Converter fly ash homogenization treatment briquetting method

A converter dust removal and homogenization treatment technology, which is applied in the direction of improving process efficiency, can solve the problems of low energy consumption, difficult pretreatment of converter dust removal ash pressure balls, and unsatisfactory

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

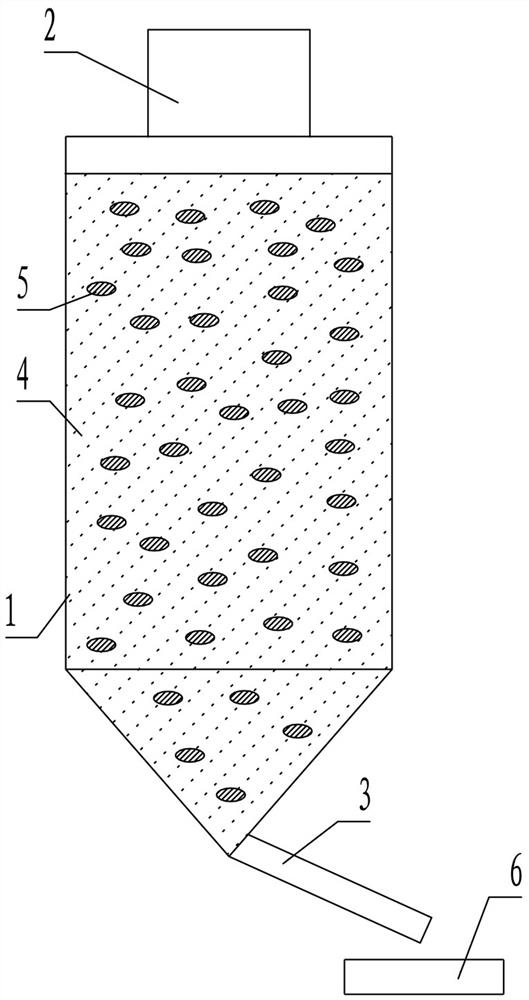

[0024] Such as figure 1 The shown method for homogenizing the briquetting of the converter dedusting ash includes using an evolutionary processing device to perform homogenization treatment on the converter dedusting ash.

[0025] The homogenization treatment equipment includes a closed hopper 1 with a dust collector 2 on the top, a narrowed lower part and a discharge port at the smallest point, a discharge pipe 3 is installed obliquely at the discharge port at the bottom of the closed hopper 1, and a discharge pipe 3 A vibrating screen 6 is provided below.

[0026] The homogenization process includes: the converter dust 4 at 120°C is pneumatically transported into the powder ash bin by suction and discharge tanker or pipeline, and enters the closed hopper 1 after weighing, and the freshly cold-pressed dedusted ash pellets 5 are transported into the closed hopper at the same time 1. After the converter dust removal ash 4 and the dust removal ash pellets 5 are filled with the ...

Embodiment 2

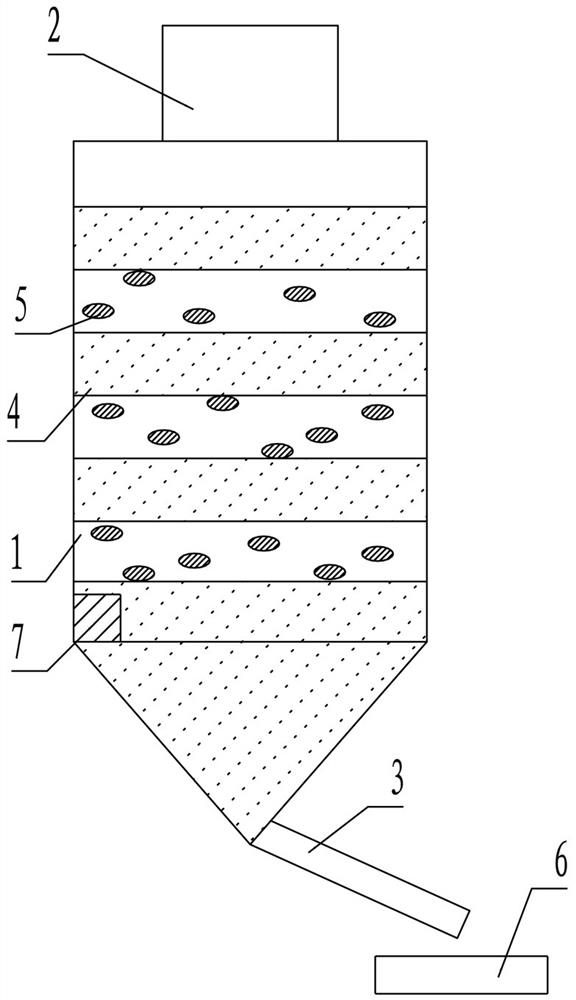

[0028] Such as figure 2 The shown method for homogenizing the briquetting of the converter dedusting ash includes using an evolutionary processing device to perform homogenization treatment on the converter dedusting ash.

[0029] The homogenization treatment equipment includes a closed hopper 1 with a dust collector 2 on the top, a narrow lower part and a discharge port at the smallest point, a discharge pipe 3 is installed at the discharge port at the bottom of the closed hopper 1, and the inside of the closed hopper 1 A meter 7 is provided at the starting position where the airtight hopper shrinks, and a vibrating screen 6 is provided under the discharge pipe 3 .

[0030]The homogenization treatment includes: conveying the converter dust 4 at 120°C to the closed hopper 1 through the gas delivery pipeline, and the dust collector 2 discharges clean gas into the closed hopper 1. When the height of the dedusting ash from the starting position is 0.5 meters, stop conveying the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com