Barrier bottle and manufacturing method thereof

A production method and full barrier technology, applied in the direction of bottles, dairy product packaging, bottle/can parts, etc., can solve the problems of deterioration, waste of PET materials, barrier leaks, etc., to reduce the workload of recycling, prolong the service life, The effect of reducing the difficulty of recycling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

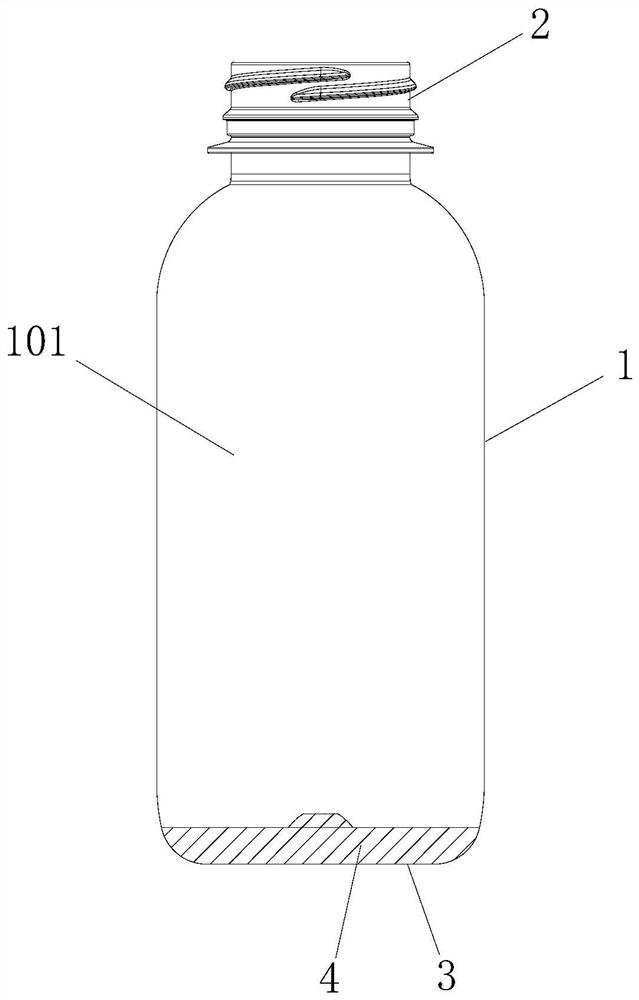

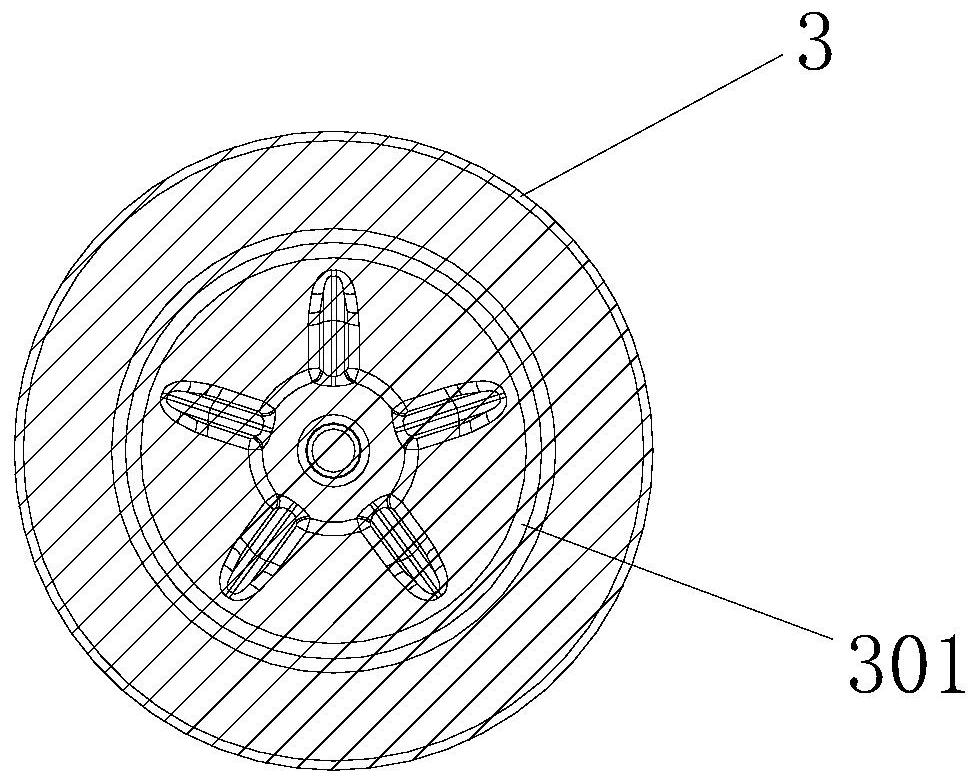

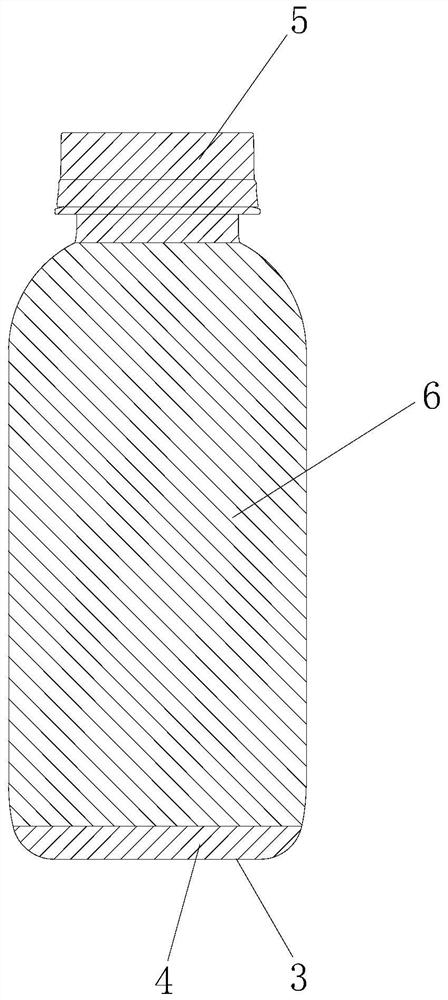

[0052] Such as figure 1 , figure 2 As shown, the present invention provides a barrier bottle, including a bottle body 1, a bottle mouth 2 and a bottle bottom 3, the bottle body 1 is a cylindrical structure arranged in a vertical direction, and the inside of the bottle body 1 is formed to hold the contents The bottle mouth 2 is located above the bottle body 1, the bottom of the bottle mouth 2 is connected to the top of the bottle body 1, and the bottle mouth 2 is connected with the container chamber 101, and the bottle bottom 3 is located below the bottle body 1 , the top of the bottle bottom 3 is connected to the bottom of the bottle body 1, and the inside of the bottle bottom 3 along the extending direction of the bottle bottom 3 is provided with a barrier interlayer 4 capable of blocking light, gas and moisture.

[0053]In the present invention, a barrier interlayer 4 is provided inside the bottle bottom 3 along the extension direction of the bottle bottom 3, through which...

Embodiment 2

[0068] Such as Figure 6 to Figure 9 As shown, the present invention provides a kind of barrier bottle manufacturing method, and this barrier bottle manufacturing method comprises the steps:

[0069] Step S1: using multi-layer twin-screw injection molding equipment 9 to process and produce such Figure 6 Shown semi-finished bottle body (that is: bottle base), wherein, the process of processing the bottle base in step S1 comprises:

[0070] Step S101: Inject the bottle body raw material in a molten state into the preform mold 902, and injection mold the preform from the bottle mouth 2 to the bottle bottom 3 directions;

[0071] Step S102: When the bottle body material is injected into the bottle body 1 and the bottle bottom 3 is not injected, the barrier interlayer material in a molten state is injected into the middle of the bottle body material, and the barrier interlayer material is injected into the bottle body along with the bottle body material. In the preform mold 902,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com