A purification device and purification method for strongly acidic components in exhaust gas

A purification device and strong acid technology, which is applied in separation methods, chemical instruments and methods, and separation of dispersed particles. It can solve the problems of large input costs, large processing gas volume, and large floor area, and achieve high chemical reactions. High activity, high reaction rate, and extended service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

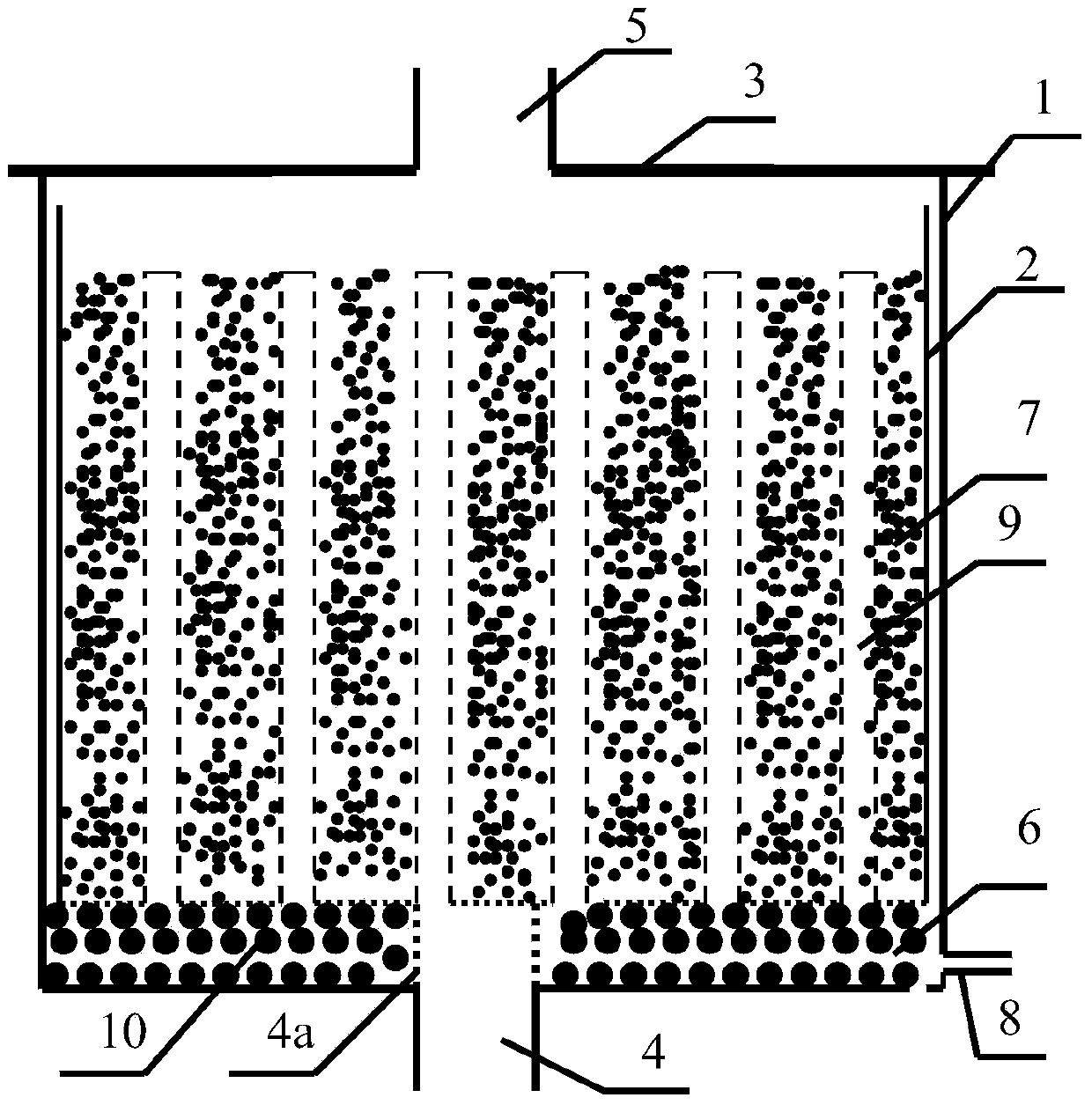

[0038] The structural schematic diagram of the vertical purification device of this embodiment is as follows figure 1 Shown:

[0039] The purification device of strongly acidic components in the exhaust gas is vertically placed with a plexiglass tube with a tube wall thickness of 4mm, an outer diameter of 300mm, and a height of 800mm as the reactor shell 1, and a plexiglass plate with a thickness of 5mm is used to make a disc with a diameter of 300mm, and Open a circular hole with a diameter of 50 mm in the center of the disc, and use acetone to dissolve the plexiglass powder as a binder to bond the plexiglass disc to the bottom of the above-mentioned plexiglass tube to form the bottom cover of the reactor shell. Gas inlet at the bottom of the reactor shell 1 .

