Patents

Literature

41results about How to "Easy peeling operation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

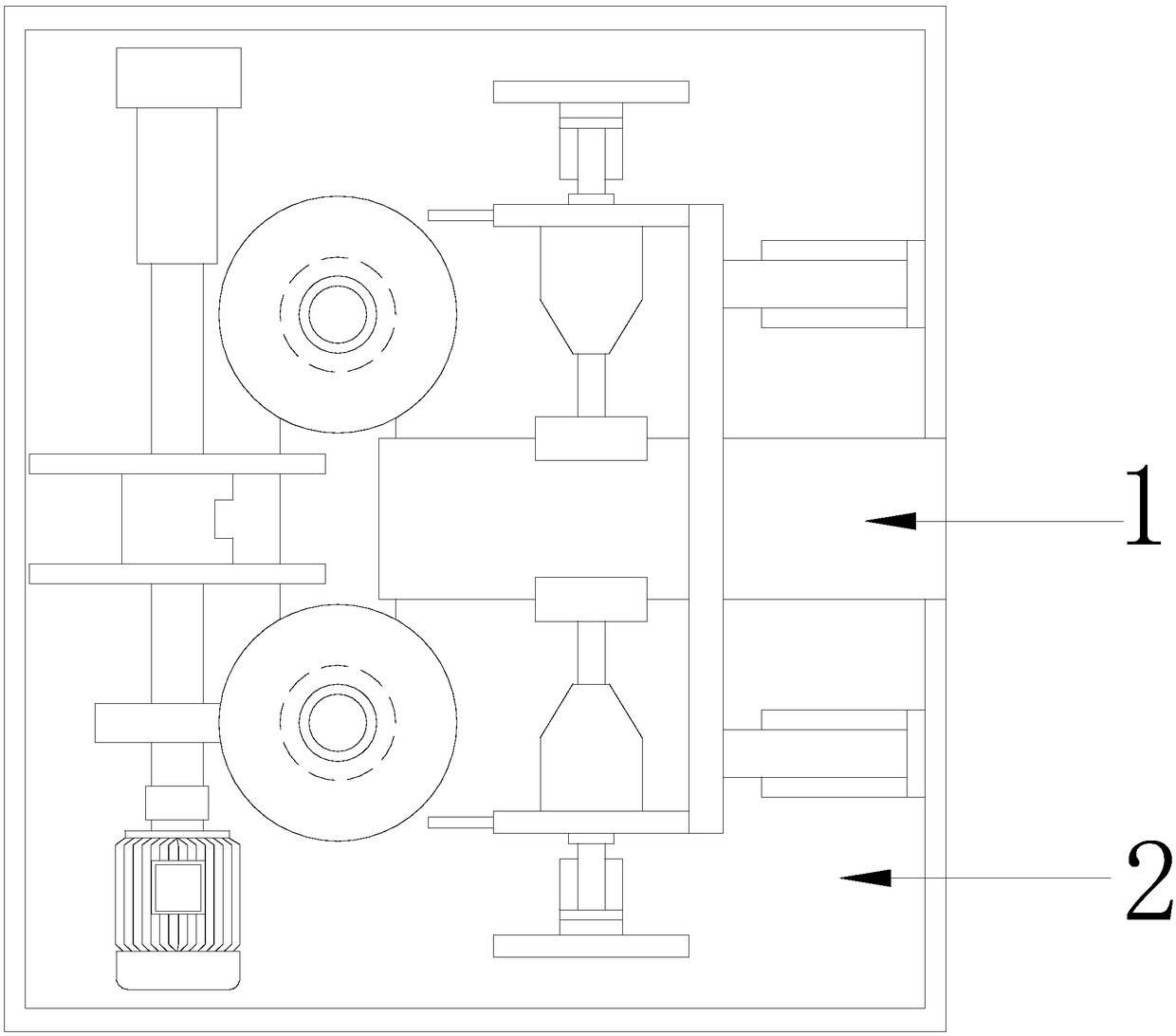

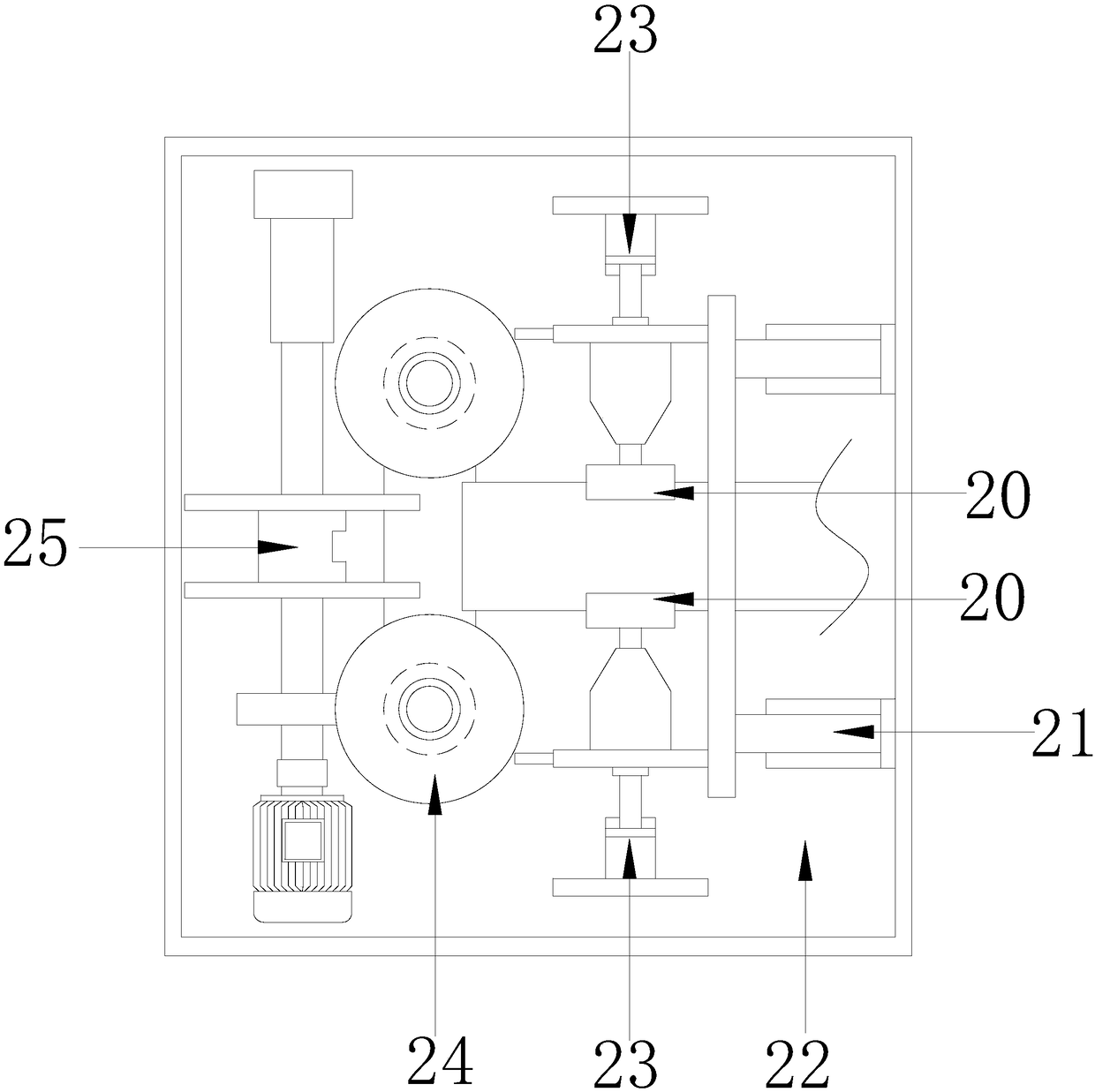

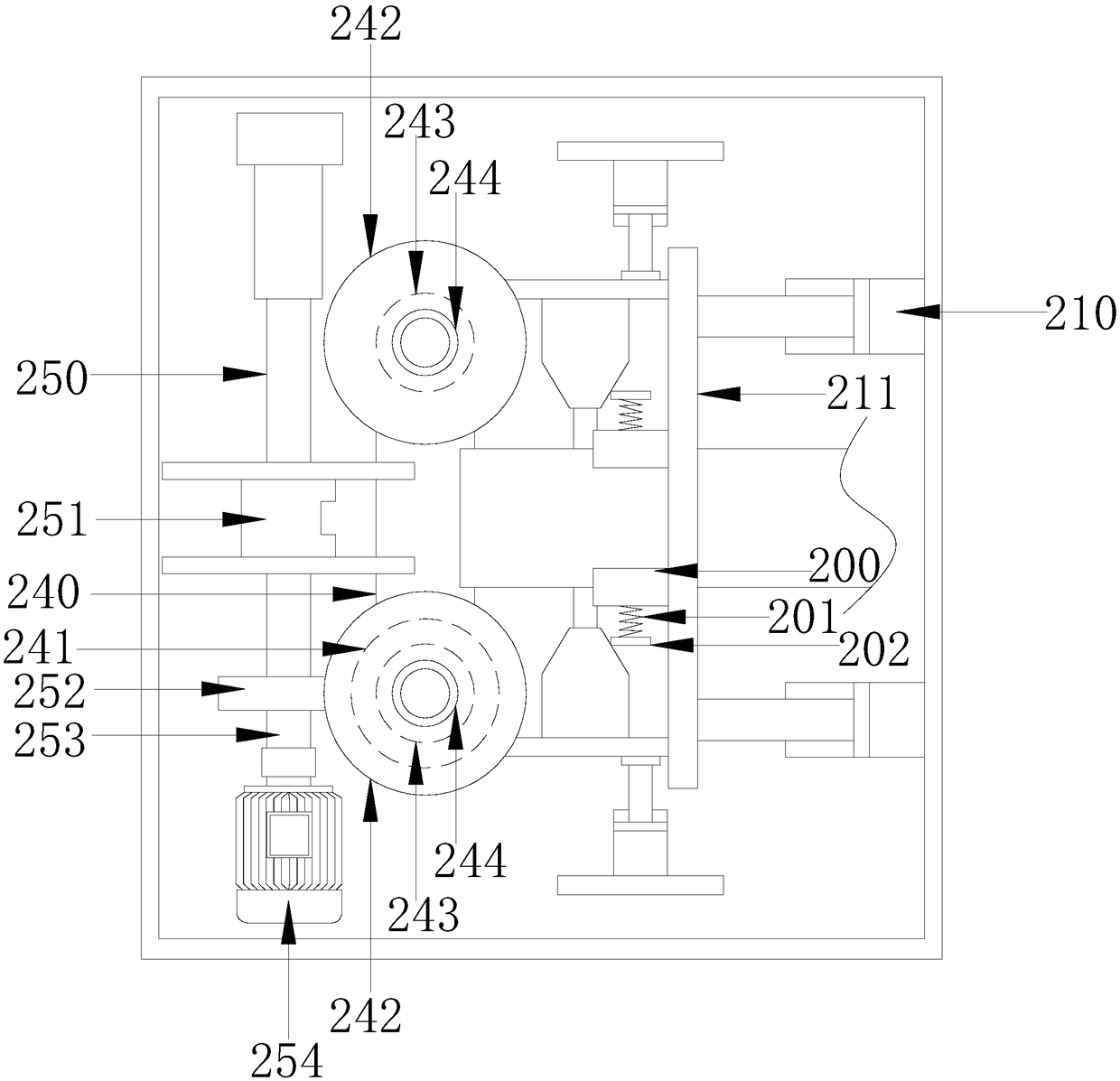

