Vibrating tray with adjustable feeding output

A vibrating plate and feeding technology, which is applied in the direction of vibrating conveyors, conveyors, conveyor objects, etc., can solve the problems of reducing production efficiency and increasing equipment costs, and achieve the effect of reducing supporting costs and improving quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

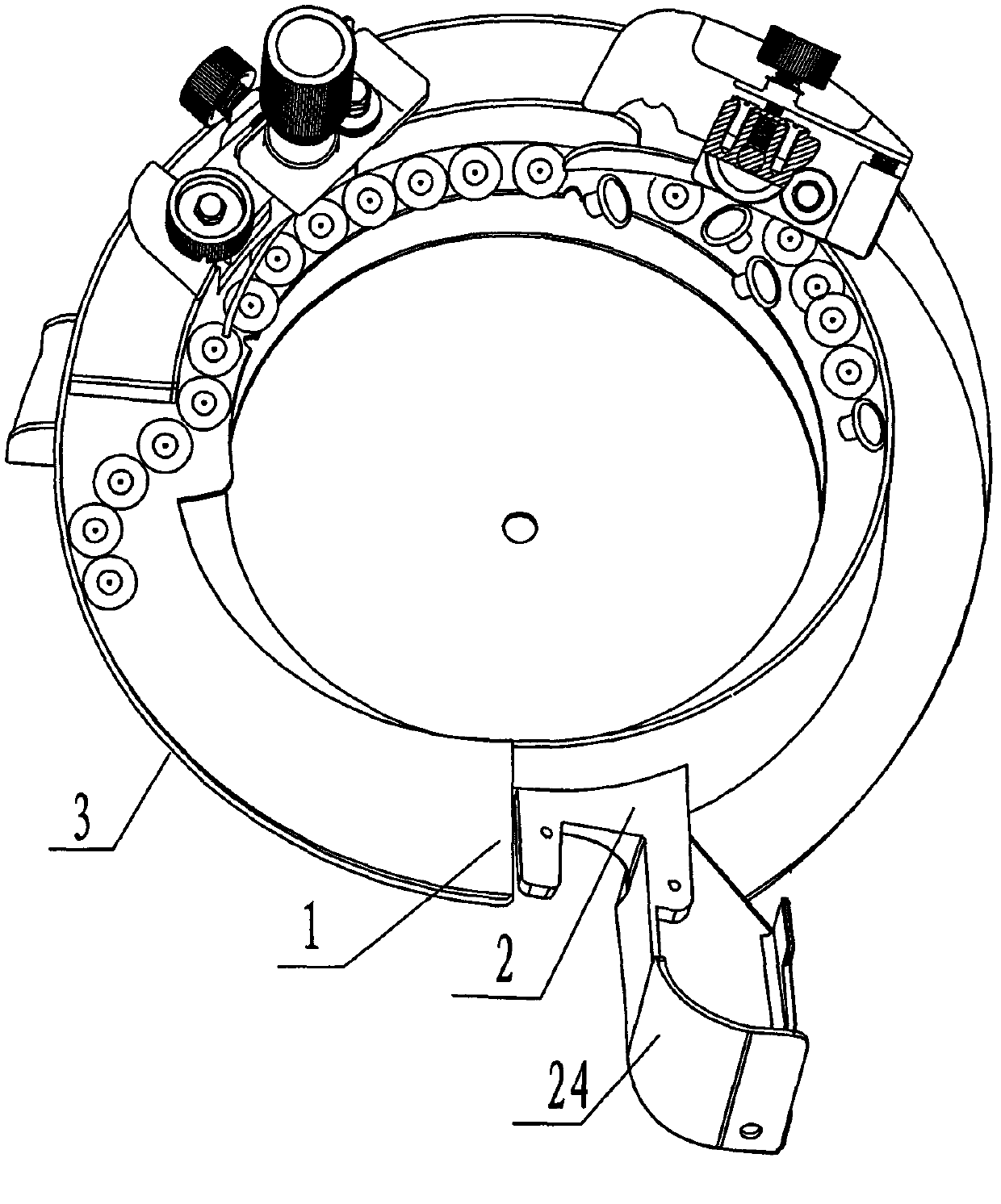

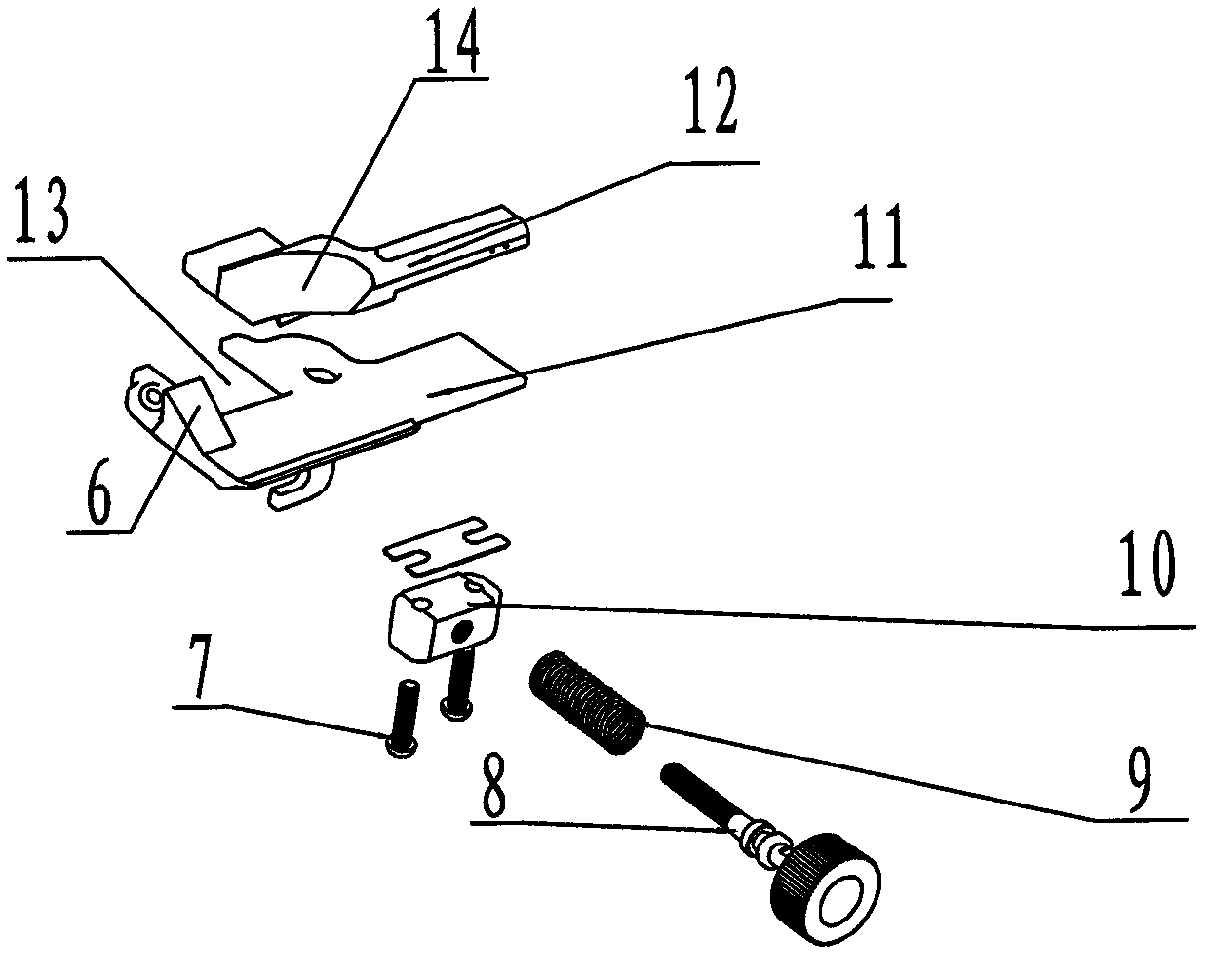

[0021] Such as Figure 1-Figure 3 As shown, this embodiment includes a top plate 3 , a top plate spiral slideway 1 , a feed output transition connection slideway 4 , a slideway support 2 and a return box 24 .

[0022] Such as figure 2 As shown, the slideway support 2 is fixed on the top plate 3, the feeding output transition connection slideway 4 is fixed on the slideway support 2, and the input end of the feeding output transition connection slideway 4 is connected to the The outlet of the top plate spiral slideway 1 is connected, and the output end of the transitional connection slideway 4 of the feeding output is connected with the entrance of the material receiving slideway 5 of the next machine.

[0023] The return box 24 is arranged below the feeding output transition connecting slideway 4 and is fixed on the slideway support 2, so that it can centrally recycle the workpieces accidentally dropped during the conveying process and reduce the recycling workload. .

[00...

