Patents

Literature

30results about How to "Production indicators are stable" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

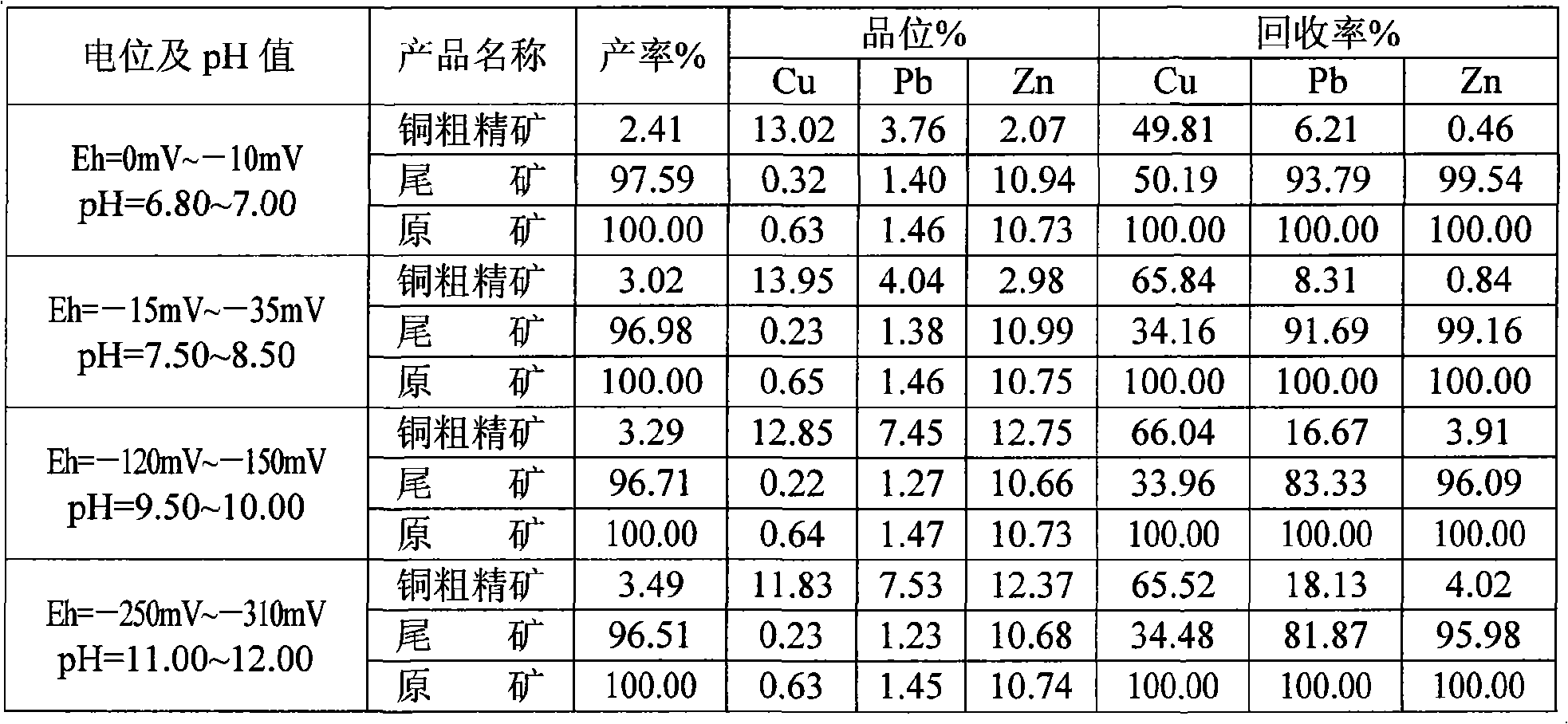

Electric potential regulating and controling differential flotation process for copper-plumbum-zinc vulcanizing mine

InactiveCN101402071AAdaptableAvoid defects that are difficult to grasp with precisionMultistage water/sewage treatmentFlotationSlurryCopper

The invention relates to an ore dressing technology for separating copper, lead and zinc in complex polymetallic sulphide ores, in particular to an electric potential modulation and preferential flotation process for copper-lead-zinc sulphide ores, which comprises the steps of copper, lead and zinc selection; copper is preferentially floated; the electric potential Eh of an ore slurry is between 35 below zero and 15 below zero mV; the PH value of the ore slurry is between 7.50 and 8.50; LP-01 is used as a collecting agent; and YN and ZnSO4 are used as inhibitors. The process has the advantages of solving the problems that the prior flotation process has large difficulty in separating the copper and lead and the copper and zinc, poor quality of concentrated ore and higher cost.

Owner:罗仙平

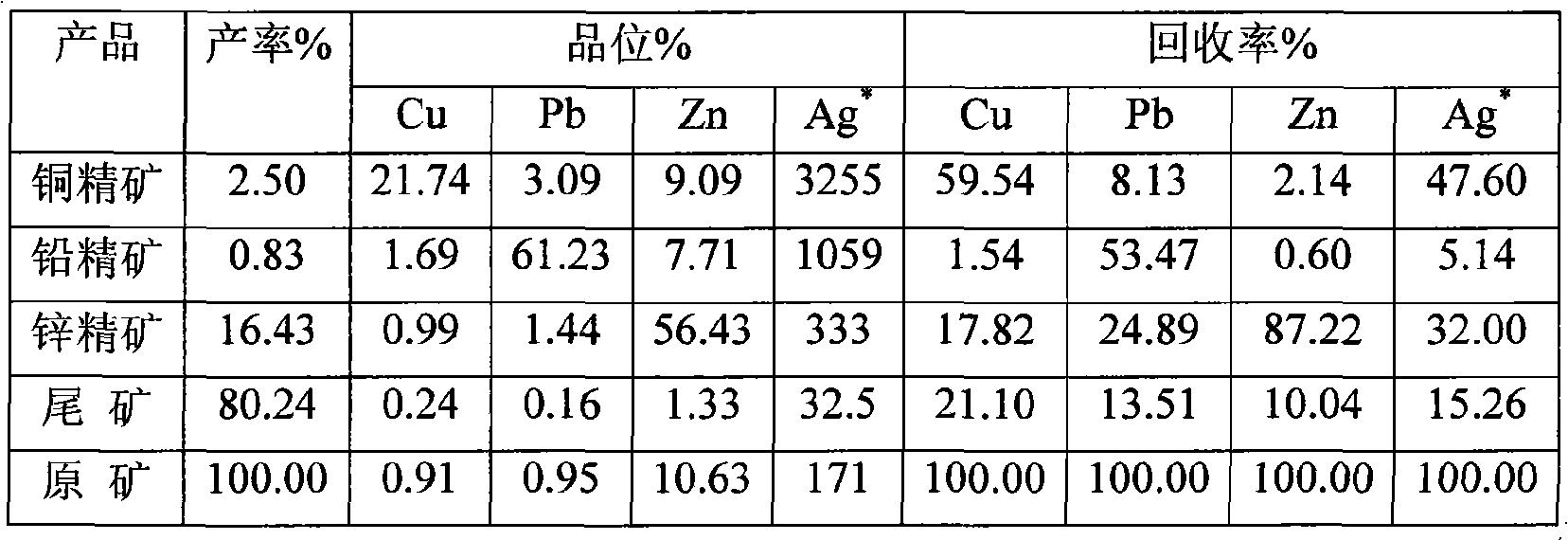

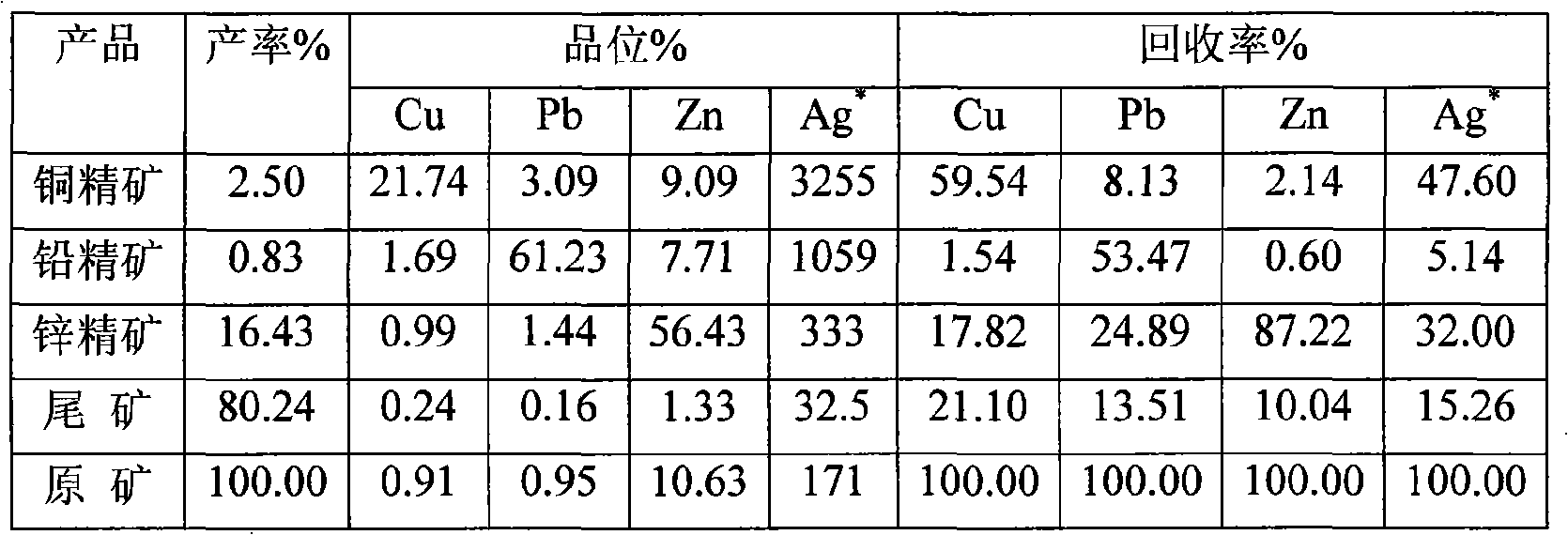

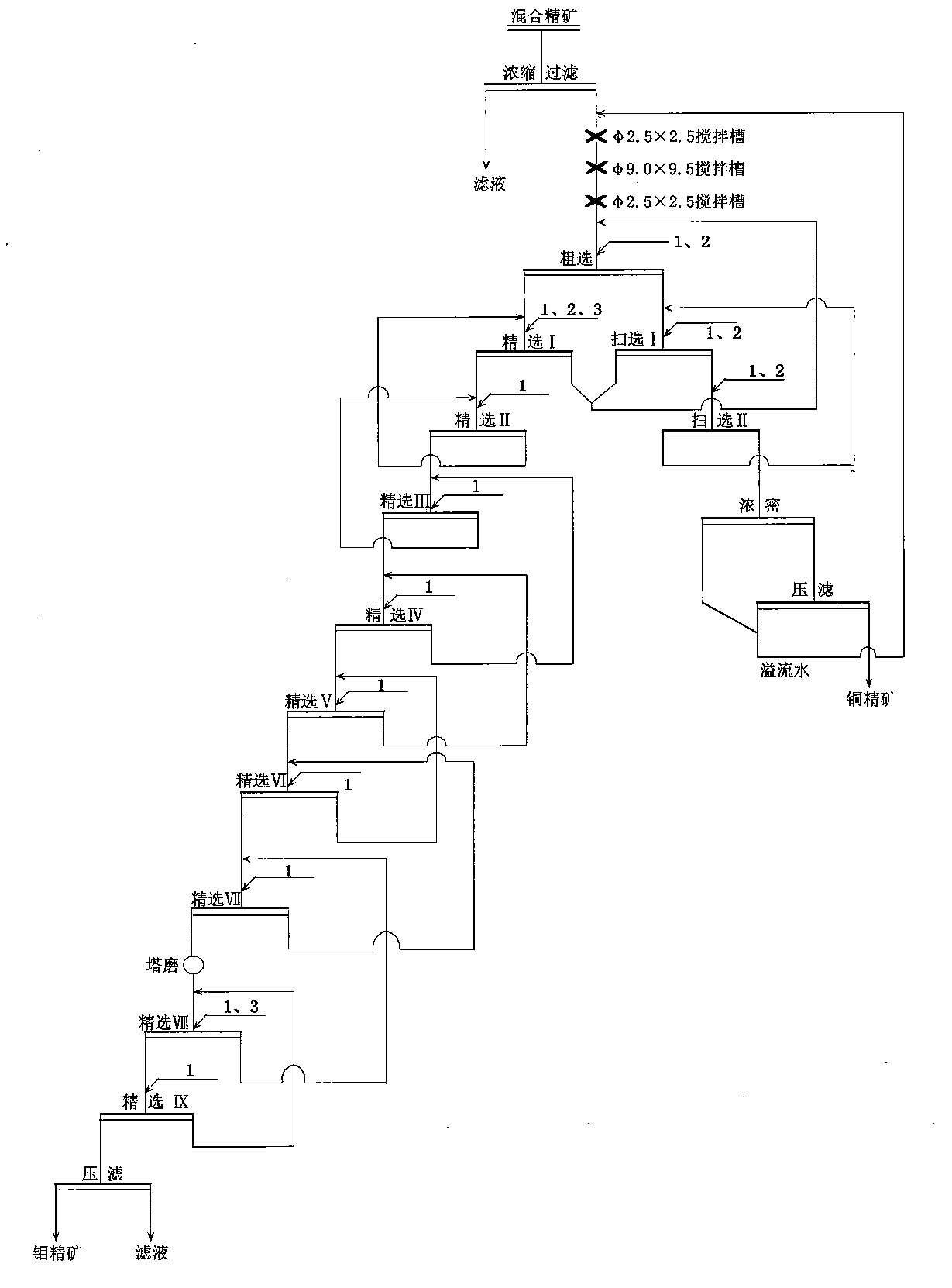

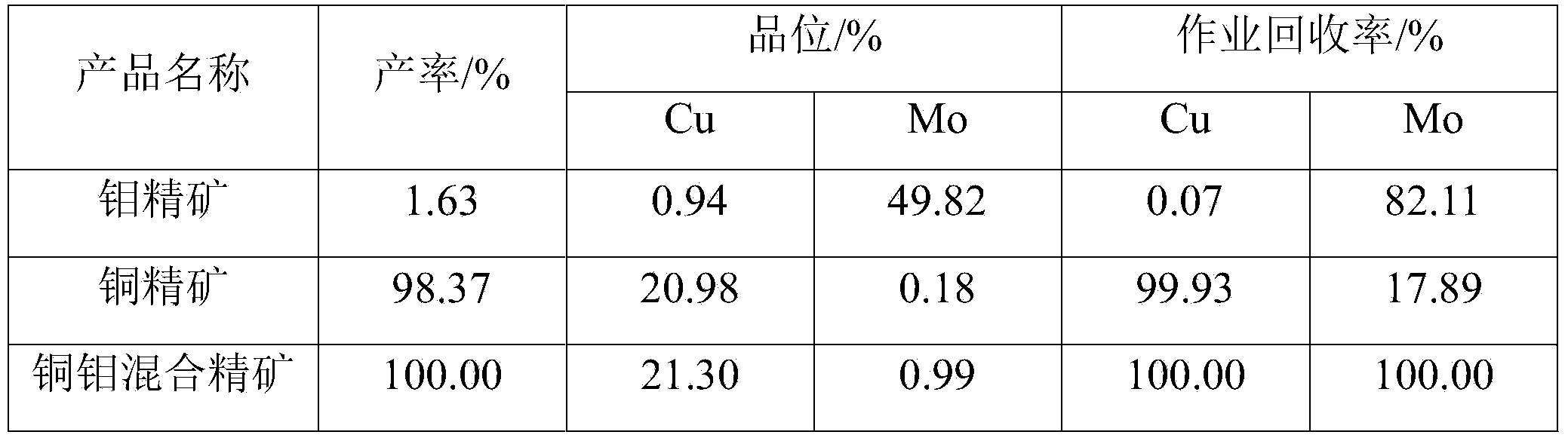

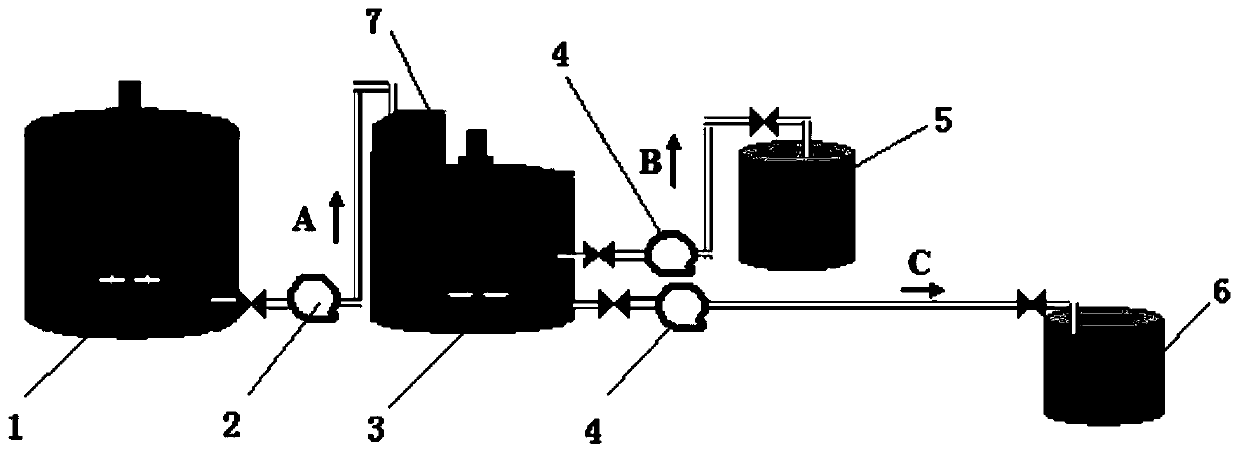

Method for separating copper-molybdenum mixed concentrate high in secondary copper content

InactiveCN103521347AEfficient separationSave waterSolid separationWater resourcesSodium hydrosulfide

The invention discloses a method for separating copper-molybdenum mixed concentrate high in secondary copper content. The method includes the steps of concentrating and filtering, water returning and size mixing, floatation separation, concentrate filtering and the like. The method abides by floatability property difference between copper molybdenum minerals, adopts sodium hydrosulfide to effectively inhibit primary copper and secondary copper and realizes high-efficiency separation of the copper-molybdenum mixed concentrate according to an idea of 'light pressing and slow selecting'. Copper concentrate going through dense overflow water can be used for size mixing of the copper-molybdenum mixed concentrate after concentrating and filtering, so that water resources are saved, and pollution caused by discharging of medicament is reduced. The method has the advantages of simplicity in medicament system and flowage structure, easiness in management operation, stability in technical process and production index and the like.

