Full-automatic inner and outer box sleeving system

A fully automatic, box-fitting technology, applied in paper/cardboard containers, envelope/bag manufacturing machinery, packaging, etc., to achieve the effect of compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0062] The invention will be described in further detail below in conjunction with the accompanying drawings.

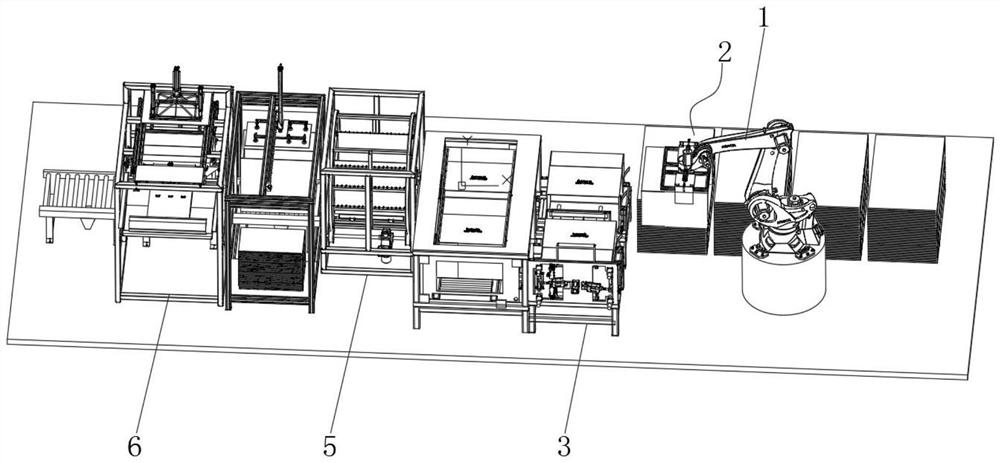

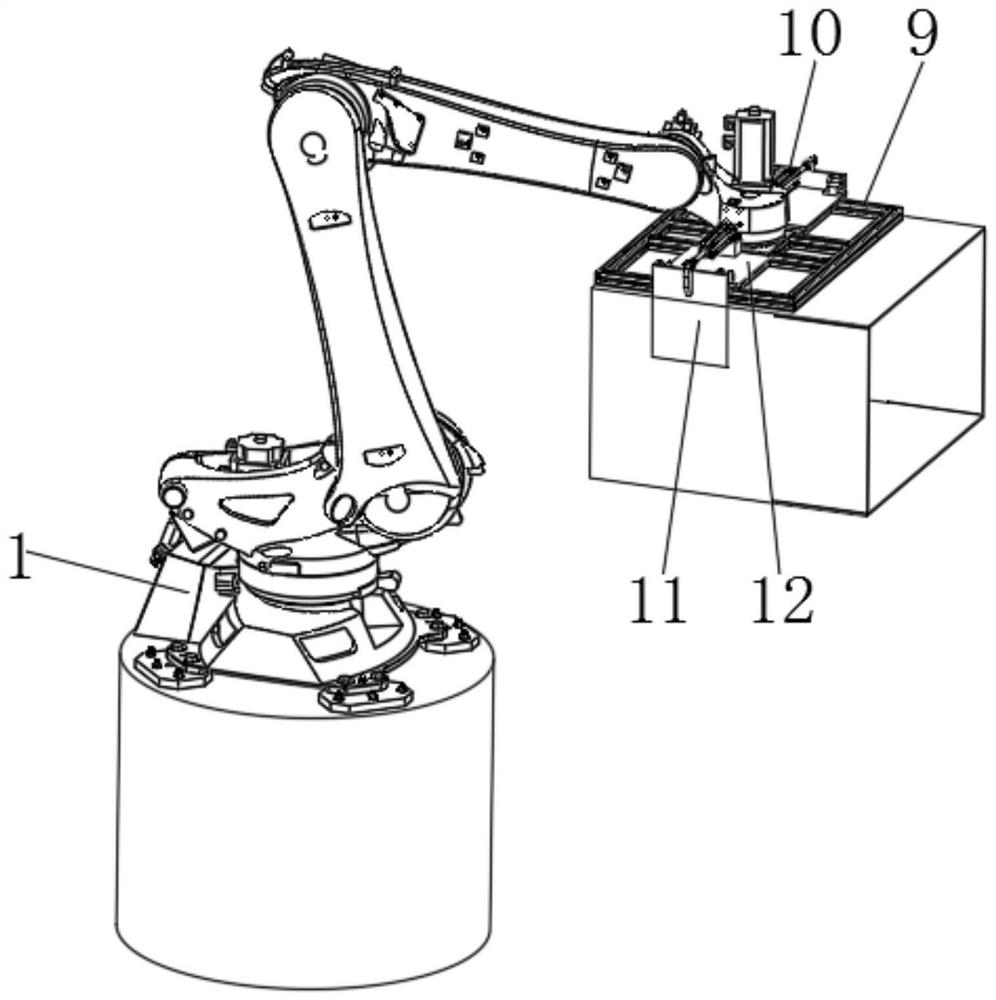

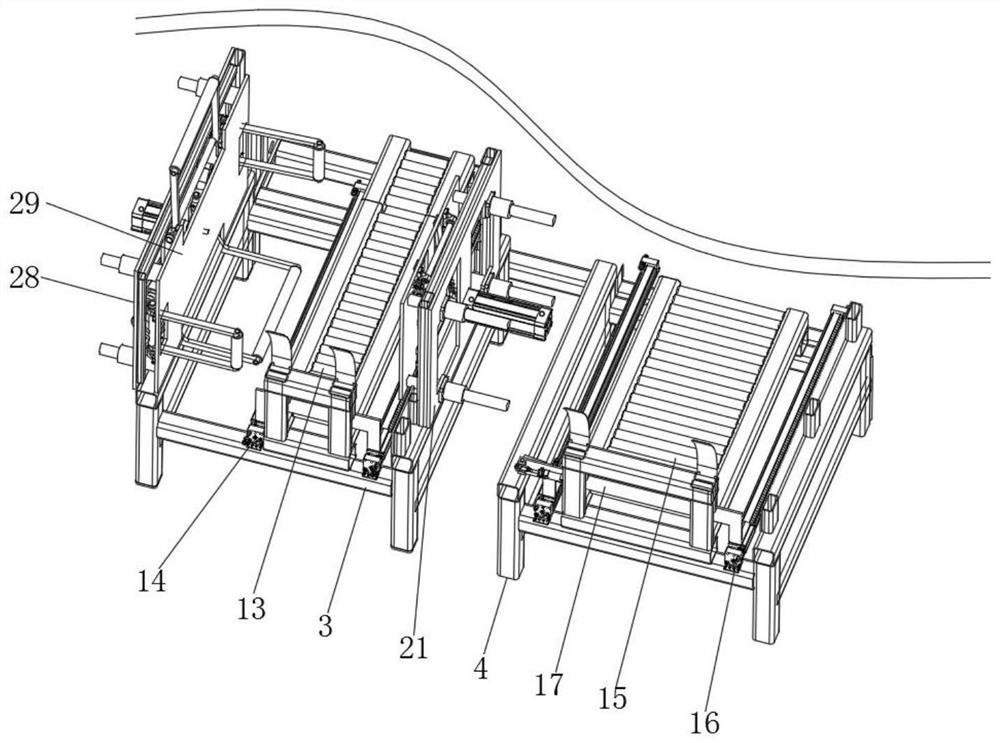

[0063] During specific implementation: if Figure 1 to Figure 23 As shown, the fully automatic inner and outer case casing system includes a feeding unit, a box forming unit, a casing unit, a turning unit, a bottom plate installation unit and a film unit arranged in sequence, wherein,

[0064] The box forming unit is used to receive the inner box and outer box supplied by the feeding unit, and send them into the box unit after positioning and forming. Here, the inner carton and the outer carton are used separately according to the quantity to be processed. The forklift is placed at the place to be taken, and while the feeding unit is clamping the inner carton, it is initially positioned and formed before being sent to the sleeve unit;

[0065] The casing unit can send the inner box into the outer box in a horizontal manner to form the first box body (the first box b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com