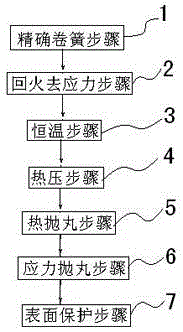

Manufacturing process of high-stress suspension spring

A suspension spring and manufacturing process technology, which is applied to the manufacturing process field of high-stress suspension springs, can solve the problems that the spring production process cannot meet the spring stress level and the spring production is difficult, so as to improve the stability and fatigue life, and avoid stress. concentrated effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Through the shape comparison technology, debug the coil spring program, so that the coiled spring shape is consistent with the designed shape. After the program is debugged in place, the spring is rolled, and the sample is checked periodically to see if it still meets the shape requirements. The finished spring after rolling is sent into the tempering furnace by a conveyor belt for stress relief annealing. The tempering furnace in this embodiment is divided into six zones, with zones 1 to 4 being tempering zones, zone 5 being a transition zone, and zone 6 being a constant temperature zone. Among them: the temperature of the first zone is controlled at about 300-380°C, the temperature of the second zone to the fourth zone is controlled at 380-395°C, the temperature of the fifth zone is controlled at about 200-280°C, and the temperature of the sixth zone is controlled at about 200-285°C. The tempering time was 60 minutes. The springs from the constant temperature zone ar...

Embodiment 2

[0031] Through the shape comparison technology, debug the coil spring program, so that the coiled spring shape is consistent with the designed shape. After the program is debugged in place, the spring is rolled, and the sample is checked periodically to see if it still meets the shape requirements. The rolled spring is sent to the tempering furnace through the conveyor belt for stress relief annealing. The tempering furnace is divided into four zones. The temperature is controlled at about 300-350°C, the fourth zone is a constant temperature zone, and the temperature is controlled at about 300-350°C; the tempering time is 30 minutes. The springs from the constant temperature zone are exported through the conveyor belt, and placed on the Morita hot pressing equipment by the manipulator for hot pressing. The temperature during hot pressing is between 220 and 300°C, and the compression height is about 1 / 3 of the original length of the spring (the exact compression height Accordi...

Embodiment 3

[0033]Through the shape comparison technology, debug the coil spring program, so that the coiled spring shape is consistent with the designed shape. After the program is debugged in place, the spring is rolled, and the sample is checked periodically to see if it still meets the shape requirements. The rolled spring is sent to the tempering furnace through the conveyor belt for stress relief annealing. The tempering furnace is divided into five zones. It is the transition zone, the temperature is controlled at about 200-250°C, the fifth zone is the constant temperature zone, the temperature is controlled at about 200-250°C; the tempering time is 90 minutes. The springs from the constant temperature zone are exported through the conveyor belt, and placed on the Morita hot-pressing equipment by the manipulator for hot-pressing. The temperature during hot-pressing is between 170 and 230°C, and the compression height is about 1 / 4 of the original length of the spring (accurate compr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com