Owner:CHANGCHUN GOLD RES INST +1

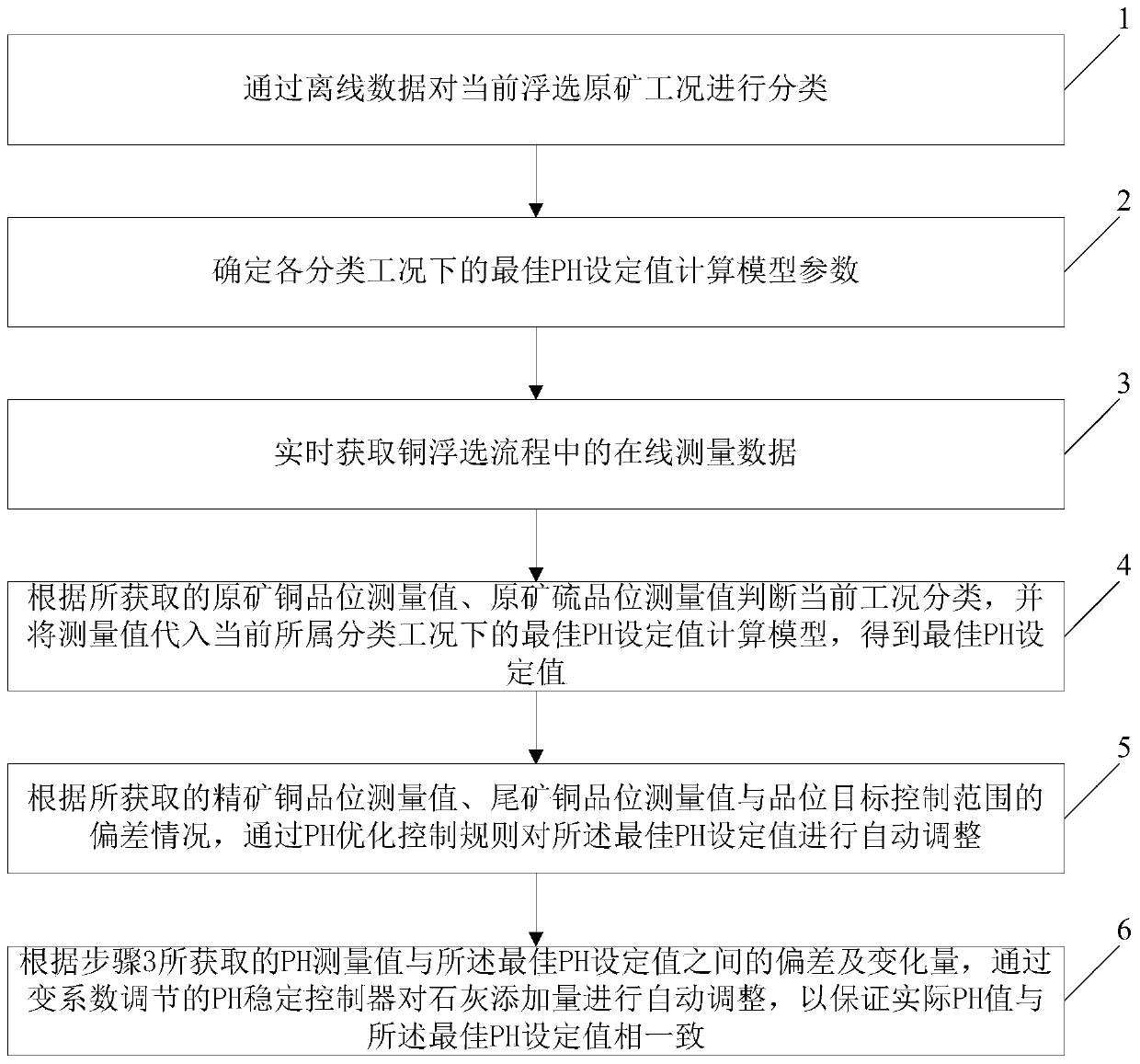

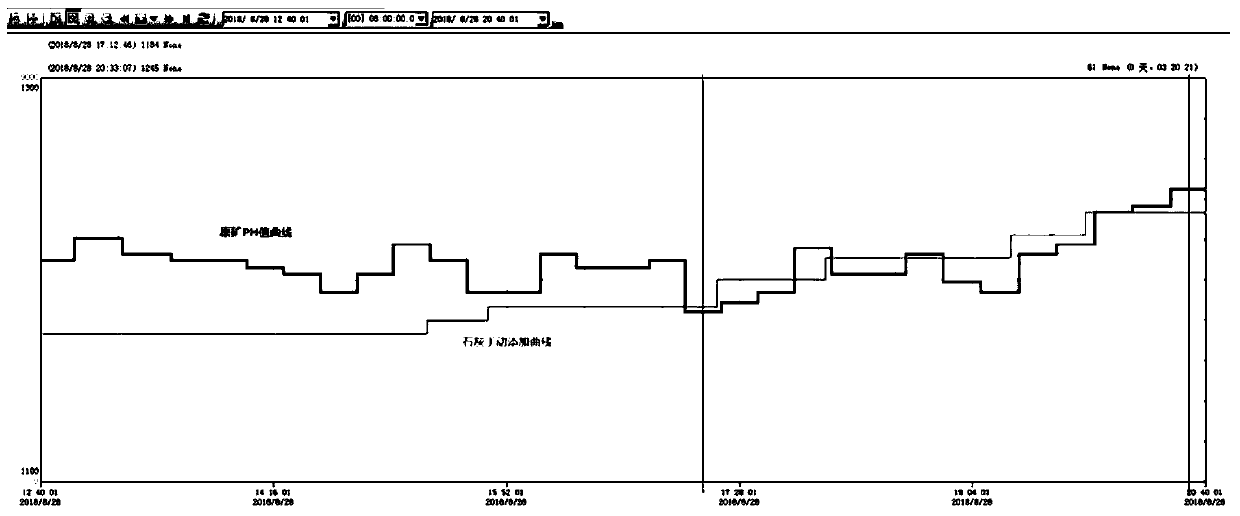

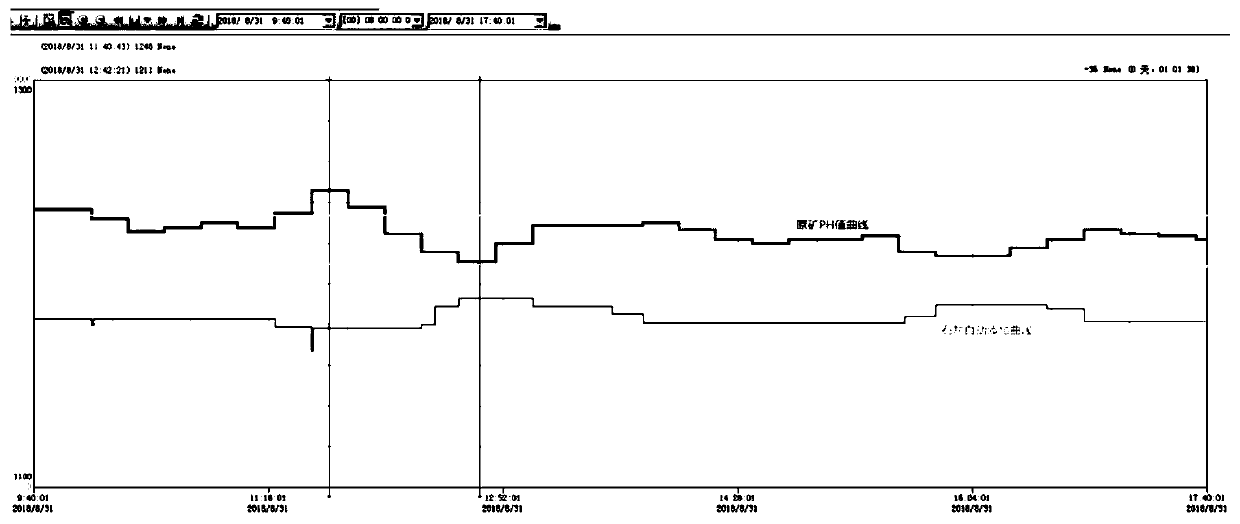

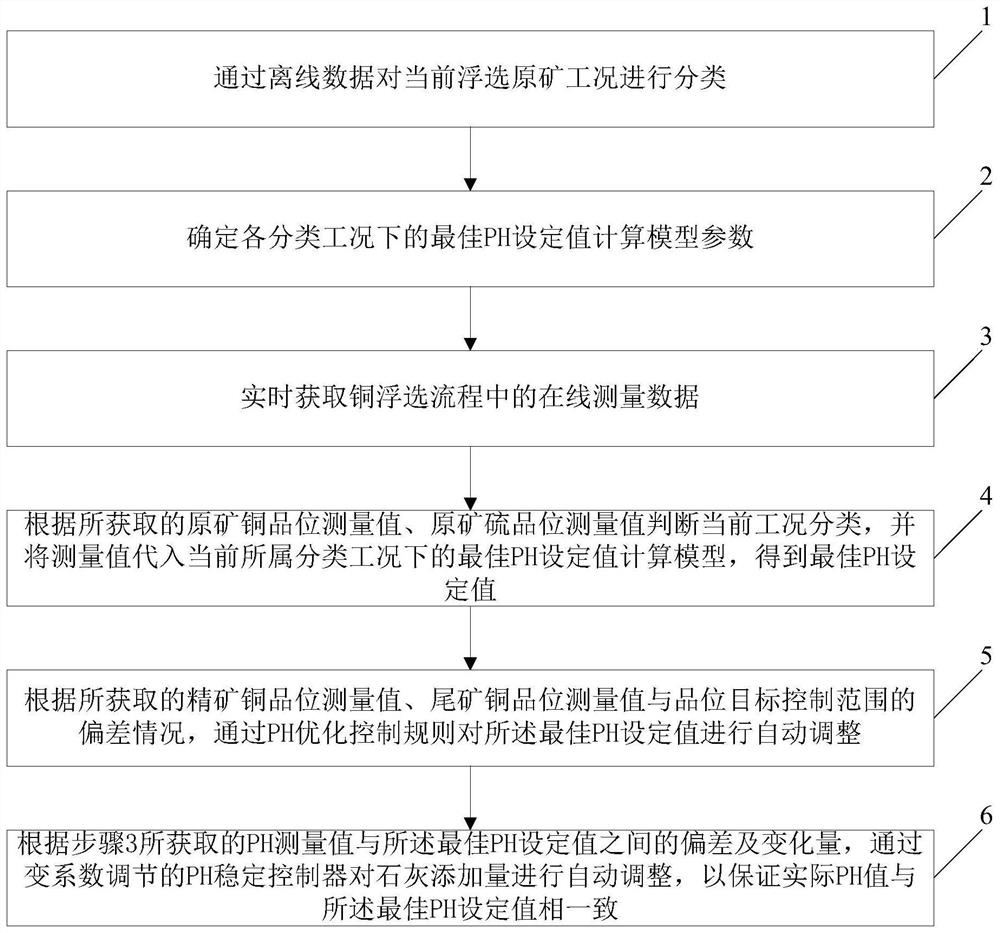

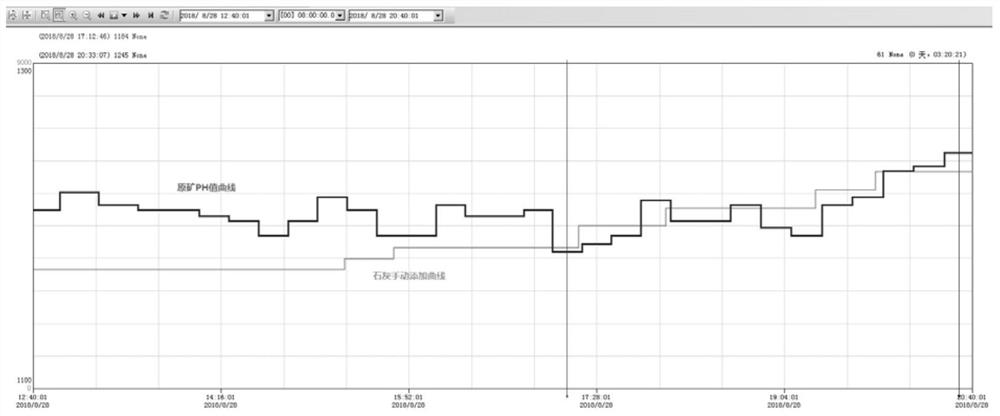

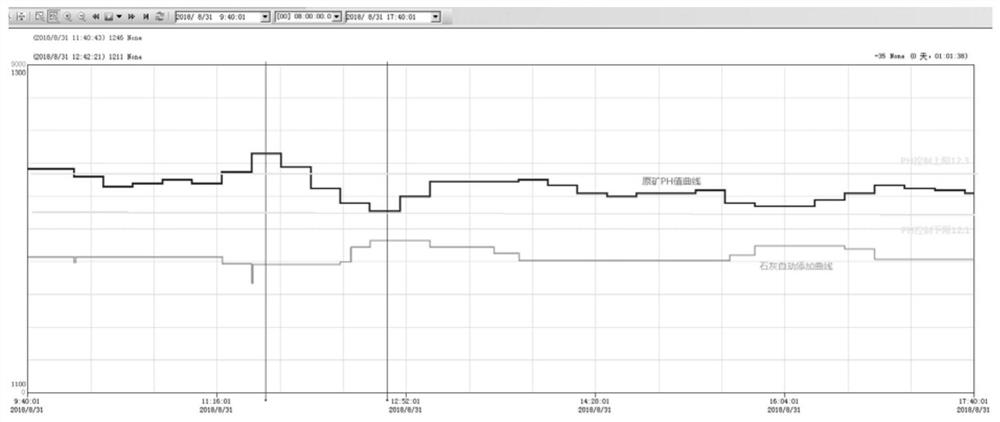

Method for automatically controlling lime addition amount in copper flotation process

ActiveCN110193427AGuaranteed uptimeProduction indicators are stableFlotationAutomatic controlTarget control

The invention discloses a method for automatically controlling the lime addition amount in a copper flotation process. The method comprises: classifying the current crude ore flotation working conditions through off-line data; determining the optimal PH set value calculation model parameters under each classified working condition; real-timely obtaining the online measurement data in a copper flotation process; judging the classification of the current working conditions according to the obtained raw ore copper grade measurement value and the crude ore sulfur grade measurement value to obtainthe optimal PH set value; according to the deviation between the obtained concentrate copper grade measurement value and the grade target control range and between the tailings copper grade measurement value and the grade target control range, automatically adjusting the optimal PH set value through a PH optimization control rule; and according to the deviation between the obtained PH measurementvalue and the optimal PH set value and the change amount, automatically adjusting the lime addition amount through a pH value stabilization controller capable of adjusting in a variable coefficient manner. With the method of the present invention, the pH value of the ore slurry can be rapidly stabilized within the optimal range so as to stabilize the production index and ensure the stable operation of the flotation process.

Owner:BEIJING MINING & METALLURGICAL TECH GRP CO LTD

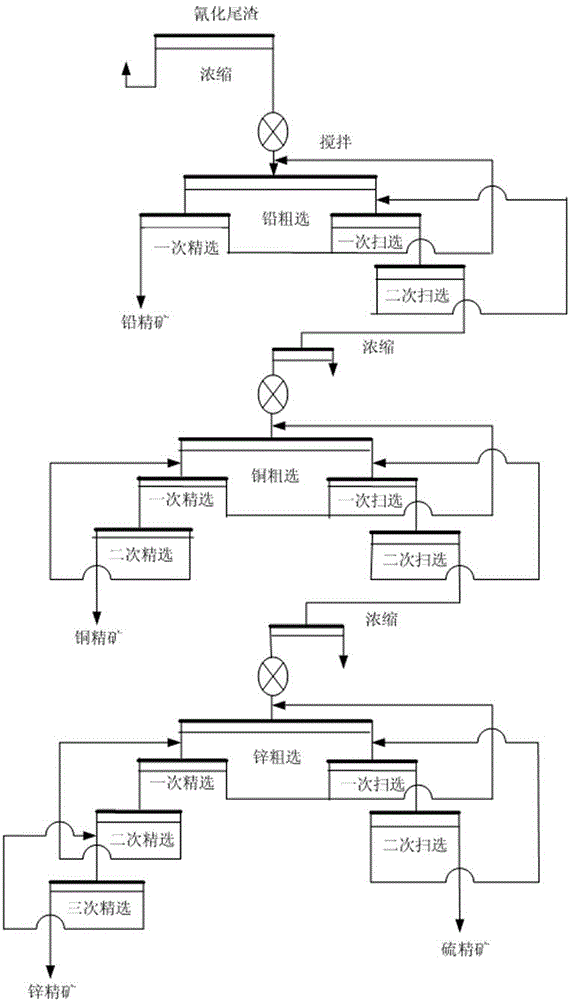

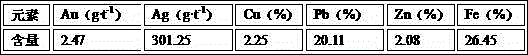

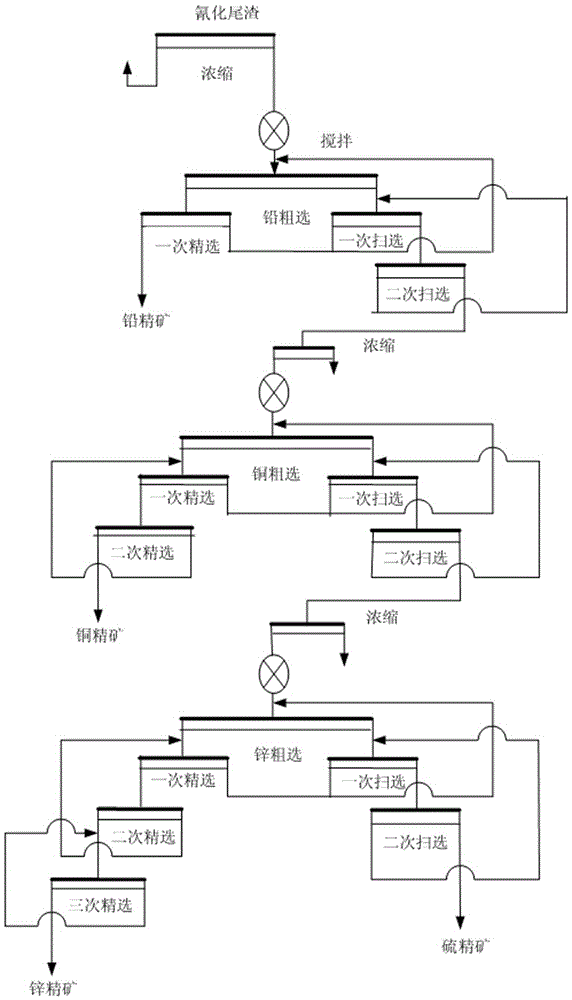

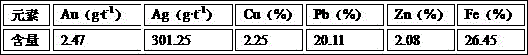

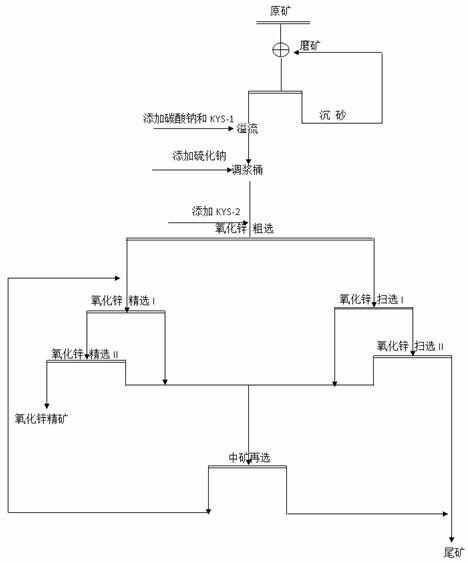

Method for recovering copper, lead and zinc from ultra-fine complicated cyanidation tailings

ActiveCN104646185AThe process is easy to operateProduction indicators are stableFlotationSodium carbonateOre concentrate

The invention provides a method for recovering copper, lead and zinc from ultra-fine complicated cyanidation tailings, and belongs to the technical field of mineral processing. The method comprises the following steps that (1) the ultra-fine complicated cyanidation tailings are concentrated through a thickener, and water and sodium carbonate are added and are stirred to be made into primary ore pulp; (2) the primary ore pulp is conveyed to a flotation machine unit, once-coarse once-fine twice-sweeping flotation flow process is adopted for recovering lead; the tailings obtained through secondary sweeping flotation are lead sweeping flotation tailings; (3) the lead sweeping flotation tailings are concentrated, then, water is added, and secondary ore pulp is prepared; the secondary ore pulp is conveyed to the flotation machine unit, once-coarse twice-fine and twice-sweeping flotation flow process is adopted for recovering copper, and the tailings obtained through secondary sweeping flotation are copper sweeping flotation tailings; (4) the copper sweeping tailings are concentrated, then, water is added, and tertiary ore pulp is obtained, and the pH value is regulated; once-coarse three-time-fine and twice-sweeping flotation flow process is adopted for recovering zinc; concentrates obtained through tertiary concentration are zinc concretes. The method provided by the invention has the advantages that the operation in the technical process is simple, the production index is stable, in addition, the recovery and the use of production tailing water are realized, and the environment pollution is reduced.

