Combined agent for pyrite flotation

A combination of reagents and pyrite technology, applied in flotation, solid separation, etc., can solve the problems of high cost, human body, environmental hazards, strong corrosion of equipment, etc., achieve low cost, low corrosion of equipment, and improve comprehensive benefits Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

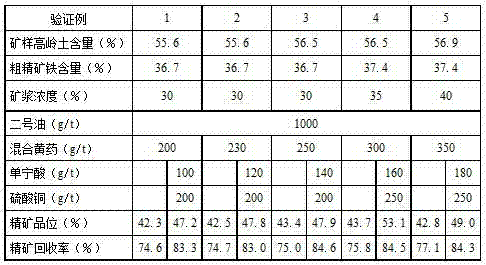

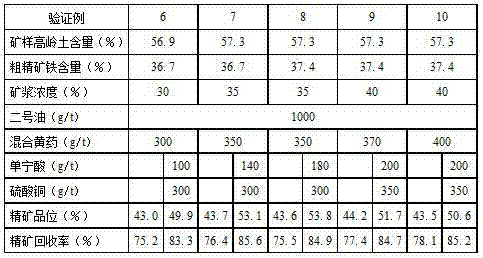

[0010] A combined medicament for pyrite flotation, the combined medicament includes foaming agent No. 2 oil and a collector mixed with ethyl xanthate and butyl xanthate. In the present invention, when the mass content of iron in the pyrite is 36.7-37.4% and the mass content of the impurity kaolin is 55.6-57.3%, the pyrite slurry with a mass concentration of 30-40% is used as a reference, In this combination, there are No. 2 oil 1000g / t, ethyl xanthate and butyl xanthate mixed in a ratio of 1:1 total 200-400g / t, tannic acid 100-200g / t, copper sulfate 200-350g / t.

[0011] Based on the above disclosure and combined with the foregoing introduction to the beneficial effects of the present invention, those skilled in the art can already understand and implement the present invention. Therefore, the verification of the present invention will be described below.

[0012] The verified ore sample is pyrite with kaolin as the main impurity. After preliminary gravity beneficiation, a crude ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com