Pulp picture manufacturing method

A production method and pulp technology, which are applied in pulp beating/refining method, natural cellulose pulp/paper, papermaking, etc., can solve the problems of color influence of pulp painting, inability to handle blank spaces, inaccurate pattern shape, etc. The effect of ornamental and popular, non-toxic and harmless production materials, simple and practical production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with the accompanying drawings and examples, but the present invention should not be limited in any way, and any changes or improvements made based on the teaching of the present invention belong to the protection scope of the present invention.

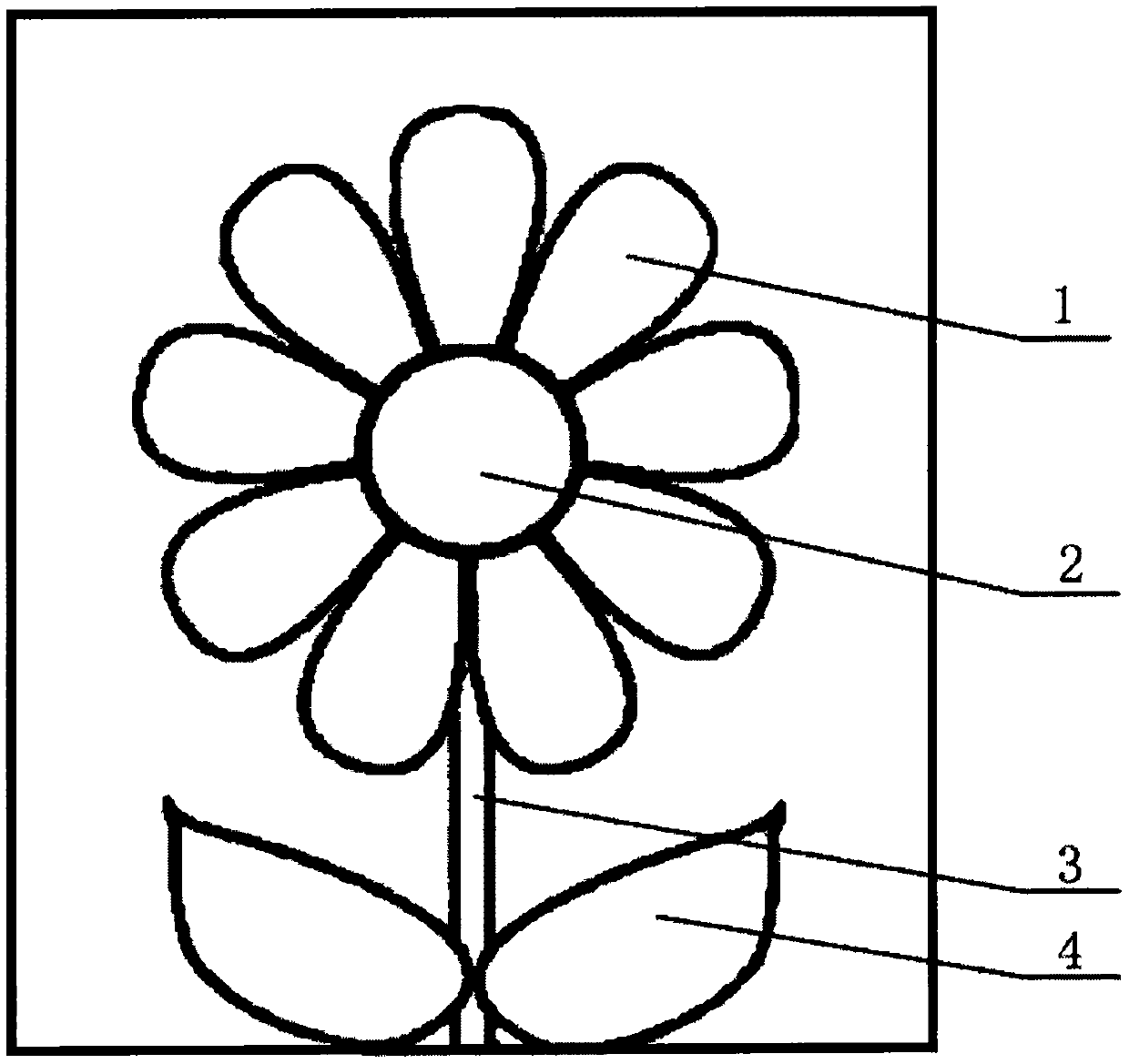

[0016] Firstly, use the computer to design the pattern, and print a picture that needs to be made into a pulp painting on a breathable white canvas. As shown in Figure 1, 2, 3, and 4, choose a suitable size wooden frame to print the canvas with the color picture using a stretcher. The drawing nails are flattened and tightened to finally obtain the target pulp painting bottom plate; the pulp board with a whiteness of 93-95% is used for papermaking, and the paper pulp is prepared by a paper pulping mechanical refiner, and 10-30% white latex and pigments are added to the pulp. The required color pulp is prepared, and each bottom plate is matched with a correspond...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com