Owner:NORTHEASTERN UNIV

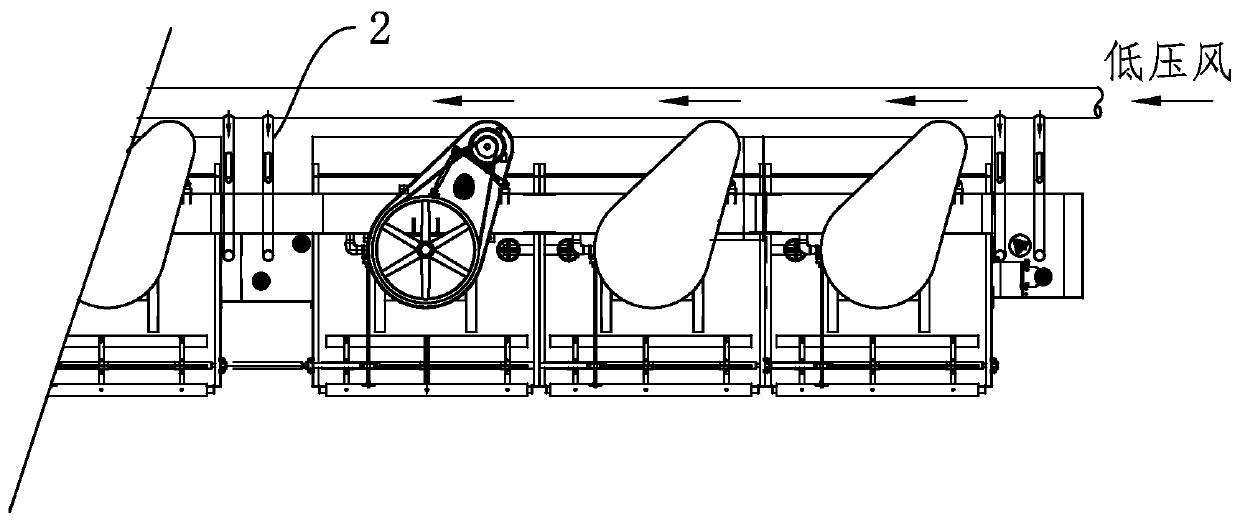

Undisturbed switch method for ore feeders of ball mill

ActiveCN102008994AAvoid "Bloated Belly" PhenomenonAvoid yield lossGrain treatmentsAutomatic controlEngineering

The invention belongs to the technical field of a switch method for ore feeders of a ball mill, in particular to an undisturbed switch method for ore feeders of a ball mill. On the premise of realizing ball milling basic automatic control function, namely on the premise of ensuring the normal work of systems of ore feeding amount frequency changing speed regulation of a ball mill, automatic switch of the ore feeders, and the like, the undisturbed switch control part content of the ore feeders is added into the control program. When the switch condition of the ore feeders is met, the system calls a selecting program of the ore feeders, judges the starting of two ore feeders and then calls parameters K** of the two ore feeders; the K** is divided by a set value of the current ore feeding amount to obtain the initial frequency of the ore feeders; the frequency is corrected; and the corrected frequency controls the running of the ore feeders by an executing system in t1 time. Therefore, undisturbed switch is realized.

Owner:ANSTEEL GRP MINING CO LTD

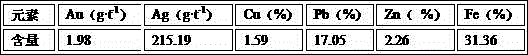

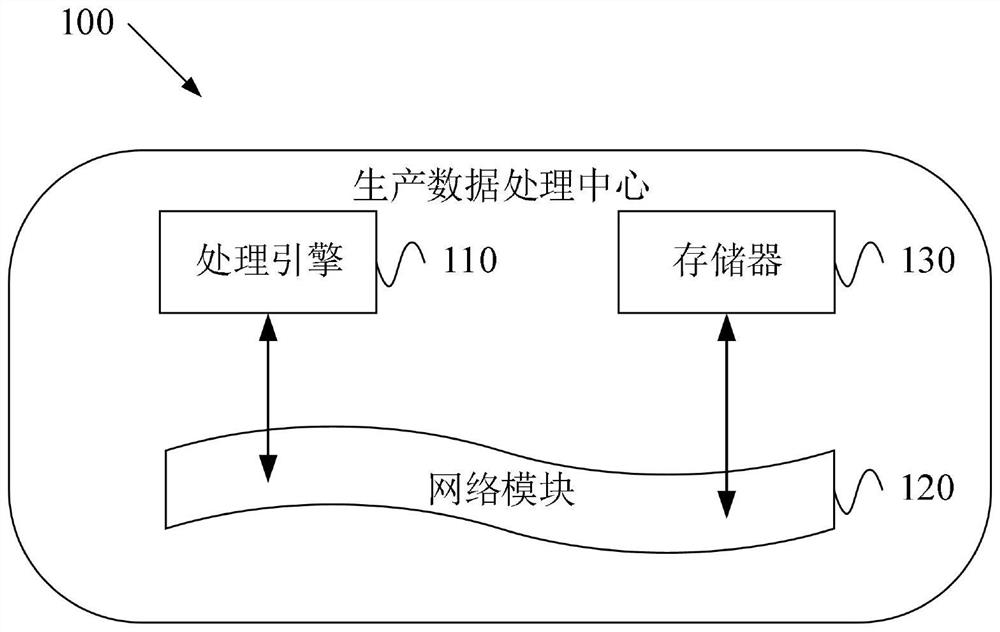

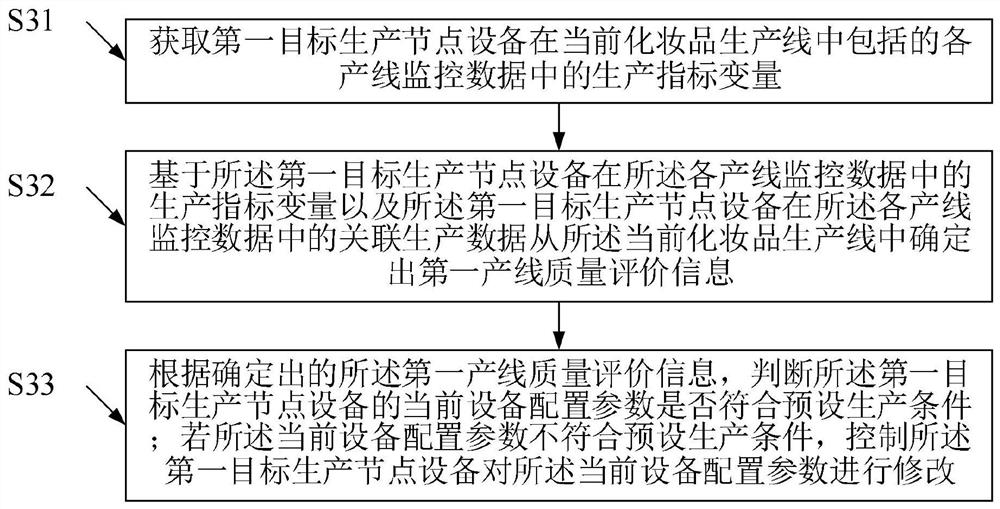

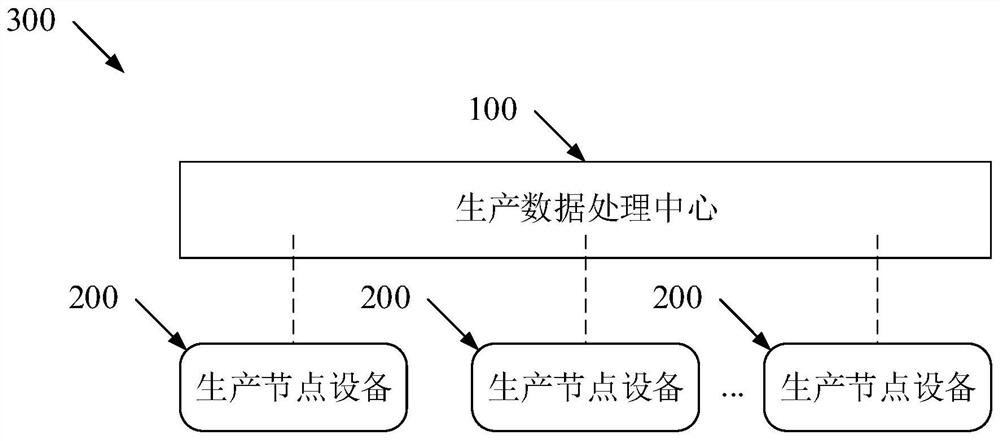

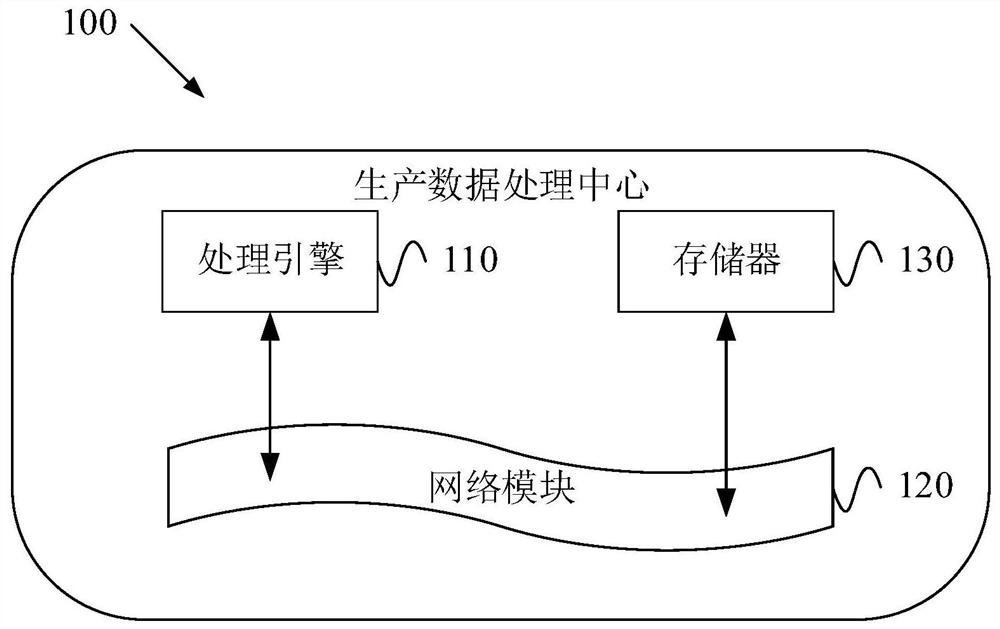

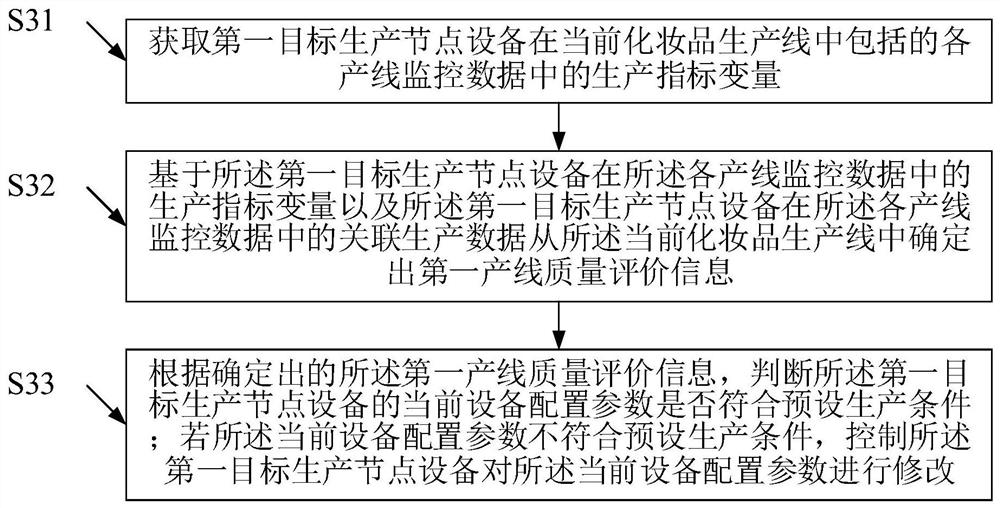

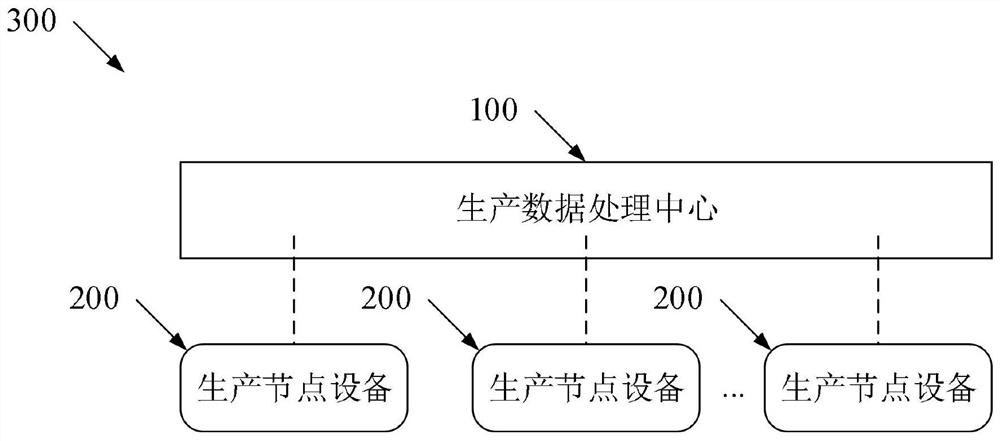

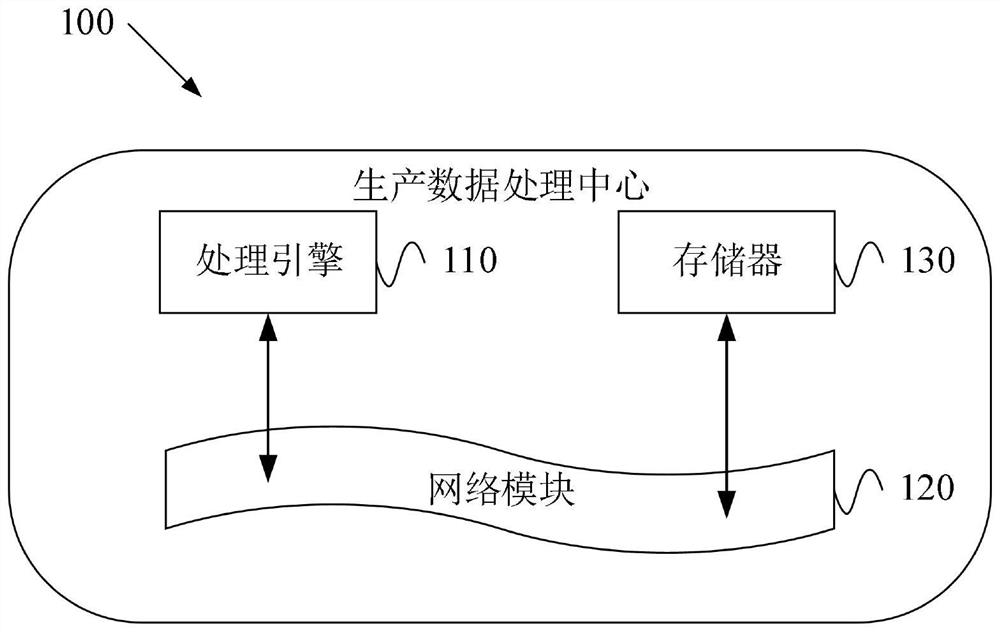

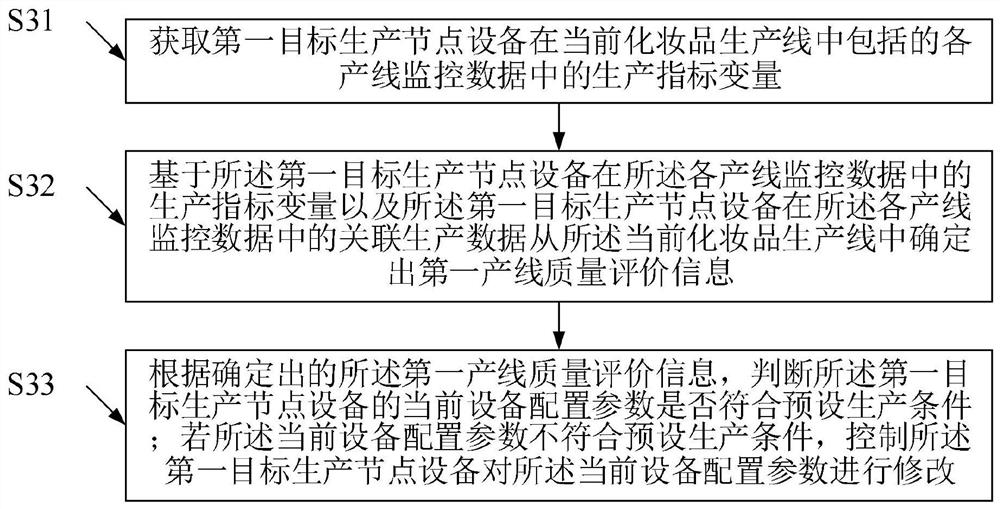

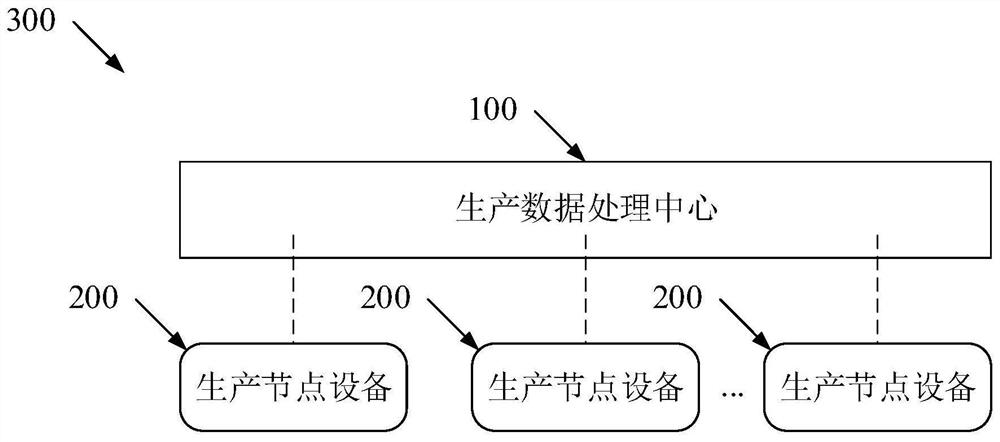

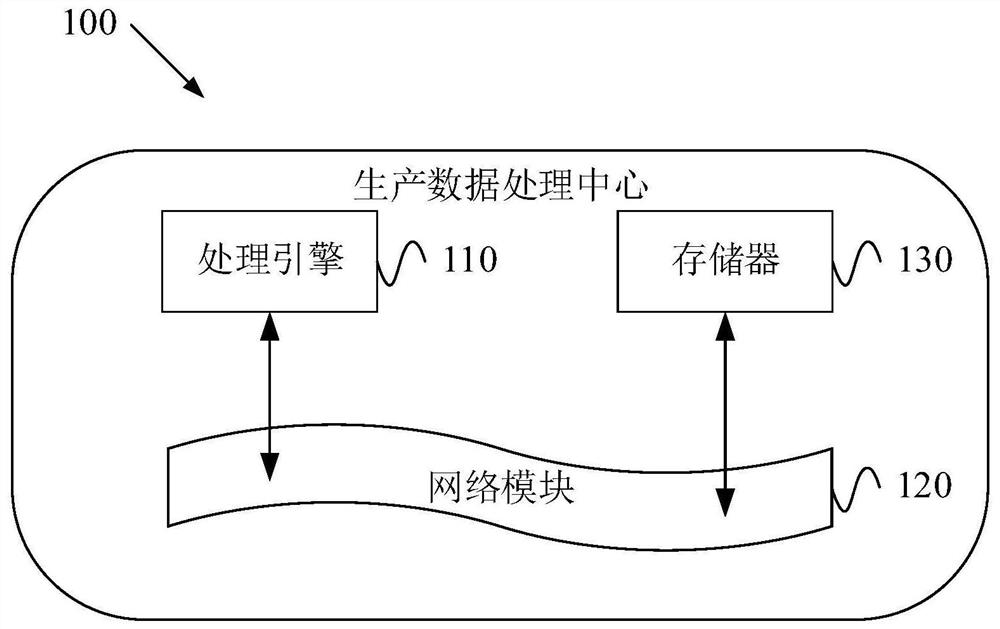

Big data processing method based on cosmetic production, and production data processing center

ActiveCN112255983AQuality assuranceProduction indicators are stableData processing applicationsGeneral water supply conservationManufacturing lineIndustrial engineering

The invention relates to a big data processing method based on cosmetic production, and a production data processing center. The method comprises the following steps: analyzing the monitoring data ofeach production line of first target production node equipment in a current cosmetic production line, and determining first production line quality evaluation information. In this way, various production indexes of the first target production node equipment can be monitored in real time through the first production line quality evaluation information, so that the first target production node equipment is controlled to modify the current equipment configuration parameters when the current equipment configuration parameters of the first target production node equipment do not meet the preset production conditions. According to the design, the first target production node equipment is controlled to modify the current equipment configuration parameters, so that the production indexes of the first target production node equipment can be adjusted in time when the production indexes of the first target production node equipment are abnormal in the operation process,the stability of various production indexes of the current cosmetic production line in operation is ensured, and the quality of the produced cosmetics can be ensured.

