Automatic tin wire rolling mill

A wire rolling mill, automatic technology, applied in the direction of rolling mill control devices, metal rolling, metal rolling, etc., can solve the problem of low precision of manual control, and achieve the effect of overcoming the low accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

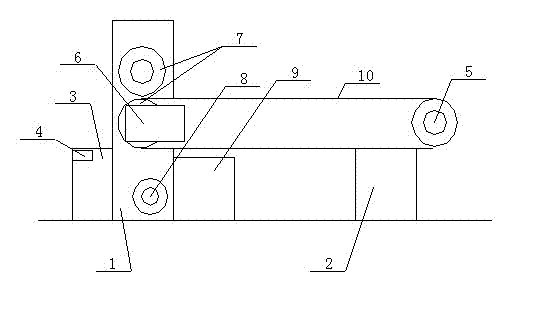

[0009] see figure 1 , the specific embodiment adopts the following technical solutions: it comprises a left frame 1, a right frame 2, a console 3, a length counter 4, guide wheels 5, a length controller 6, a stick 7, an electric motor 8, a gearbox 9 and the wire guide table 10; the left side of the left frame 1 is provided with a console 3, the console 3 is provided with a length counter 4, the guide wheel 5 is arranged on the right side of the right side support 2 top, and two sticks 7 It is set up and down on the left frame 1, the length controller 6 is set on the lower bar 7, the motor 8 is set on the bottom of the left frame 1, the gearbox 9 is set on the right side of the left frame 1, and the guide The left end of wire platform 10 is fixed on the bar 7 of bottom, and its right end is fixed on the guide wheel 5.

[0010] The working principle of this embodiment is:

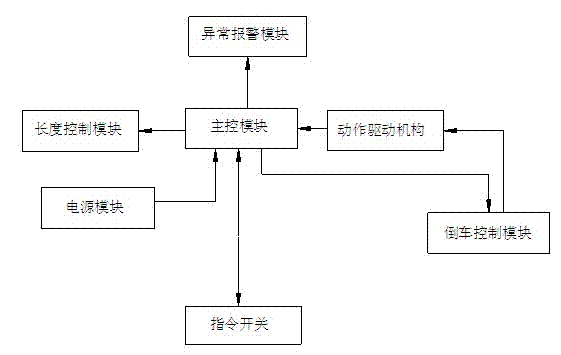

[0011] 1. The main control module accepts the action command through the command switch, and transmits t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com