Recycling methods of waste wine bottles

A technology for recycling and processing wine bottles, which is applied in the field of recycling and processing waste wine bottles, can solve problems such as glass processing difficulties, achieve the effect of reducing the workload of recycling processing and accelerating the softening speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

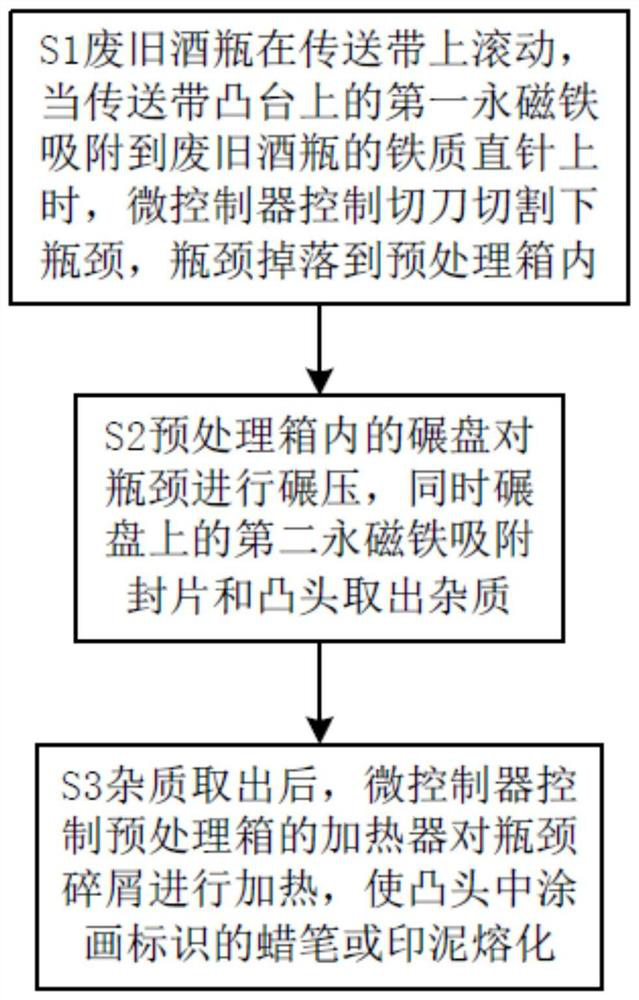

Method used

Image

Examples

Embodiment Construction

[0030] The following will be further described in detail through specific embodiments.

