Tackifying and foaming stirring device for preparing foamed aluminum

A technology of stirring device and foamed aluminum, which is applied to mixers with rotating stirring devices, mixer accessories, dissolution, etc., can solve the problems of inability to prepare high-quality foamed aluminum, and achieve the effect of ingenious design, rapid and uniform stirring, and suppression of floating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with accompanying drawing

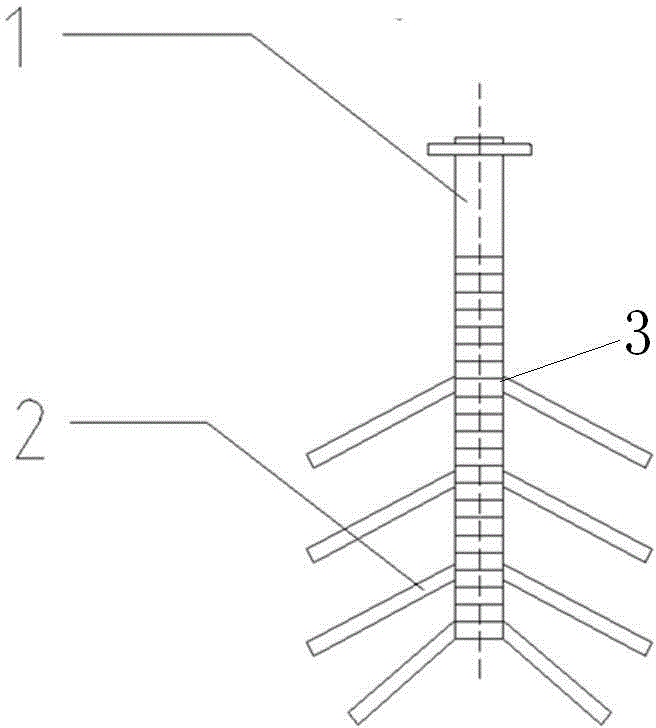

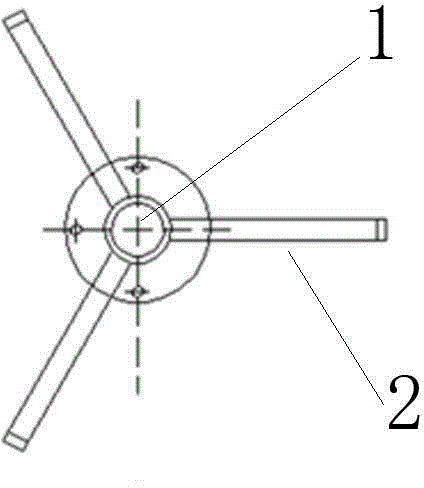

[0023] Such as Figure 6 , 7 A viscosification and foaming stirring device for preparing aluminum foam is shown, comprising a cylindrical stirring furnace body 3, a heating device 7 is fixed outside the furnace body 3, and a stirring paddle 8 is arranged inside, and the stirring paddle 8 is installed in the furnace Cover 4; wherein the stirring paddle 8 is a 4-layer folding paddle type, and 4 layers of paddles 2 are arranged on the central axis 1 of the stirring paddle 8, and each layer has 3 paddles 2, and the paddles 2 of each layer are sold Arranged at a staggered angle of 120°, the inclination angle of the bottom blades 2 is smaller than that of the upper three layers of blades, and the upper part of the central axis 1 is fixed on the furnace cover 4 through a fixed plate, and is driven by a motor 5 to rotate.

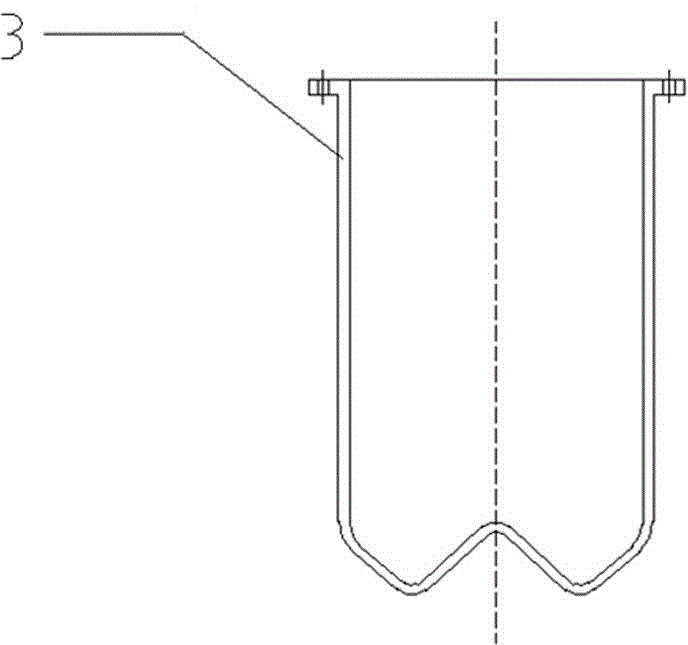

[0024] Such as image 3 , 4 The shown furnace body 3 ha...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com