Owner:陈彦均

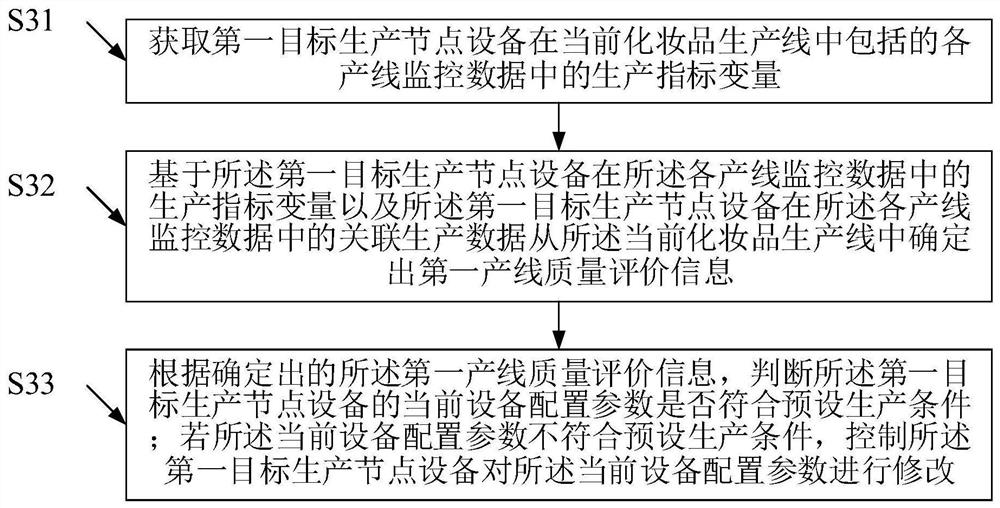

Production index variable acquisition method based on cosmetics and readable signal medium

InactiveCN113110318AQuality assuranceAdjust in timeGeneral water supply conservationMicrobiological testing/measurementMicroorganismProcess engineering

The invention relates to a production index variable acquisition method based on cosmetics and a readable signal medium. The method comprises the steps: under the condition of determining that first production line monitoring data included in the current cosmetic production line comprises the equipment identifier of first target production node equipment, acquiring the microbial monitoring data of the first target production node equipment in the first production line monitoring data, and determining a microbial pollution index of the first target production node equipment in the first production line monitoring data based on the microbial monitoring data and a production data updating path; and under the condition of determining that the first production line monitoring data does not include the equipment identifier of the first target production node equipment, determining that the microbial pollution index of the first target production node equipment in the first production line monitoring data is a production line configuration index for indicating a microbial detection process of the first target production node equipment. According to the invention, related indexes of the microorganism monitoring process of upstream and downstream node equipment can be considered, and the whole industry chain analysis of the microorganism pollution indexes is ensured.

Owner:陈彦均

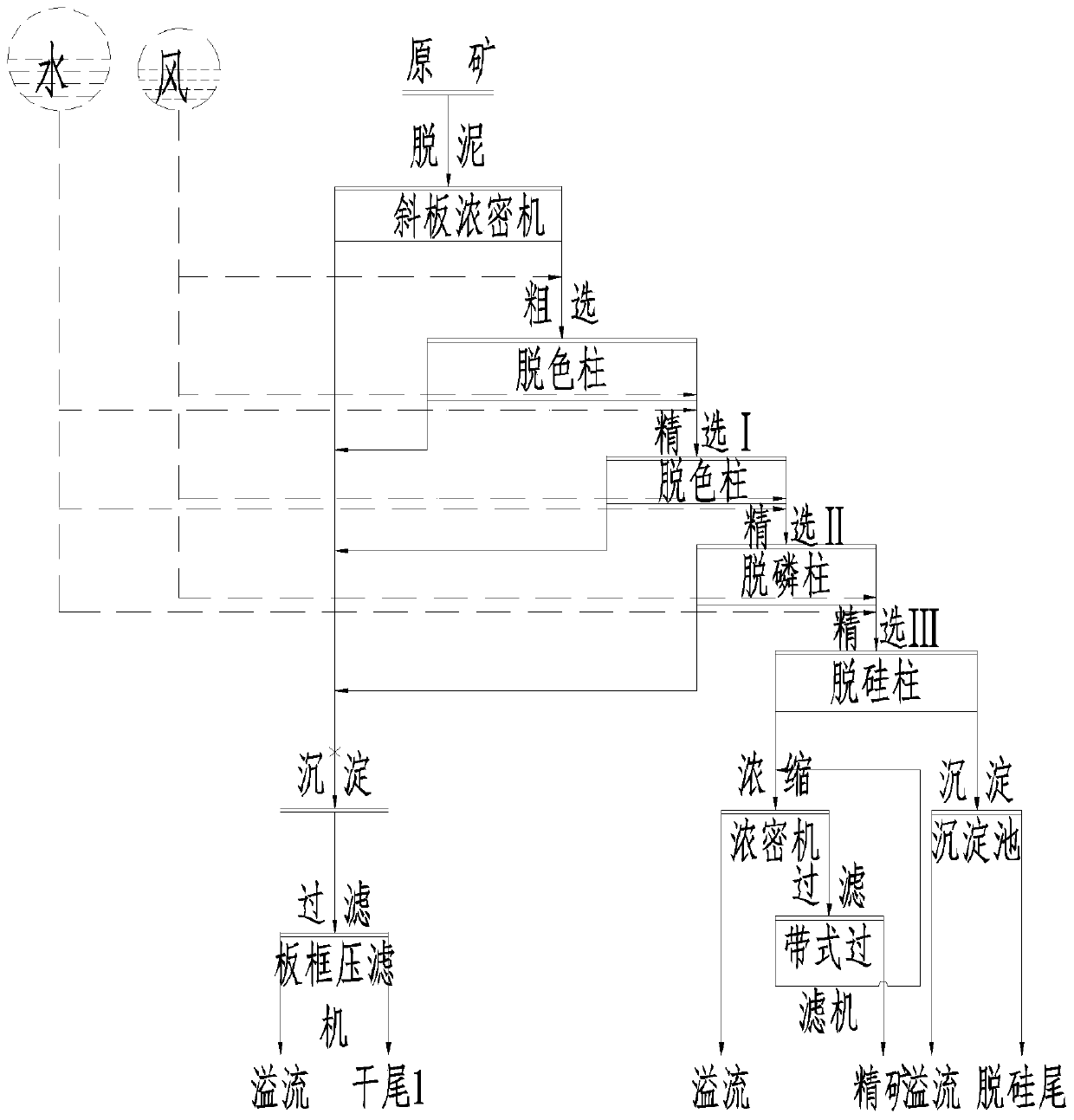

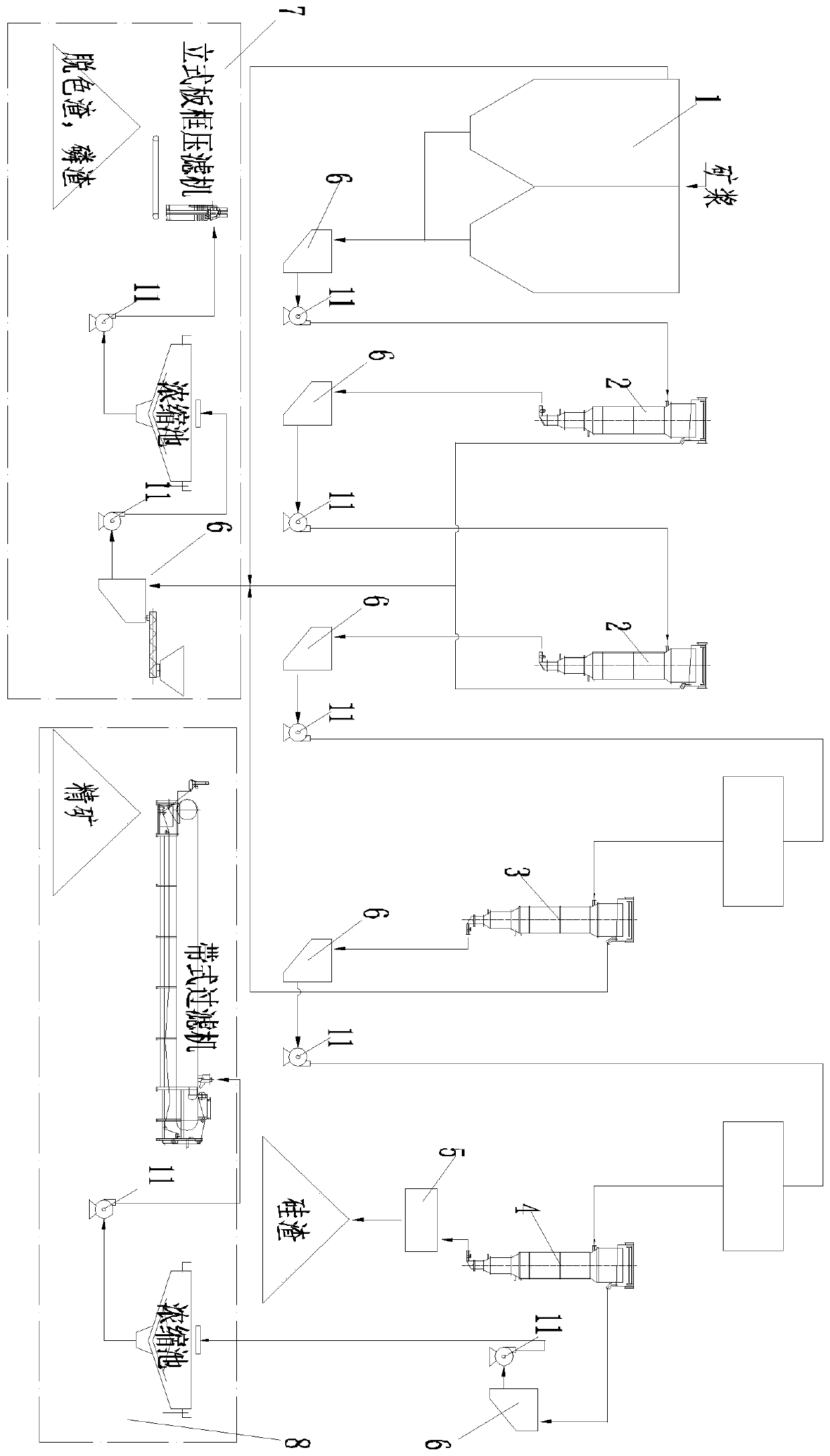

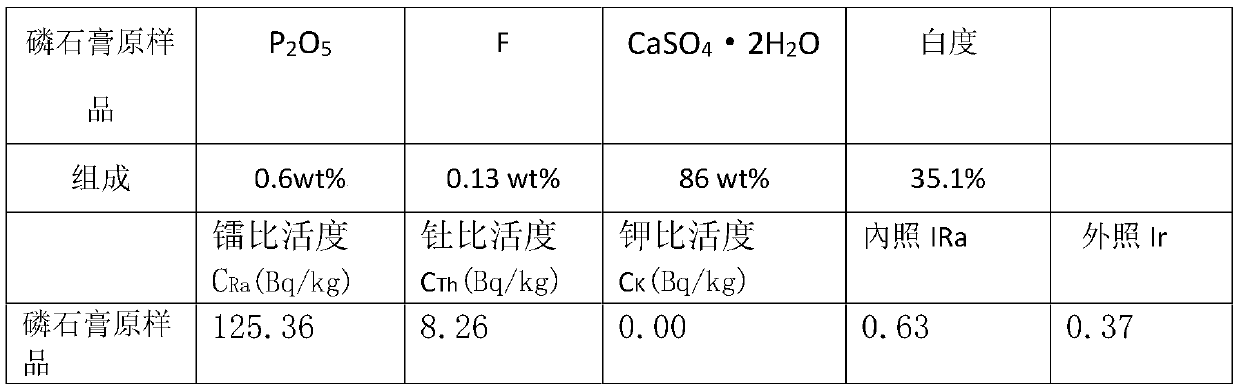

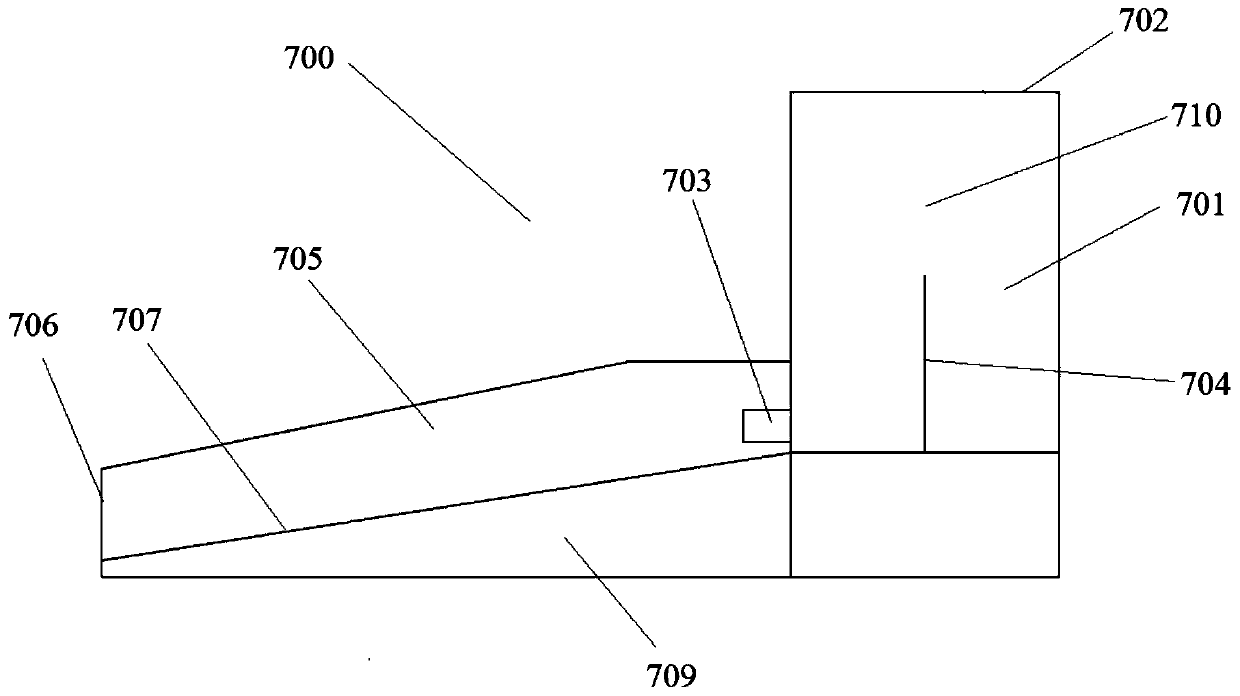

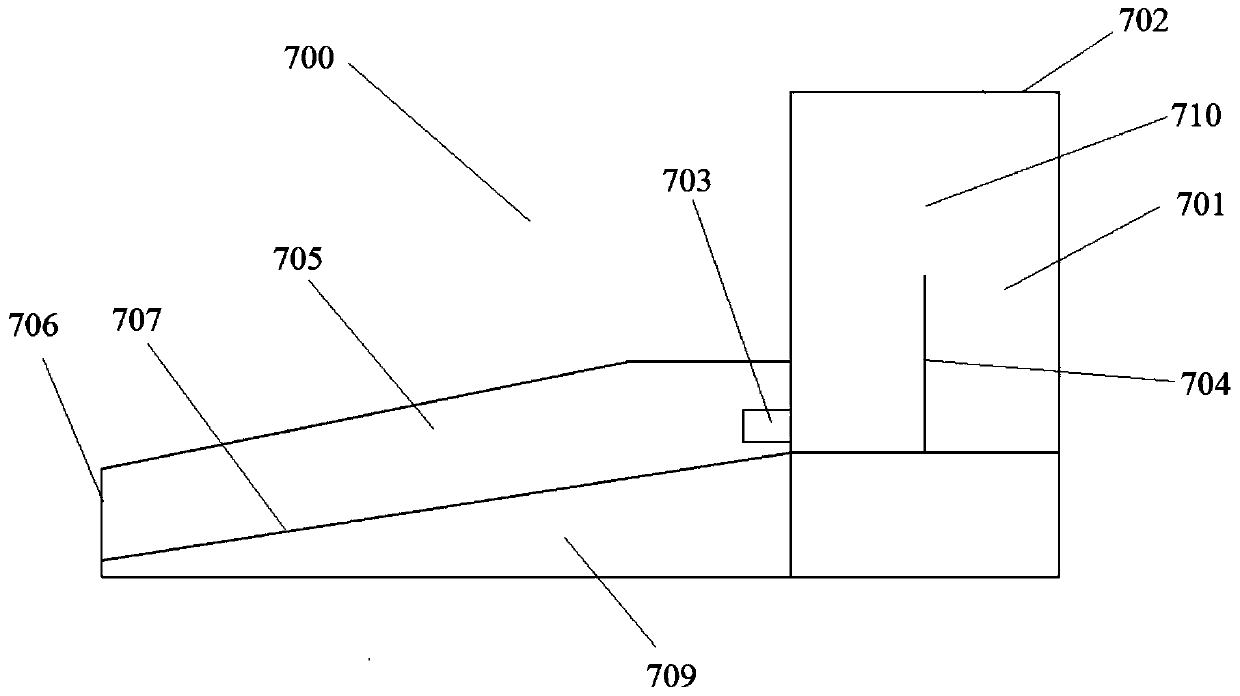

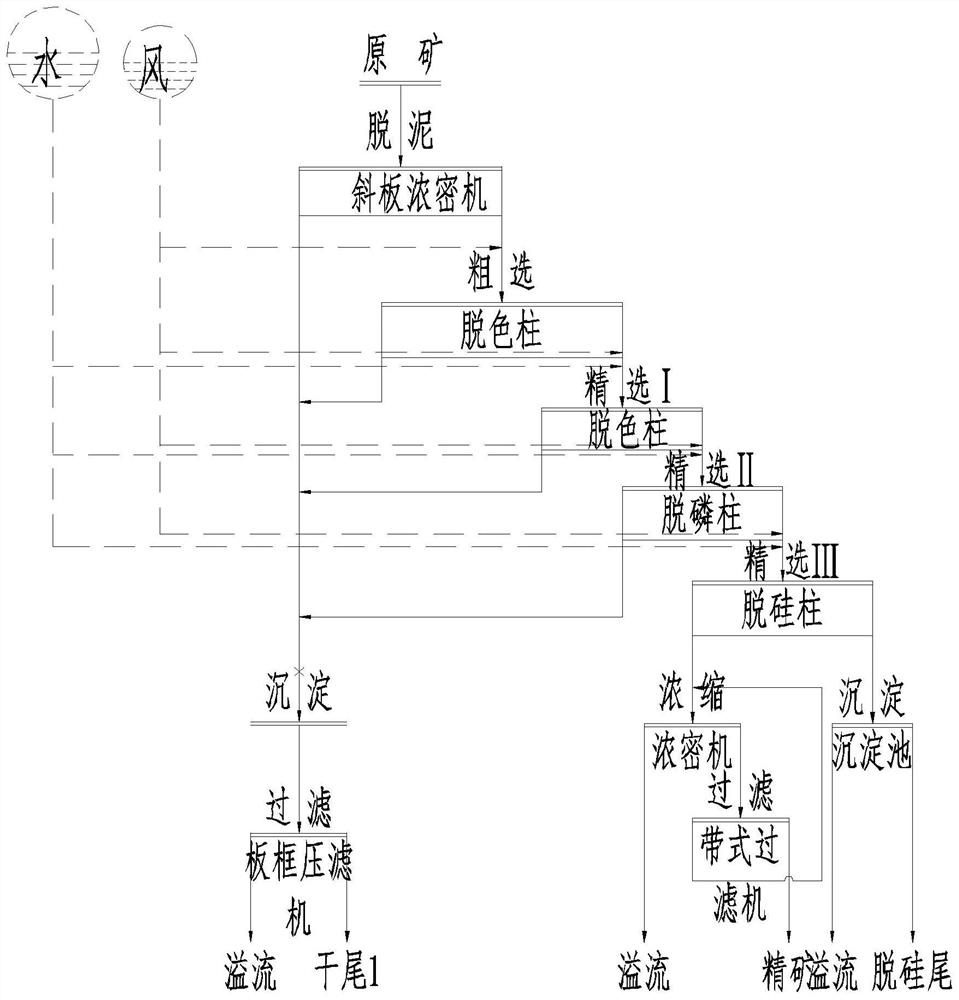

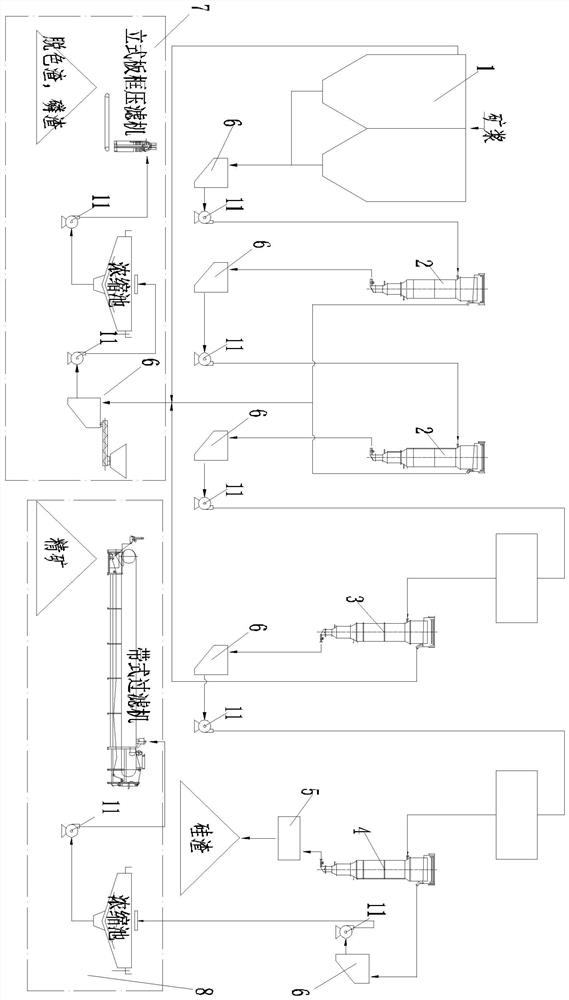

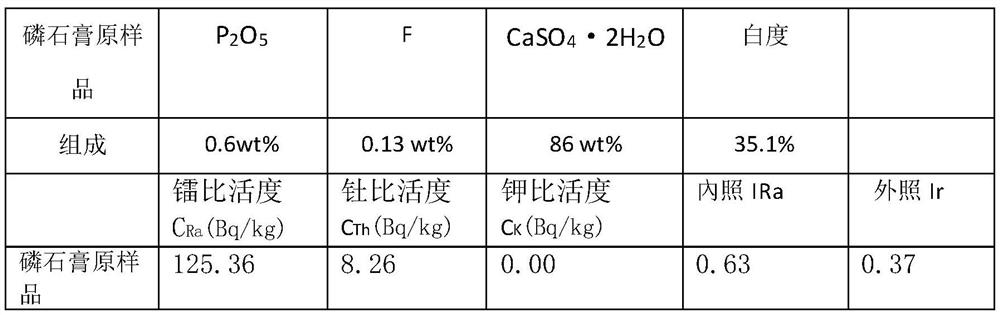

Method for purifying ardealite based on filler flotation columns and reselection columns

