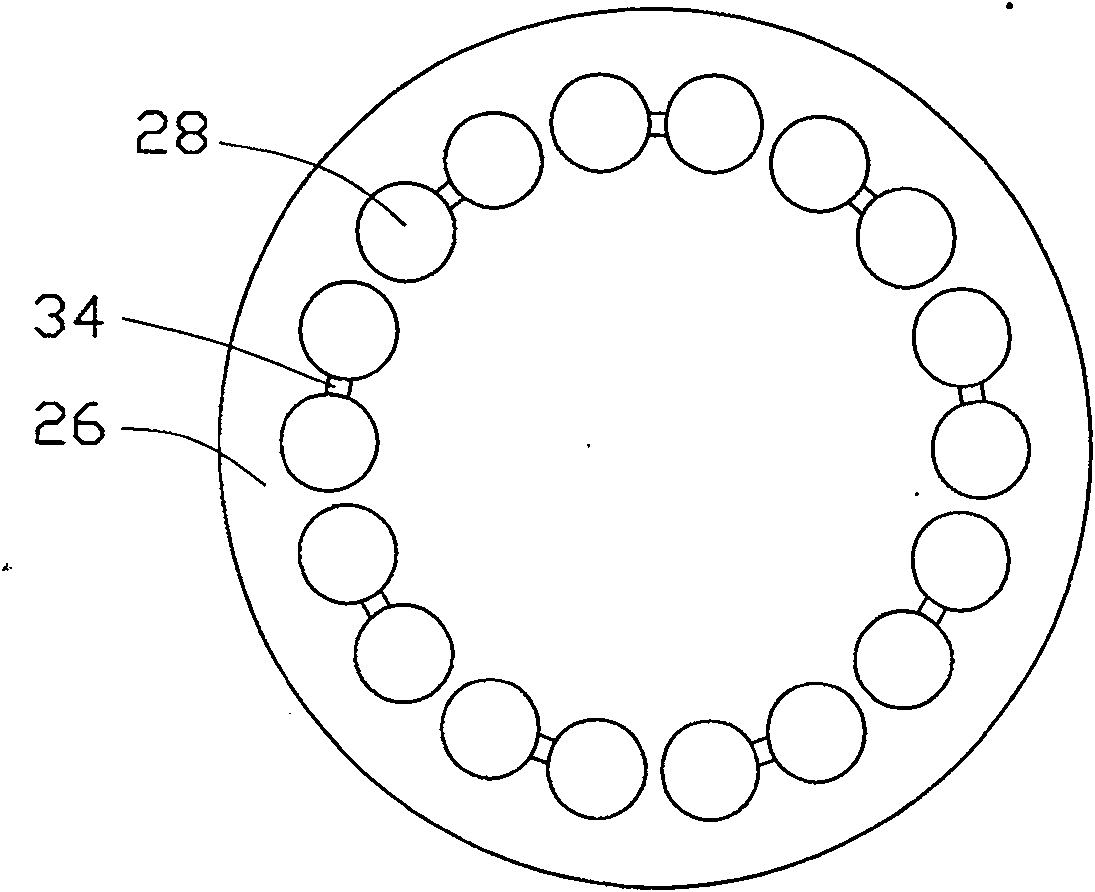

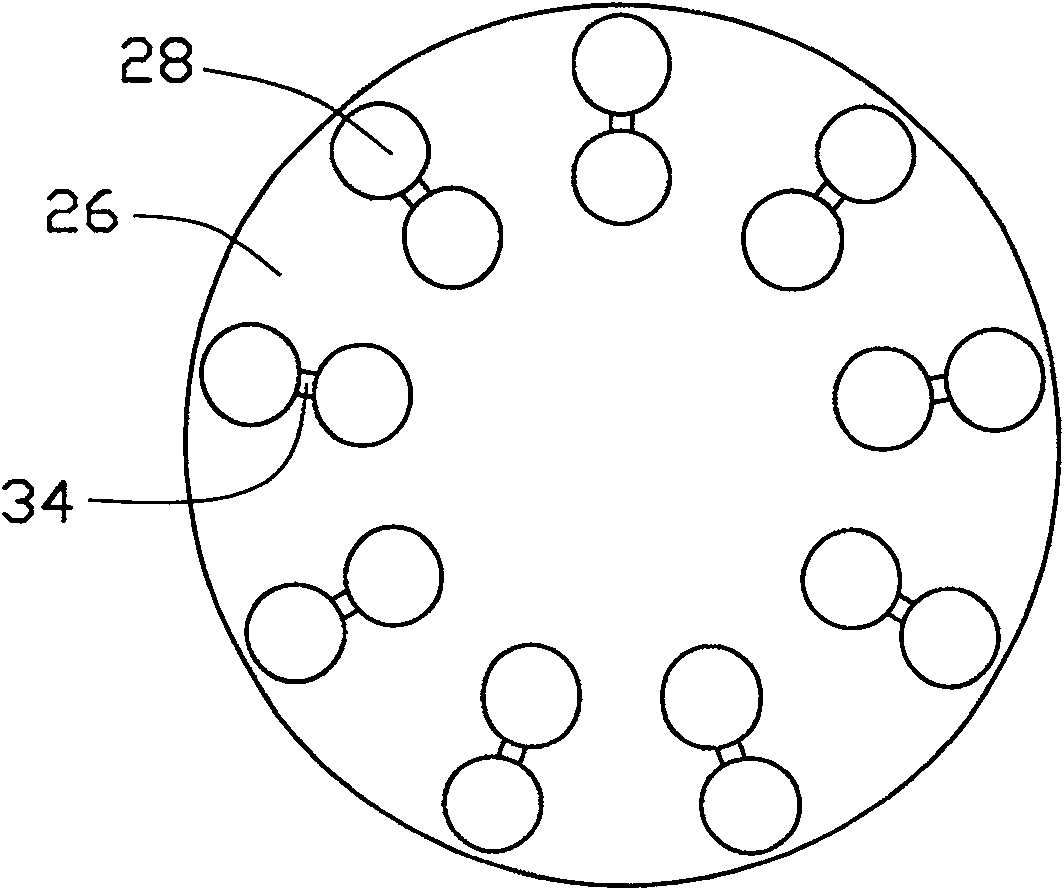

Sputtering device and method

InactiveCN100560786CIncrease productivityEasy to operateVacuum evaporation coatingSputtering coatingSputteringBearing surface

The invention relates to a sputtering device, which includes a sputtering cavity, and the sputtering cavity is provided with a first sputtering target, a second sputtering target, a base turntable and multiple pairs of bearing platforms. The first sputtering target is set opposite to the upper surface of the base turntable, and the second sputtering target is set around the base turntable. The base turntable is connected with a rotation device, and the rotation device is used to drive the base turntable to rotate around the center of the base turntable. The multiple pairs of bearing platforms are arranged on the upper surface of the base turntable, each pair of bearing platforms is connected by a connecting rod, and the connecting rod is connected with a driving device to drive the two bearing platforms connected by the connecting rod to rotate around the center point of the connecting rod. The present invention also relates to a sputtering method using the sputtering device. Using the sputtering device for sputtering is simple and convenient to operate, and can uniformly coat a plurality of irregular-shaped workpieces at the same time, effectively improving the sputtering production of irregular-shaped workpieces. Efficiency, in order to achieve the purpose of mass production.

