Automatic glue pouring production line and glue pouring method for preparing electrophoresis gel column and application

A technology of electrophoretic gel and production line, which is applied to the surface coating liquid device, spray device, coating, etc., which can solve the problems of poor product performance and low pass rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

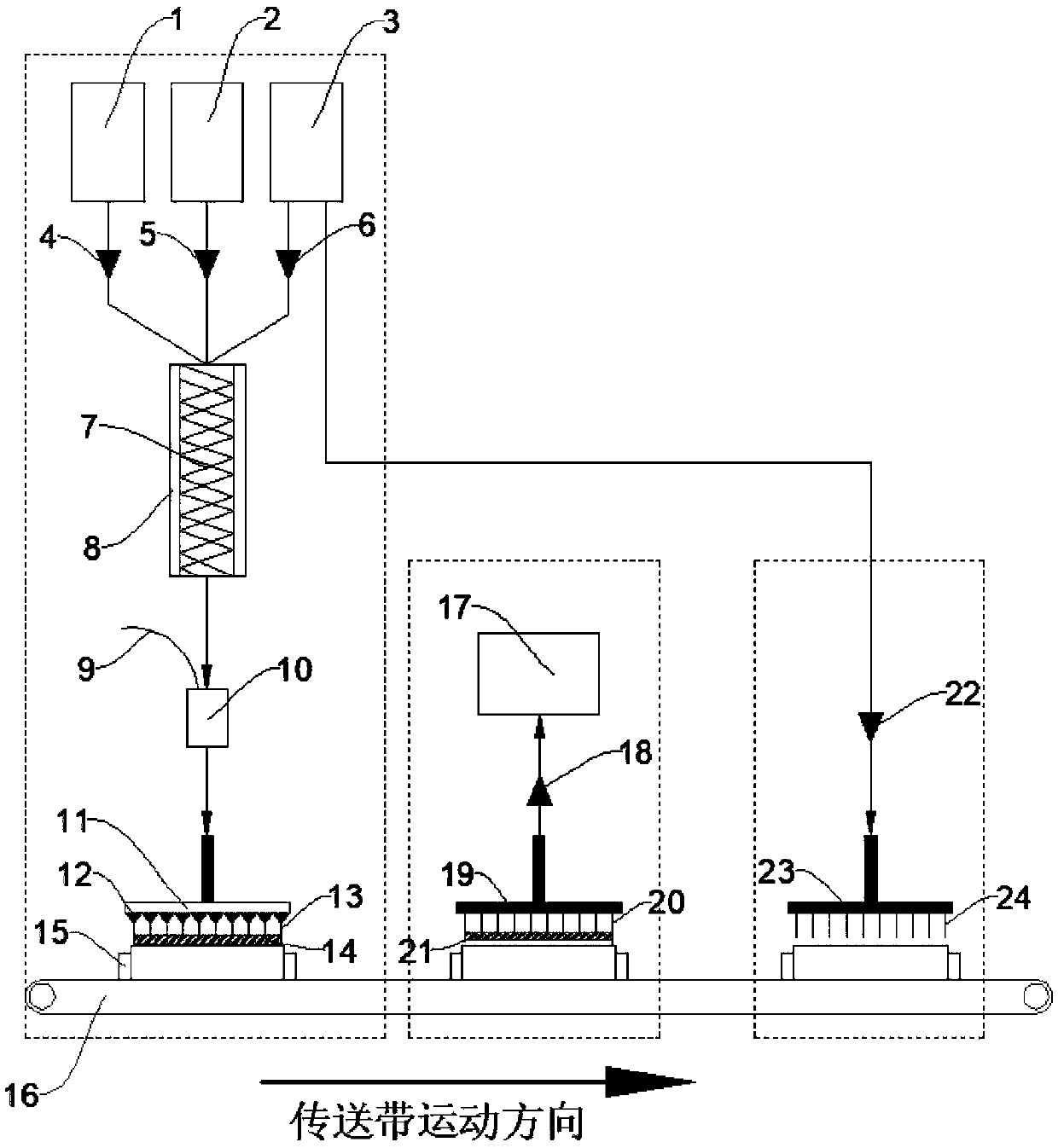

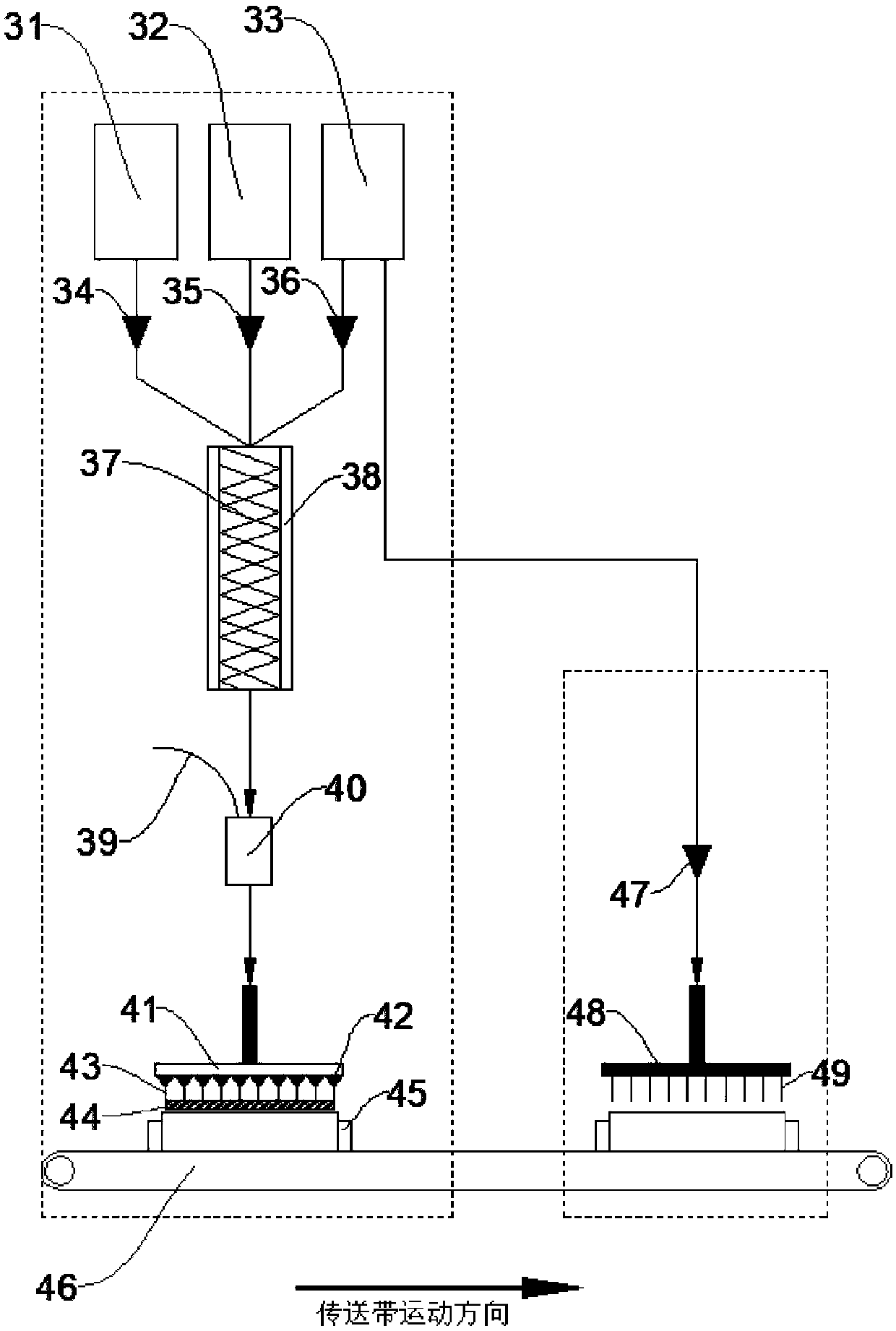

[0089] This embodiment provides an automatic glue filling production line for preparing electrophoretic gel columns. The production line includes a first layer of glue filling module, a water absorption module and a second layer of glue filling module arranged in sequence according to the glue filling process route .

[0090] The structure of the first layer of glue filling module is as follows: figure 1 As shown, it includes a first conveyor belt 16 and a first layer of glue filling unit arranged above the first conveyor belt 16; the first conveyor belt 16 is provided with a draw-in groove 15 for fixing the glue filling orifice plate; the first layer of glue filling The glue unit includes first glue pouring equipment, leveling equipment and first glue pressing equipment arranged in sequence according to the glue pouring process route.

[0091] The first glue pouring equipment includes a feeding device, a mixing device 7 , a mechanical arm 11 and a glue injection head 13 conn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com