ActiveCN111545342AEasy to slideImprove stabilityCalcium/strontium/barium sulfatesFlotationBrickPhosphate

The invention discloses a method for purifying ardealite based on filler flotation columns and reselection columns. The method comprises the steps that organic matter is removed through flotation, dissoluble phosphorus and fluorine impurities are removed through reelection, silicon containing impurities are removed through reelection, through the difference of the densities, particle sizes and surface chemical characters between silicon dioxide, chalcedony, sulfate, sulfate, fluoride and carbonized organic matter in ardealite and the ardealite, the manner of combining reelection and flotationis adopted, the purification effects of decoloration, whitening, phosphorus reduction and impurity reduction of the ardealite are achieved, the ardealite can serve as building raw materials, silicon slag can serve as unfired hollow bricks or silicon soil modifier raw materials, and organic phosphorus containing impurity slag and the like can serve as water retention feeding block raw materials. Two kinds of waste water are generated at the same time and include waste water including no organic matter and soluble salt after desilicication filtering, and the waste water accounts for 2 / 3 of the total waste water quantity; and the other kind is waste water with organic matter and soluble salt filtered, the waste water accounts for 1 / 3 of the total waste water quantity, the waster can be cyclically utilized by itself after being treated, and the situation that the waste water is discharged out to pollute the environment is avoided.

Owner:武汉格物致知矿业有限公司 +1

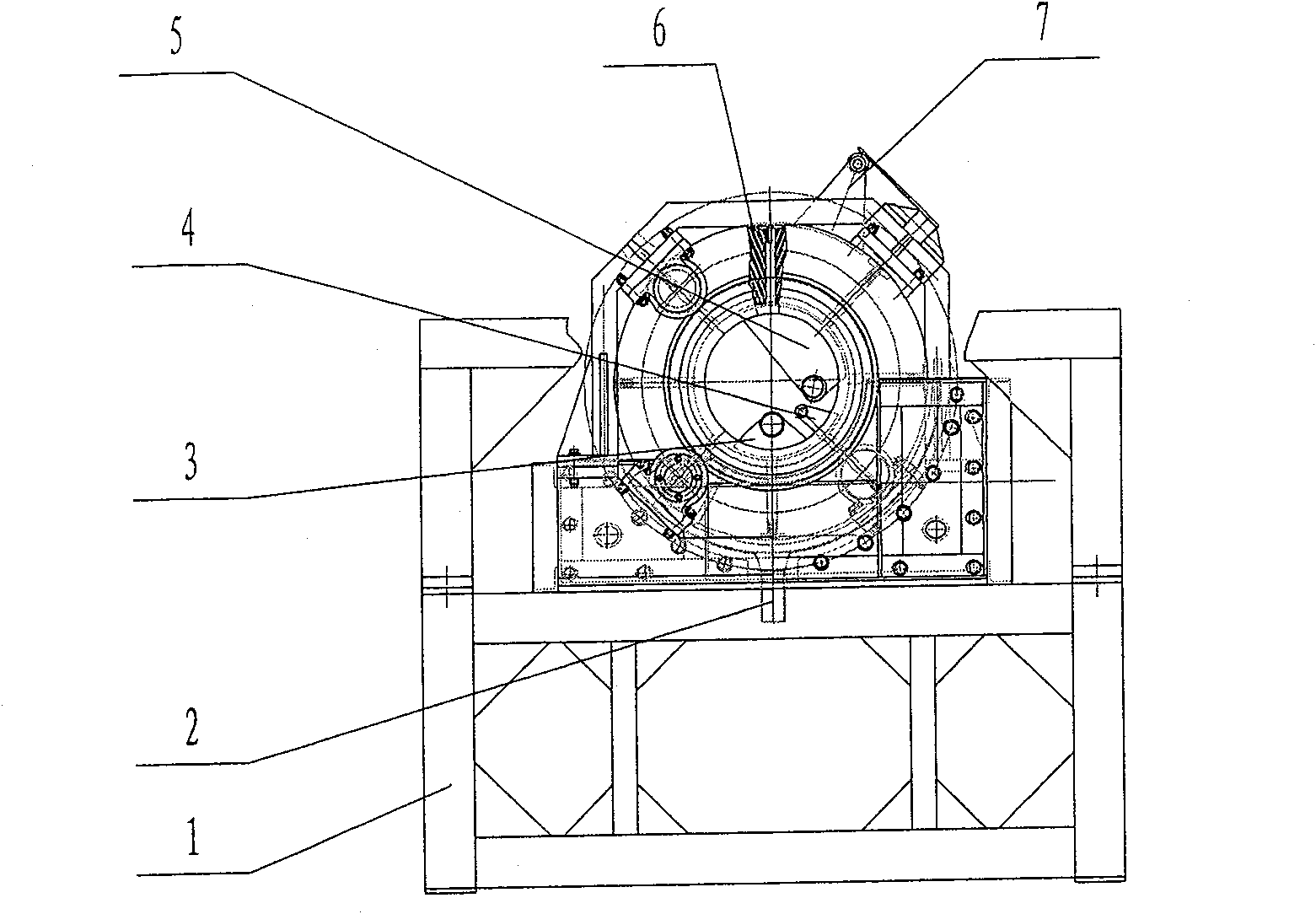

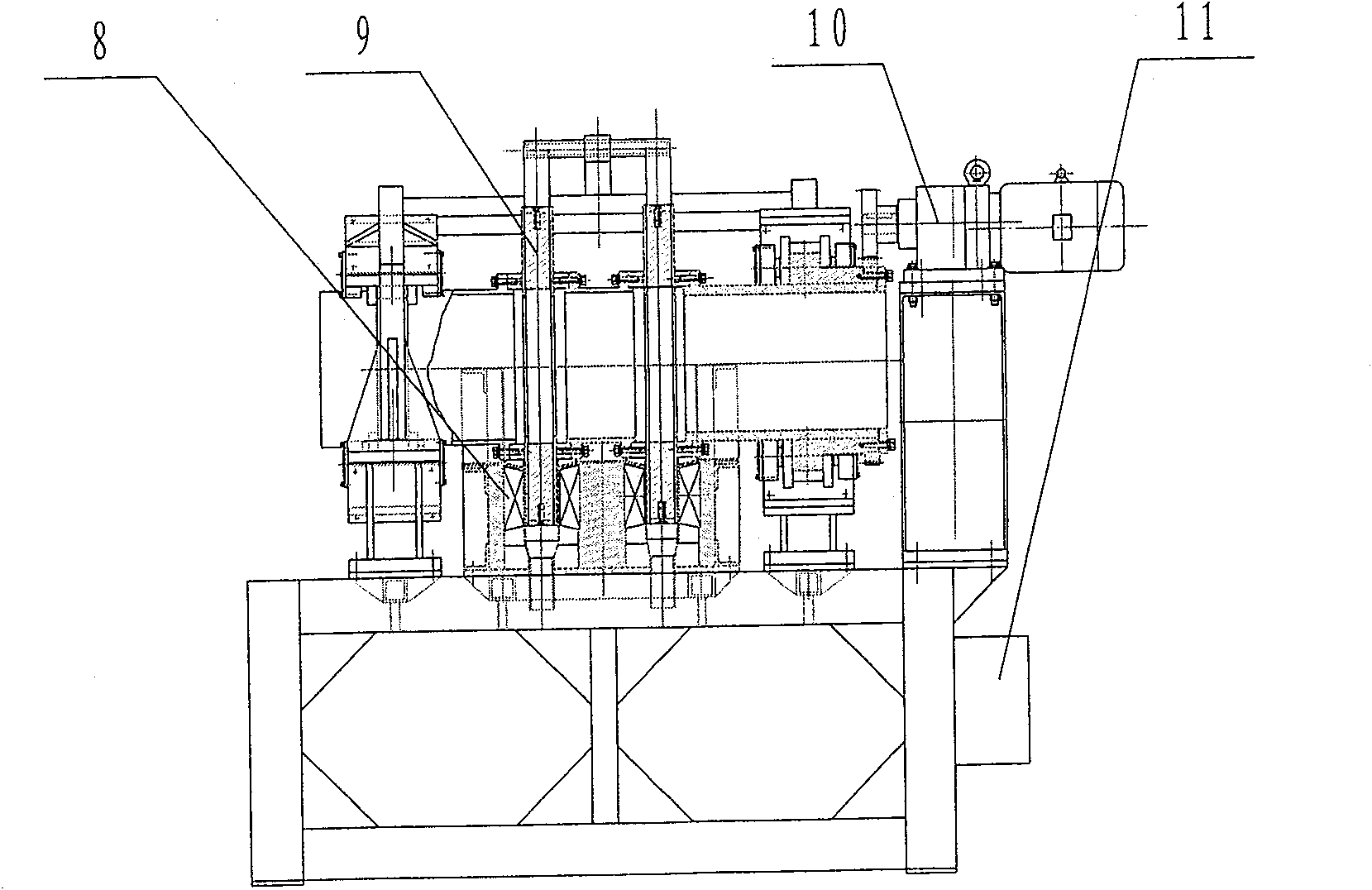

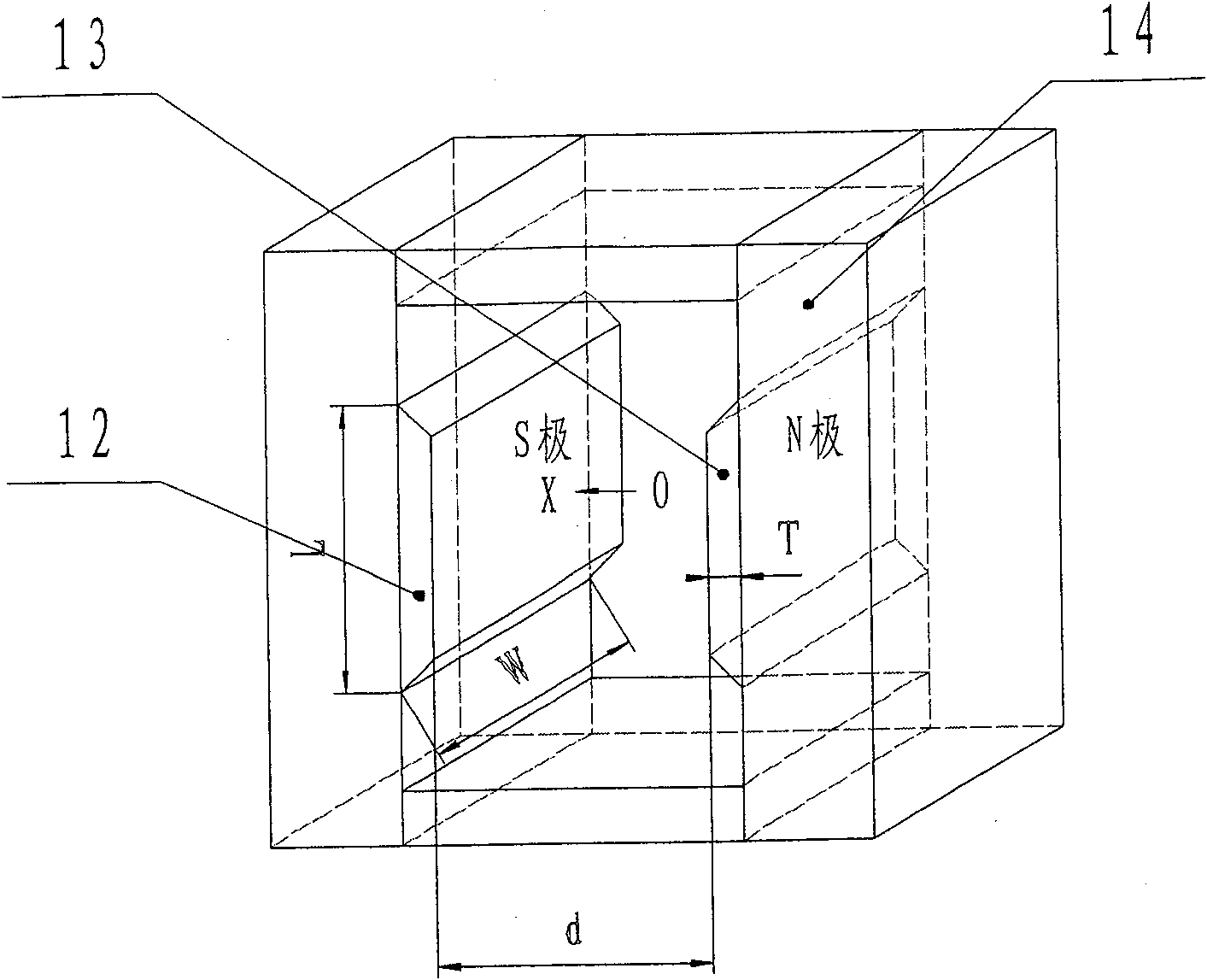

Continuous discrete type rare earth permanent magnet high gradient magnetic separator

InactiveCN100577300CEasy to handleReduce mutual adsorptionHigh gradient magnetic separatorsMagnetic mediaRare earth

The invention relates to a continuous-discrete rare earth permanent magnet high-gradient magnetic separator which can sort the fine materials under the role of high specific magnetic force generated by a strong magnetic field and high-gradient magnetic medium according to differences of magnetic coefficient of particle volume. The separator consists of a rack, a drive device, a sorting disk, a sorting box, a rare earth permanent magnet, a mine feeder, a magnetic product trough connector and a rinser. The separator is provided with a large cavity size heterotype permanent magnet shaped window frame high field strong rare earth permanent magnet, a multi-dimensional magnetic-separation media heap, a discrete ore slurry sorting box system, a multiple continuous sorting disk axial stack combination and a frequency conversion control device. The separator provided by the invention has large capacity as a single device, simple structure, convenient operation and maintenance, energy conservation, stable production process, high-precision of separation, low investment of equipment, low production cost and good sorting technical target, etc. The separator can be effectively used for micro-fine and weak magnetic metal minerals as well as impurity removal and purification of non-metallic mineral.

Owner:CHANGSHA RES INST OF MINING & METALLURGY

Indirect detection method of cyclone clogging

ActiveCN102261930AReduce processing timeProduction indicators are stableMeasurement devicesVortex flow apparatusCycloneAutomatic control

The invention relates to the technical field of ore dressing cyclones, in particular to a method for indirectly detecting cyclone blockage. According to a working principle of a cyclone, when an operating state of the cyclone is changed, operating states of last and next process equipment are inevitably influenced; an ore dressing automation instrument and a programmable logic controller (PLC) automatic control system which are widely used at present are utilized, and comprehensive judgment is performed according to three data of the ore supply quantity of a ball mill, the water supply quantity of a cyclone water feed pump and the cyclone ore supply concentration; and when the three data reach or exceed a preset limit, that the cyclone is blocked can be estimated, and the system determines the cyclone blockage and sends an alarm. Production practice proves that: by the method, the blockage phenomenon can be discovered at an early stage of cyclone blockage, and the alarm is sent; therefore, an operator can timely take adjustment measures, the processing time of the cyclone blockage is greatly shortened, a production index is stabilized, the labor intensity is lightened, and an operating environment is improved.

Owner:ANSTEEL GRP MINING CO LTD

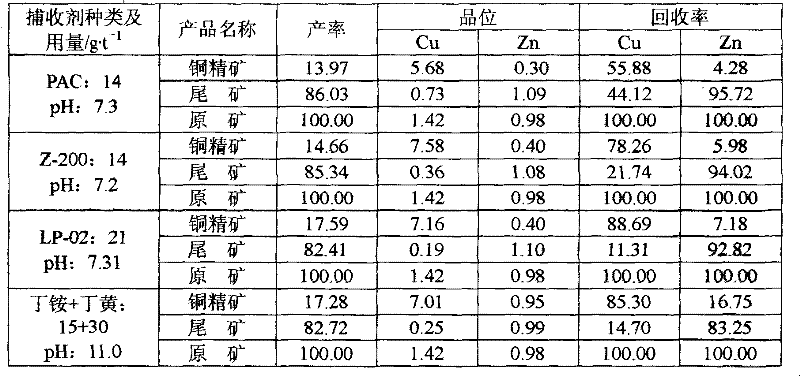

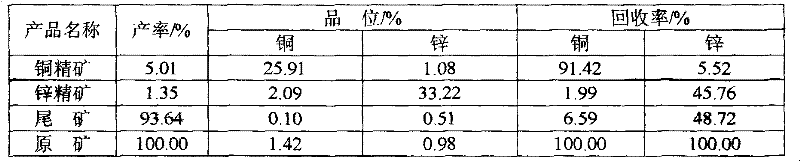

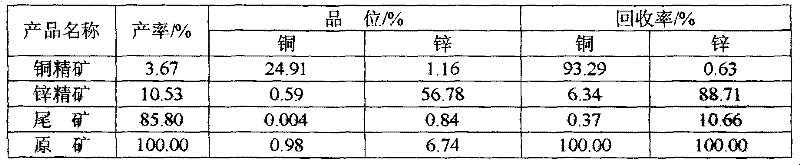

Technique for floatation separation of hard washing copper zinc sulfuration mine

The present invention relates to a floatation separation mineral concentration technology for metal sulfuration mine, especially a technique for floatation separation of hard washing copper zinc sulfuration mine. The copper ore concentrate quality produced by a general copper-zinc differential flotation technique at the present time is low and cost is high. The technique of the invention includesa step of selecting copper and selecting zinc, the copper is floated firstly, the copper and the zinc is separated by using a collecting agent LP-02 with the addition of a combined inhibitor LY-02 under a neutrality condition of the slurry pH value. The technique has a strong adaptability, a stable production target; it is not only used for recovering copper, also improves the quality of the copper and zinc ore concentrate, as well as the copper and zinc recovery rate; the production cost is reduced greatly, the earnings level is improved and it has non environmental pollution.