Owner:HONG FU JIN PRECISION IND (SHENZHEN) CO LTD +1

Ice cream making machine with observable raw material barrel

The invention belongs to the technical field of making apparatuses for cold drinks and snacks, and further discloses an ice cream making machine with an observable raw material barrel. The ice cream making machine with the observable raw material barrel comprises a shell, a frame, a charging device, a mold supporting turn table, a rotating shaft, an assembly control device, a discharging clamping jaw, an oil pump and a transparent raw material barrel, wherein the upper side of the shell is provided with the mold supporting turn table; the lower side of the center of the mold supporting turn table is provided with the rotating shaft; the frame is arranged on the two sides of the shell; the upper part of one side of the frame is provided with the charging device; the shell is provided with the assembly control device; the charging device is electrically connected with the assembly control device; the other side of the frame is provided with a cross arm; the cross arm is fixedly connected with the frame through a welding way and the frame is fixedly connected with the shell through the welding way; the upper side of a charging rod is provided with a charging cabin. According to the ice cream making machine with the observable raw material barrel, through the transparent raw material barrel, whether a raw material is clean and sanitary can be observed; moreover, through the mold supporting turn table, the ice cream making machine with the observable raw material barrel is applicable to multiple types of ice cream filling machines; the rate of finished products is improved drastically.

Owner:黄晓晨

Manufacturing method for pulp picture foiled with faithful depiction background

PendingCN107187263AIt is not easy to solve the perspective relationship between far and nearDifficult to solve large and difficult problemsSpecial ornamental structuresIndustrial engineeringManufacturing engineering

The invention discloses a manufacturing method for a pulp picture foiled with a faithful depiction background. The manufacturing method comprises the steps that a bottom plate and pulp are prepared, the pulp picture is manufactured and shaped, and follow-up processing is conducted. Specifically, a faithful depiction background picture is printed on a canvas, a pulp-painting-area blank is reserved in the faithful depiction background picture, a pulp painting contour line is printed in the blank area, figures or characters representing pulp colors are marked within the contour line, and thus the bottom plate is prepared; a paper making pulp board with the whiteness being 70-92% is adopted to prepare pulp with the beating degree being 14-42 degrees SR and water content being 21-40% through a pulping machine, pigment and white emulsion are added to prepare pulp with needed colors, each bottom plate is equipped with pulp of the corresponding amount and corresponding colors, and the pulp colors are marked with figures or characters; according to color marking on the blank position of the bottom plate, the blank position of the bottom plate is filled with the pulp of the corresponding colors, the thickness of the pulp is adjusted, the pulp is shaped, and then the target pulp picture is obtained; and the pulp picture is dried, mended, trimmed and mounted, and thus manufacturing of the whole pulp picture is completed.

Owner:敦化市金兴纸制品有限公司

Preparation method of burnt-out lace jeans wear

InactiveCN108754779AGuaranteed not to slipImprove aestheticsGarmentsWoven fabricsEngineeringBurning out

The invention belongs to the field of the preparation of burnt-out jeans wear, and particularly relates to a preparation method of burnt-out lace jeans wear. The method comprises the following steps:preparation of warp and weft yarns, size dyeing, weaving, finishing, processing clothes, burnt discharge, washing and ironing; the warp and weft yarns adopt covered yarns formed by covering core silkthrough double strands of cotton; the covered yarns adopt zero twist or low twist; the core silk adopts 1F to 24F nylon yarns, two strands of nylon yarns with the same thickness are twisted oppositely, the degrees of twist of the two strands of nylon yarns are the same, the two strands of nylon yarns are twined to each other, and generally, the core silk adopts zero twist; the double strands of cotton used for covering are twisted around the core silk; size dyeing adopts low-temperature dyeing and the tension during size dyeing is improved; weaving adopts weft yarn non-joint weaving; finishingadopts outer covered button zero shrink finishing; the clothes are manufactured through a preset style, a template figure is coated with winter cherry for burnt discharge, the clothes are washed with70 to 100 degree water, and drying and ironing are performed. The burnt-out jeans wear is comfortable and artistic, and laces are not slipped.

