Production technology for lead and zinc floatation mineral powder

A production process, lead-zinc technology, applied in flotation, solid separation, etc., can solve the problems that the production index cannot meet the requirements, the effect is not obvious, and the consumption of chemicals is large, so as to achieve unlimited source of raw materials and green production process Environmental protection, good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

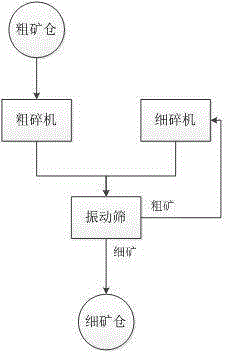

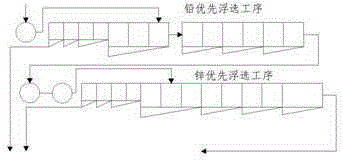

[0034] In the working process of the production process of the lead-zinc flotation ore powder of the present invention, the ore is first crushed, finely ground and formulated into a solution, and inhibitors, collectors, activators and foaming agents are added to the solution to inhibit The components of the collector are 0.2-0.6 parts of zinc sulfate, 5-10 parts of lime, 0.01-0.1 parts of sodium sulfide and 0.2-0.3 parts of sodium sulfite. ~0.06 parts and 0.03~015 parts of dixanthate, 0.15~0.35 parts of copper sulfate as an activator component, 0.1~0.2 parts of No. For flotation, zinc flotation is performed on the solution after lead flotation for 10 minutes, then the flotation lead and zinc products are dehydrated and packaged, and finally the tailings are dehydrated.

[0035] In the present invention, the inhibitor is one or more of zinc sulfate, lime, sodium sulfide and sodium sulfite, so that the clear water of the zinc ore is enhanced, and the floating of the zinc ore is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com