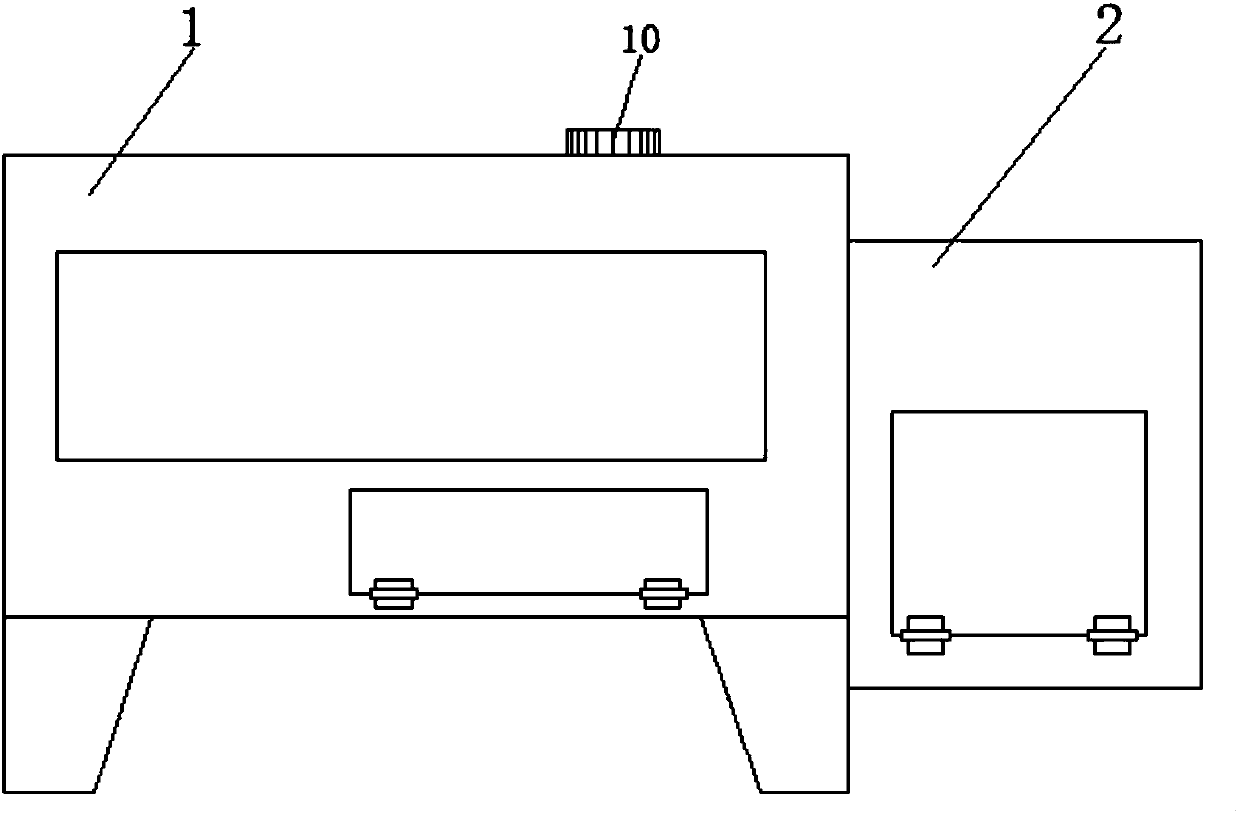

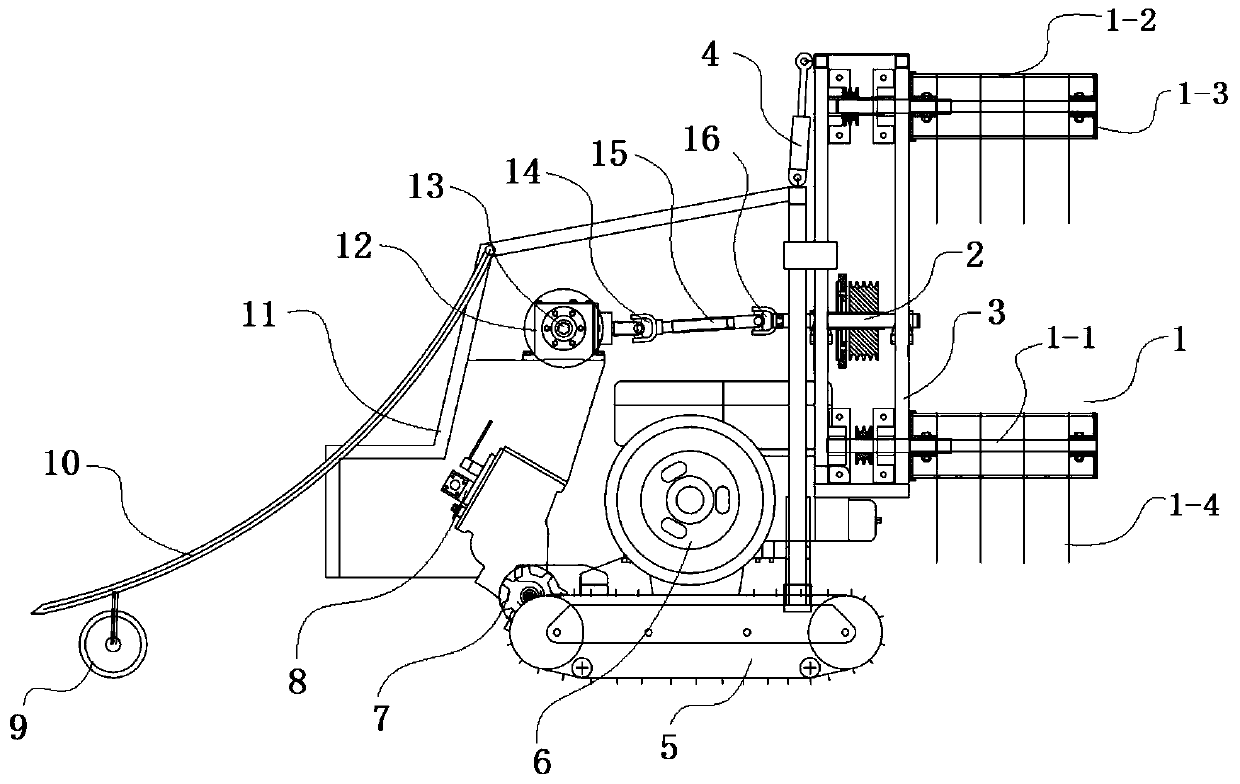

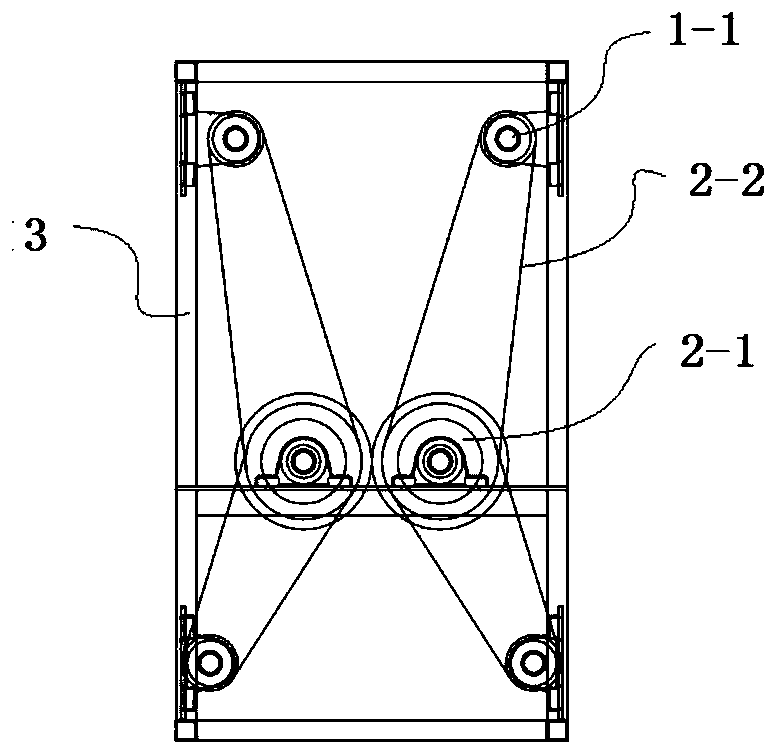

