A kind of beneficiation method of gravity separation and reverse flotation decalcification of high-calcium fine-grained mica-type vanadium ore

A beneficiation method and reverse flotation technology, applied in flotation, solid separation, etc., can solve the problems of reduced grinding efficiency, high slurry viscosity, waste of resources, etc., and achieve the goal of improving efficiency, improving separation effect, and reducing calcium oxide content Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

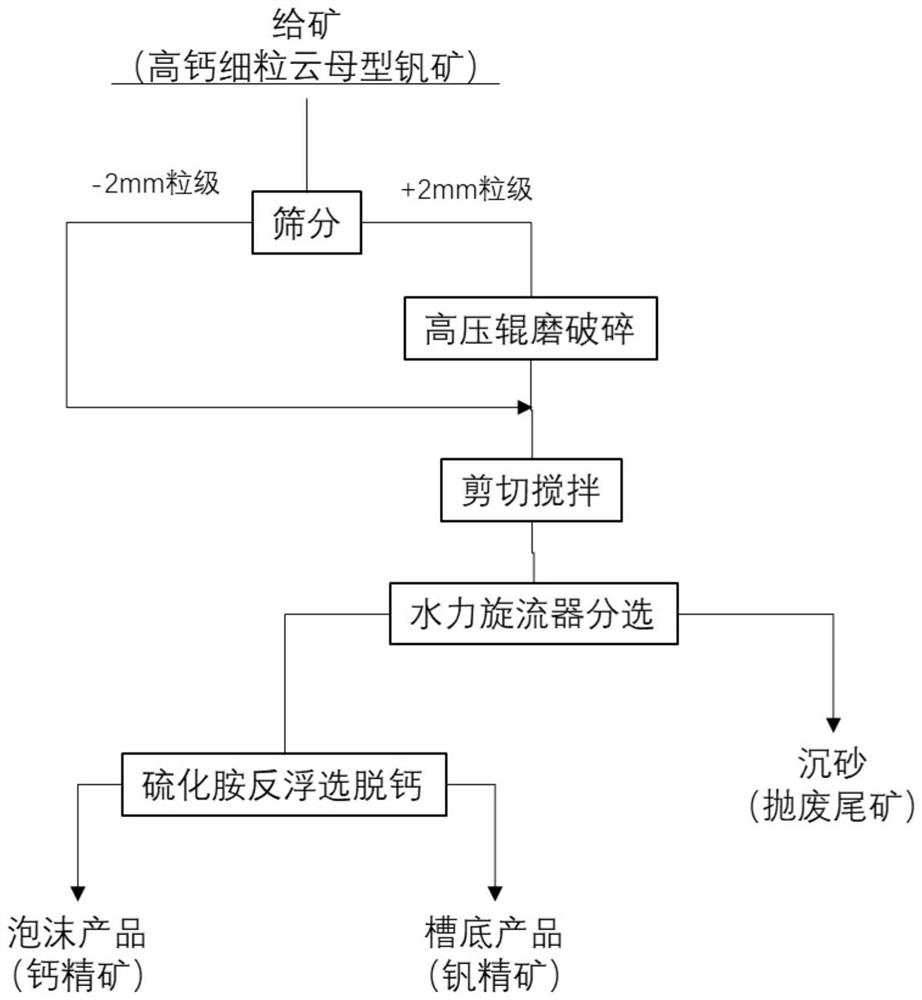

[0028] The technical solutions of the present invention will be clearly and completely described below in conjunction with the accompanying drawings. Apparently, the described embodiments are some of the embodiments of the present invention, but not all of them. The technical features involved in different embodiments of the present invention described below may be combined with each other as long as they do not constitute a conflict with each other.

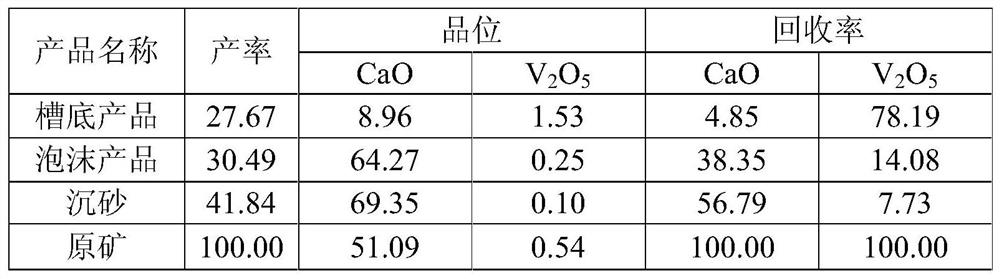

[0029] Such as figure 1 Shown, the present embodiment provides the beneficiation method of the gravity separation reverse flotation decalcification of a kind of high-calcium fine-grained mica vanadium ore, with a certain high-calcium fine-grained mica vanadium ore (CaO content 51.09%, V 2 o 5Content 0.54%) as ore feeding, it comprises the following steps:

[0030] Stage 1: Screen the raw ore with a high-frequency vibrating screen to obtain two products with particle size of -2mm and +2mm;

[0031] Stage 2: Use a high-pressure...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com