Prefabricated facing bare concrete wallboard and manufacturing process

A technology of fair-faced concrete and prefabricated assembly, which is applied in the direction of manufacturing tools, supply devices, mold fixing devices, etc., to achieve the effect of stable product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

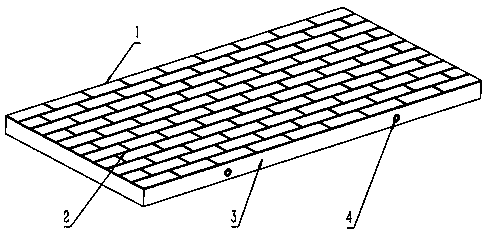

[0038] A prefabricated assembly-style clear-faced concrete wall panel, which includes a wall panel body, a decorative surface is provided on the outer surface of the wall panel body, the wall panel body is made of fair-faced concrete, and a sleeve is preset in the wall panel body ;

[0039] The thickness of the wallboard body described in this embodiment is greater than 50mm;

[0040] The sleeve described in this embodiment is arranged perpendicular to the thickness direction of the wallboard, and the diameter of the sleeve is greater than 12mm;

[0041] The decorative surface is a clear water surface, and the decorative effect of the decorative surface is imitating stone or imitating wood grain or imitating tiles.

[0042] refer to figure 1 , the prefabricated and assembled facing clear-water concrete wall panel provided in this embodiment adopts a one-time pouring molding process to produce a decorative clear-water concrete wall panel, and uses a silicone mold or mold line...

Embodiment 2

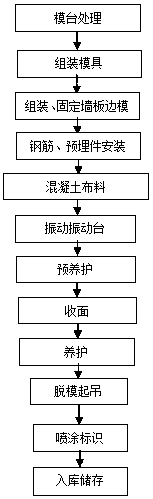

[0044] The manufacturing process of the prefabricated assembly type facing clear-faced concrete wall panel provided in this embodiment is to produce the prefabricated assembly type facing clear-faced concrete wall panel provided in Example 1. The prepared prefabricated wall panel has short production cycle, high efficiency, The quality is stable, and the finishing effect is beautiful after molding. The flow chart of the manufacturing process is as follows figure 2 As shown, the manufacturing process includes:

[0045] (1) Mold table treatment: cleaning of the mold table surface before use, including the cleaning of various side molds and mold lining molds. After cleaning and acceptance, enter the CNC marking station to complete automatic marking, and the side mold molds are in contact with the mold table. The surface needs to be flat and straight pasted with a 5mm thick foam sealing strip (other similar compressible sealing materials can also be selected), and then the side ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com