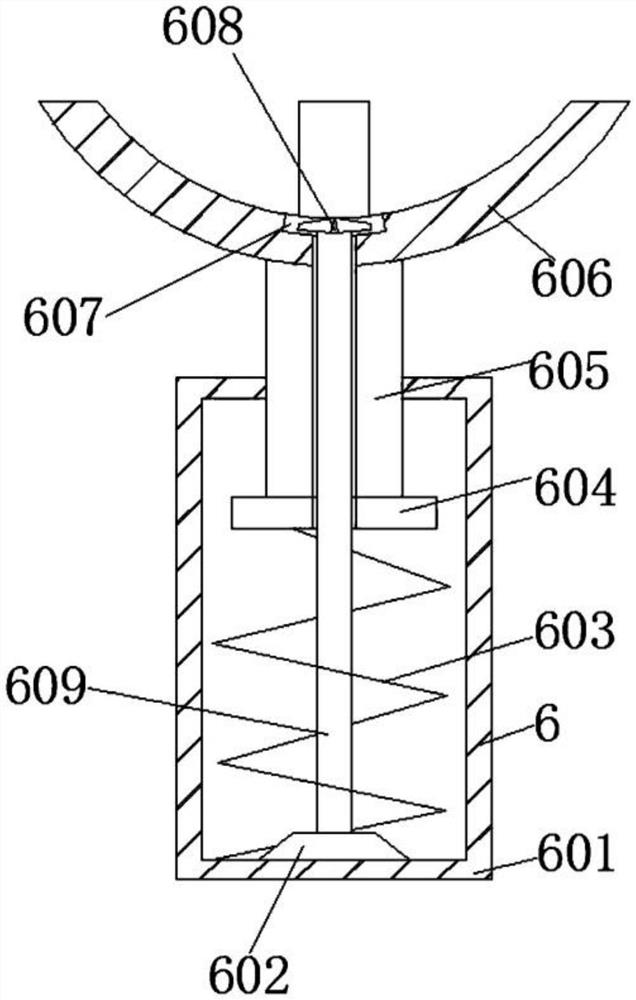

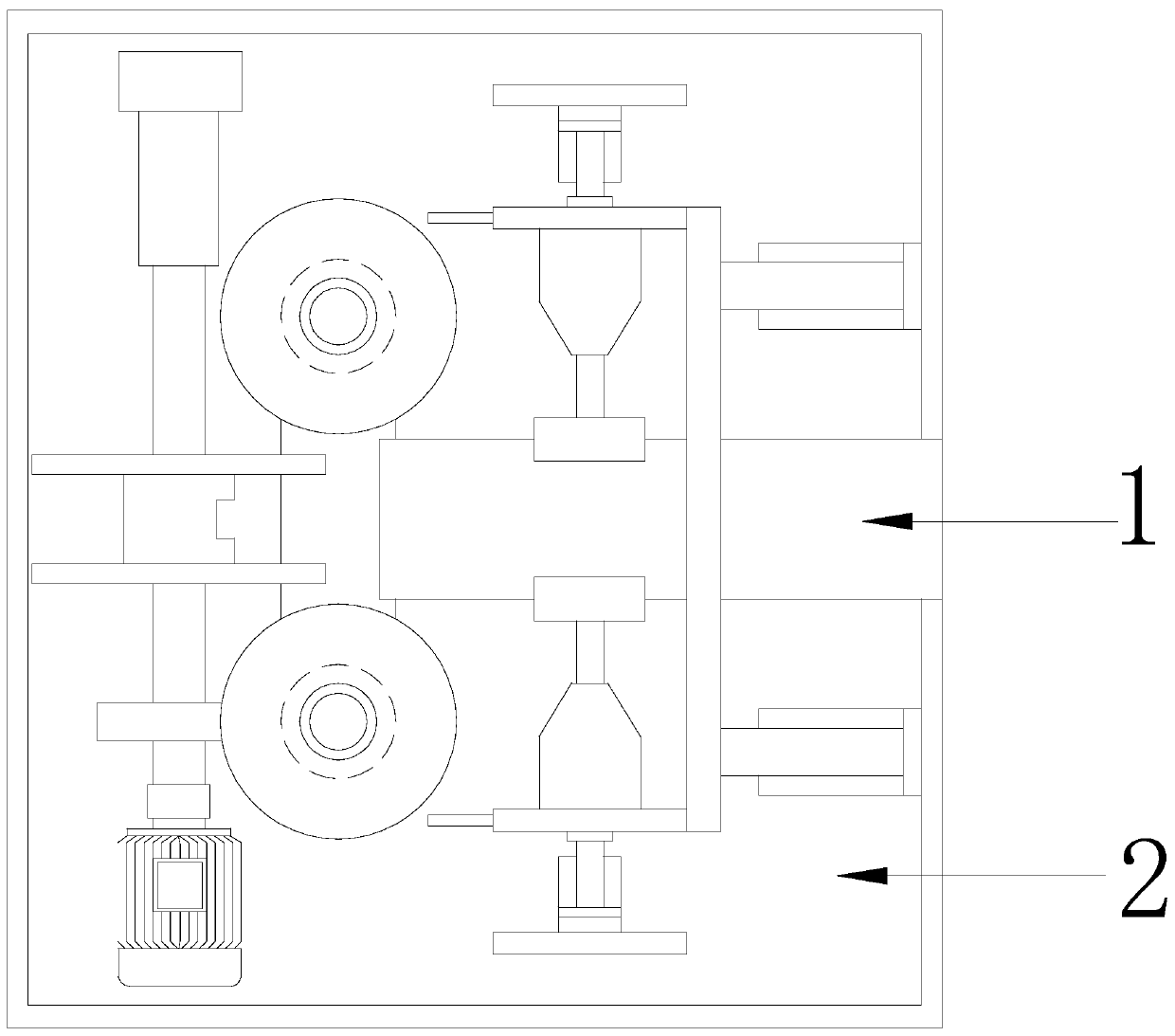

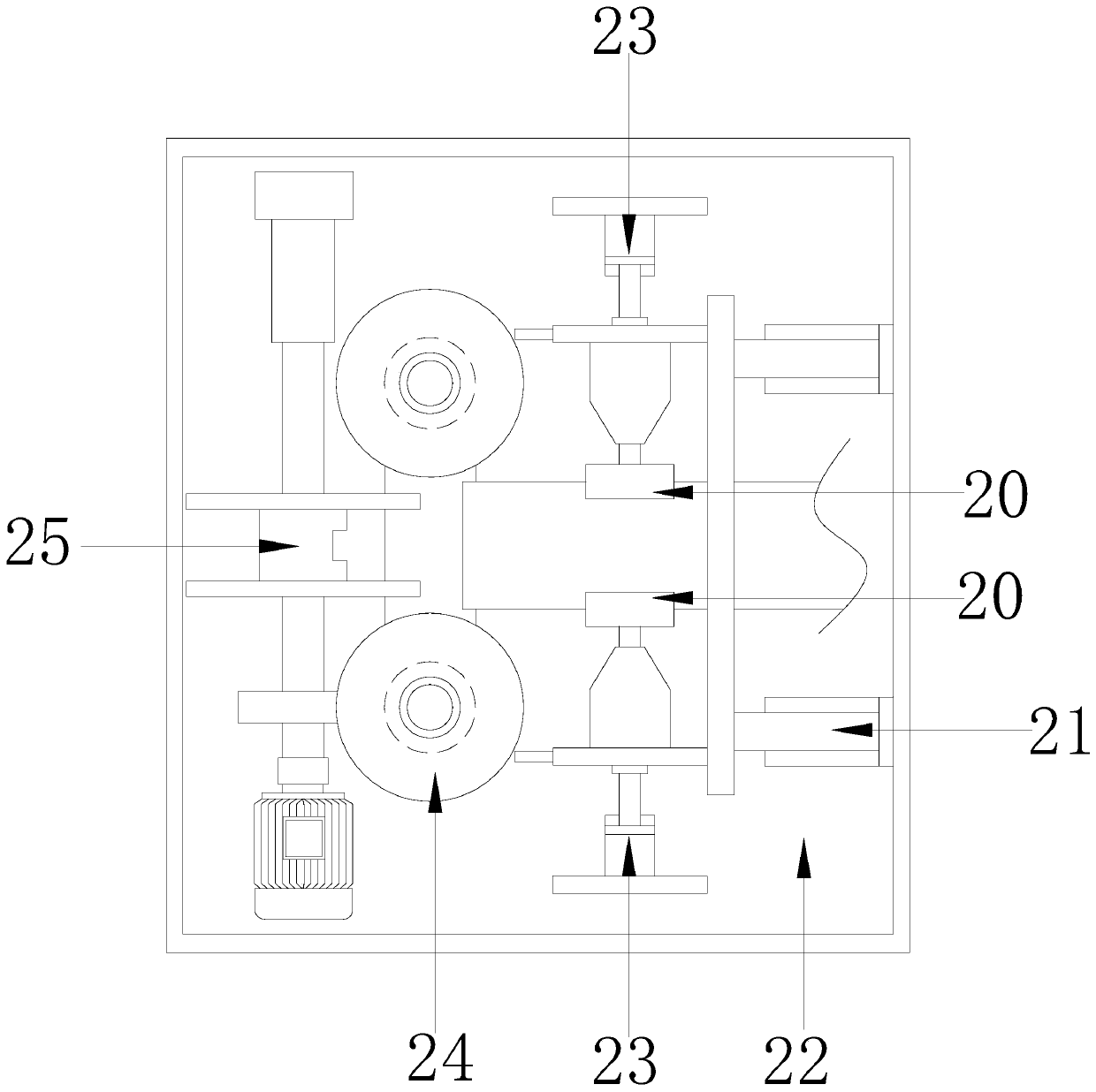

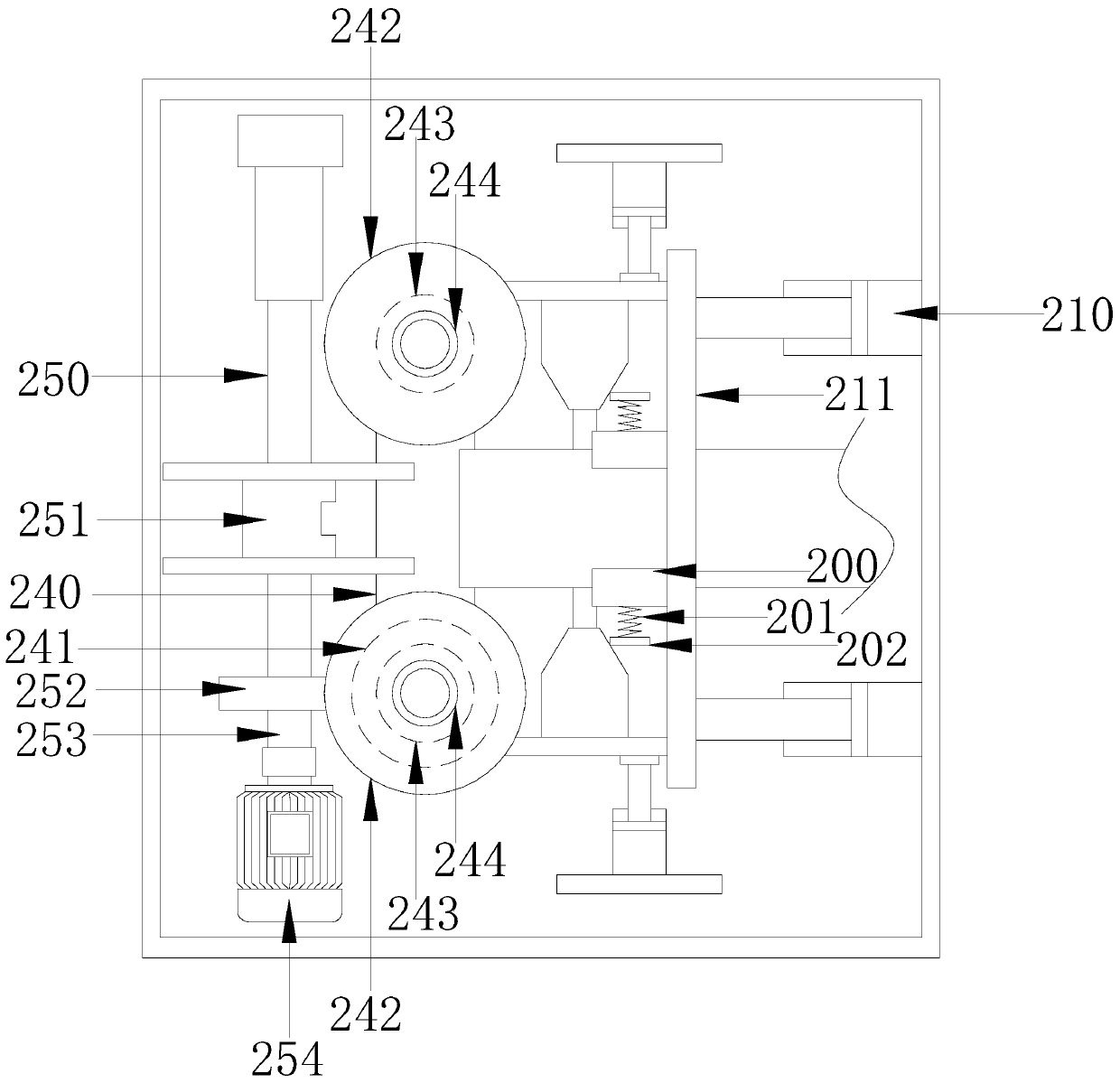