Owner:张家港市隆利氨纶纱线厂

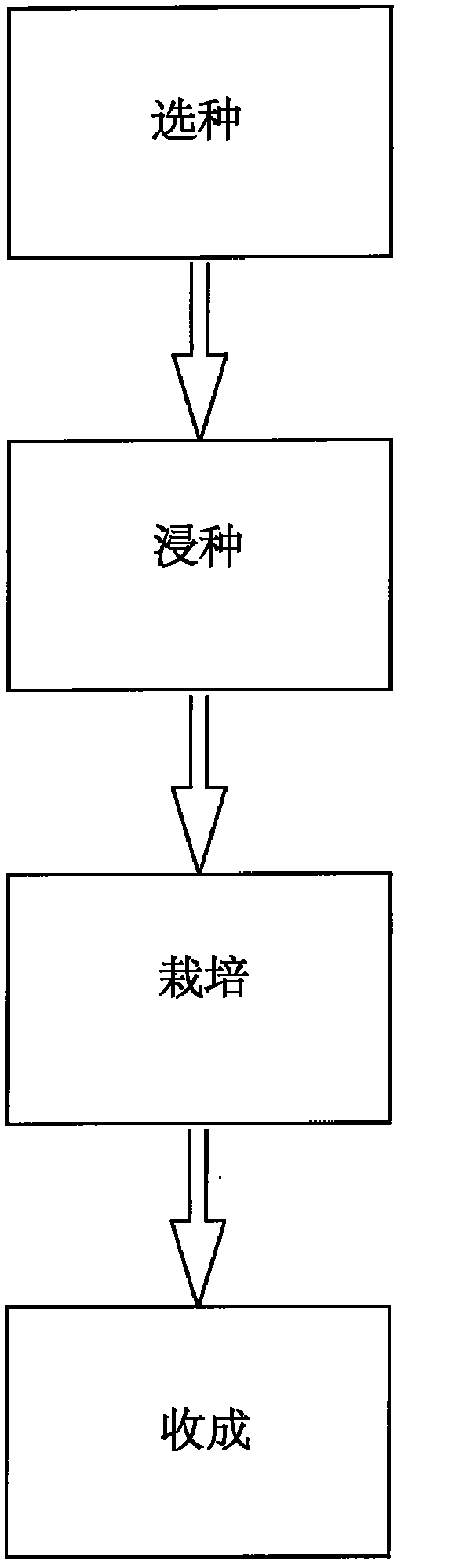

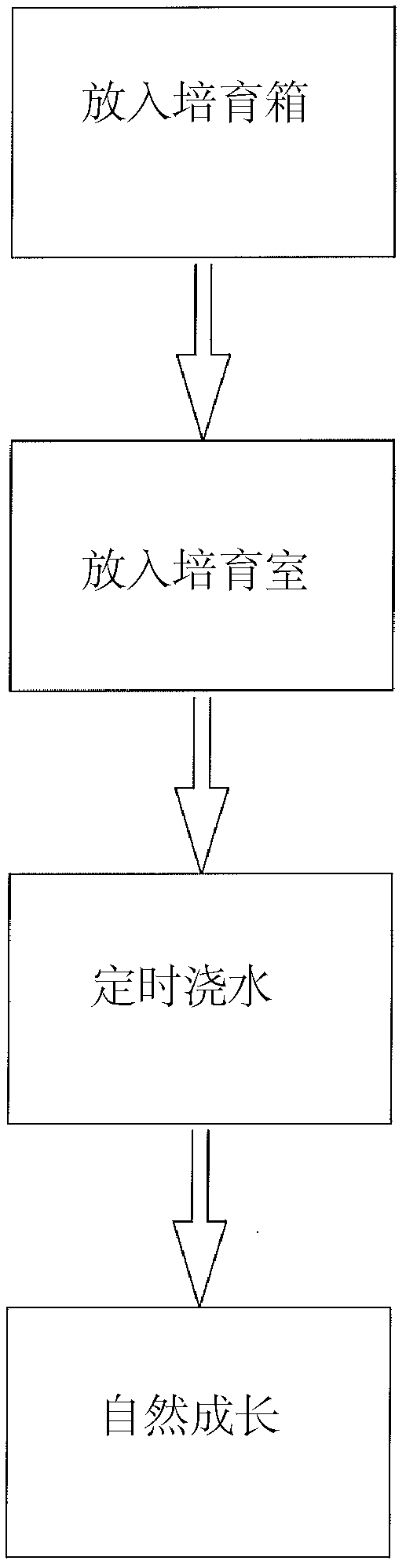

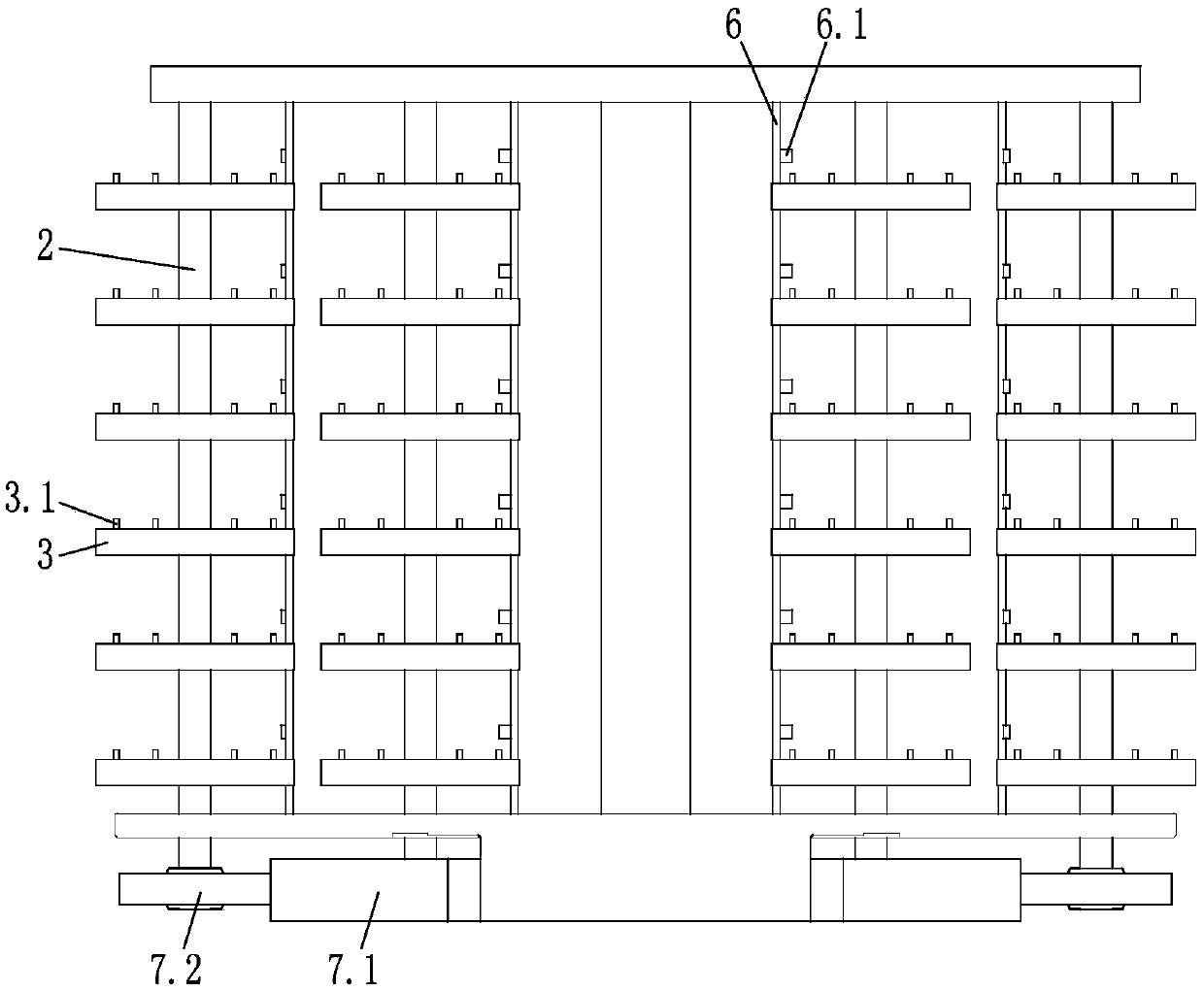

Method and device for bean sprout mass production cultivation

InactiveCN103155843ATo achieve the purpose of mass productionAgriculture gas emission reductionCultivating equipmentsPipingEcology

The invention provides a method and a device for bean sprout mass production cultivation. The method includes seed selection, seed soaking, cultivation and harvest. The cultivation process further includes that seeds are placed into cultivation boxes, and a plurality of cultivation boxes are stacked to be vertical-shaped. The plurality of cultivation boxes stacked are placed into a cultivation room, the seeds are watered at regular time, and when watered, each seed is fully supplied with water. The seeds grow naturally, any growth agent is not necessary to be added, and healthy bean sprouts of mass production can be harvested. The cultivation device comprises a cultivation box and a cover plate, the cultivation box comprises a ventilation hole, a linear hole, and an overflow tube, wherein the ventilation hole is used for adjusting the temperature in the cultivation box, the linear hole facilitates water discharging, the situation that the cultivated seeds are rotted due to water accumulation can not happen, holes can be prevented from being blocked, and the height of the overflow tube is designed to be one third shorter than that of the circum of the cultivation box so that redundant water can be discharged when water is added. The cover plate is provided with symmetrical handles so as to be picked up favorably in a balanced mode, a round hole is formed in one of the handles, the overflow tube can penetrate through the round hole, and therefore an optimized growing environment is provided for the cultivated seeds.

Owner:颜文成

Automobile exterior trimming part based on enhanced carbon fiber composite material plate and preparation method thereof

InactiveCN107443817AFully infiltratedIncrease stiffnessSynthetic resin layered productsVehicle componentsFiberThermoplastic

The invention relates to an automobile exterior trimming part based on an enhanced carbon fiber composite material plate and a preparation method of the automobile exterior trimming part based on the enhanced carbon fiber composite material plate. The automobile exterior trimming part based on the enhanced carbon fiber composite material plate is characterized by comprising an upper cover plate layer, a lower cover plate layer and a middle bonding layer, wherein the upper and lower cover plate layers comprise thermoplastic fiber reinforced laminated composite material plates, the middle bonding layer comprises a plastic layer or a foam resin layer, the upper cover plate layer, the lower cover plate layer and the middle bonding layer are integrally connected through a mould pressing manner; the middle bonding layer is solidified at room temperature while performing mould pressing to form a bonding connection structure of the upper cover plate layer and the lower cover plate layer to enhance the rigidity and strength of the product. According to the invention, the thermoplastic fiber plates are utilized for processing to simplify the manufacturing process of the product so as to improve the efficiency and reduce the cost; an upper cover plate and a lower cover plate are bonded by using foaming resin, and taken as reinforced layers to improve the rigidity, strength and impact resistance of the product so as to achieve a damping effect.