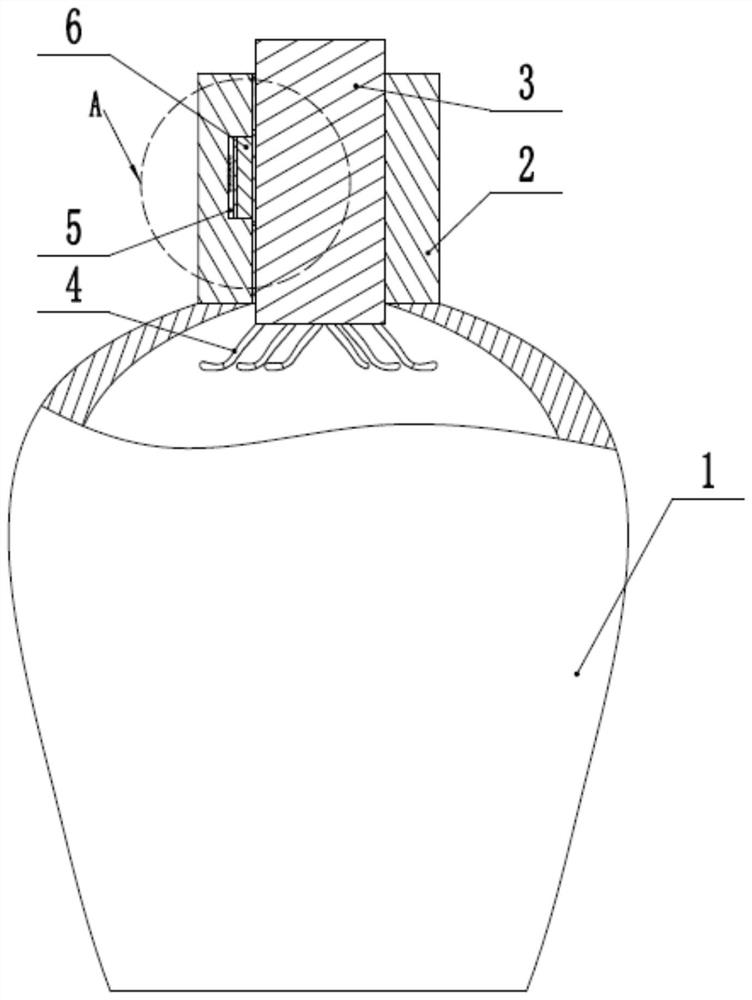

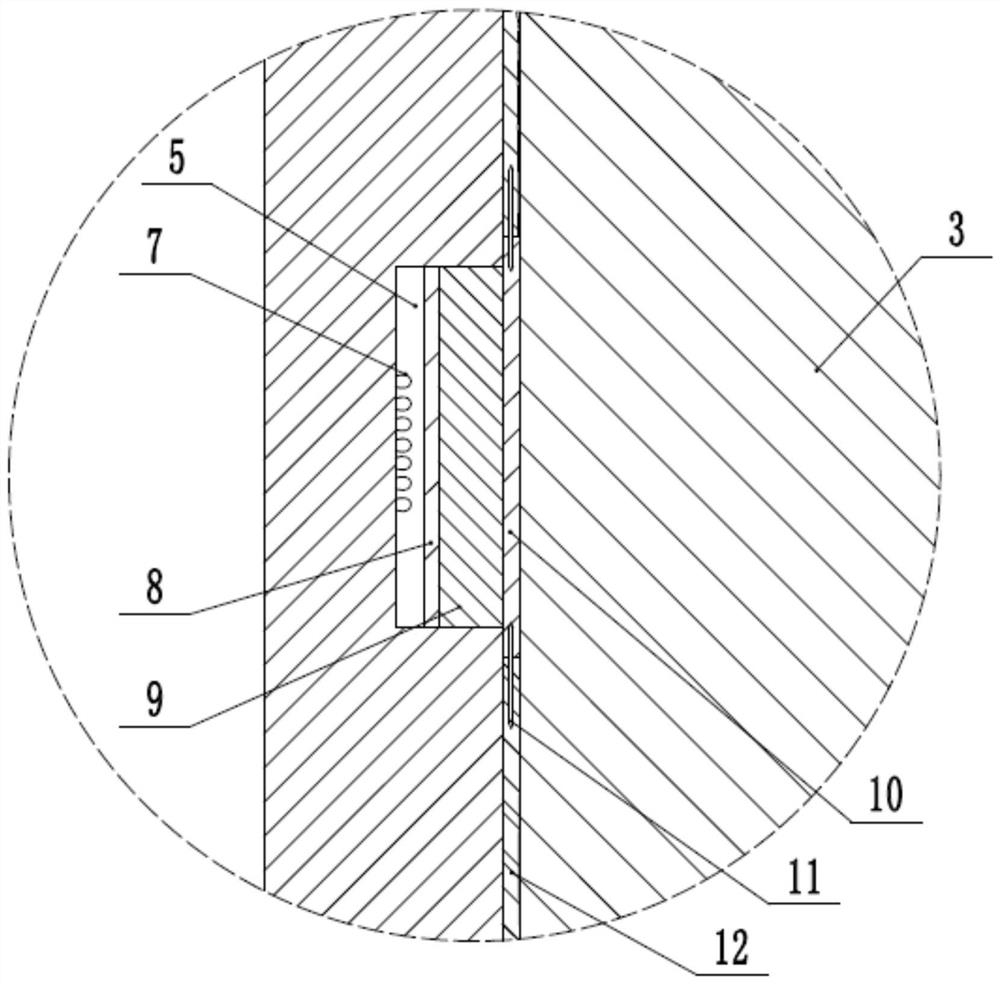

[0031] The reference signs in the drawings of the description include: bottle body 1, bottle neck 2, bottle stopper 3, elastic push head 4, groove 5, anti-counterfeiting sealing sheet 6, protruding head 7, painting film 8, cover sheet 9, base sheet 10. Iron straight needle 11, glass column 12, conveyor belt 13, boss 14, cutter 15, elastic air bag 16, pretreatment box 17, telescopic cylinder 18, grinding plate 19, second permanent magnet 20, second cavity 21 , clip bar 22, lifting plate 23, support 24, electromagnet 25, bearing 26, pole 27, infrared receiver 28, infrared emitter 29, through hole 30, case cover 31, supporting plate 32, slot 33.

[0032] The structure of waste wine bottle in this method is as figure 2 and image 3 As shown, it includes a bottle stopper 3 and a transparent bottle body. The bottle body includes a bottle body 1 and a bottle neck 2. The bottle stopper 3 is loc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com