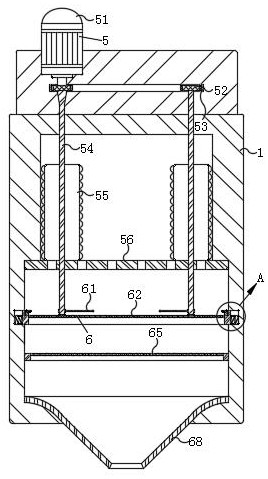

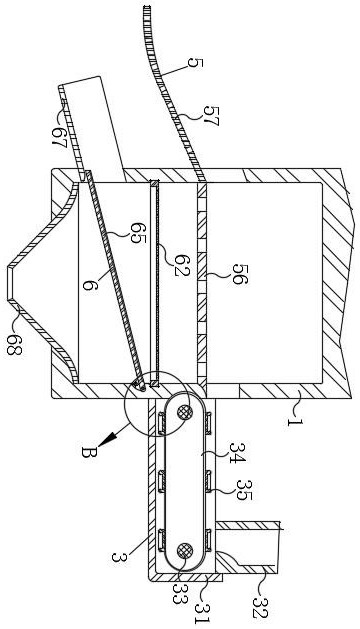

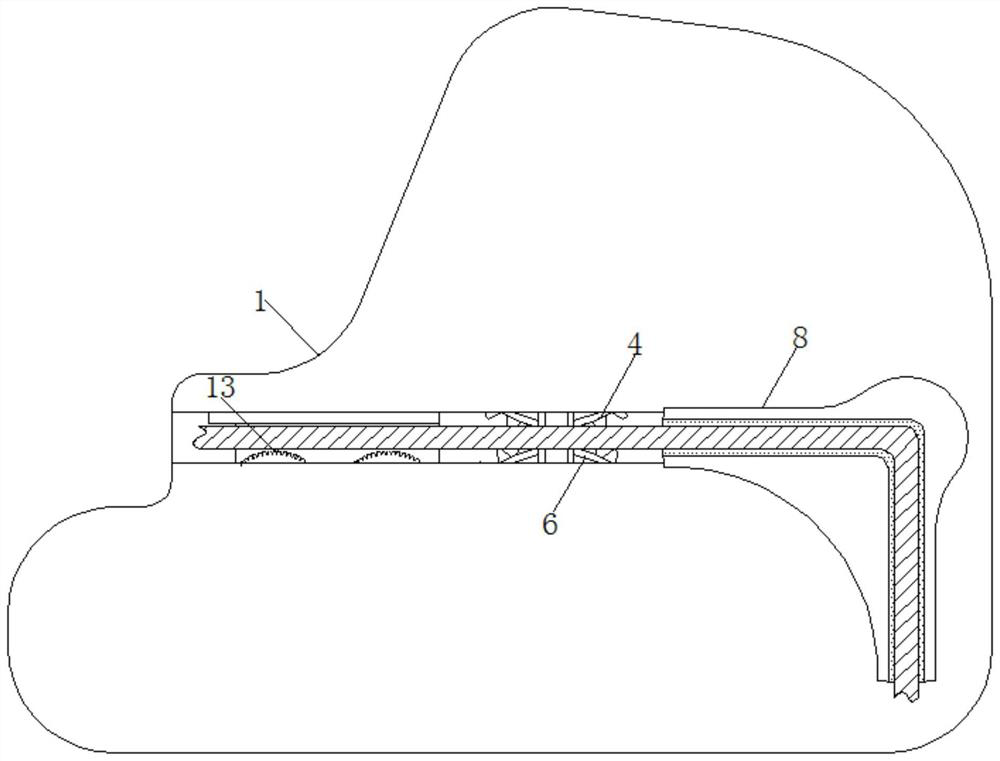