Owner:东莞市海旭新材料技术有限公司

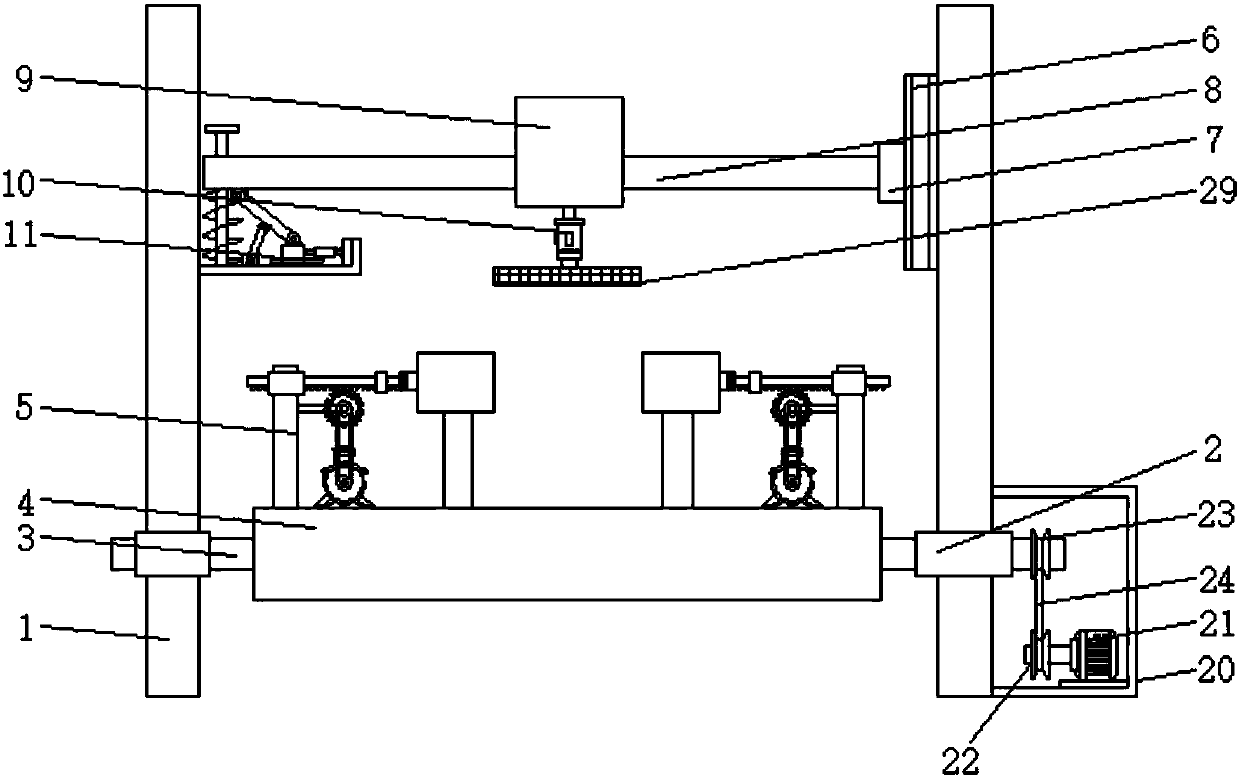

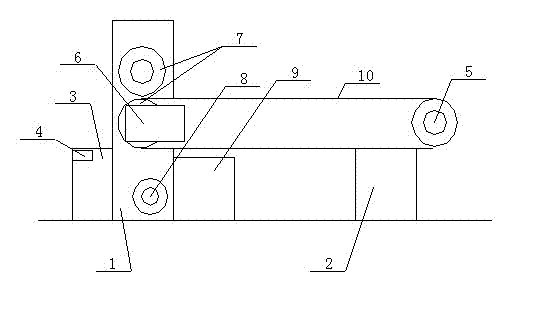

Automatic tin wire rolling mill

ActiveCN102728612ATo achieve the purpose of mass productionOvercome the shortcomings of manual control that is not accurate enoughRoll mill control devicesMeasuring devicesHigh volume manufacturingEngineering

An automatic tin wire rolling mill relates to the technical field of automation control. The left side of a left rack (1) is provided with a console (3), a length counter (4) is arranged on the console (3), a guide wheel (5) is arranged at the right side of the upper part of a right rack (2), two rollers (7) are arranged on the left rack (1) up and down, a length controller (6) is arranged on the lower roller (7), a motor (8) is arranged at the lower part of the left rack (1), a transmission gear (9) is arranged at the right side of the left rack (1), the left end of a wire guide platform (10) is fixed on the lower roller (7), and the right end of the wire guide platform (10) is fixed on the guide wheel (5). By the automatic tin wire rolling mill, the defect of low manual control precision is overcome, and the purpose of mass production of tin wires can be realized.