Owner:西部矿业集团科技发展有限公司

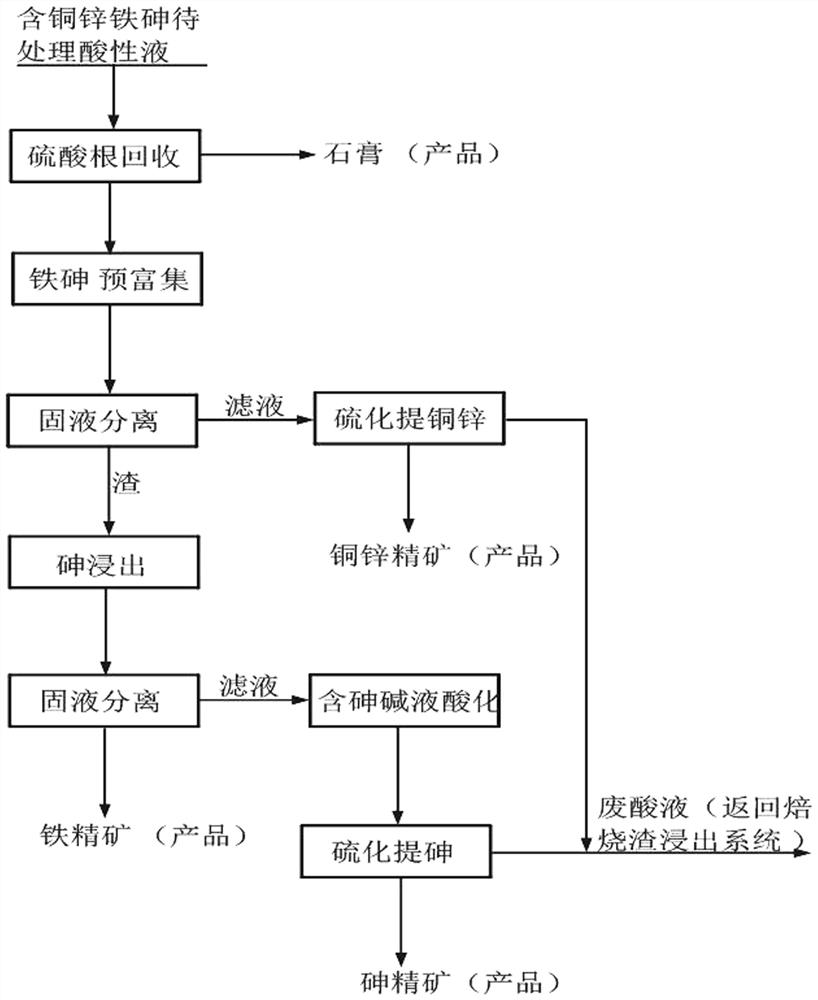

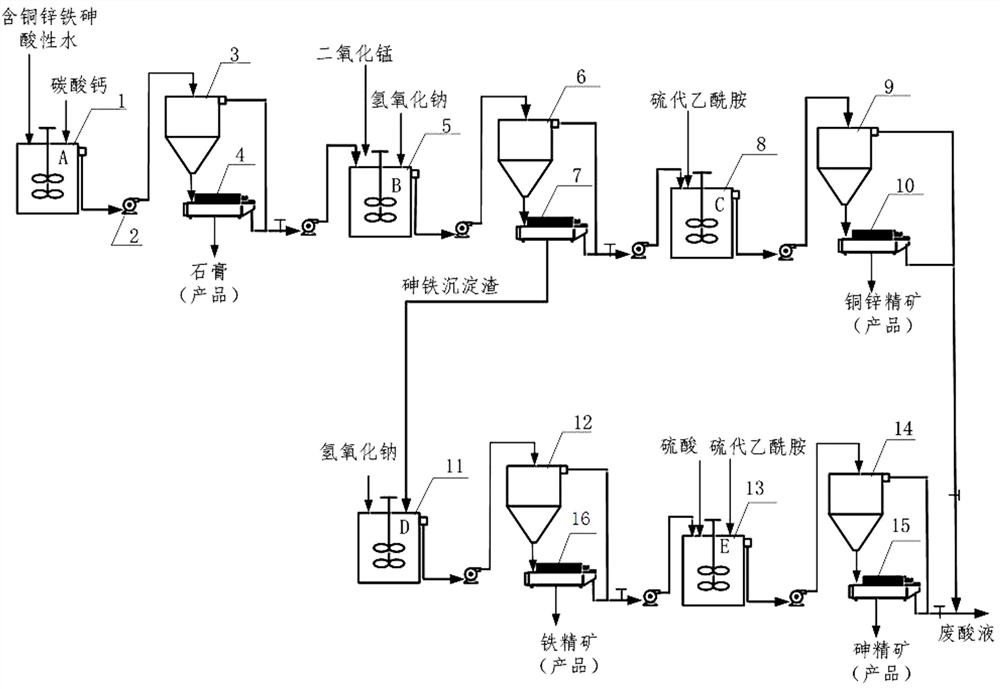

A method for recovering valuable elements from acid leaching solution of gold-containing sulfur concentrate roasting slag

ActiveCN113088702BEfficient separation and extractionReduce typesIron oxides/hydroxidesCalcium/strontium/barium sulfatesSulfate radicalsLiquid copper

Owner:YUNNAN GOLD MINING GRP

A method for recovering copper, lead and zinc from ultrafine complex cyanide tailings

A method for recovering copper, lead and zinc from ultra-fine complex cyanide tailings, which belongs to the field of mineral processing technology and includes the following steps: (1) Concentrate the ultra-fine complex cyanide tailings through a thickener, add water and sodium carbonate, and stir Make primary slurry; (2) Send the primary slurry to the flotation unit, and use one coarse, one fine and two sweep flotation processes to recover lead; the tailings obtained from the second sweep are lead sweep tailings; (3) lead After the scavenging tailings are concentrated, water is added to make a secondary slurry; the secondary slurry is sent to the flotation unit, and copper is recovered using a coarse, second fine, and two-sweep flotation process. The tailings obtained from the secondary scavenging are copper scavenged tailings. ; (4) Concentrate the copper sweep tailings and add water to make a tertiary slurry, and adjust the pH value; the zinc will be recovered using a crude, three fine, and two sweep flotation processes; the concentrate obtained from the tertiary beneficiation is a zinc concentrate. The method of the invention has simple process operation, stable production index, realizes the recycling and application of production tail water, and reduces environmental pollution.

Owner:NORTHEASTERN UNIV LIAONING

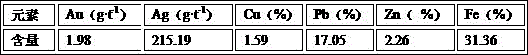

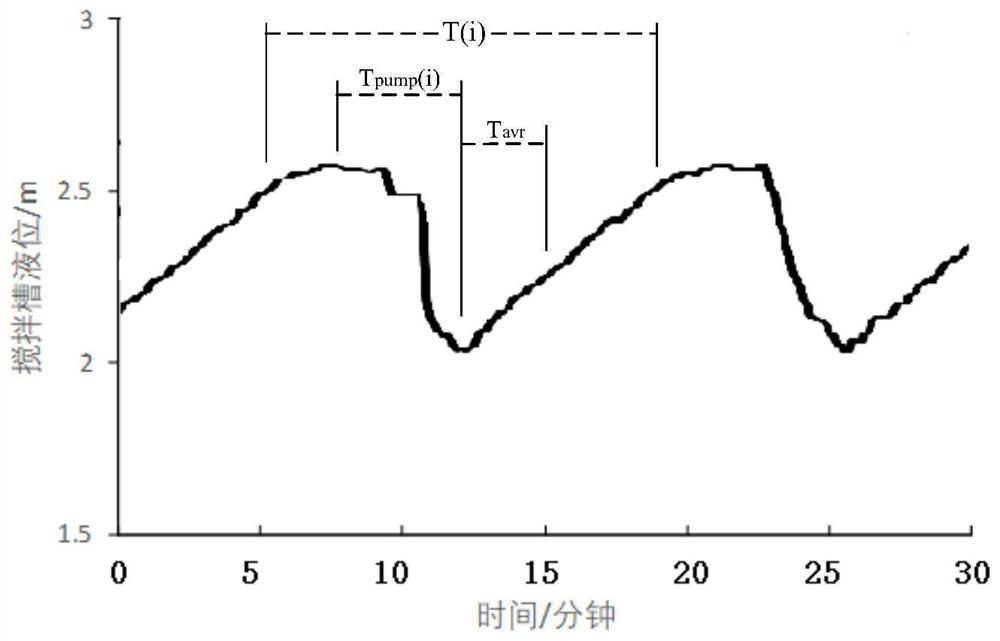

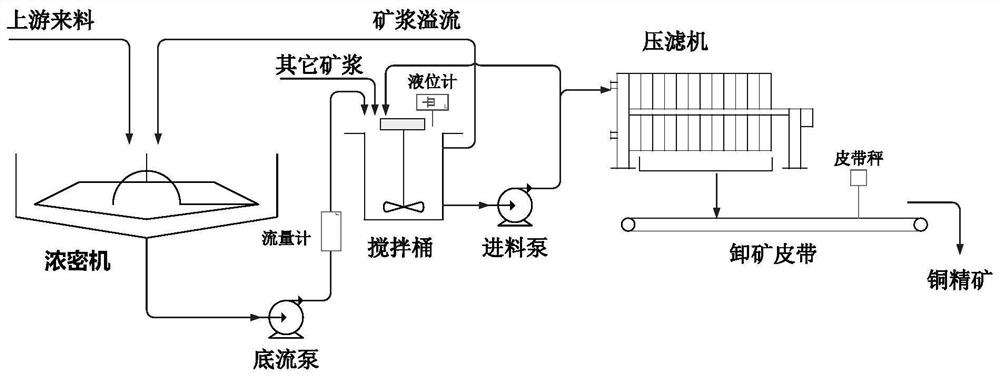

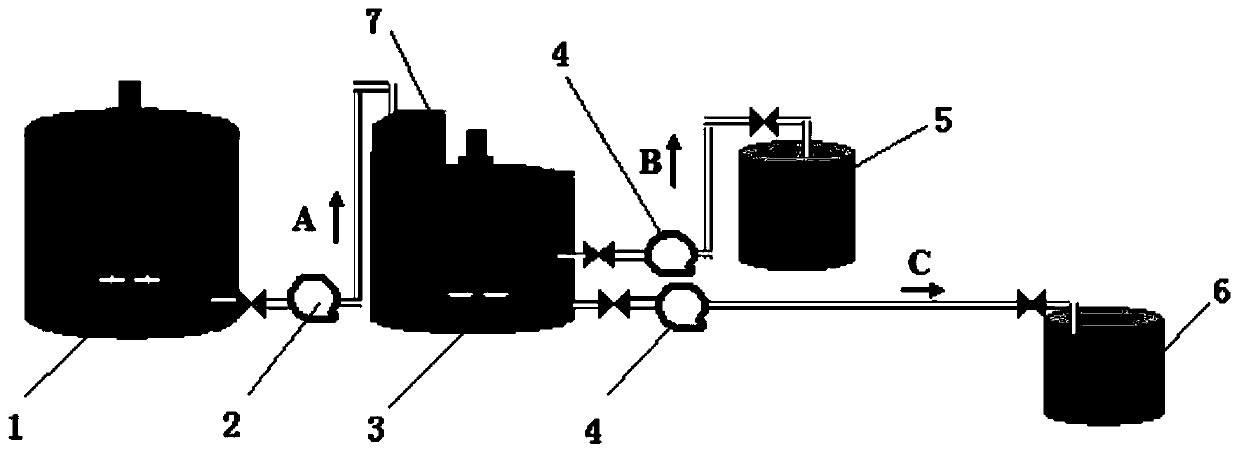

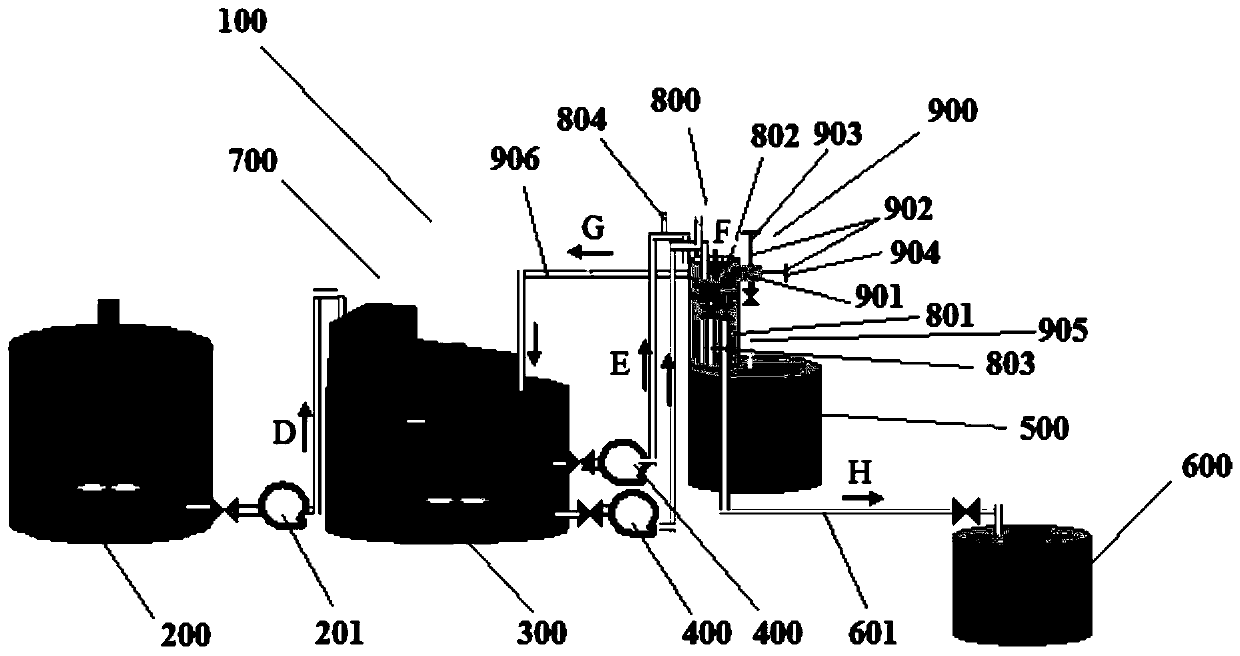

A collaborative optimization control method based on thickener-filter press production balance

ActiveCN110947237BGuaranteed stabilityStable productionFiltration circuitsControl objectiveProcess engineering

The invention discloses a synergistic optimization control method based on the production balance of a thickener-filter press. First, the real-time detection data and equipment operation data in the production process of the thickener-filter press are obtained; the thickener-filter press is established according to the obtained data. The production balance model of the filter press is used to calculate the current production capacity of the filter press to process ore pulp; based on the established production balance model, the calculated value of the underflow discharge flow of the thickener is updated, and combined with the liquid level control target value of the stirring tank, the obtained The new set value of the underflow discharge flow of the thickener; and then use the new set value of the underflow discharge flow of the thickener as the control target value to automatically adjust the speed of the thickener underflow slurry pump to achieve the production balance of the thickener-filter press and collaborative control. This method can not only ensure sufficient incoming materials for the filter press, but also ensure the stability of the underflow ore discharge of the thickener, so that the production of the thickener-filter press is always in a balanced state, ensuring a stable production process and high production efficiency .

Owner:BEIJING MINING & METALLURGICAL TECH GRP CO LTD

Undisturbed switch method for ore feeders of ball mill

ActiveCN102008994BAvoid "Bloated Belly" PhenomenonAvoid yield lossGrain treatmentsAutomatic controlEngineering

The invention belongs to the technical field of a switch method for ore feeders of a ball mill, in particular to an undisturbed switch method for ore feeders of a ball mill. On the premise of realizing ball milling basic automatic control function, namely on the premise of ensuring the normal work of systems of ore feeding amount frequency changing speed regulation of a ball mill, automatic switch of the ore feeders, and the like, the undisturbed switch control part content of the ore feeders is added into the control program. When the switch condition of the ore feeders is met, the system calls a selecting program of the ore feeders, judges the starting of two ore feeders and then calls parameters K** of the two ore feeders; the K** is divided by a set value of the current ore feeding amount to obtain the initial frequency of the ore feeders; the frequency is corrected; and the corrected frequency controls the running of the ore feeders by an executing system in t1 time. Therefore, undisturbed switch is realized.

Owner:ANSTEEL GRP MINING CO LTD

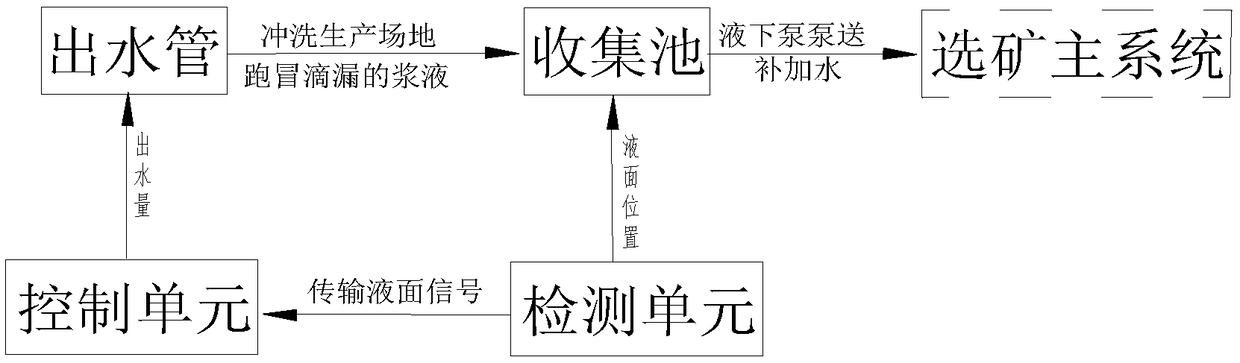

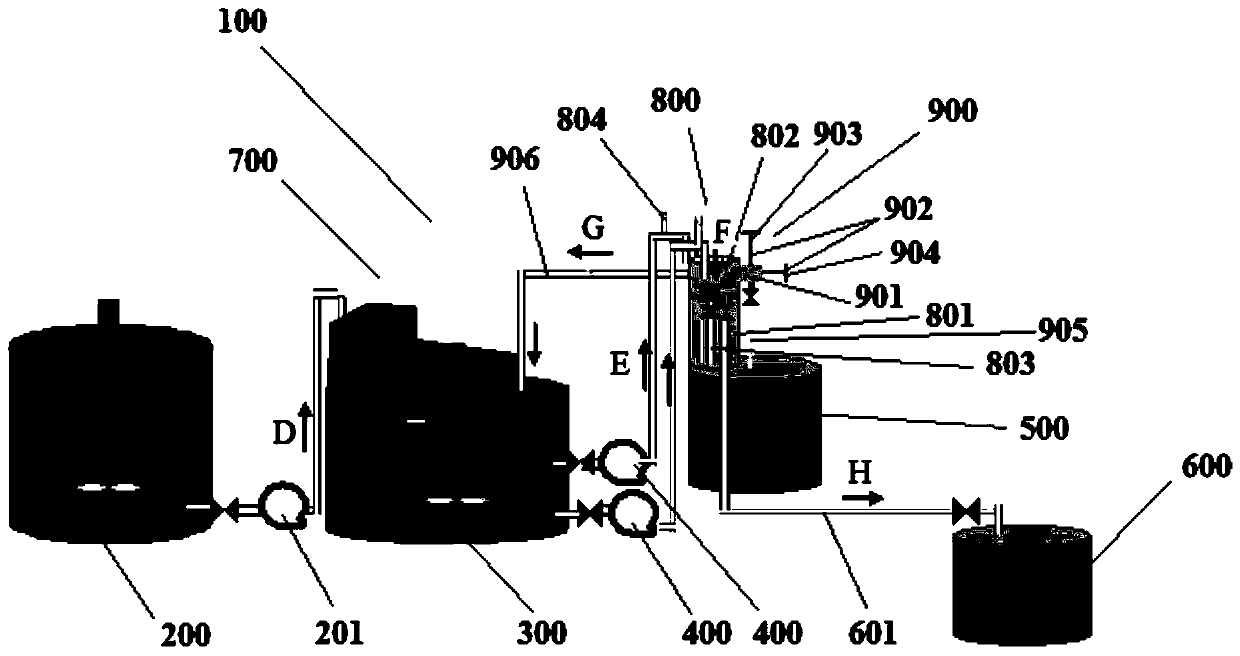

Water recycle system of beneficiation

PendingCN108980620AAvoid wastingThe amount of slurry remains constantPipeline systemsSlurryEngineering

The invention aims to provide a water recycle system of beneficiation. The water recycle system can circularly utilize leakage and venting slurry and guarantee the stability of the ore pulp amount ofa main system. The leakage and venting slurry can be effectively returned to a beneficiation main system, and unnecessary resource waste is avoided while a production site is cleaned; and a fluid pumpalways conveys the slurry into the beneficiation main system at a stable flow rate, the total flow of the slurry in the beneficiation main system is kept stable, and the production indexes in a beneficiation process are correspondingly stable as well.

Owner:TONGLING NON FERROUS METAL GROUP CORP

Drug adding device for mineral flotation and drug adding method

ActiveCN110038731AEnsure production environment is cleanStable and continuous additionFlotationFeed devicesSieveMedicine

The invention discloses a drug adding device for mineral flotation. The drug adding device comprises a filtering device, a feeding box and a linear screening type filter, wherein the filtering deviceis arranged upstream a drug stirring tank; the feeding box comprises a box body, a feeding port, a discharging port and a built-in separating plate for stopping a drug to flow; the drug flow between the feeding port and the discharging port is not completely cut off by the separating plate; a drug overflows to the discharging port from the feeding port through the separating plate, so as to realize the primary filtering for the drug; the linear screening type filter is connected with the discharging port of the feeding box so as to secondarily filter the drug; the linear screening type filtercomprises an opening type straining box, a sieve plate with sieve pores and a detachable baffle; the sieve plate has an inclined angle with the horizontal plane and is detachably arranged in the straining box; the detachable baffle is vertical to a flow direction of the drug and is arranged in the middle of the sieve plate; a gap exists between the sieve plate and the bottom of the straining box;one side of the sieve plate close to the discharging port of the feeding box is higher than the other side of the sieve plate away from the discharging port of the feeding box. The invention also provides a drug adding method for mineral flotation. The drug adding device and the drug adding method provided by the invention can be widely applied to the industries of metallurgy, coals, nonferrous industry, and the like.