[0040] Cut out a plexiglass tube with an outer diameter of 50 mm and a length of 300 mm, cut out 20 slits with a width of 3 mm and a length (along the radial direction of the plexiglass tube) of 40 mm at one end as t...

Embodiment 2

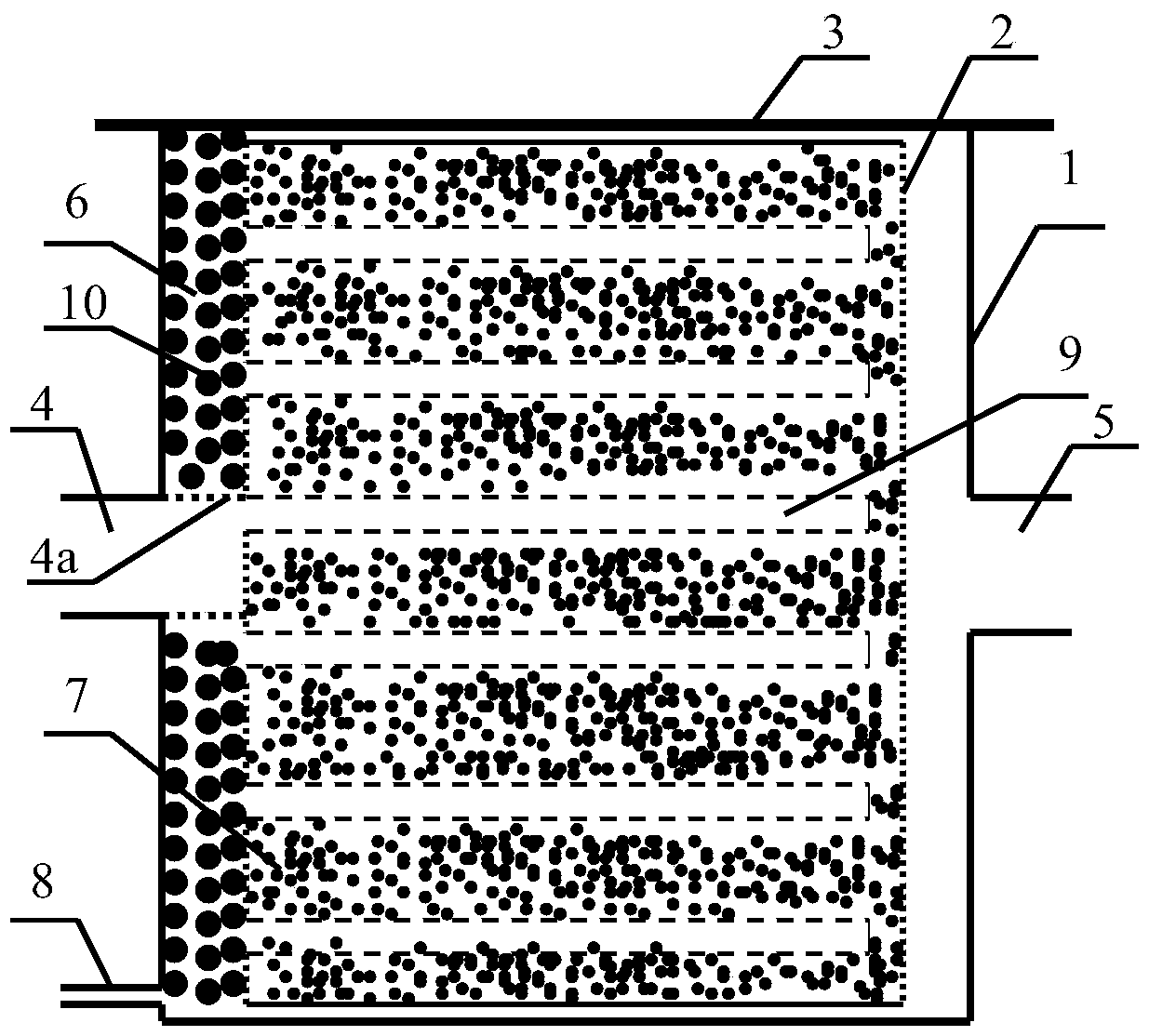

[0052] The schematic diagram of the structure of the flat-horizontal purification device in this embodiment is as follows: figure 2 Shown:

[0053] The purification device for strong acidic components in the exhaust gas uses a plexiglass plate with a thickness of 4mm to make a shell frame with a length of 500mm, a width of 300mm, and a height of 300mm. Use the same plexiglass plate to cut a 500mm×300mm plate and glue it to the above shell frame. As the bottom surface, the reactor shell 1 is formed. A circular hole with a diameter of 50 mm is opened on one side of the reactor shell as an air inlet, and a plexiglass tube with an outer diameter of 50 mm and a length of 300 mm is cut out at one end with a saw blade at a uniform interval of 3 mm in width and a length (along the plexiglass tube). 20 slits of 40 mm in radial direction are used as gas distribution slits 4a, insert one end processed with gas distribution slits 4a into the air inlet of 50 mm above, and protrude 50 mm ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com