Owner:上海锡喜材料科技有限公司

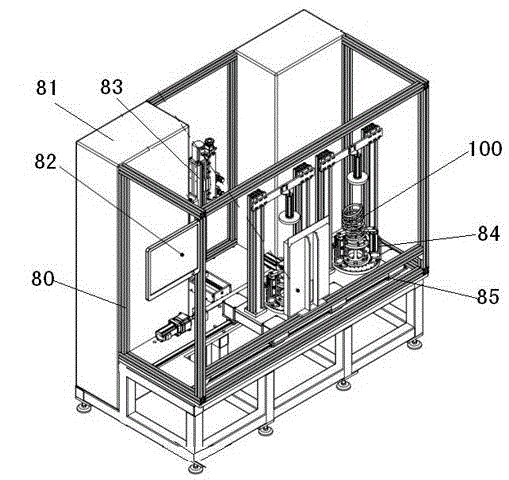

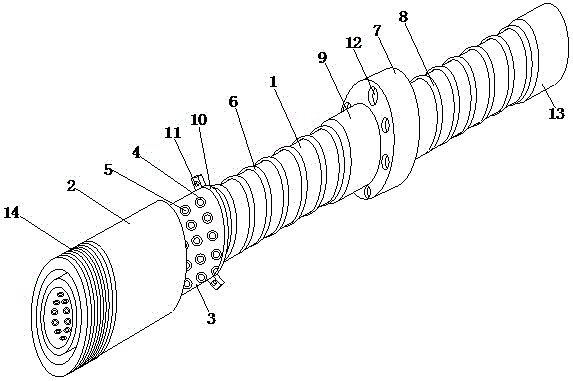

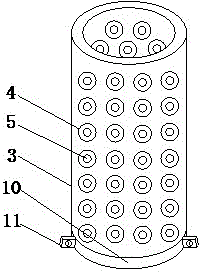

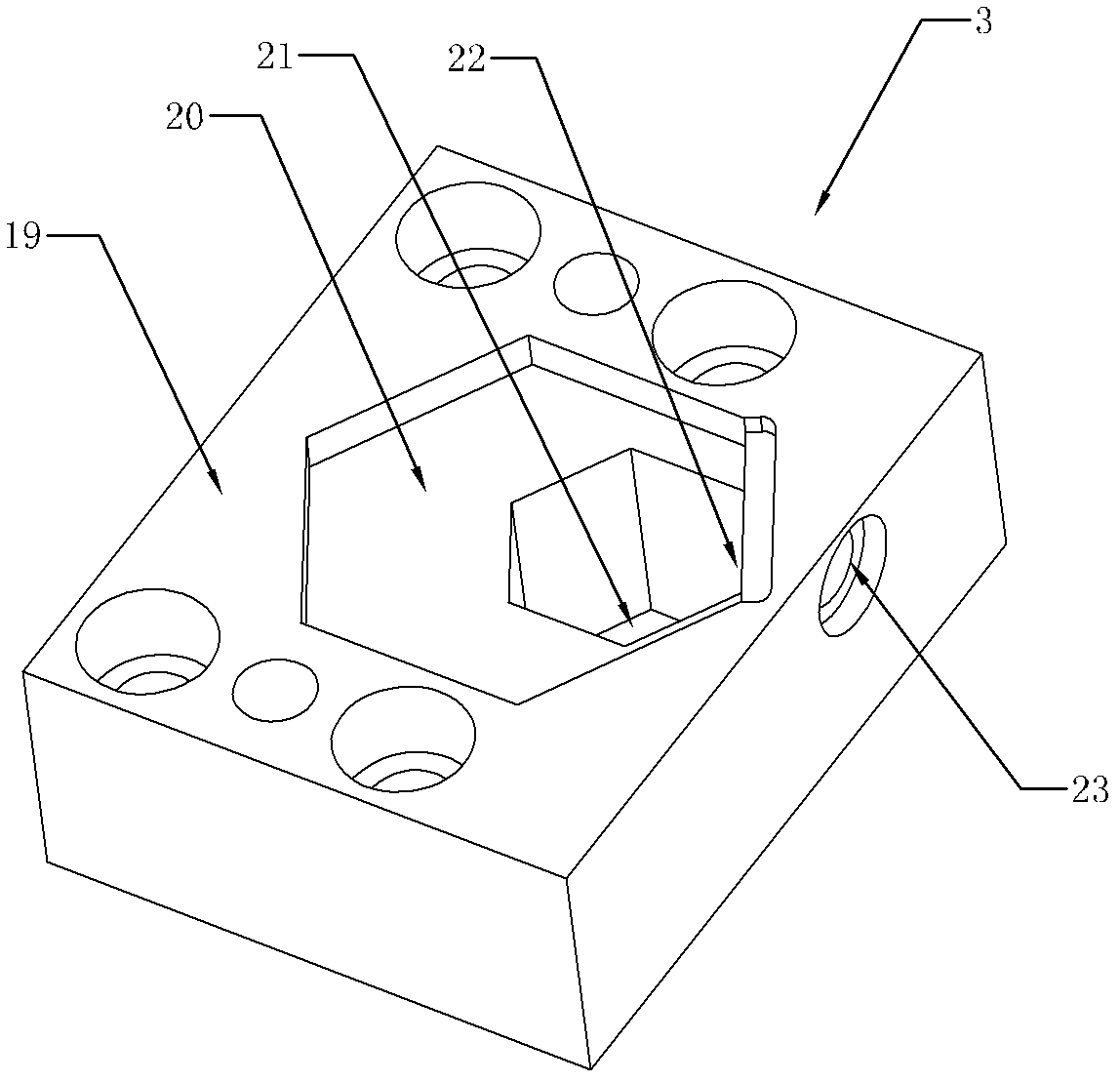

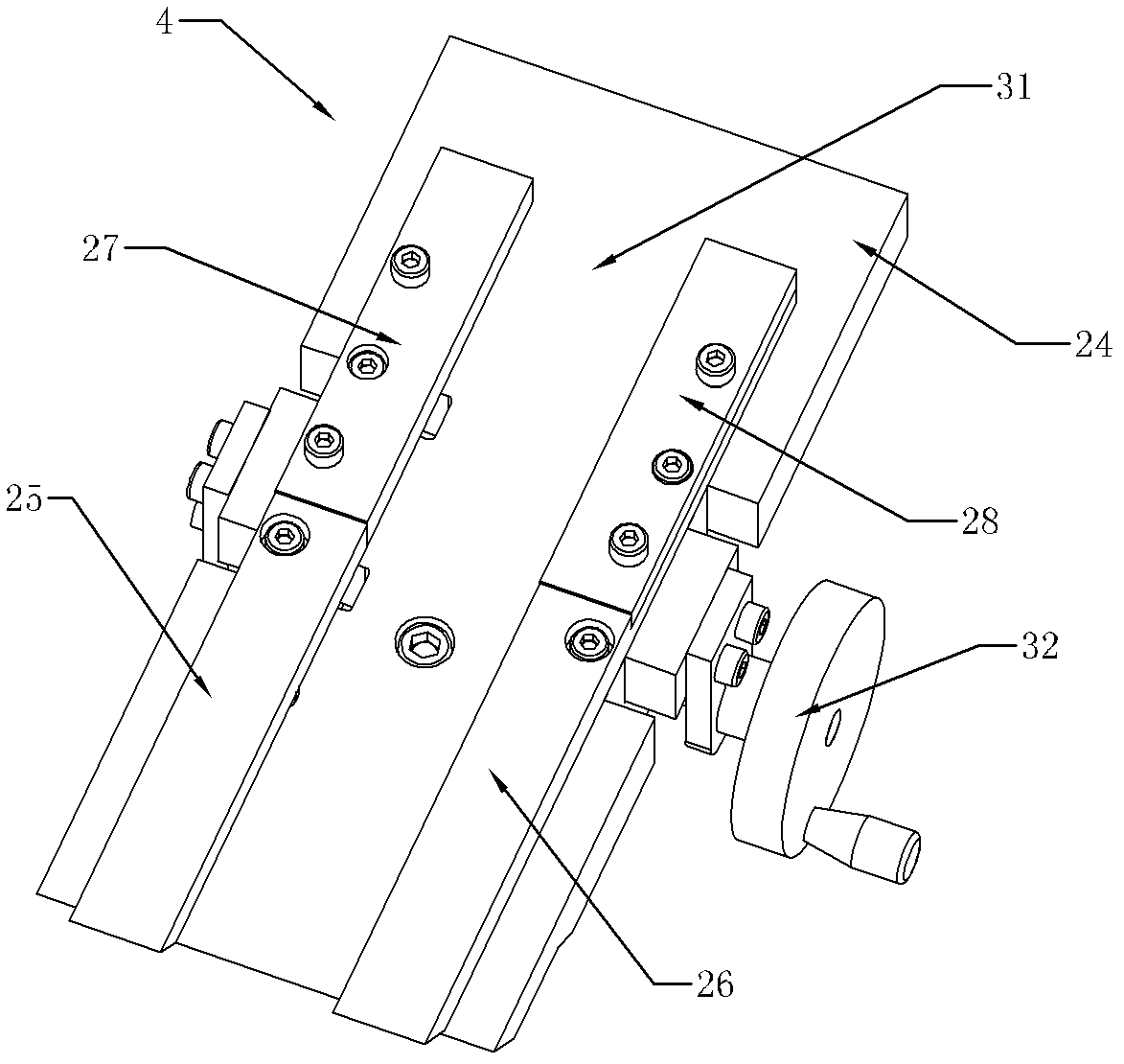

Special clamp for valve element coating

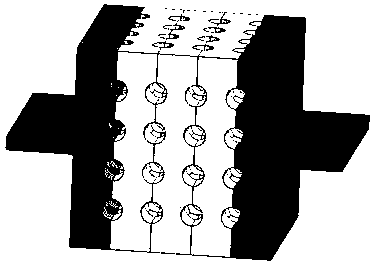

PendingCN109594052ASimple structureEasy to operateVacuum evaporation coatingSputtering coatingEngineeringMechanical engineering

