A kind of production equipment and using method of spatial structure prefabricated body

A technology for production equipment and space structure, which is applied in the direction of manufacturing tools, ceramic molding workshops, ceramic molding machines, etc., can solve the problem that the space structure preform cannot be mass-produced, the strength of the space structure preform is not high, and the space structure preform Continuity and complexity limitations, etc., to achieve the effect of shortened production time, shortened heating time, and a wide range of applications

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

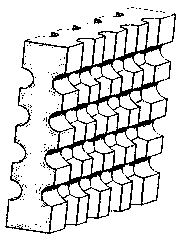

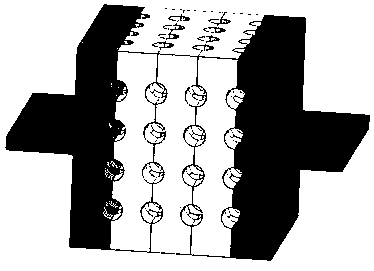

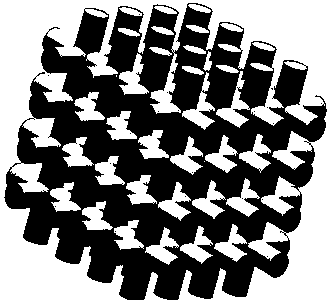

[0035] A kind of production equipment of spatial structure prefabricated body, comprises cylinder block 6, circulating water cooling device 5, microwave heating device 15, mold, core 20, pressing plate and pulley; Described mold comprises upper mold and lower mold 8, and upper mold is made of The upper left mold 12 and the upper right mold 11 are composed; the pressing plate includes a left pressing plate 2 and a right pressing plate 10; the pulley includes a large pulley 3 and a small pulley 14;

[0036] The lower mold 8 is embedded in the groove at the top center of the cylinder body 6 and fixed by bolts. Both the upper left mold 12 and the upper right mold 11 are fixedly connected to the lower mold 8 by bolts 13; the core 20 is placed in the mold cavity; the microwave heating device 15 is arranged around the lower mold 8; the circulating water cooling device 5 is arranged on the outer periphery of the microwave heating device 15, and the water inlet 7 and the water outlet 16...

Embodiment 2

[0039] The structure of this embodiment is basically the same as that of Embodiment 1, except that there are 30 exhaust holes with a radius of 5 mm. The left pressing plate 2, the right pressing plate 10, and the cylinder body 6 are made of cobalt-based high temperature resistant alloy material.

Embodiment 3

[0041] The structure of this embodiment is basically the same as that of Embodiment 1, except that 20-30 molds are simultaneously installed in the groove at the center of the top of the cylinder body 6 . The materials of the left pressing plate, the right pressing plate and the cylinder body are nickel-based high temperature resistant alloy materials.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com