Processing method of boiled petasites tatewakianus

A processing method and technology of yam, applied in food preparation, food science, application, etc., can solve the problems of poor color protection effect of yam raw materials, difficulty in peeling yam raw materials, blackening of yam raw materials, etc., and achieve good protection Color effect, easy peeling operation, low viscosity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

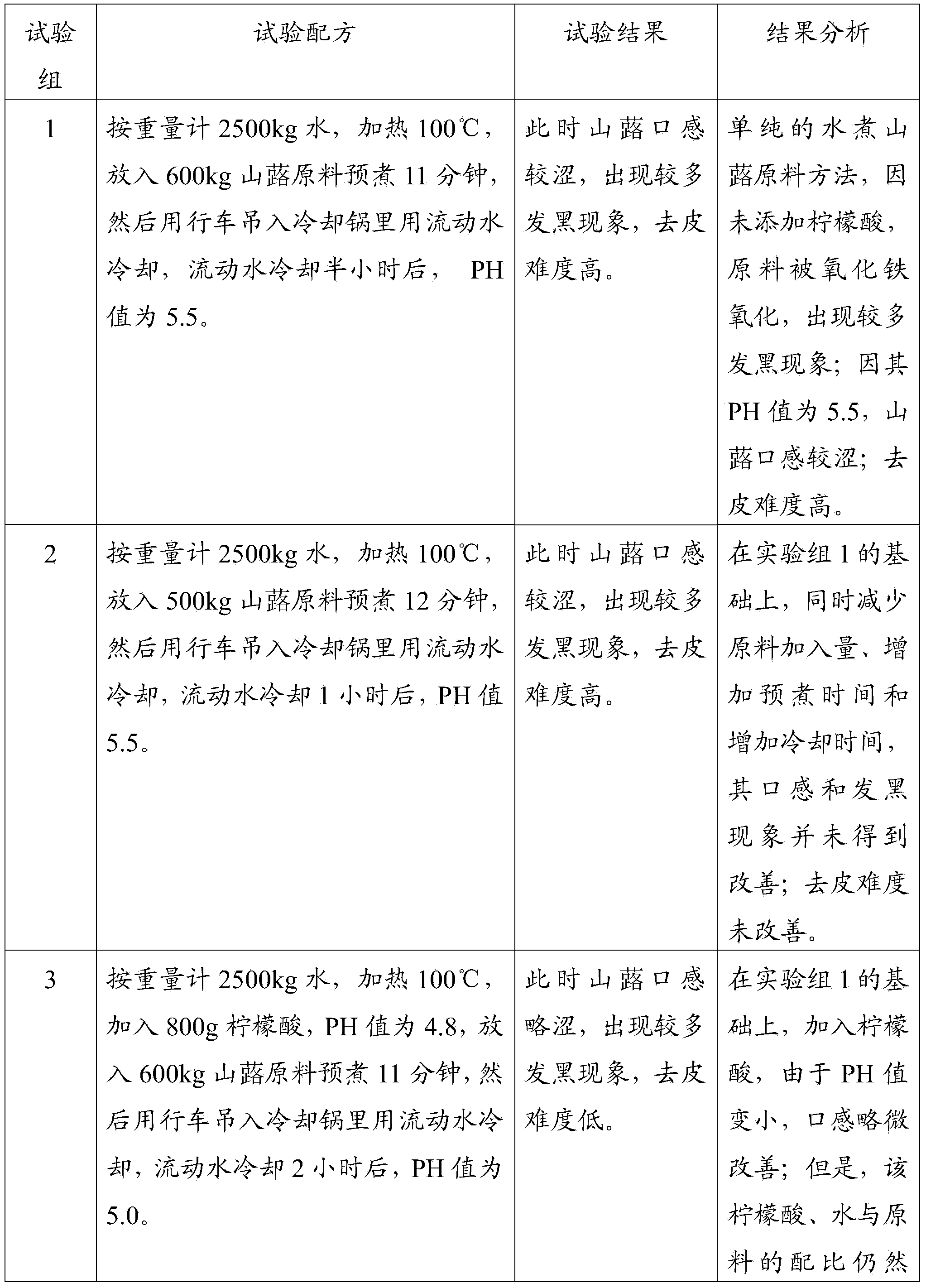

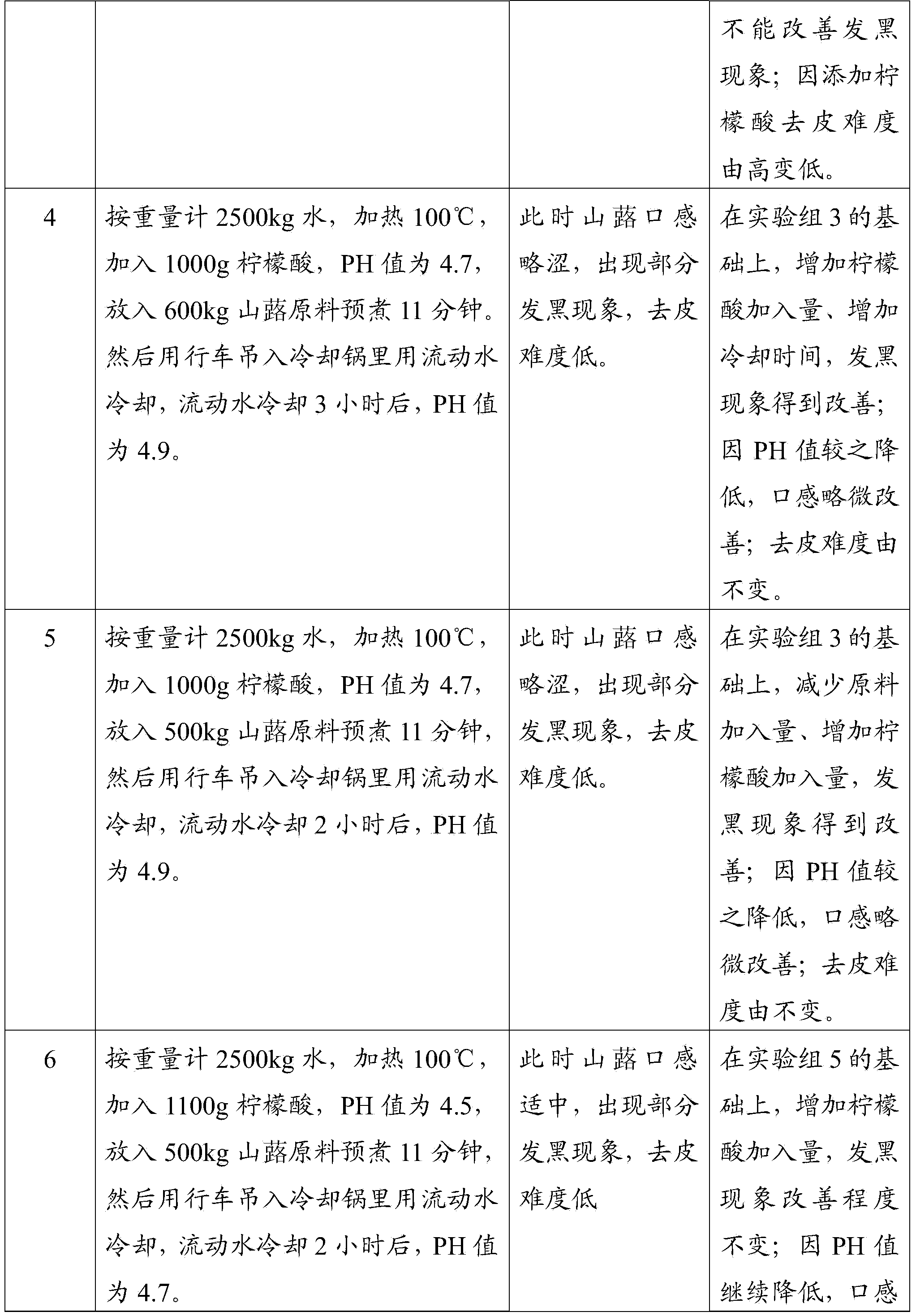

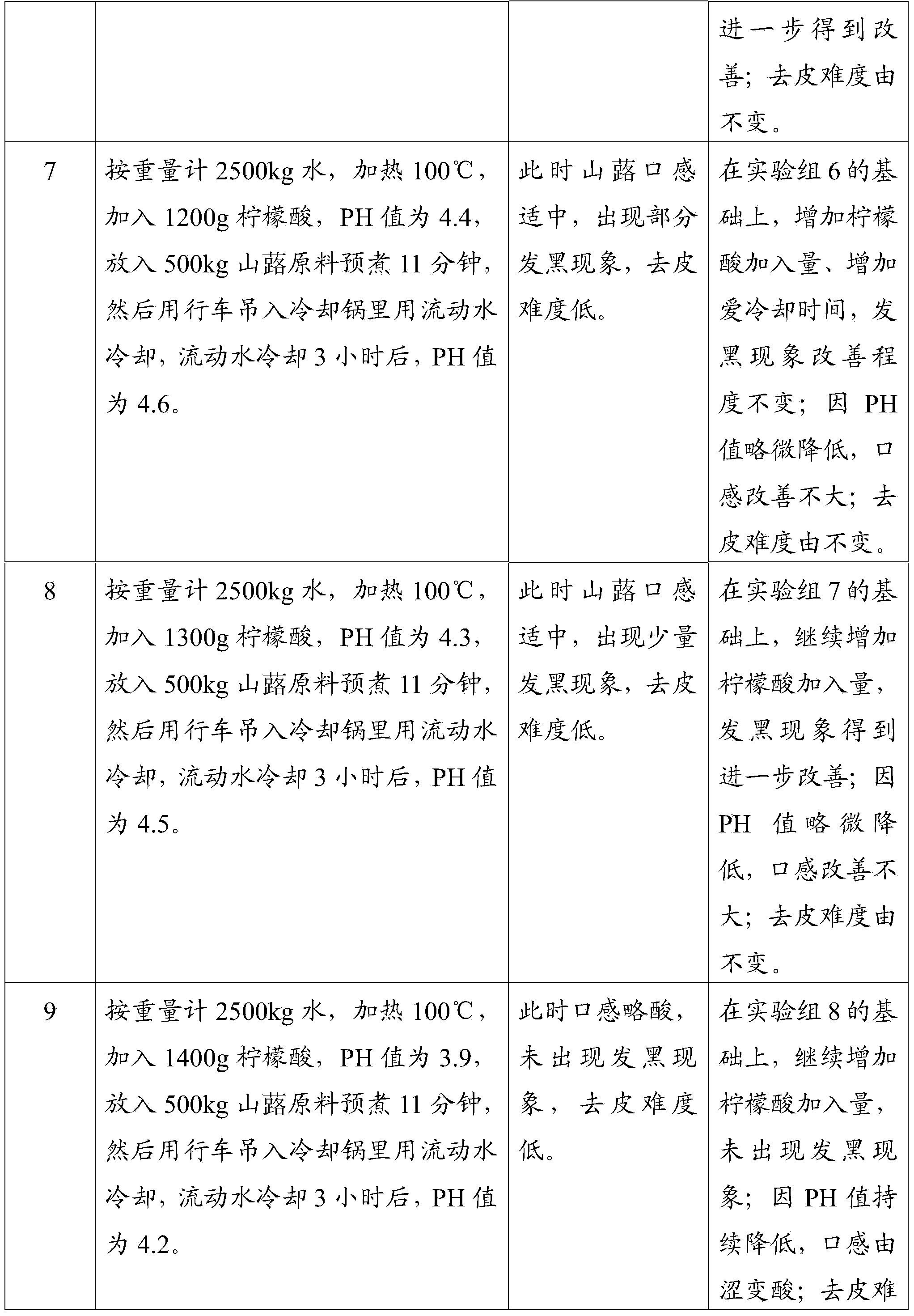

Method used

Image

Examples

Embodiment 1

[0022] Classify the raw materials of fresh Chinese radishes according to their specifications. The raw materials of Chinese radishes with a length greater than or equal to 60cm and a diameter of the bottom greater than or equal to 1.70cm are large-sized raw materials, and the rest are small-sized raw materials. Raw materials of the same size are divided into 12 -15kg for binding; choose a stainless steel cooking pot