The invention relates to the field of tool clamps, and aims to provide a special clamp for valve element coating. The clamp has the advantages of being good in coating quality and large in batch. According to the technical scheme, the special clamp for valve element coating is characterized in that the clamp comprises a main rotating frame driven by a motor to rotate, a plurality of auxiliary rotating rotating frames arranged around the main rotating frame, a planetary transmission mechanism driving the auxiliary rotating frames to rotate correspondingly and a valve element clamp used for positioning a valve element on the auxiliary rotating frames, wherein the auxiliary rotating frames comprise supporting shafts which can be rotationally positioned in the main rotating frame around vertical axes and a plurality of clamp discs which are fixed on the supporting shafts, clamp fixing pins matched with the valve element clamp are arranged on the top surfaces of the clamp discs, the valve element clamp comprises a base and a top cover, valve element fixing pins matched with the valve element are arranged at the top of the base, and positioning holes used for being arranged on the clampfixing pins in a sleeve manner are formed in the bottom of the base.

Owner:杭州东兴电讯材料有限公司

Terminal mold accessory for precision mold casting

InactiveCN105537512AGuaranteed accuracyAvoid errorsFoundry mouldsFoundry coresEngineeringPosition error

The invention discloses a terminal mold accessory for precision mold casting. The terminal mold accessory comprises a guide pillar and a guide sleeve. One end of the guide pillar penetrates an anti-abrasion inner barrel arranged in the guide sleeve. The outer surface and the inner wall of the anti-abrasion inner barrel are each provided with a plurality of grooves arranged at equal distances. A ball is arranged in each groove. A first spring, a guiding connecting piece and a second spring are sequentially arranged on the outer surface of the guide pillar from left to right. A first casing pipe is arranged on the outer surface of the guide pillar. One side face, close to the guide sleeve, of the guiding connecting piece is fixedly connected with one end of the first casing pipe. According to the terminal mold accessory for precision mold casting, in the long-time work state, abrasion damage between the guide pillar and the guide sleeve can be effectively avoided, and therefore accuracy of guiding locating of a terminal mold is guaranteed, then the phenomenon that large shape and position errors happen to a precision mold can be effectively avoided, the casting cost is reduced, the production efficiency is improved, and the aim of batch production is achieved.

Owner:WUXI YONGYI PRECISION CASTING

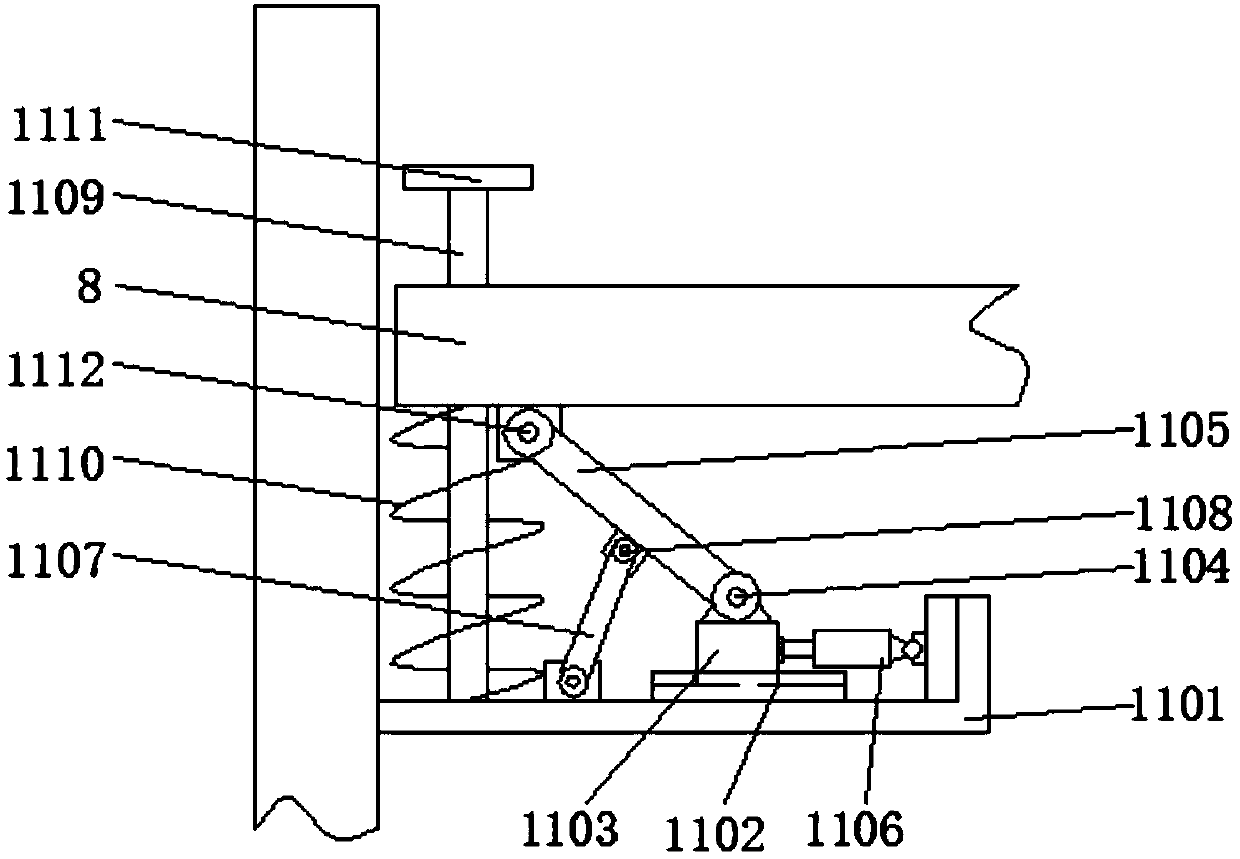

Semi-automatic needle-threading device used for buckling pin on pipe joint

InactiveCN102430689BTo achieve the purpose of mass productionEasy to operateBiochemical engineeringSemi automatic

The invention discloses a semi-automatic needle-threading device used for buckling a pin on a pipe joint. The needle-threading device comprises a stand, a press plate, a core-ejecting mechanism, a discharging mechanism, a receiving mechanism, a first cylinder, a second cylinder and a threading needle, wherein the press plate and the second cylinder are arranged on the stand; the core-ejecting mechanism, the receiving mechanism and the first cylinder are arranged on the press plate; the discharging mechanism is arranged on the receiving mechanism by forming an oblique angle through a rear seat and arranged at the right side of the core-ejecting mechanism; an outlet at the lower end of the discharging mechanism is arranged on an inlet of the receiving mechanism; the first cylinder is arranged in front of the receiving mechanism and connected with the receiving mechanism through a push rod arranged on the first cylinder; and the second cylinder is arranged at the right side of the receiving mechanism, and the threading needle is arranged on the second cylinder. The invention realizes semi-automatic production, thus production efficiency is increased, cost is saved, and massive batch production becomes possible.

