Hypoxia-aerobic comprehensive treatment method for tannery waste water

A technology for comprehensive treatment of tannery wastewater, applied in animal processing wastewater treatment, water/sewage multi-stage treatment, water/sludge/sewage treatment, etc. Total nitrogen removal effect, undisclosed relevant parameters and treatment effect, etc., to achieve the effect of inhibiting sludge floating, reducing oil content, and preventing sludge loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

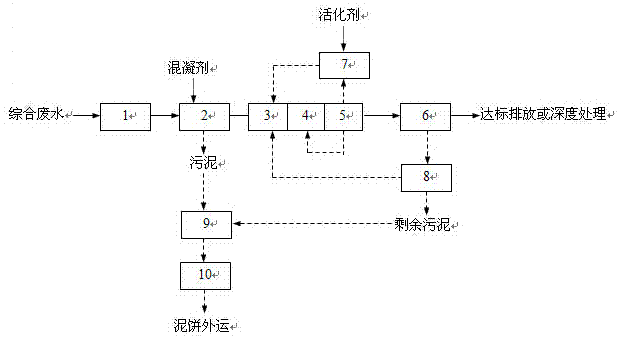

Method used

Image

Examples

Embodiment 1

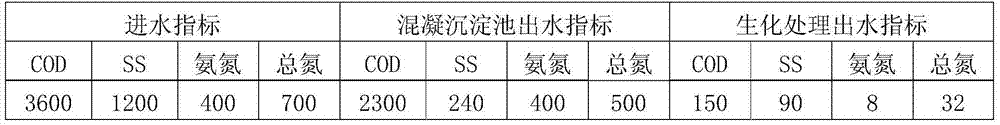

[0043] (1) After the chromium-containing wastewater and sulfur-containing wastewater from the leather production workshop are classified and pretreated, they enter the adjustment tank 1 together with other wastewater, and the residence time is 24 hours. The tank is fully aerated to maintain an aeration rate of 1.8m 3 / m 2 h.

[0044] (2) The adjusted effluent is lifted to the coagulation sedimentation tank 2, and 250mg / l iron salt coagulant is added simultaneously, the reaction time of the coagulation zone of the coagulation sedimentation tank is 15min, and the surface load of the sedimentation zone is 0.7m 3 / (m 2 h), waste water residence time 4 hours. Make the supernatant pH 7-10, S 2- ≤50mg / L, total chromium <1.5mg / L and SS (suspended solids concentration) ≤500mg / L.

[0045] (3) The supernatant after coagulation and sedimentation is introduced into the anoxic / aerobic pool; the wastewater is fully nitrified and denitrified in the pool; the hydraulic retention time of th...

Embodiment 2

[0053] (1) The comprehensive wastewater from the leather production workshop flows to the adjustment tank 1 after being screened out by coarse and fine screens to remove large particles. 3 / m 2 h.

[0054] (2) The adjusted effluent is lifted to the coagulation sedimentation tank 2, and 250mg / l iron salt coagulant is added simultaneously, the reaction time of the coagulation zone of the coagulation sedimentation tank is 15min, and the surface load of the sedimentation zone is 0.7m 3 / (m 2 h), the wastewater residence time is 4h. Make the supernatant pH 7-10, S 2- ≤50mg / L, total chromium <1.5mg / L and SS (suspended solids concentration) ≤500mg / L.

[0055] (3) The supernatant after coagulation and sedimentation is introduced into the selective reaction zone 3 of the anoxic / aerobic tank, fully mixed with the sludge returned from the return sludge well 8 of the secondary settling tank, and then flows to the anoxic zone 4 and well in sequence Oxygen zone 5, the wastewater is ful...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Surface load | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com