with a length of 300cm, a width of 150cm, and a height of 100cm, add 2500kg of water and 1350g of citric acid to the cooking pot, adjust the pH value to 4.1, and heat to 100°C; choose stainless steel Put the bundled large-scale raw materials into the cooking basket, place about 500kg of raw materials in each basket, and hang the cooking frame into the cooking pot for pre-cooking by driving. The pre-cooking time for raw materials is 11 minutes. After fully pre-cooking , hoist the cooking frame out of the cooking pot by driving, and then hang the cooking frame into th...

Embodiment 1

[0023] Beneficial effects of Example 1: At this time, the obtained yam has no blackening phenomenon, completely overcome the blackening phenomenon of yam; the taste of yam is moderate; the difficulty of peeling is low; the distribution ratio of each component in Example 1 is optimal Compare. The color of the finished yam is clear, and compared with fresh yam, the taste becomes crisp, tender and more delicious.

Embodiment 2

[0025] Classify the raw materials of fresh Chinese radishes according to their specifications. The raw materials of Chinese radishes with a length greater than or equal to 60cm and a diameter of the bottom greater than or equal to 1.70cm are large-sized raw materials, and the rest are small-sized raw materials. Raw materials of the same size are divided into 12 -15kg for binding; choose a stainless steel cooking pot with a length of 300cm, a width of 150cm, and a height of 100cm, add 2500kg of water and 1300g of citric acid to the cooking pot, adjust the pH to 4.3, and heat to 100°C; choose stainless steel Put the bundled large-scale raw materials into the cooking basket, place about 500kg of raw materials in each basket, and hang the cooking frame into the cooking pot for pre-cooking by driving. The pre-cooking time for raw materials is 11 minutes. After fully pre-cooking , hoist the cooking frame out of the cooking pot by driving, and then hang the cooking frame into the cool...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com