Multifunctional adjustable vibrating tray

A vibration plate, multi-functional technology, applied in the direction of vibrating conveyors, conveyor objects, conveyors, etc., can solve the problems of reducing production efficiency, delaying production cycle, increasing supporting costs of automation equipment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

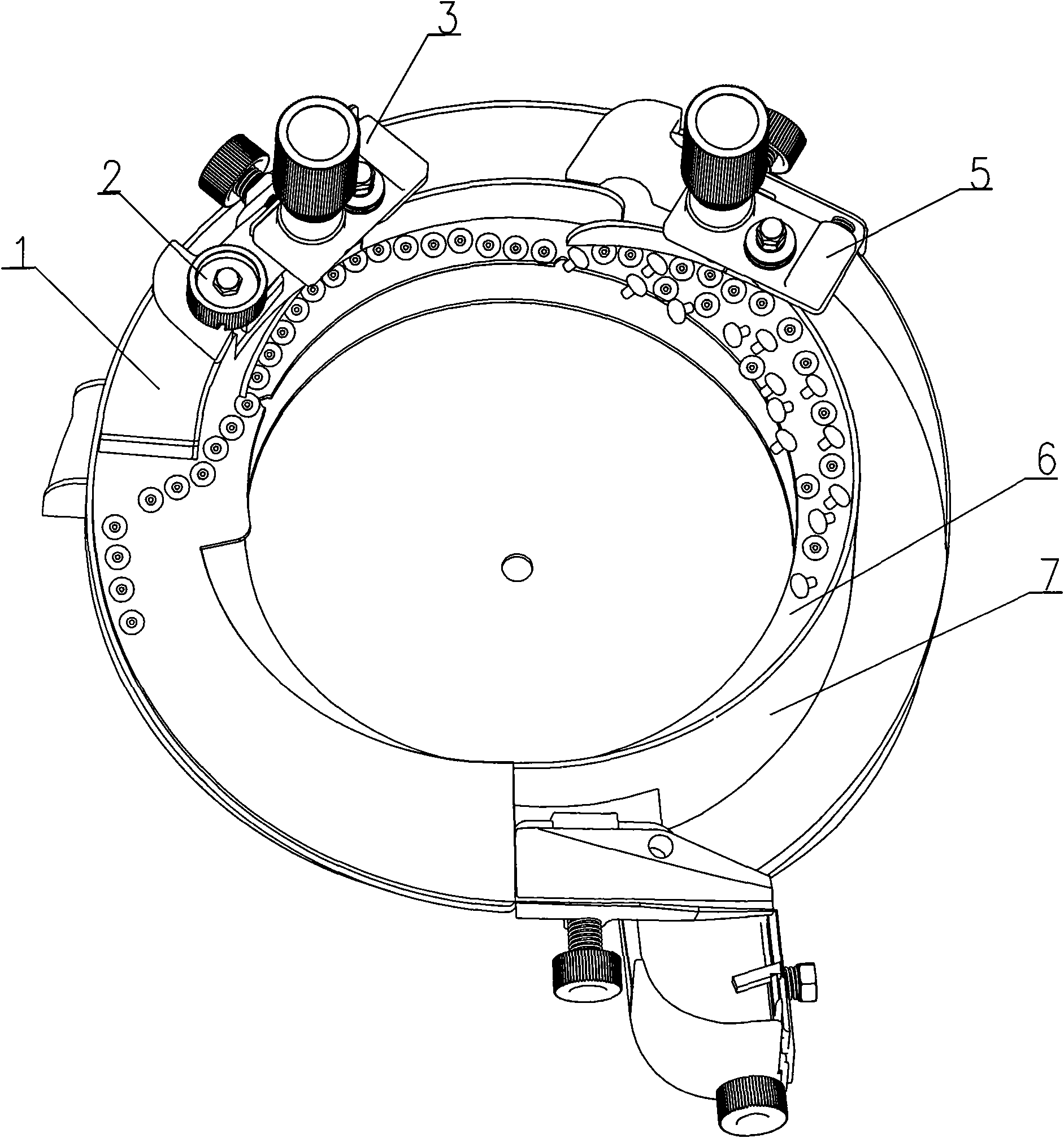

[0019] like figure 1 As shown, this embodiment includes a top plate, two sets of workpiece position adjustment processors 3 and 5 , a material discharge control processor 1 and a material discharge channel 1 .

