Method for recovering copper, lead and zinc from ultra-fine complicated cyanidation tailings

A technology for cyanidation tailings and copper recovery, which is applied in solid separation, flotation and other directions, can solve the problems of complex operation, high loss, low lead-copper-zinc mineral quality and low recovery rate, and achieves simple operation and high quality in the process. , to achieve the effect of recycling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

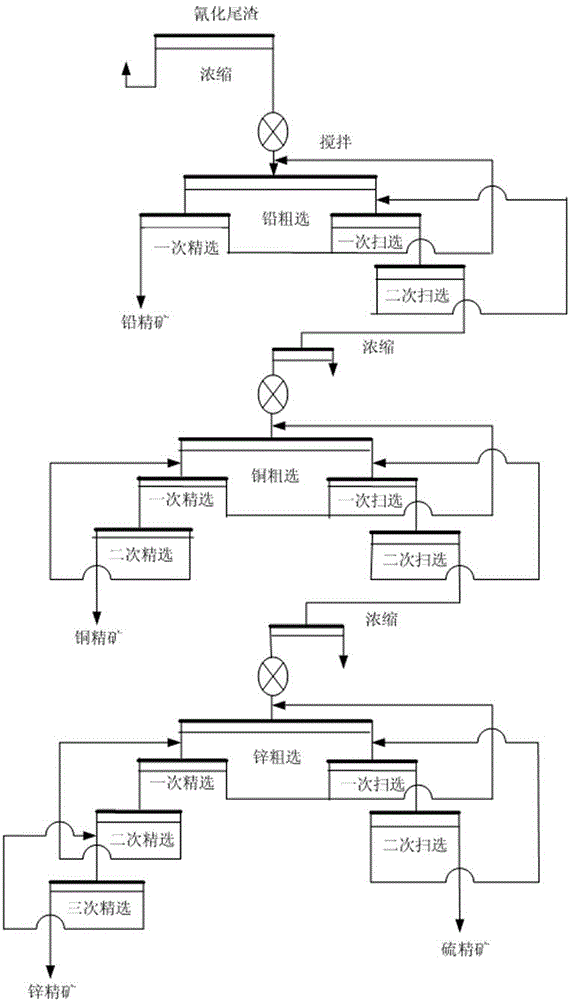

Image

Examples

Embodiment 1

[0021] The tailings of the gold concentrate cyanidation gold extraction operation are shown in Table 1, and the particle size is -500 mesh, accounting for more than 90% of the total weight;

[0022] Table 1 Analysis of components of tailings in gold concentrate cyanidation gold extraction operation

[0023] element Au (g·t -1 ) Ag (g·t -1 ) Cu (%) Pb (%) Zn (%) Fe (%) content 2.75 673.92 1.70 22.35 2.45 29.42

[0024] (1) Stirring and pulping: The ultra-fine and complex cyanidation tailings produced by the cyanidation of gold concentrate are concentrated by a thickener, and the underflow obtained from the concentration is fed into the slurry mixing tank, and water and sodium carbonate are added to control the concentration of the slurry. Stir to fully mineralize the pulp; the mass concentration of the pulp is 40%, the dosage of sodium carbonate is 2kg / t, and the stirring time is 20min;

[0025] (2) Lead recovery by flotation: Send the or...

Embodiment 2

[0030] The tailings of the gold concentrate cyanidation gold extraction operation are shown in Table 2, the particle size is -500 mesh accounts for more than 95% of the total weight, and the cyanide tailings with a particle size of <10 microns accounts for more than 30% of the total weight;

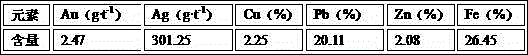

[0031] Table 2 Analysis of components of tailings in gold concentrate cyanidation gold extraction operation

[0032]

[0033] (1) Stirring and pulping: Concentrate the ultra-fine and complex cyanidation tailings produced by the cyanide gold extraction operation of gold concentrate through a thickener, and feed the underflow obtained from the concentration into the slurry mixing tank, add water and sodium carbonate to control the mass concentration of the pulp , stirring to fully mineralize the pulp; wherein the mass concentration of the pulp is 43%, the amount of sodium carbonate is 2kg / t, and the stirring time is 25min;

[0034] (2) Lead recovery by flotation: Send the ore slurry to t...

Embodiment 3

[0039] The tailings of gold concentrate cyanide gold extraction operation are shown in Table 3, the particle size is -500 mesh accounts for more than 95% of the total weight, and the cyanide tailings with a particle size of <10 microns accounts for more than 30% of the total weight;

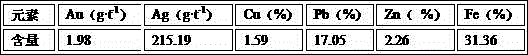

[0040] Table 3 Analysis of components of tailings in gold concentrate cyanidation gold extraction operation

[0041]

[0042] (1) Stirring and pulping: The ultra-fine and complex cyanidation tailings produced by the cyanidation of gold concentrate are concentrated by a thickener, and the underflow obtained from the concentration is fed into the slurry mixing tank, and water and sodium carbonate are added to control the concentration of the slurry. Stir to fully mineralize the pulp; the mass concentration of the pulp is 45%; the amount of sodium carbonate is 2kg / t; the stirring time is 30min;

[0043] (2) Lead recovery by flotation: Send the ore slurry to the flotation unit, and recover lead by...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com