Owner:TAIYUAN IRON & STEEL GROUP +1

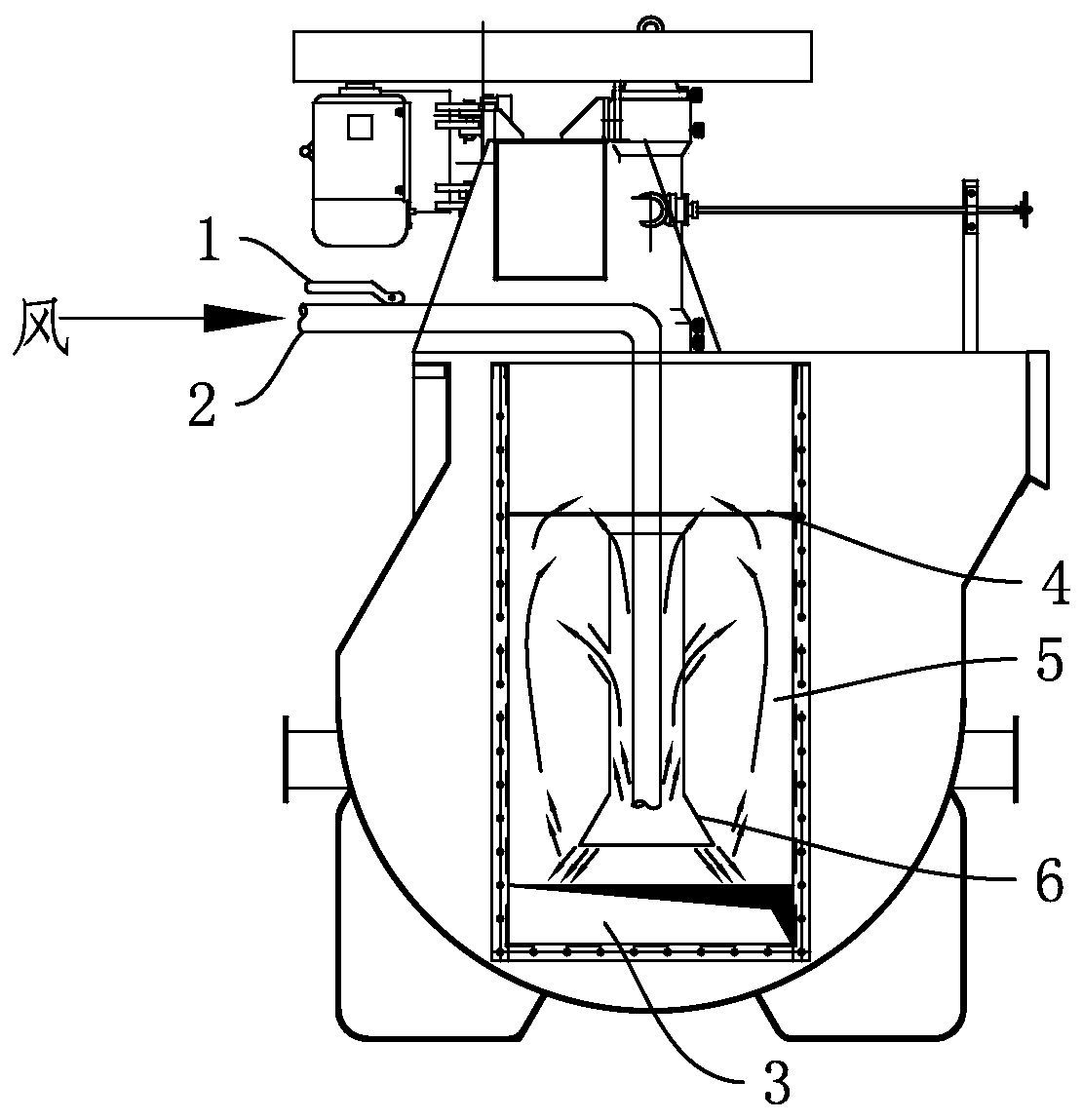

Flotation machine middle box anti-ore-settling device and working method

ActiveCN111013830AMine sinking preventionSolve the problem of sinking minesFlotationMining engineeringMineralogy

The invention discloses a flotation machine middle box anti-ore-settling device and a working method. According to the device, an air pipe (2) is led out of a main pipeline of an air supply system andinserted into a middle box (5) of a flotation machine, a flashboard (4) is arranged on the upper middle portion in the middle box (5), a circulating barrel (6) is arranged in the middle box (5) and is in an inverted funnel shape, and a coarse sand channel (3) is formed in the bottom of the middle box (5). The device can effectively prevent ore sedimentation of the middle box of a flotation cell,thoroughly solves the problem of ore settling of the middle box, and reduces the abnormal shutdown frequency.

Owner:中矿金业股份有限公司

An automatic control method for lime addition amount in copper flotation process

ActiveCN110193427BGuaranteed uptimeProduction indicators are stableFlotationAutomatic controlTarget control

The invention discloses an automatic control method for lime addition in a copper flotation process. Firstly, the current flotation raw ore working conditions are classified through off-line data; the optimum pH setting value calculation model parameters for each classified working condition are determined; real-time Obtain the online measurement data in the copper flotation process; judge the current working condition classification according to the obtained raw ore copper grade measurement value and raw ore sulfur grade measurement value, and obtain the optimal PH setting value; according to the obtained concentrate copper grade measurement value 1. The deviation between the tailings copper grade measurement value and the grade target control range, the optimal pH setting value is automatically adjusted through the PH optimization control rule; according to the difference between the obtained pH measurement value and the optimal pH setting value The deviation and change amount, the lime addition amount is automatically adjusted through the PH stability controller adjusted by the variable coefficient. The method can ensure that the pH value of the pulp is quickly stabilized within the optimal range, thereby stabilizing the production index and ensuring the stable operation of the flotation process.

Owner:BEIJING MINING & METALLURGICAL TECH GRP CO LTD

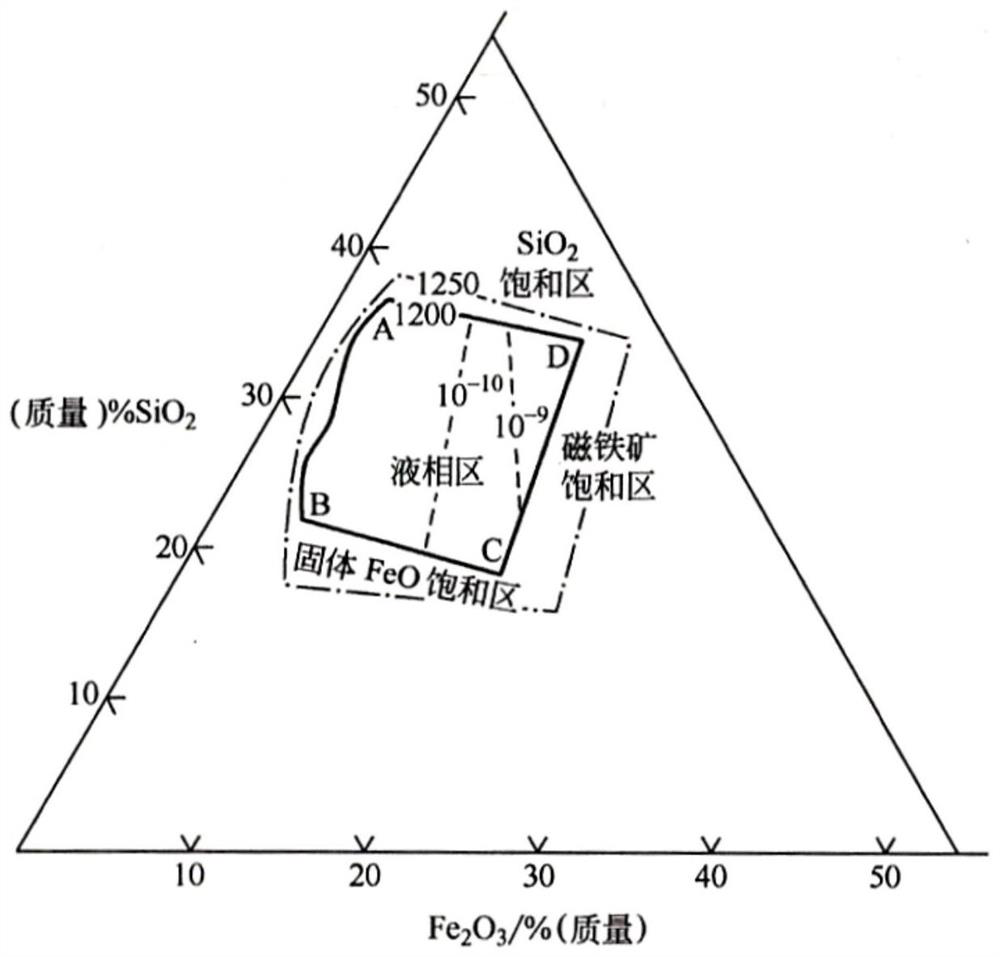

Oxygen-enriched side-blowing smelting method of impurity-poor high-silicon copper concentrate

InactiveCN111041225BLow costReduce shipping costsProcess efficiency improvementSmelting processCopper

The oxygen-enriched side blowing smelting method of a kind of impurity-poor high-silicon copper concentrate of the present invention is as follows: take impurity-poor high-silicon low-copper copper concentrate 10-64% and impurity-poor high-silicon low-sulfur copper concentrate ≤ 44%, Add copper-rich high-sulfur ore 29‑42% and slag concentrate 4‑10% to it, mix evenly to obtain composite ore, and add 2.15‑4.5% CaO to the composite ore, add it to the side blowing furnace, and add the composite ore quality 3.6-6.8% fuel is smelted, the melting temperature is 1250-1290°C, during the smelting process, oxygen-enriched air with a concentration of 72-84% is continuously blown into the side blowing furnace, and the injection flow rate is 17000-23000Nm 3 / h, to obtain matte liquid and copper smelting slag. This method fully solves the problem of insufficient supply and quality of domestic copper concentrate. Using high-silicon ore as the ingredient skeleton, by adjusting the ratio, combined with measures such as optimizing the side-blowing smelting slag type, increasing the oxygen-enriched concentration, and improving the bed capacity, it can achieve Achieved a breakthrough of zero flux rate, and optimized the comprehensive matte grade and slag copper content data.

Owner:吉林紫金铜业有限公司

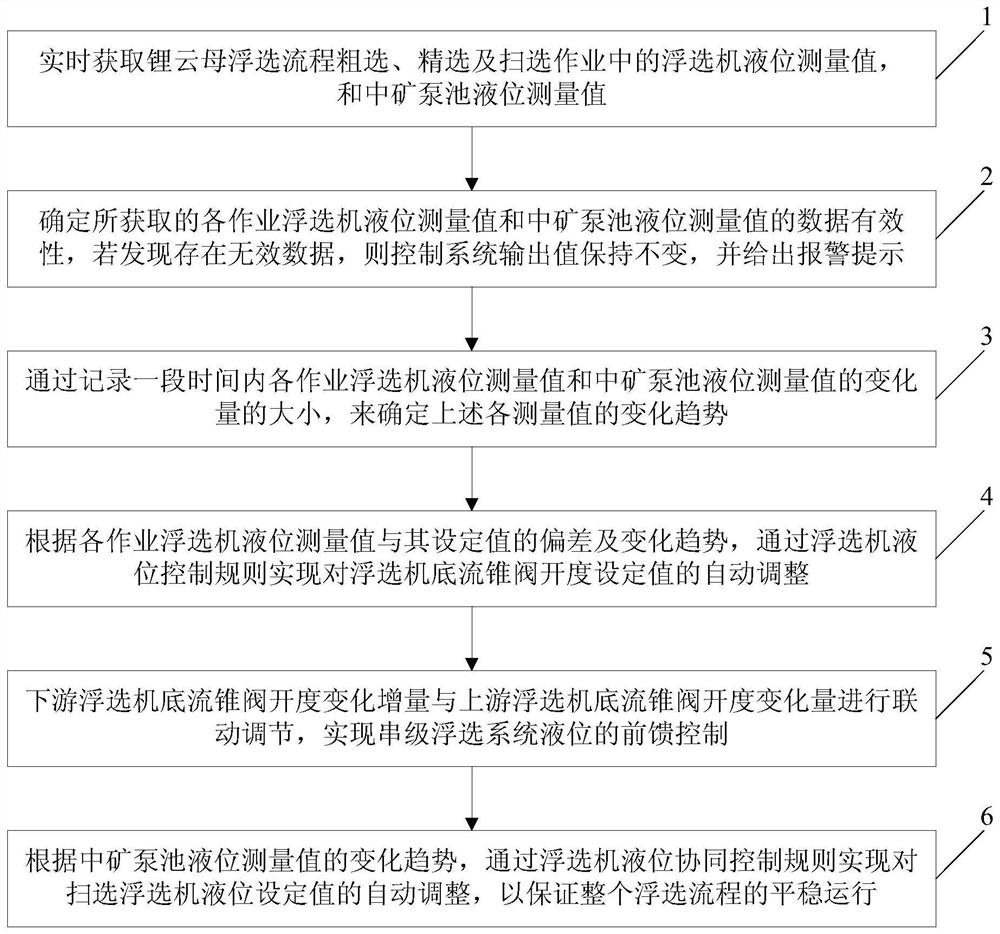

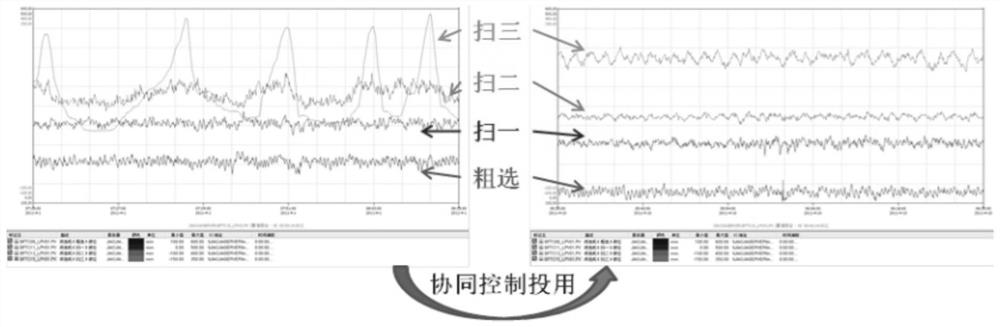

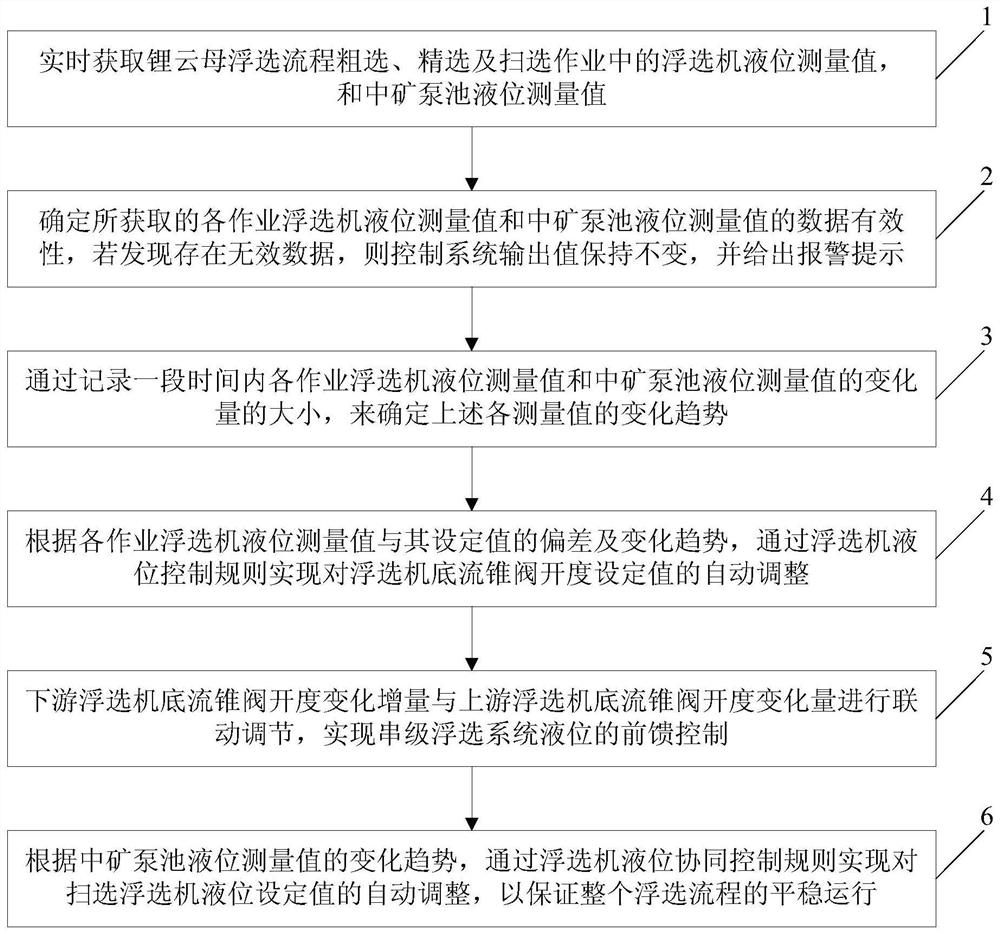

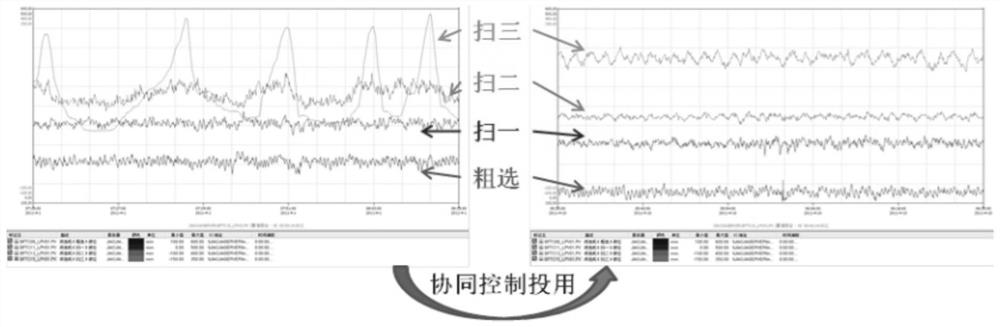

A kind of intelligent control method of liquid level of lepidolite flotation system

ActiveCN112517248BGuaranteed uptimeProduction indicators are stableLevel controlFlotationLiquid level measurementProcess engineering

The invention discloses an intelligent control method for the liquid level of a lepidolite flotation system. According to the recorded liquid level measurement value of the flotation machine and the liquid level measurement value of the medium mine pump pool, the change trend is obtained; step 3, according to the deviation of the real-time measurement value of the liquid level of the flotation machine and the set value of the liquid level of the flotation machine and the The change trend of the measured value of the liquid level of the flotation machine, the change of the set value of the bottom flow cone valve of the flotation machine determined by the liquid level control rule of the flotation machine automatically adjusts the opening of the bottom flow cone valve of the flotation machine, so that the actual liquid level and the bottom flow cone valve of the flotation machine are automatically adjusted. The set value of the liquid level is the same; step 4, according to the change trend of the liquid level measurement value of the pump pool in the mine, automatically adjust the set value of the liquid level of the scavenger flotation machine through the coordinated control rule of the liquid level of the flotation machine until it is stable. The method can ensure that the liquid level of the lepidolite flotation system is quickly and stabilized within a reasonable set range, stabilizes the production index, and ensures the stable operation of the flotation process.

Owner:YICHUN TANTALUM & NIOBIUM MINE +1

Big data processing method and production data processing center based on cosmetics production

ActiveCN112255983BQuality assuranceProduction indicators are stableData processing applicationsGeneral water supply conservationProcess engineeringManufacturing line

The present invention relates to a big data processing method based on cosmetics production and a production data processing center, which analyzes the monitoring data of each production line included in the current cosmetics production line of the first target production node equipment to determine the quality evaluation of the first production line Information, so that the production indicators of the first target production node equipment can be monitored in real time through the first production line quality evaluation information, so as to control the first target when the current equipment configuration parameters of the first target production node equipment do not meet the preset production conditions The production node device modifies the current device configuration parameters. With this design, by controlling the first target production node equipment to modify the current equipment configuration parameters, the production index of the first target production node equipment can be adjusted in time when the production index of the first target production node equipment is abnormal during operation, ensuring that the current cosmetics production line The stability of various production indicators during operation can ensure the quality of the cosmetics produced.

