Attenuation method and device for flat glass substrate

A technology for glass substrates and flat glass, which is applied to the thinning field of glass substrates for flat-panel displays, and can solve the problems of uneven etching, small production batch, low production efficiency, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

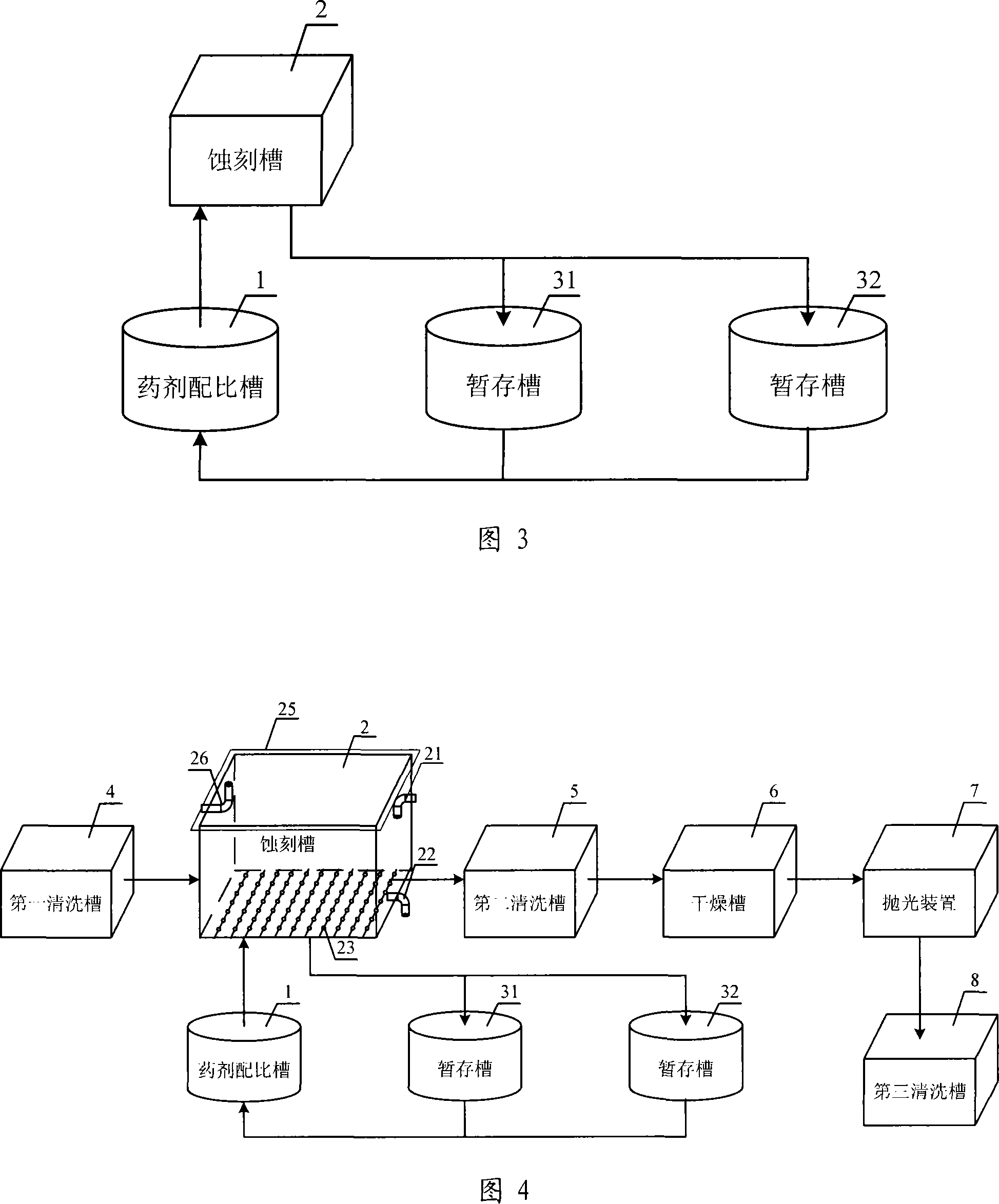

[0023] The technical scheme of the present invention draws on the process methods of ordinary glass cleaning and glass pattern engraving. By adopting the method of using a circulating etching liquid in the etching tank to perform etching and a matching etching device, the glass substrate is etched, so that the thinned glass substrate is Meet the technical requirements of thin glass substrates for flat display.