Owner:宁波联润流体机械制造有限公司

Semi-automatic needle-threading device used for buckling pin on pipe joint

InactiveCN102430689ATo achieve the purpose of mass productionEasy to operateBiochemical engineeringSemi automatic

The invention discloses a semi-automatic needle-threading device used for buckling a pin on a pipe joint. The needle-threading device comprises a stand, a press plate, a core-ejecting mechanism, a discharging mechanism, a receiving mechanism, a first cylinder, a second cylinder and a threading needle, wherein the press plate and the second cylinder are arranged on the stand; the core-ejecting mechanism, the receiving mechanism and the first cylinder are arranged on the press plate; the discharging mechanism is arranged on the receiving mechanism by forming an oblique angle through a rear seat and arranged at the right side of the core-ejecting mechanism; an outlet at the lower end of the discharging mechanism is arranged on an inlet of the receiving mechanism; the first cylinder is arranged in front of the receiving mechanism and connected with the receiving mechanism through a push rod arranged on the first cylinder; and the second cylinder is arranged at the right side of the receiving mechanism, and the threading needle is arranged on the second cylinder. The invention realizes semi-automatic production, thus production efficiency is increased, cost is saved, and massive batch production becomes possible.

Owner:宁波联润流体机械制造有限公司

A kind of production equipment and using method of spatial structure prefabricated body

ActiveCN109049280BTo achieve the purpose of mass productionWith strengthCeramic shaping plantsCylinder blockIndustrial engineering

The invention discloses production equipment for space structure prefabricated bodies. The production equipment comprises a cylinder block, a circular water cooling device, a microwave heating device,a mold, a molding core, a pressing plate and a pulley; the mold comprises an upper mold and a lower mold; the upper mold consists of a left upper mold and a right upper mold; the pressing plate comprises a left pressing plate and a right pressing plate; and the pulley comprises a large pulley and a small pulley. An application method comprises the following steps: the molding core is put in a mold cavity; meanwhile, prefabricated body powder is added for extrusion molding, and is heated through the microwave device; after the molding core is burnt, the heating formation is performed; and themold is taken after cooling to obtain a finished product. The device is simple in structure; and the processes of pressing, molding and drying of various prefabricated bodies with different space structures can be finished at the same time through the whole set of devices, so that the production efficiency of space structure composite materials is effectively improved, the product quality is improved, and the production cost is reduced.

Owner:KUNMING UNIV OF SCI & TECH

An automatic glue filling production line, glue filling method and application for preparing electrophoresis gel columns

ActiveCN109590170BImprove product qualityReduce scrap rateLiquid surface applicatorsSpraying apparatusElectrophoresesAdhesive glue

The invention provides an automatic glue pouring production line and glue pouring method for preparing an electrophoresis gel column and application. According to the glue pouring process route, the production line comprises a first layer glue pouring module, a water absorption module and a second layer glue pouring module. The method comprises the steps that a glue pouring holed plate fixedly provided with gel glass tubes is arranged onto a clamping groove of a conveying belt; the automatic glue pouring production line is started to implement operation of first layer glue pouring; after firstlayer glue is solidified, pressure glue on the gel surface is absorbed; operation of second layer glue pouring is conducted; and after second layer glue is solidified, pressure glue on the gel surface is absorbed, so that the electrophoresis gel column is obtained. By means of the automatic glue pouring production line and glue pouring method for preparing the electrophoresis gel column and the application, two types of solutions are pumped therein quantitatively through a plunger pump, and on-line mixing is conducted; and high-throughput glue pouring operation is conducted, the glue surfaceis treated subsequently, and the problems that in the manual operation process, products are poor in performance and low in qualification rate are solved.

Owner:SHANGHAI BIOTECAN PHARMA +1

Pulp picture manufacturing method

InactiveCN109551958ASimple manufacturing processEasy to viewNatural cellulose pulp/paperSpecial ornamental structuresPulp and paper industryPigment

The invention discloses a pulp picture manufacturing method. The pulp picture manufacturing method includes the steps of baseboard preparation, pulp preparation, pulp picture manufacturing and shapingand subsequent processing, and the pulp picture manufacturing method particularly includes the steps that multicolor pattern printing is conducted on a breathable canvas after a computer is utilizedto conduct pattern design, the canvas printed with multicolor patterns is tightened by a wood frame, pulp is prepared from a pulp board with the whiteness being 93-95% for papermaking through a papermaking pulp-making mechanical pulping machine, and a pigment and 10-30% of white latex are added to prepare the acquired-color pulp; and the pulp with different colors is packaged in a sealed mode, each baseboard is matched with the pulp with the corresponding numbers and colors, according to the color in baseboard multicolor pictures, the matching pulp of the same color is selected, the same colorof the baseboard multicolor pictures are filled with the matching pulp of the same color, the pulp thickness is adjusted, a target object pulp picture is obtained by shaping the pulp shape accordingto shapes of the multicolor pictures, the pulp picture is dried, mended and mounted, and manufacturing of the entire pulp picture is finished.