[0020] The top plate is mainly composed of a spiral slide channel 6 and an outer ring 7 of the spiral slide channel, and the discharge channel 1 is arranged outside the outer ring 7 of the spiral slide channel.

[0021] The workpiece position adjustment processors 3 and 5 are arranged on the spiral slideway of the top plate before and after, and are installed and fixed on the outer ring 7 of the spiral slideway. Each group of workpiece position adjustment processors is controlled by a radial adjustment device and a height adjustment The device consists of:

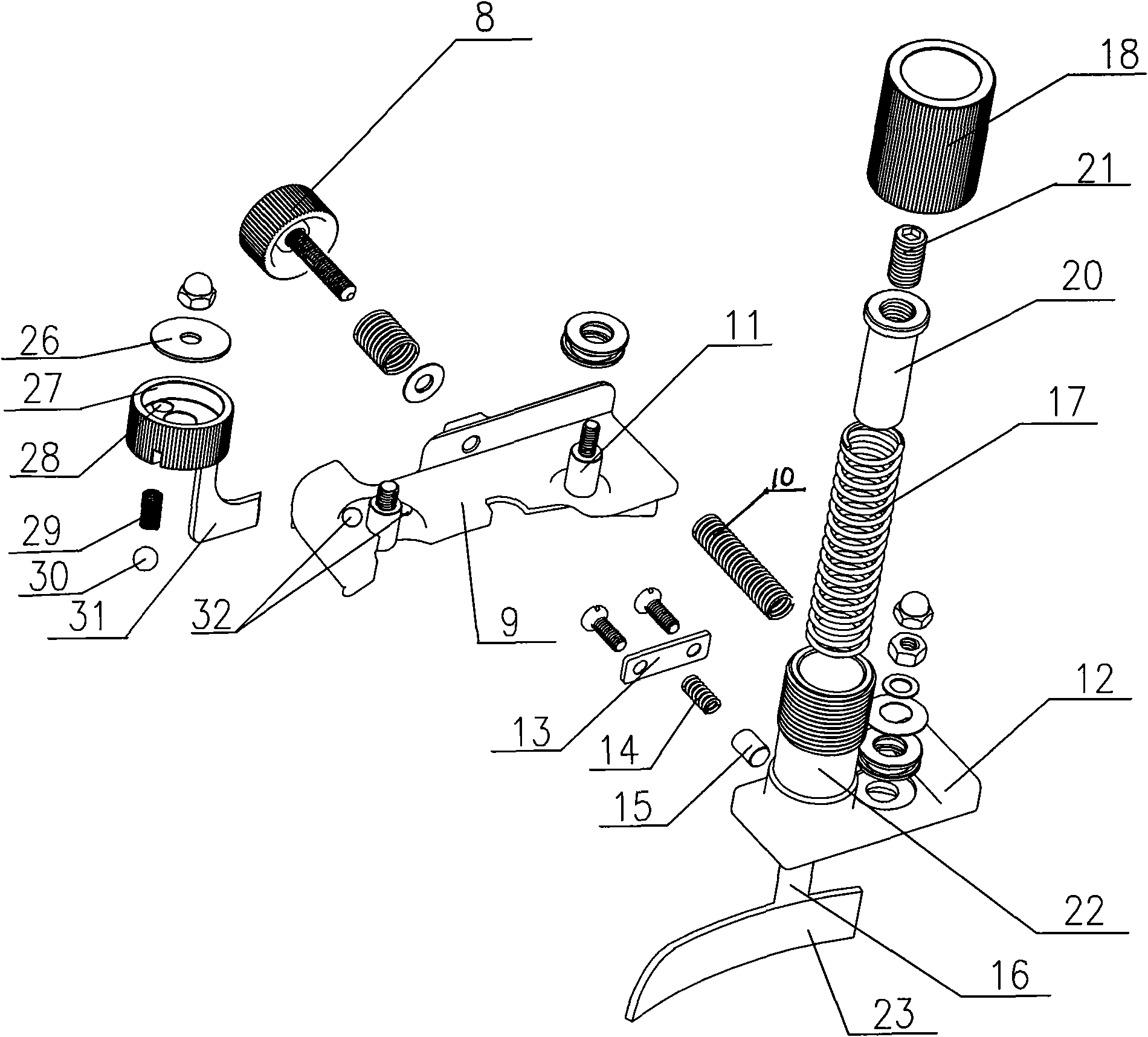

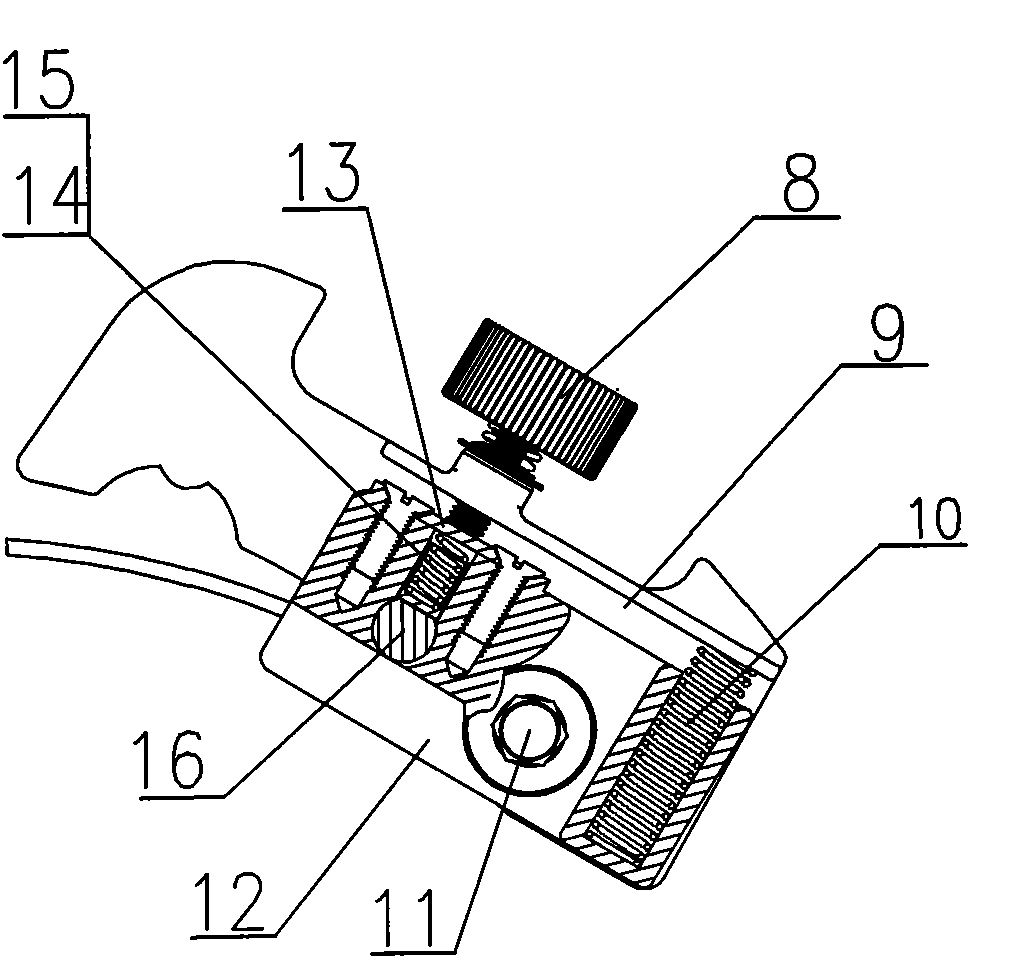

[0022] like figure 2 , image 3 As shown, the radial adjustment device includes a radial adjustment handwheel 8, a sleeve seat 12, a barrel seat mounting bracket 9, and a return spring 10. The barrel seat mount...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com