Owner:陈彦均

Intelligent control method for liquid level of lepidolite flotation system

ActiveCN112517248AGuaranteed uptimeProduction indicators are stableMachines/enginesFlotationLiquid level measurementControl engineering

The invention discloses an intelligent control method for the liquid level of a lepidolite flotation system. The intelligent control method comprises the steps that 1, a flotation machine liquid levelmeasurement value and a middling pump pool liquid level measurement value in flotation operation are obtained in real time; 2, a change trend is obtained according to the recorded liquid level measurement value of a flotation machine and the recorded liquid level measurement value of a middling pump pool; 3, according to the deviation between the real-time flotation machine liquid level measuredvalue and the flotation machine liquid level set value and the change trend of the flotation machine liquid level measured value, the opening degree of a flotation machine underflow cone valve is automatically adjusted according to the set value variable quantity, determined through a flotation machine liquid level control rule, of the flotation machine underflow cone valve, and the actual liquidlevel is made to be consistent with the liquid level set value; and 4, the set value of the liquid level of a scavenging flotation machine is automatically adjusted through the flotation machine liquid level cooperative control rule according to the change trend of the measured value of the liquid level of the middling pump pool until the set value is stable. The method can ensure that the liquidlevel of the lepidolite flotation system is rapidly stabilized within a reasonably set range, production indexes are stabilized, and stable operation of the flotation process is ensured.

Owner:YICHUN TANTALUM & NIOBIUM MINE +1

Method for indirectly detecting cyclone blockage

ActiveCN102261930BReduce processing timeProduction indicators are stableMeasurement devicesVortex flow apparatusCycloneAutomatic control

The invention relates to the technical field of ore dressing cyclones, in particular to a method for indirectly detecting cyclone blockage. According to a working principle of a cyclone, when an operating state of the cyclone is changed, operating states of last and next process equipment are inevitably influenced; an ore dressing automation instrument and a programmable logic controller (PLC) automatic control system which are widely used at present are utilized, and comprehensive judgment is performed according to three data of the ore supply quantity of a ball mill, the water supply quantity of a cyclone water feed pump and the cyclone ore supply concentration; and when the three data reach or exceed a preset limit, that the cyclone is blocked can be estimated, and the system determines the cyclone blockage and sends an alarm. Production practice proves that: by the method, the blockage phenomenon can be discovered at an early stage of cyclone blockage, and the alarm is sent; therefore, an operator can timely take adjustment measures, the processing time of the cyclone blockage is greatly shortened, a production index is stabilized, the labor intensity is lightened, and an operating environment is improved.

Owner:ANSTEEL GRP MINING CO LTD

Chemical addition equipment and chemical addition method for beneficiation and flotation

ActiveCN110038731BEliminate the risk of cloggingEliminate high level overflowFlotationFeed devicesBiochemical engineeringMineral flotation

The invention discloses a drug adding device for mineral flotation. The drug adding device comprises a filtering device, a feeding box and a linear screening type filter, wherein the filtering deviceis arranged upstream a drug stirring tank; the feeding box comprises a box body, a feeding port, a discharging port and a built-in separating plate for stopping a drug to flow; the drug flow between the feeding port and the discharging port is not completely cut off by the separating plate; a drug overflows to the discharging port from the feeding port through the separating plate, so as to realize the primary filtering for the drug; the linear screening type filter is connected with the discharging port of the feeding box so as to secondarily filter the drug; the linear screening type filtercomprises an opening type straining box, a sieve plate with sieve pores and a detachable baffle; the sieve plate has an inclined angle with the horizontal plane and is detachably arranged in the straining box; the detachable baffle is vertical to a flow direction of the drug and is arranged in the middle of the sieve plate; a gap exists between the sieve plate and the bottom of the straining box;one side of the sieve plate close to the discharging port of the feeding box is higher than the other side of the sieve plate away from the discharging port of the feeding box. The invention also provides a drug adding method for mineral flotation. The drug adding device and the drug adding method provided by the invention can be widely applied to the industries of metallurgy, coals, nonferrous industry, and the like.

Owner:太原钢铁(集团)有限公司 +1

A method for purifying phosphogypsum based on a flotation column with a filler and a gravity column

ActiveCN111545342BEasy to slideImprove stabilityCalcium/strontium/barium sulfatesFlotationBrickPhosphate

Owner:武汉格物致知矿业有限公司 +1

Production line quality evaluation method based on cosmetics and production data processing center

InactiveCN113110319AQuality assuranceAdjust in timeGeneral water supply conservationMicrobiological testing/measurementMicrobial pollutionProcess engineering

The invention relates to a production line quality evaluation method based on cosmetics and a production data processing center, and the method comprises the steps: determining index description matrixes corresponding to a microbial pollution index, a water quality pollution index and an equipment cleanliness index respectively, determining a production line index evaluation matrix of first target production node equipment in each production line monitoring data according to the microbial pollution index, the water quality pollution index and the equipment cleanliness index of the first target production node equipment in each production line monitoring data and an index description matrix corresponding to each index, and determining first production line quality evaluation information based on the production line index evaluation matrix of the first target production node equipment in each production line monitoring data and associated production data of the first target production node equipment in each production line monitoring data. It can be ensured that the first production line quality evaluation information reflects production index influence conditions of the first target production node equipment in multiple pieces of production node equipment, and an accurate and reliable analysis basis is provided for subsequent production line quality monitoring.

Owner:陈彦均

A kind of low temperature resistant zinc oxide ore flotation composite agent and its preparation method and application

ActiveCN111940146BReduce problems such as difficult flowImprove low temperature flotation environmentFlotationProcess efficiency improvementAcetic acidSodium phosphates

The invention relates to a low-temperature-resistant zinc oxide ore flotation compound agent and a preparation method and application thereof. The compound agent comprises a compound regulator and a compound collector, wherein the compound regulator is composed of sodium hexametaphosphate, starch, humic acid Sodium is mixed in a weight ratio of 5~7:3~6:1~3; the composite collector is composed of octadecylamine, glacial acetic acid, sodium benzyl hydroxamate and waste oil in a weight ratio of 5~8:5~8 :1~3:1~3 mixed. The use of these two compound beneficiation agents eliminates the need for desliming in the flotation process, thereby enhancing the recovery of fine-grained zinc oxide, and the beneficiation recovery rate of zinc oxide ore can be increased by 5-15%.

Owner:云南省地质矿产勘查开发局中心实验室

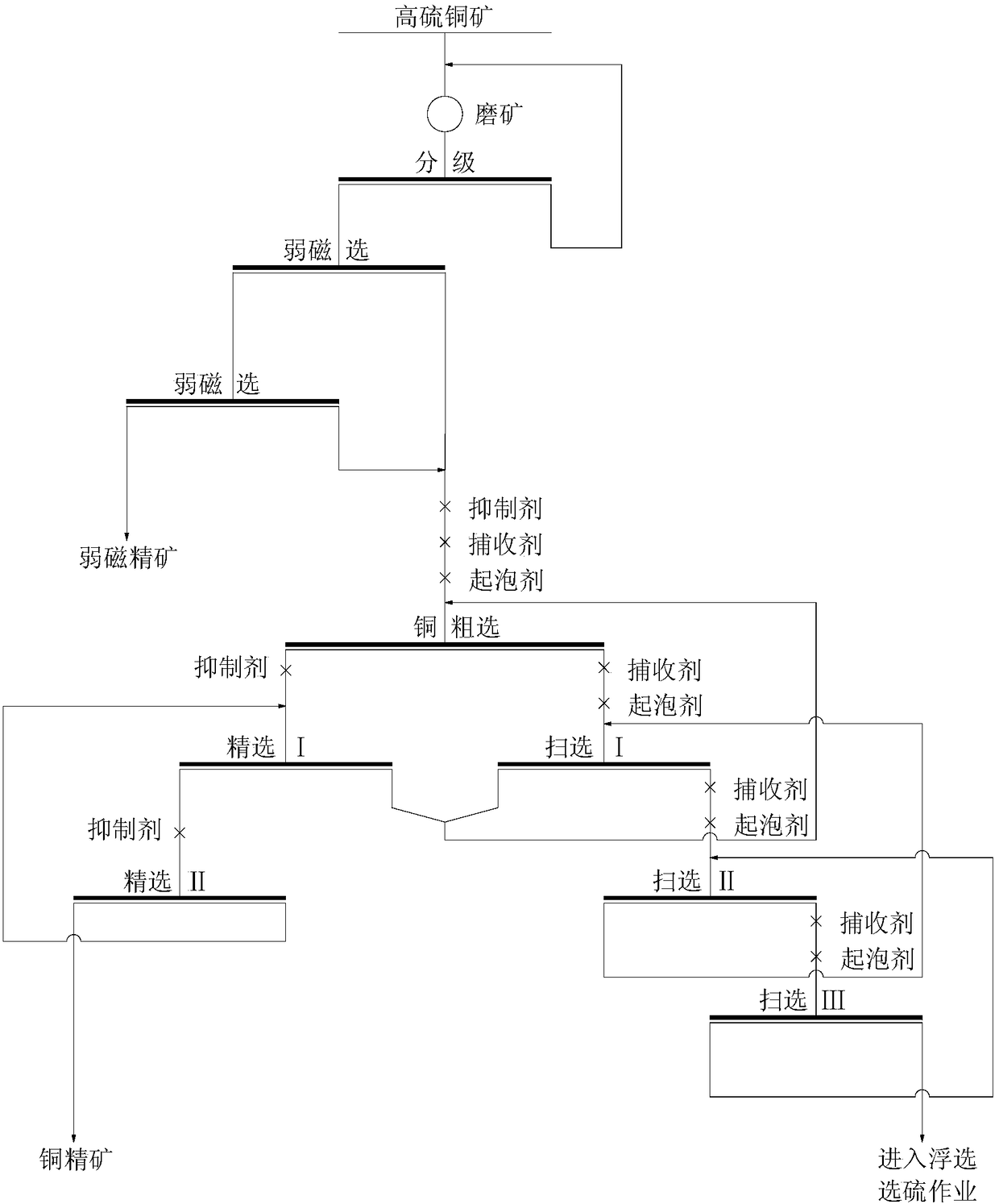

A copper-sulfur separation ore dressing method for high-sulfur copper ore

The invention discloses a copper-sulphur separation and ore dressing method for high-sulphur copper ores. The copper-sulphur separation and ore dressing method comprises the following steps: crushing, grinding and grading high-sulphur copper raw ores, feeding a grading overflow to a low-intensity magnetic separation operation, pre-selecting low-intensity magnetic concentrates, that is, pyrrhotites, and discharging low-intensity magnetic tailings; feeding the low-intensity magnetic tailings to a copper flotation operation, obtaining copper concentrates with a Cu grade of greater than 18% and a copper recovery rate of greater than 85%, and discharging copper flotation tailings, wherein during the copper flotation operation, lime is used as a pH regulator and a pyrite inhibitor, butyl xanthate is used as a collector, and No. 2 oil is used as a foamer; and feeding the copper flotation tailings to a flotation sulphur dressing operation to obtain sulphur concentrates, and throwing final tailings. The copper-sulphur separation and ore dressing method disclosed by the invention has the advantages of being stable in ore dressing indexes, low in medicament consumption, clean and environment-friendly, simple and convenient to operate, easy to operate and manage in the field, and the like; and the pyrrhotites are pre-selected through the low-intensity magnetic separation, the interference of the pyrrhotites on the copper flotation is eliminated, thus copper flotation indexes are greatly improved, the phenomena of high fluctuations of a copper concentrate grade and a copper recovery rate are avoided, and energy-saving and consumption-reducing effects are remarkable.

Owner:SINOSTEEL MAANSHAN INST OF MINING RES +1

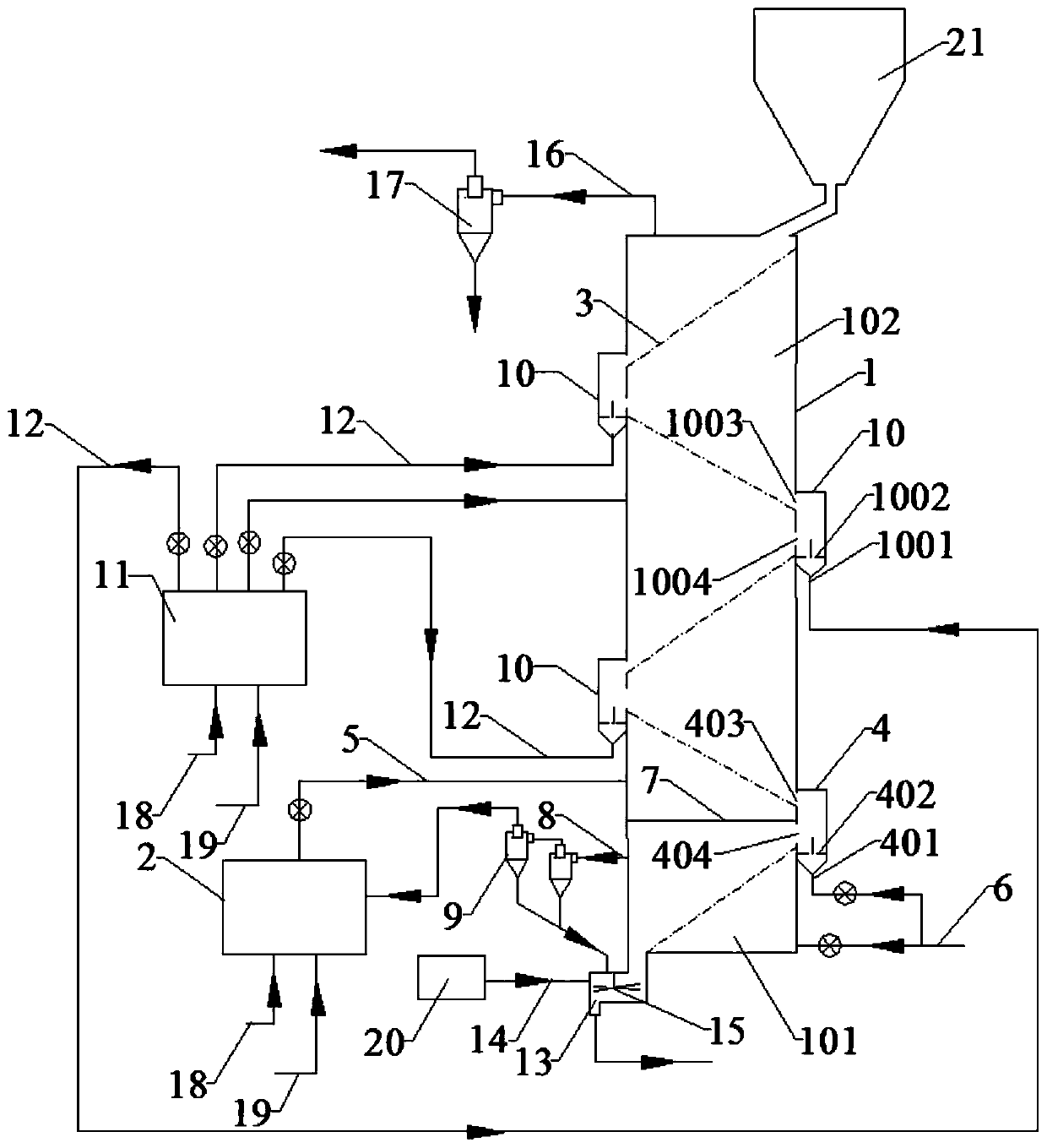

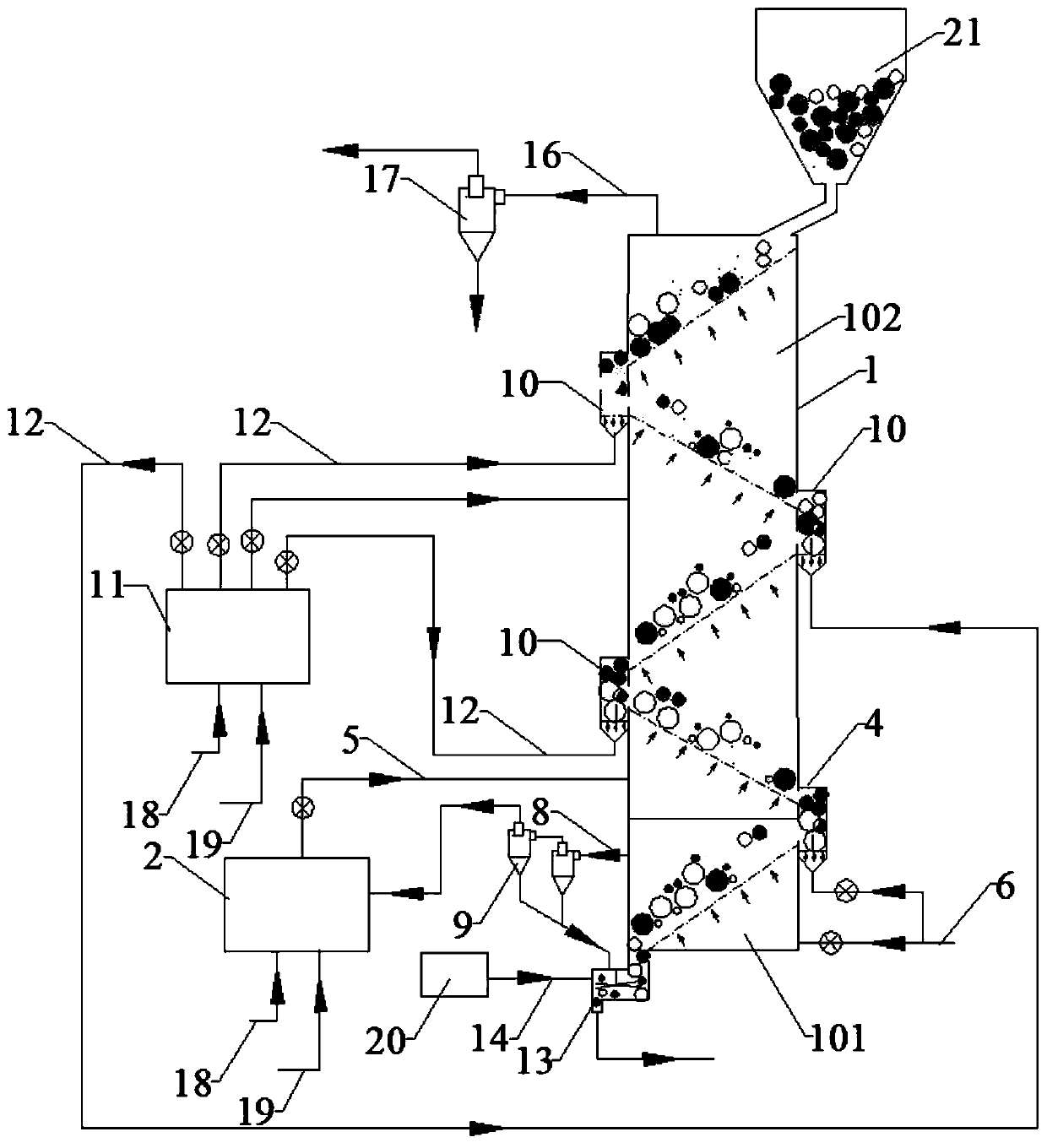

Regional control multi-stage turbulent fluidization reaction furnace

PendingCN110260656ASimple structureCompact configurationMaintainance of heating chambersCharge manipulationCombustionFlue gas

The invention discloses a regional control multi-stage turbulent fluidization reaction furnace. The reaction furnace comprises a furnace body and a main combustion furnace, the furnace body comprises a reaction zone and at least one preheating zone, the preheating zone is arranged at the upper part of the reaction zone, gas distribution plates are arranged in the reaction zone and the preheating zone, the preheating zone and the reaction zone are separated into independent cavities through a separation plate, the preheating zone and the reaction zone are communicated through a reaction zone sealing valve, the hot flue gas discharged by the main combustion furnace is connected with the bottom cavity of the gas distribution plate of the preheating zone through a first hot smoke pipeline, and the bottom cavity of the gas distribution plate of the reaction zone is connected with a reaction gas inlet pipe. The partition is used for controlling the multistage turbulent fluidization reaction furnace, the material preheating zone and the reaction zone are completed in the same device, the structure is simple, the equipment configuration is compact, the occupied area is small, and the capital construction investment is saved.

Owner:CHANGSHA RES INST OF MINING & METALLURGY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com