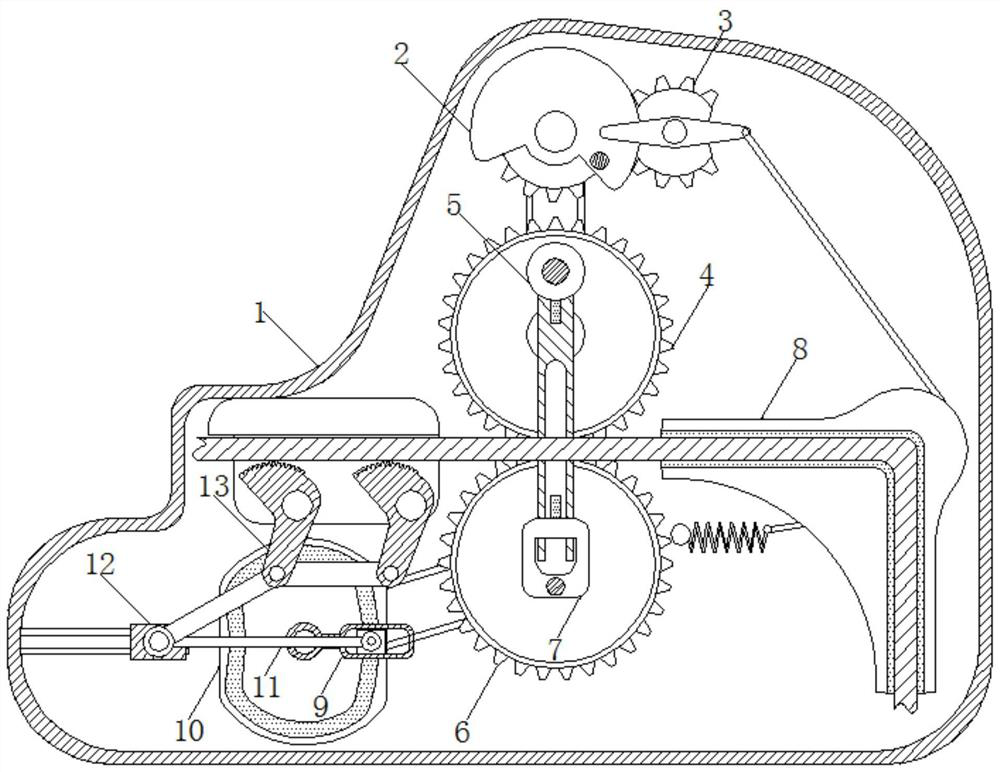

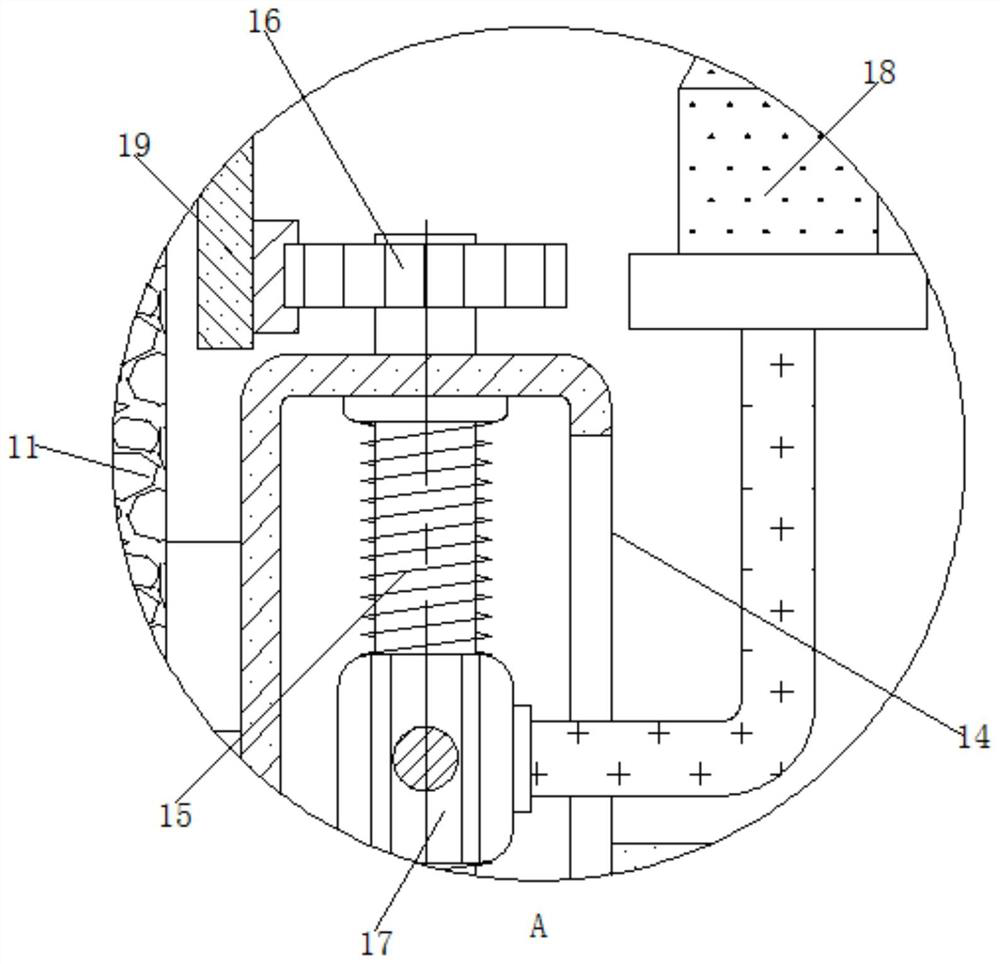

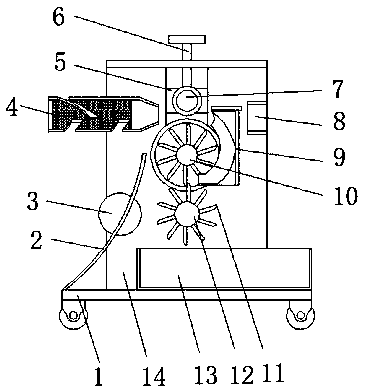