Owner:敦化市金兴纸制品有限公司

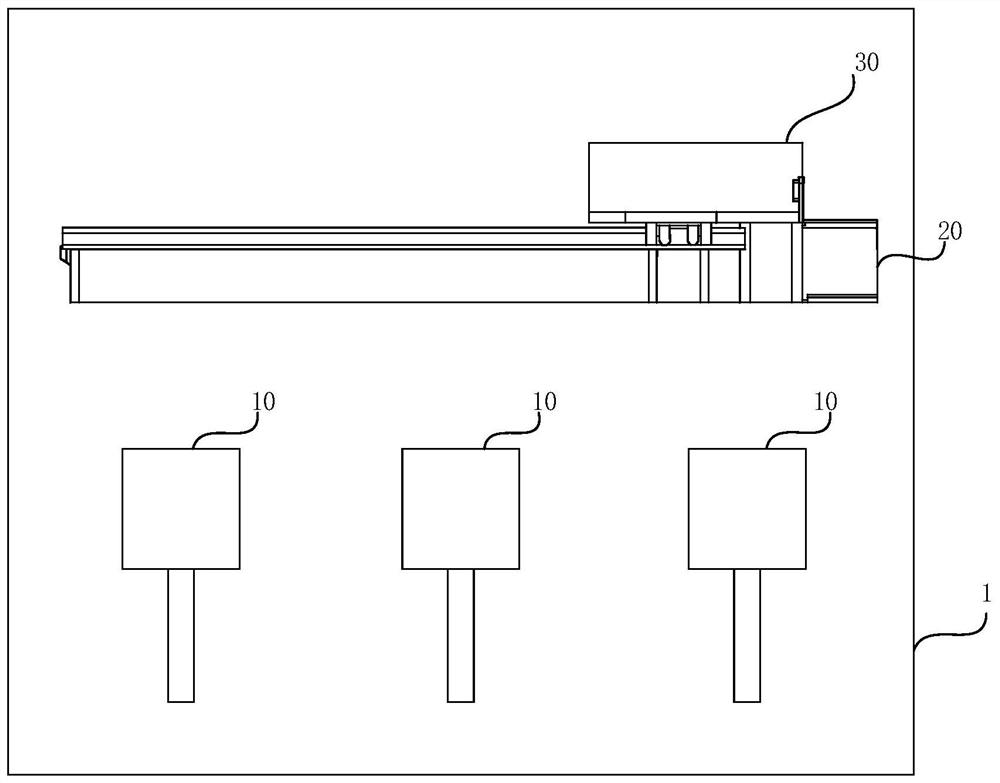

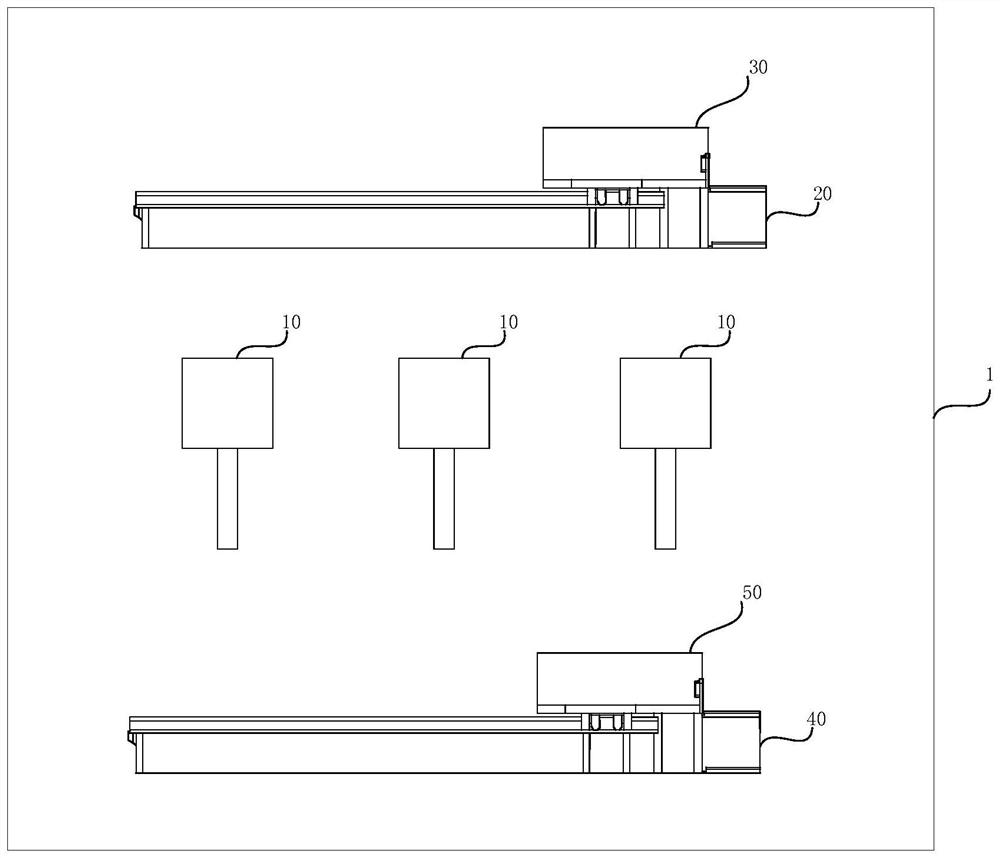

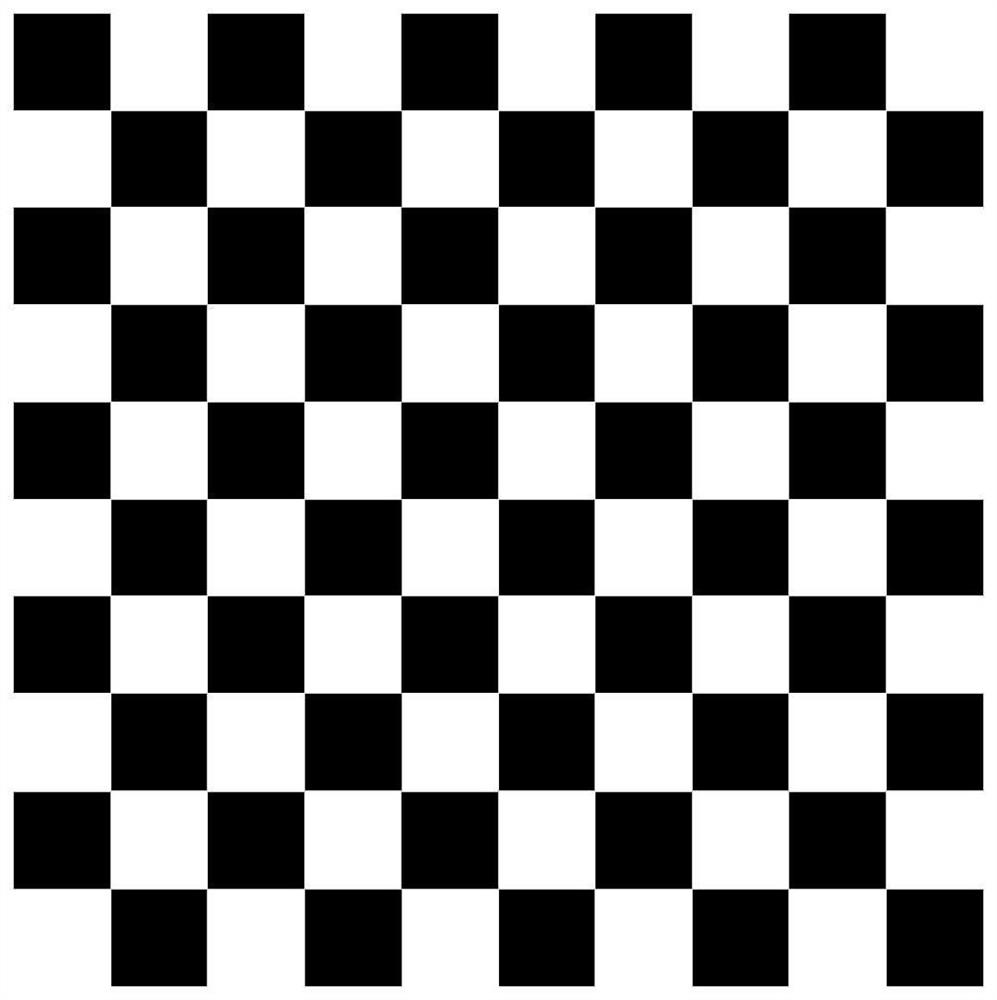

Camera calibration device

PendingCN112116662AImprove work efficiencySimple structureImage enhancementImage analysisTarget surfaceRadiology

Disclosed is a camera calibration device (1). The camera calibration device (1) comprises a plurality of image correction targets (10), a first moving mechanism (20) and a first camera fixing mechanism (30). The plurality of image correction targets (10) is arranged along the moving track of the first moving mechanism (20), and the target surface of each image correction target (10) is provided with a pattern for correcting a camera; the first camera fixing mechanism (30) is arranged on the first moving mechanism (20) and can move relative to the plurality of image correction targets (10); andone target surface of the plurality of image correction targets (10) is arranged towards the direction of the first moving mechanism (20).

Owner:SHANGHAI JUYOU SMART INTELLIGENCE TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com