Ice cream making machine with observable raw material barrel

A technology for raw material barrels and ice cream, which is applied in the field of cold food production equipment, can solve the problems of physical health impact, decline in the rate of scrap products, uneven movement speed, etc., and achieve the effect of realizing mass production and improving the yield of finished products.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

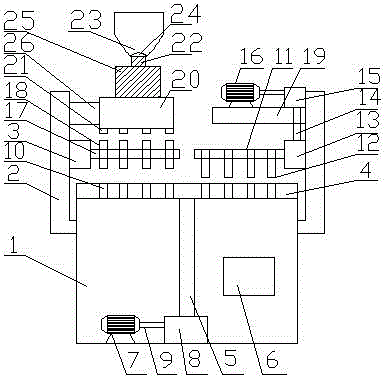

[0019] Example: see figure 1 , an ice cream making machine with observable raw material barrels of the present invention, comprising a casing 1, a frame 2, a feeding device 3, a supporting mold turntable 4, a rotating shaft 5, an assembly control device 6, a discharge jaw 12, an oil pump 15 and a transparent Raw material barrel 23, the upper side of the casing 1 is provided with a supporting mold turntable 4, the center lower side of the supporting mold rotating disk 4 is provided with a rotating shaft 5, and the two sides of the casing 1 are provided with a frame 2, and the frame 2. A feeding device 3 is provided on the upper part of one side. An assembly control device 6 is provided on the casing 1. The feeding device 3 is electrically connected with the assembly control device 6. The other side of the frame 2 is provided with a horizontal Arm 19, between the cross arm 19 and the frame 2 and between the frame 2 and the casing 1 are fixedly connected by welding, the upper sid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com