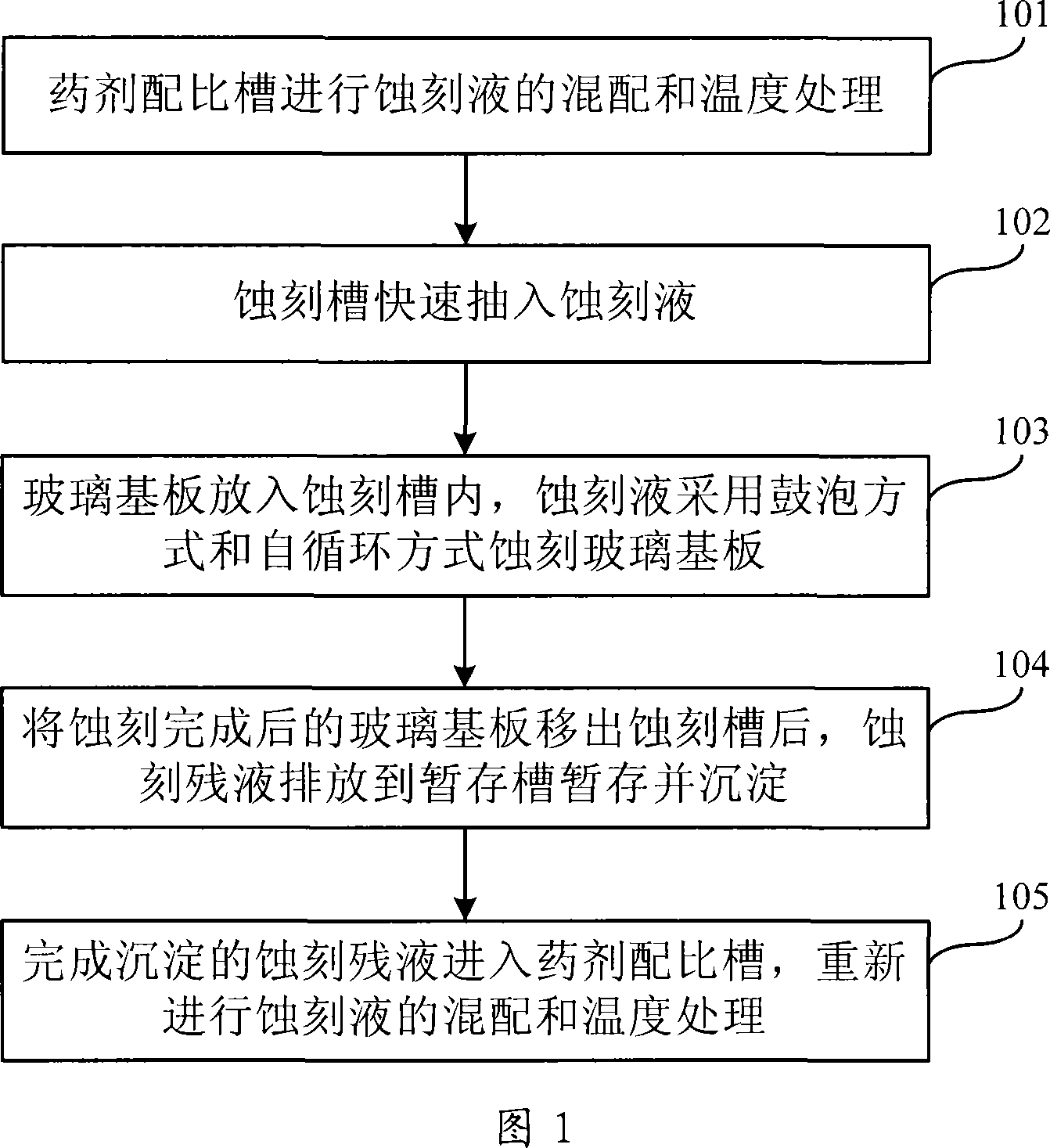

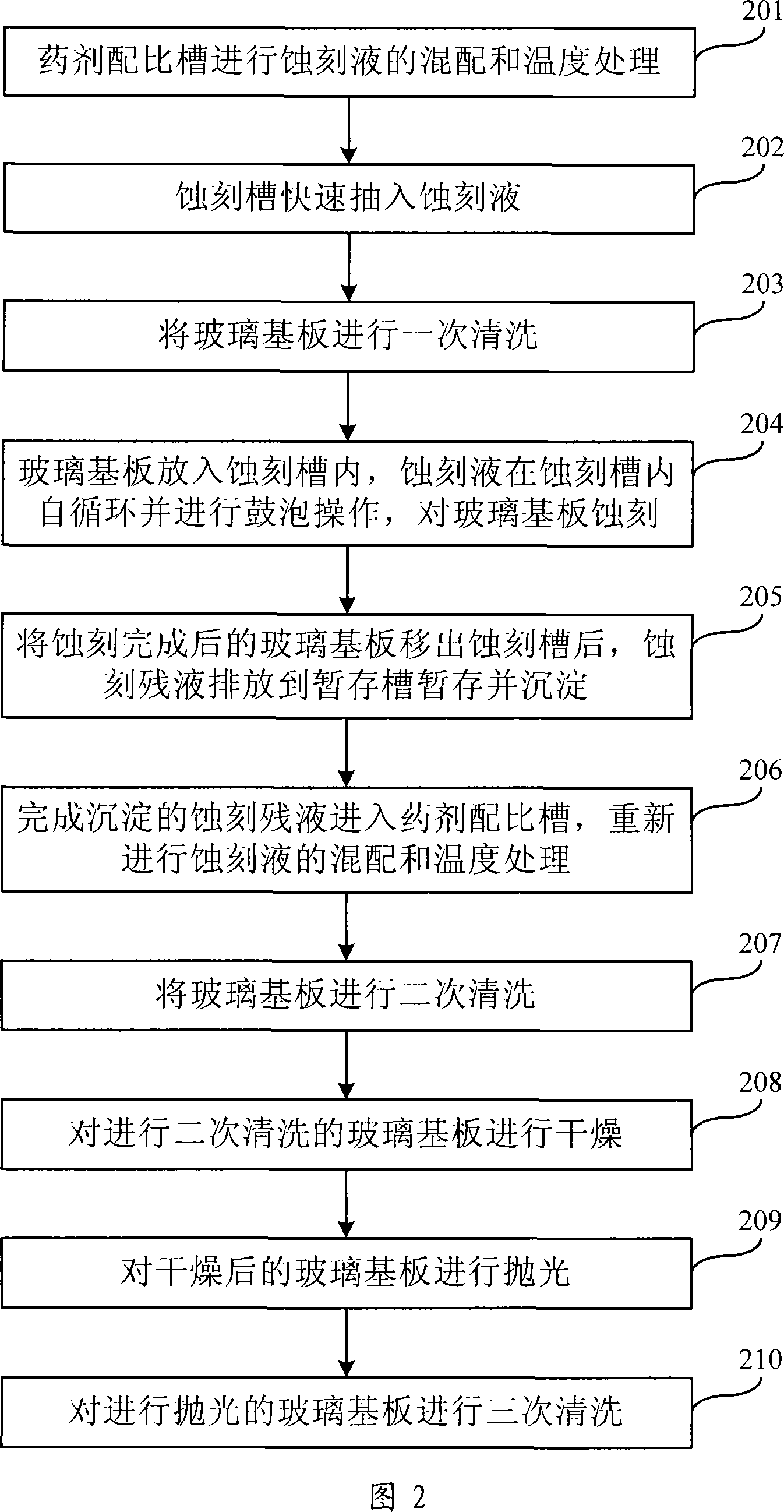

[0024] As shown in FIG. 1, it is a schematic flowchart of Embodiment 1 of the thinning method of a flat glass substrate of the present invention. Including the following steps:

[0025] Step 101: Mixing and temperature treatment of the etching solution in the agent proportioning tank;

[0026] Step 102, the etching bath is quickly drawn into the etching solution;

[0027] Step 103: The glass substrate is put into the etching tank, and the etching solution adopts a bubbling method and a self-circulation method to etch the glass substrate;

[0028] Put the glass substrate in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com