Copper sulfide ore flotation collecting agent

A technology of copper sulfide ore and collector, applied in flotation, solid separation, etc., can solve the problem of failure to achieve the expected effect of segmented drug use, failure to obtain satisfactory copper recovery rate of copper concentrate, and affecting the flotation index of the flotation process and other issues, to achieve low prices, stable production indicators, and reduce production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

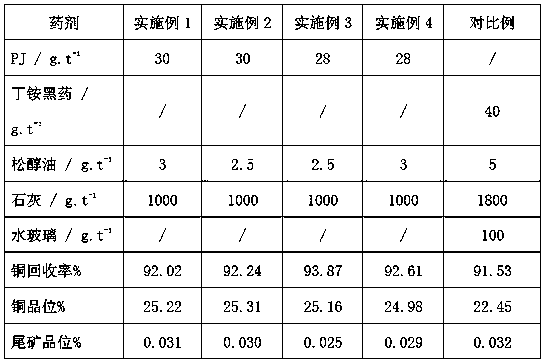

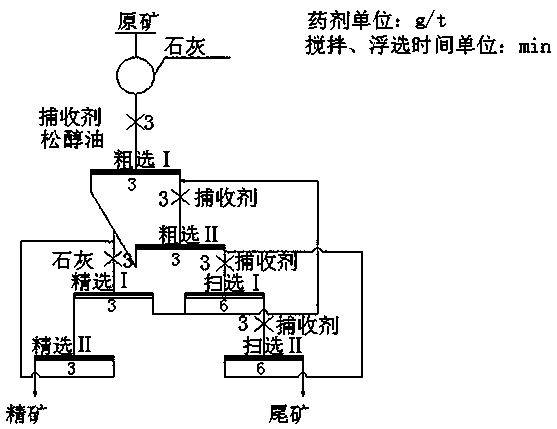

[0014] The technical scheme adopted in this embodiment is: the copper grade of the copper ore used in the examples and comparative examples is 0.40%, the grinding fineness is -0.074mm and accounts for 60%, and the flotation process adopts two-stage roughing, two-stage selection and Two-stage scanning, the detailed process see figure 2 . In order to compare the flotation index better, the flotation index of each embodiment and comparative example is summarized in figure 1 middle.

[0015] The content of xanthate diester in collector PJ is 60%, the content of butylammonium black drug is 36%, the content of regulator is 4%, and the molecular formula of xanthate diester is C 2 h 5 -OCSS-C 2 h 4 -COOC 2 h 5 , the regulator is terpineol oil. The dosage of collector is 30g / t, the dosage of lime is 1000g / t, and the dosage of terpineol oil is 3g / t.

Embodiment 2

[0017] The difference between this embodiment and Example 1 is that the xanthate diester content of collector PJ is 70%, the content of butyl ammonium black medicine is 27%, the content of regulator is 3%, and the molecular formula of xanthate diester is C 3 h 7 -OCSS-C 3 h 6 -COOC 2 h 5 , the regulator is MIBC. The amount of collector is 30g / t, the amount of lime is 1000g / t, and the amount of terpineol oil is 2.5g / t. Other compositions, technological process are all identical with embodiment 1.

Embodiment 3

[0019] The difference between this embodiment and Example 1 is that the xanthate diester content of collector PJ is 80%, the content of butyl ammonium black medicine is 18%, the content of regulator is 2%, and the molecular formula of xanthate diester is C 3 h 7 -OCSS-C 2 h 4 -COOCH 3 , the regulator is terpineol oil. The amount of collector is 28g / t, the amount of lime is 1000g / t, and the amount of terpineol oil is 2.5g / t. Other compositions, technological process are all identical with embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com