Method for recycling elementary substance iron from iron-containing dust sludge

A technology for recycling bills and iron dust, which is applied in mechanical material recycling, recycling technology, solid separation, etc., can solve the problems of unrecovered elemental Fe and achieve the effect of green and efficient separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] Embodiment 1: The iron-containing dust and sludge in this embodiment is the dust removal coarse ash in front of the blast furnace of a certain iron and steel plant in Yunnan;

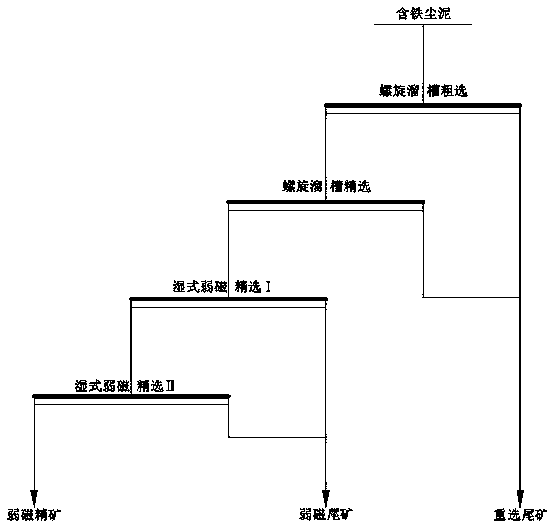

[0019] Such as figure 1 As shown, a method for recovering elemental iron from iron-containing dust sludge, the specific steps are as follows:

[0020] (1) Grinding the iron-containing dust sludge to -200 mesh accounts for 90% to obtain iron-containing dust sludge powder, adding water to adjust the slurry to a pulp concentration of 20wt%; the total iron (TFe) content in the iron-containing dust sludge is 56%, The content of elemental Fe is 46%;

[0021] (2) Put the ore slurry in step (1) into the spiral chute for a roughing and a beneficiation to obtain the spiral chute concentrate, the spiral chute middlings and the spiral chute tailings, and the spiral chute middlings and the spiral chute tailings are combined into heavy Tailings selection; the diameter of the spiral chute is Φ600mm, and the p...

Embodiment 2

[0024] Embodiment 2: The iron-containing dust and sludge of this embodiment is the converter coarse ash of a certain iron and steel plant in Yunnan;

[0025] Such as figure 1 As shown, a method for recovering elemental iron from iron-containing dust sludge, the specific steps are as follows:

[0026] (1) Grinding the iron-containing dust sludge to -200 mesh accounts for 85% to obtain iron-containing dust sludge powder, adding water to adjust the slurry to a pulp concentration of 40wt%; the total iron (TFe) content in the iron-containing dust sludge is 33%, The content of elemental Fe is 13%;

[0027] (2) Put the ore slurry in step (1) into the spiral chute for a roughing and a beneficiation to obtain the spiral chute concentrate, the spiral chute middlings and the spiral chute tailings, and the spiral chute middlings and the spiral chute tailings are combined into heavy Tailings selection; the diameter of the spiral chute is Φ1200mm, and the pitch is 340mm;

[0028] (3) Ste...

Embodiment 3

[0030] Embodiment 3: The iron-containing dust and sludge in this embodiment is fine ash from blast furnace dedusting in a certain iron and steel plant in Yunnan;

[0031] Such as figure 1 As shown, a method for recovering elemental iron from iron-containing dust sludge, the specific steps are as follows:

[0032] (1) It has been determined that the converter dedusting fine ash -200 mesh accounts for more than 95%, which can be regarded as iron-containing dust sludge powder. The fine ash is mixed with water to make the slurry concentration 30wt%; the iron-containing dust sludge contains all iron ( TFe) content is 48%, elemental Fe content is 16%;

[0033] (2) Put the ore slurry in step (1) into the spiral chute for a roughing and a beneficiation to obtain the spiral chute concentrate, the spiral chute middlings and the spiral chute tailings, and the spiral chute middlings and the spiral chute tailings are combined into heavy Tailings selection; the diameter of the spiral chut...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Pitch | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com