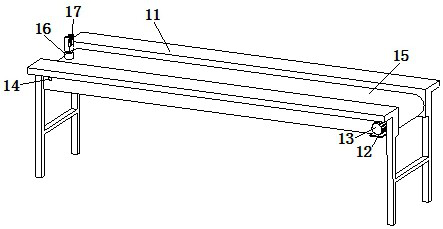

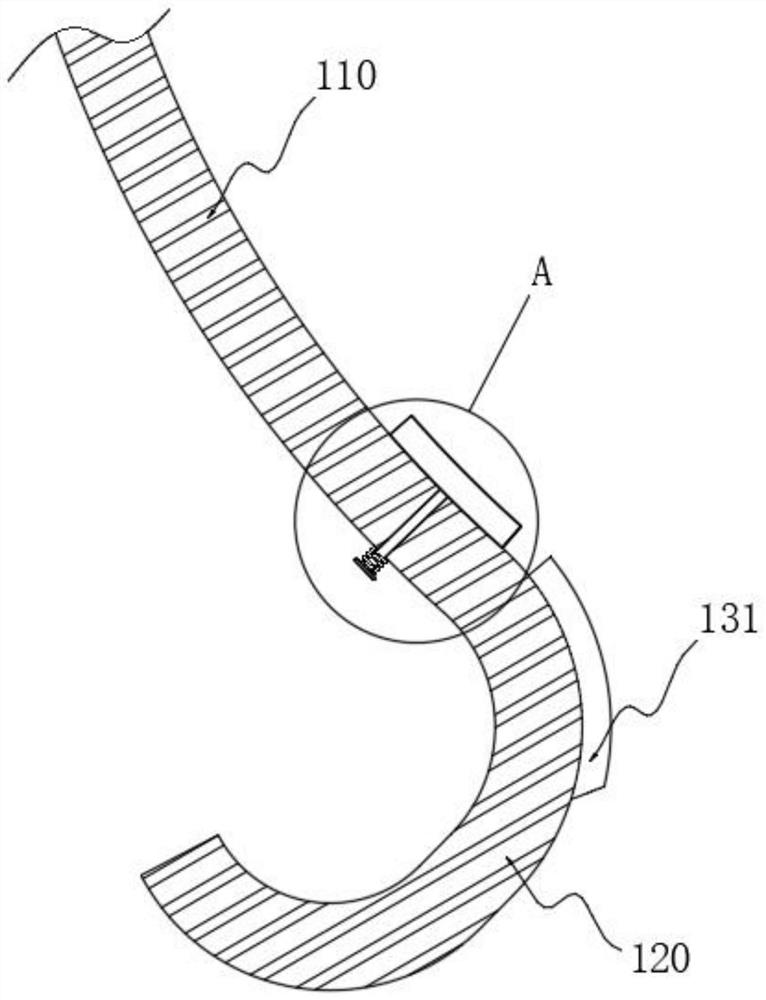

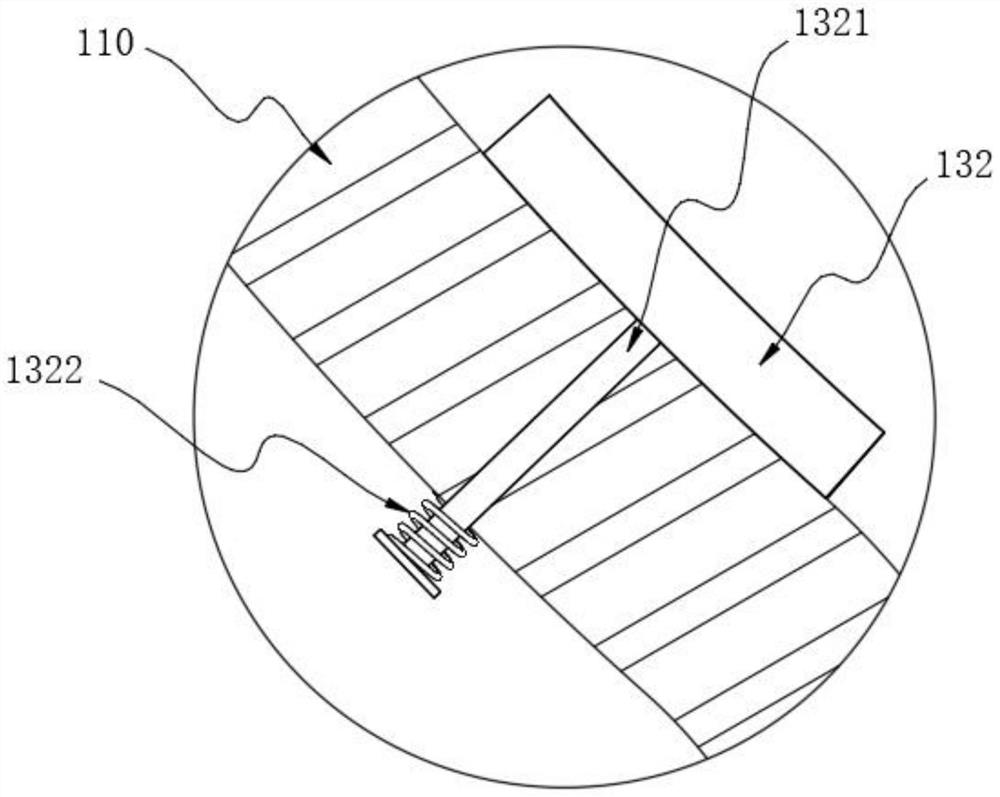

