Beneficiation process for recovering fluorite from tailings

A technology for fluorspar and tailings, which is applied in the field of beneficiation technology for recovering fluorspar from tailings. It can solve the problems of difficulty in improving the quality of concentrates, complex mineral types, and high costs, so as to reduce the amount of processing, reduce investment in equipment and chemicals , The effect of reducing the number of selected operation segments

Active Publication Date: 2020-09-11

INST OF RESOURCES UTILIZATION & RARE EARTH DEV GUANGDONG ACAD OF SCI

View PDF8 Cites 10 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

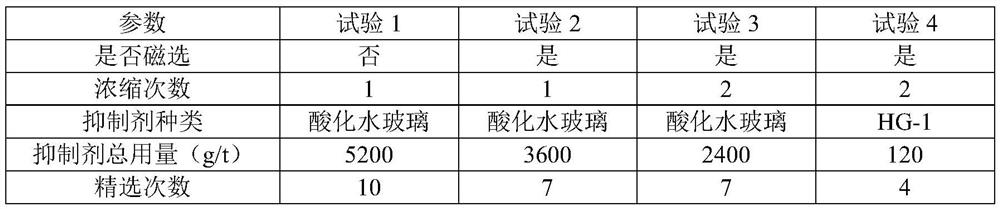

The current problems are as follows: the fluorite flotation of tailings is seriously affected by the upstream flotation operation, generally requires steps such as drug removal, desliming, concentration, activation, etc., with large processing capacity and high cost; the grade of fluorite in tailings is low, The beneficiation operation often needs 7-10 times, the process is long, the operation is complicated, and the recovery rate is low; the types of minerals in the tailings are complex, the quality of the concentrate is difficult to improve, and the final CaF2 grade of the concentrate is difficult to reach 97 %

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

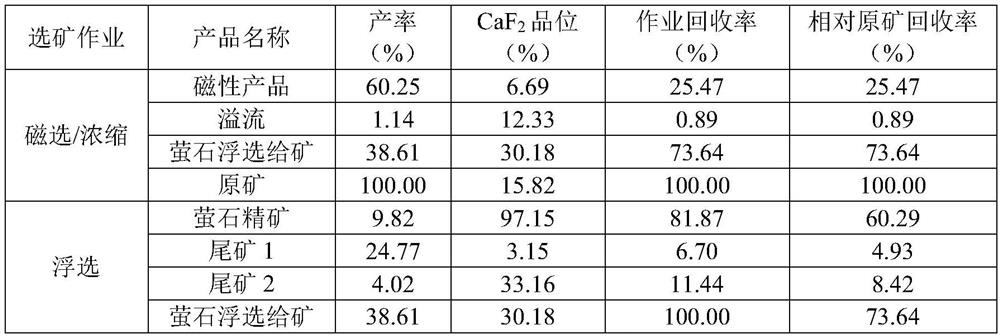

[0023] The raw ore processed in this example is the flotation tailings of a polymetallic mine in Inner Mongolia. After recovering valuable elements such as iron, copper, zinc, tungsten, and tin, the tailings contain some fluorite. The main mineral types and contents are: Calcite 22%, Andandrite 21%, Fluorite 16%, Quartz 10%, Fushanite 8%, Hornblende 8%, Pyroxene 5%, Biotite 5%, Chlorite 2%.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

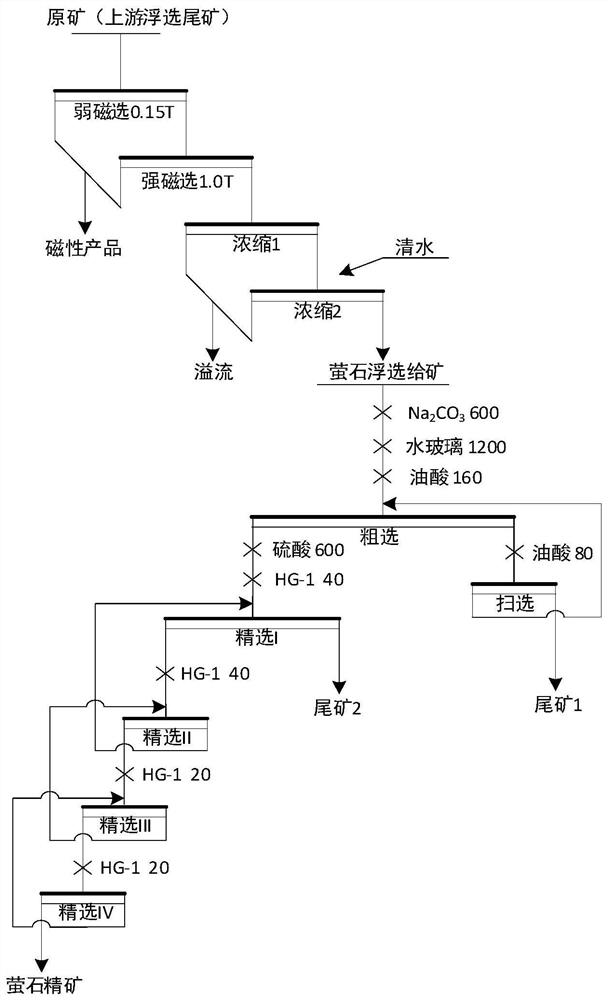

The invention discloses a beneficiation process for recovering fluorite from tailings, which comprises the following steps: carrying out weak magnetic-strong magnetic operation on raw ore to obtain anon-magnetic product; concentrating the non-magnetic product by using a first concentration box to obtain a first concentrated underflow, adding clear water to dilute the first concentrated underflow,and further concentrating the mixture in a second concentration box to obtain a second concentrated underflow; performing fluorite roughing and scavenging on the second concentrated underflow to obtain rough concentrate, performing concentration I, concentration II, concentration III and concentration IV on the rough concentrate, wherein the concentrate of the concentration IV is final concentrate. Waste is thrown through magnetic separation, so that pre-enrichment of fluorite is achieved, and the flotation operation handling capacity is reduced; through two-stage concentration operation, slime and ore pulp agents are removed, and equipment and agent investment is reduced; an efficient organic inhibitor is adopted for deeply inhibiting floating of calcite and quartz, the dosage of the efficient organic inhibitor is far smaller than that of conventional acidified sodium silicate, the number of concentration operation sections is reduced, and finally high-quality fluorite concentrate with the CaF2 grade larger than 97% is obtained.

Description

technical field [0001] The object of the present invention is to provide a kind of beneficiation process of reclaiming fluorite from tailings, the process flow is short, easy to operate, and the obtained fluorite concentrate CaF 2 Grade>97%. Background technique [0002] The content of valuable elements in the tailings is low. Generally, in the early stage of beneficiation, after grinding and chemical action, the degree of mudification is high and the chemical pollution is serious, so the follow-up treatment is very difficult. The flotation tailings of polymetallic fluorite associated ores generally contain more calcite and fluorite. In the early flotation process, fluorite was strongly suppressed as gangue. When the fluorite content was low (CaF 2 content < 20%), many mines do not consider recycling it, and discard it directly as tailings. The main reasons are: (1) high processing costs, and steps such as desliming, drug removal, concentration, and activation are req...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): B03D1/018B03C1/30B03D101/06B03D103/02

CPCB03D1/018B03C1/30B03D2201/06B03D2203/02

Inventor 王洪岭吴迪孟庆波高玉德任兴民杨晓文

Owner INST OF RESOURCES UTILIZATION & RARE EARTH DEV GUANGDONG ACAD OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com