Sputtering device and method

A technology of sputtering and sputtering chamber, applied in the field of sputtering, which can solve the problems of low production efficiency, inability to form thickness, and inability to achieve plating, etc., to achieve the effect of improving production efficiency and simple and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

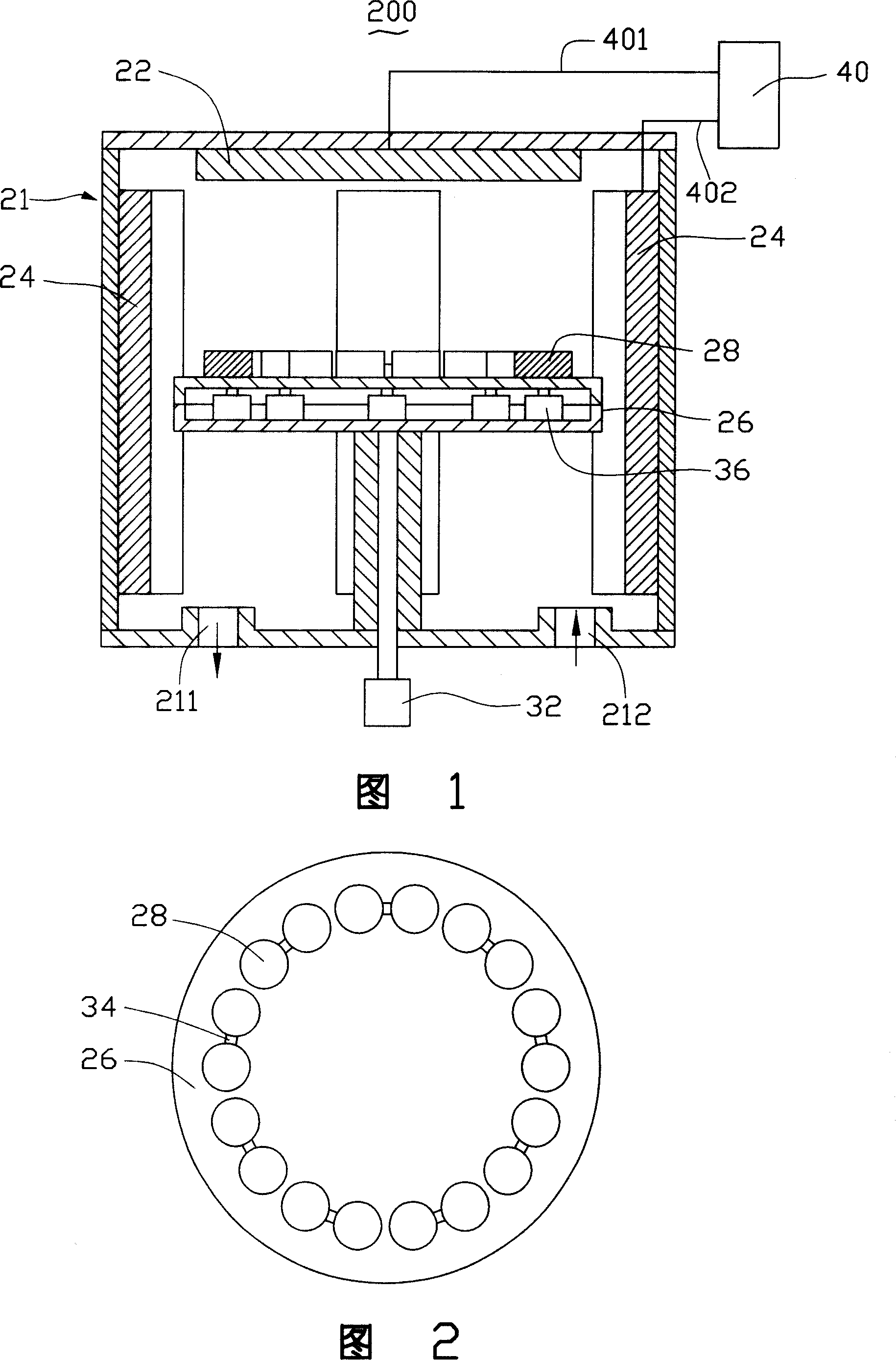

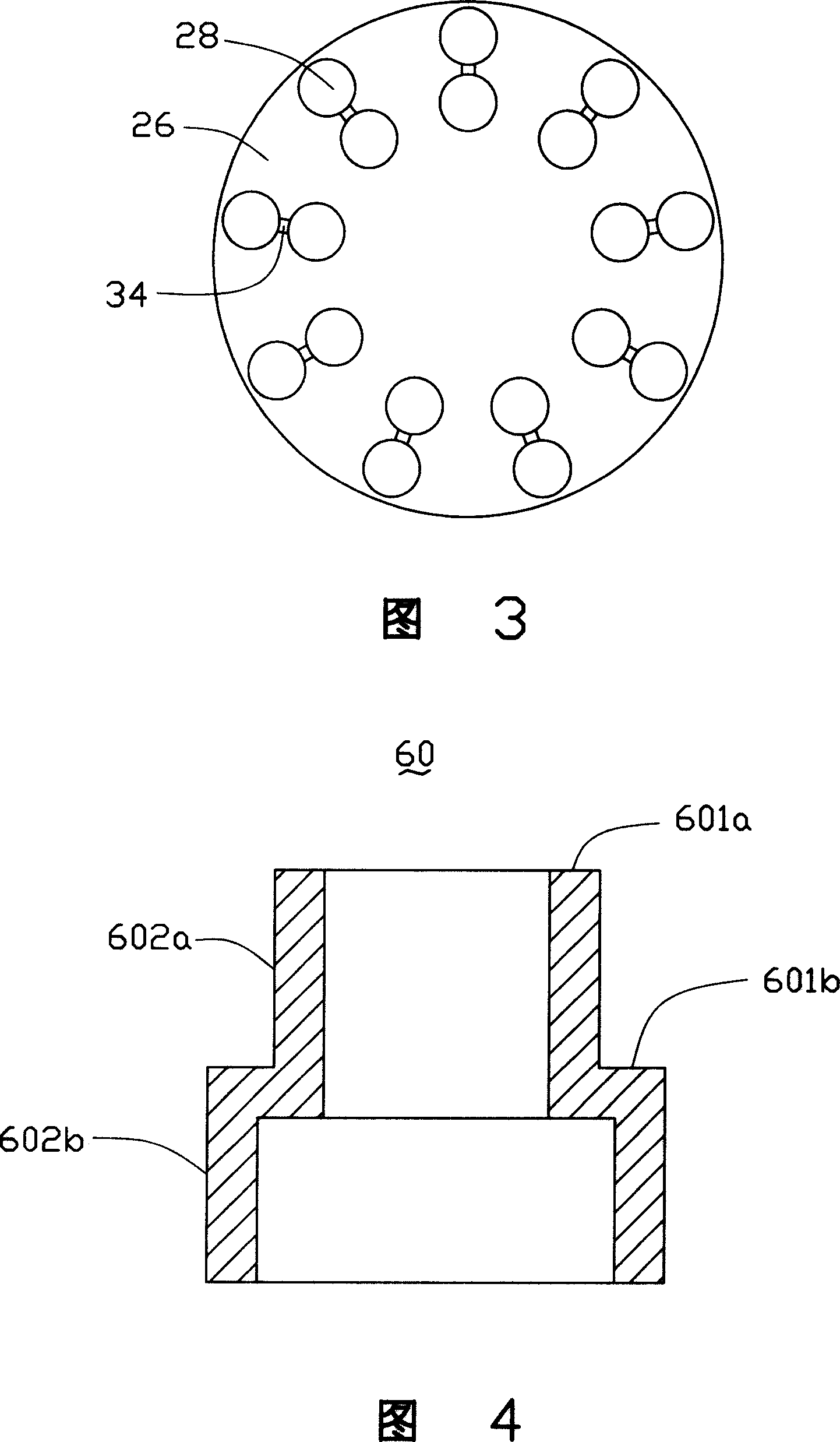

[0014] A sputtering device for sputtering workpieces with irregular shapes and a sputtering method using the sputtering device will be described below by taking sputtering on the surfaces of multiple workpieces as an example.

[0015] Please refer to FIG. 1 , which is a sputtering device 200 provided in this embodiment, which includes a sputtering chamber 21 , which forms a cavity inside. In this embodiment, the sputtering chamber 21 is a cylindrical chamber. The sputtering chamber 21 is provided with a first sputtering target 22 , a second sputtering target 24 , a base turntable 26 and multiple pairs of carrying platforms 28 .

[0016] The first sputtering target 22 is fixed on the top of the sputtering chamber 21 and is opposite to the upper surface of the base turntable 26 inside the sputtering chamber 21 . The first sputtering target 22 is directly connected to the cathode of the sputtering power supply or grounded through a wire 401 .

[0017] The second sputtering targ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com