Embodiment 2

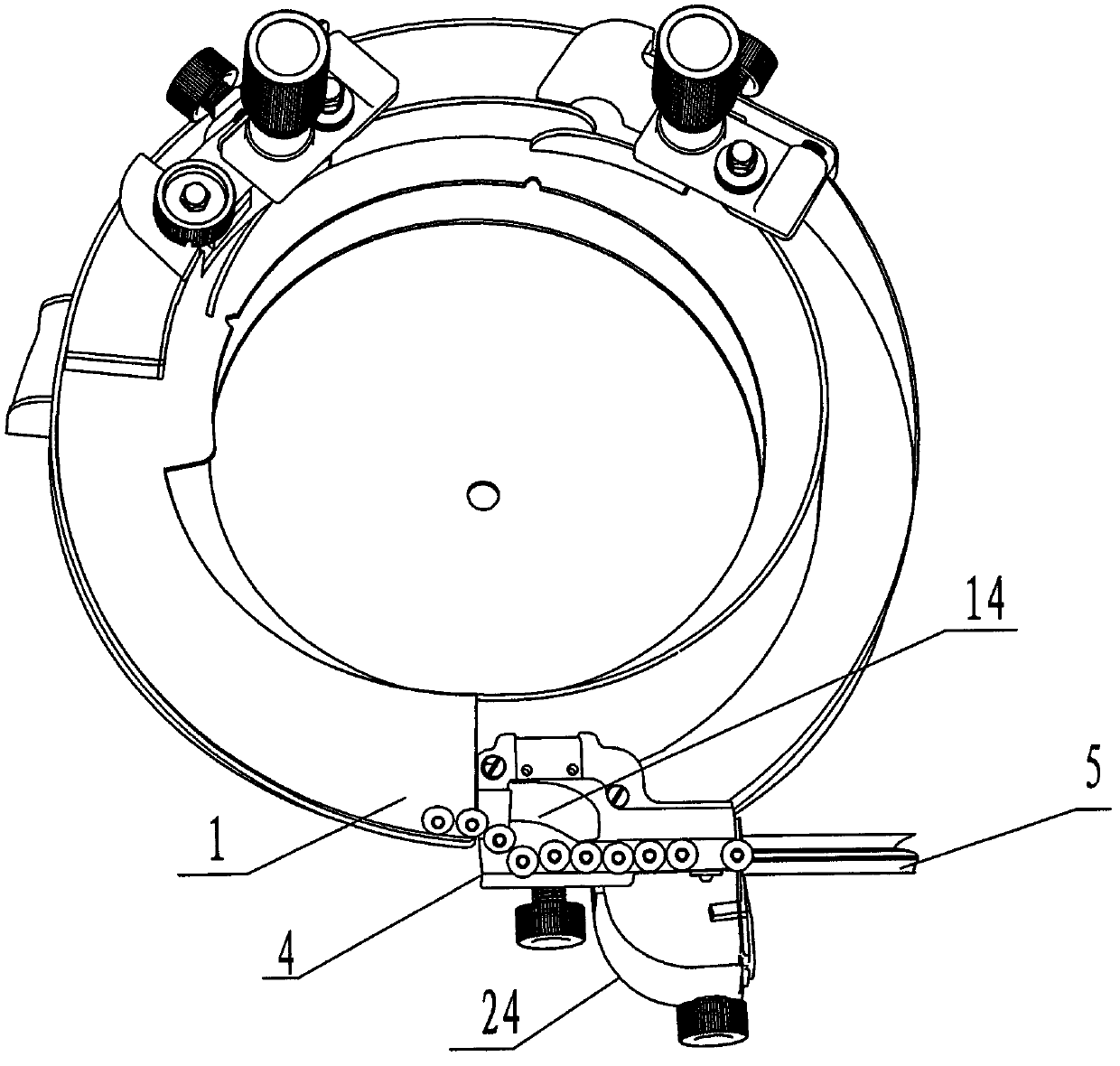

[0029] Such as figure 1 , Figure 4 , Figure 5 As shown, this embodiment includes a top plate 3 , a top plate spiral slideway 1 , a feeding output transition connection slideway 4 , a slideway support 2 , a workpiece turning and receiving device 16 and a return box 24 .

[0030] Such as figure 1 , Figure 4 As shown, the slideway support 2 is fixed on the top plate 3, the feeding output transition connection slideway 4 is fixed on the slideway support 2, and the input end of the feeding output transition connection slideway 4 is connected to the The outlet of the top plate spiral slideway 1 is connected, and the outlet of the feeding output transition connection slideway 4 is connected with the material inlet of the workpiece turning material receiving device 16, and the outlet of the workpiece turning material receiving device 16 is connected to the next machine. Material chute 5 entrances are connected.

[0031] The return box 24 is arranged below the feeding output tr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com