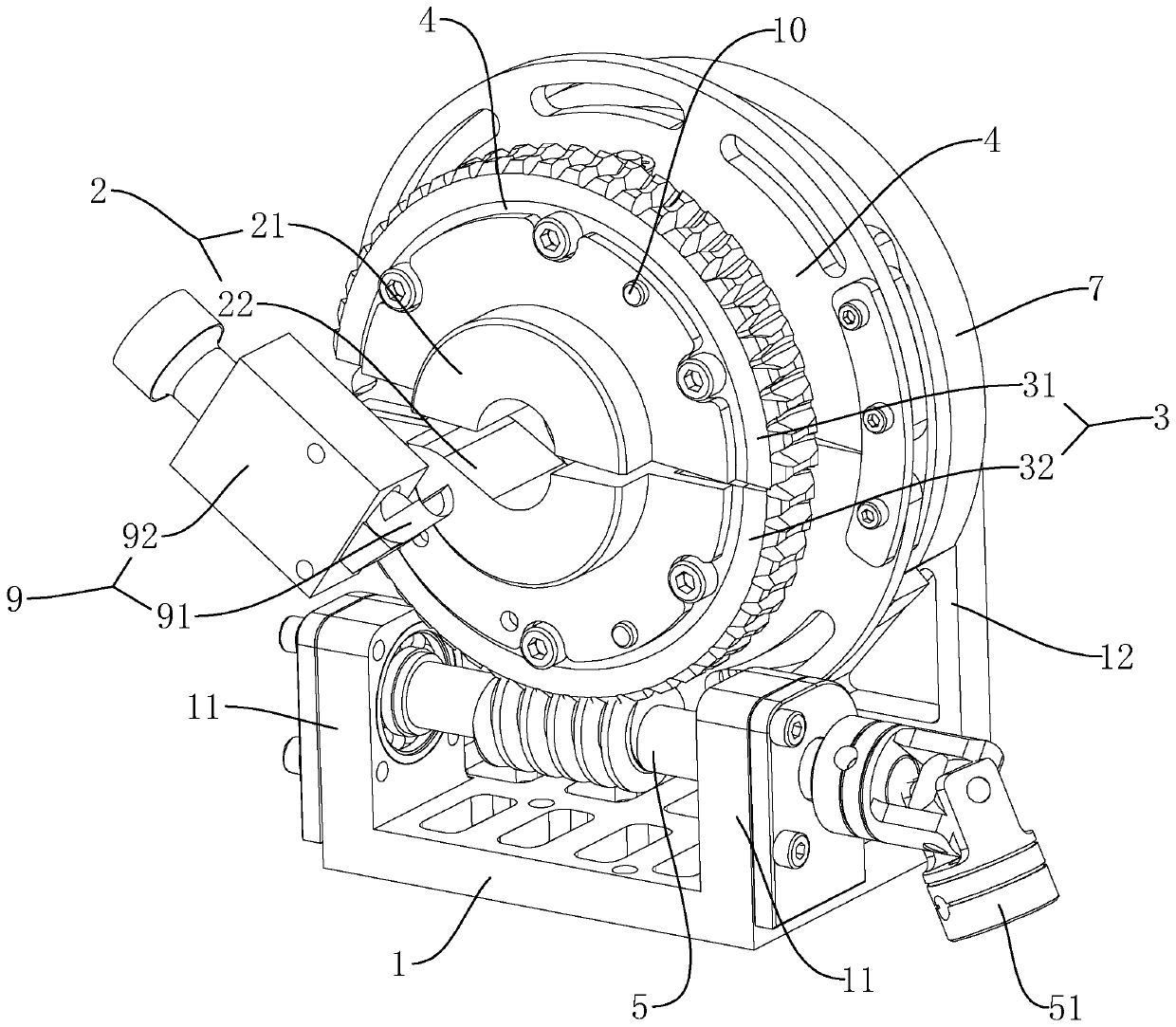

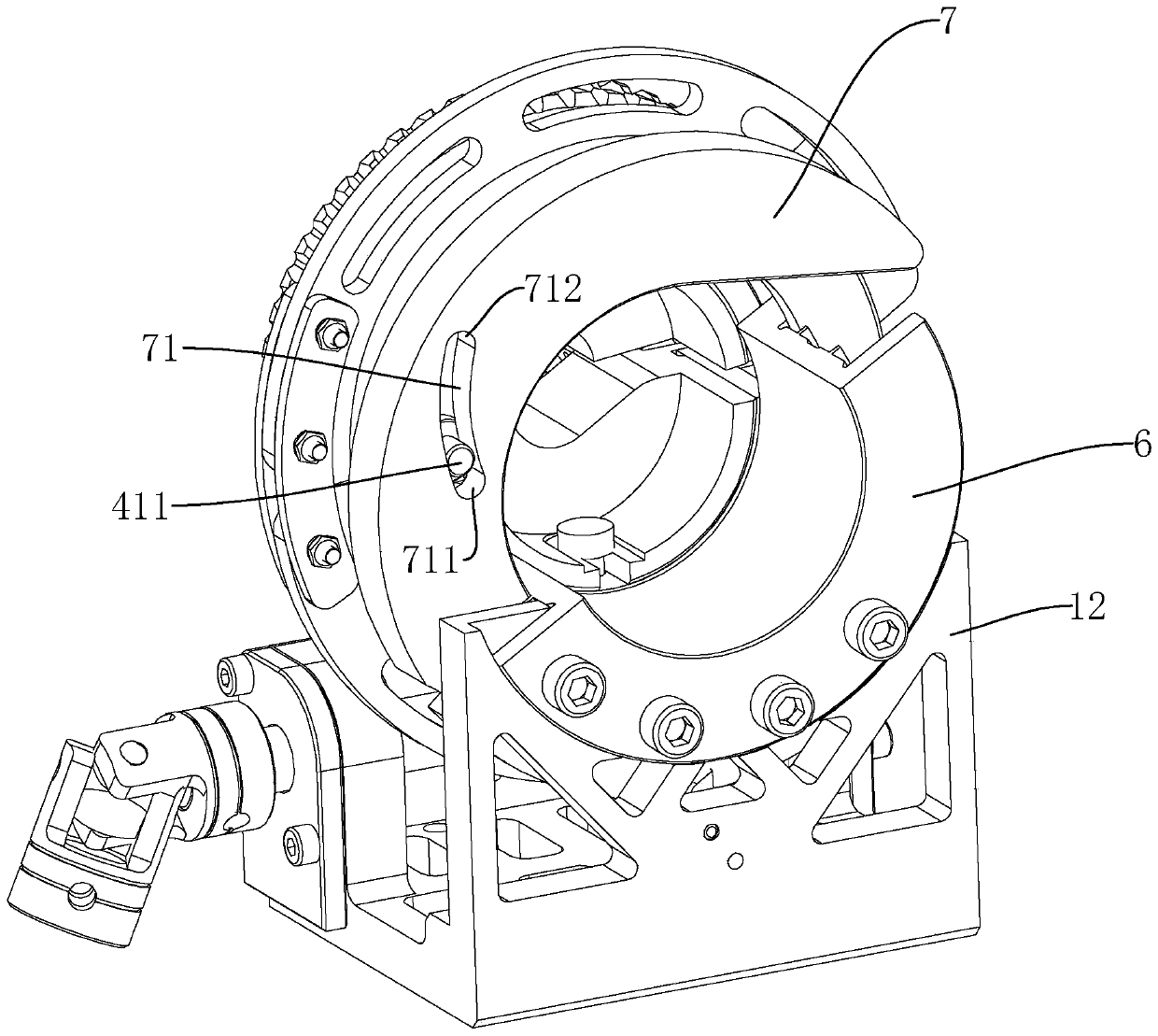

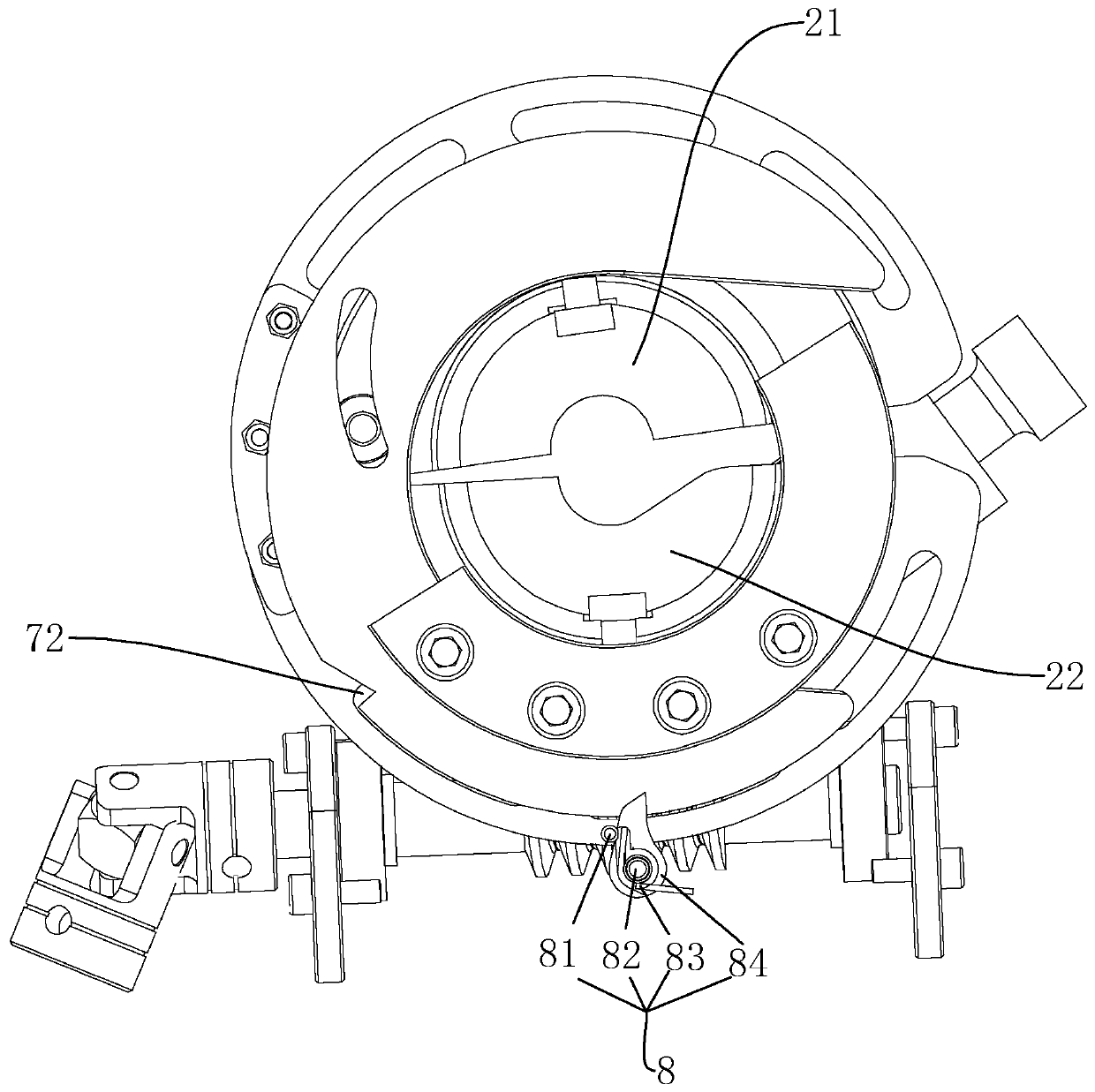

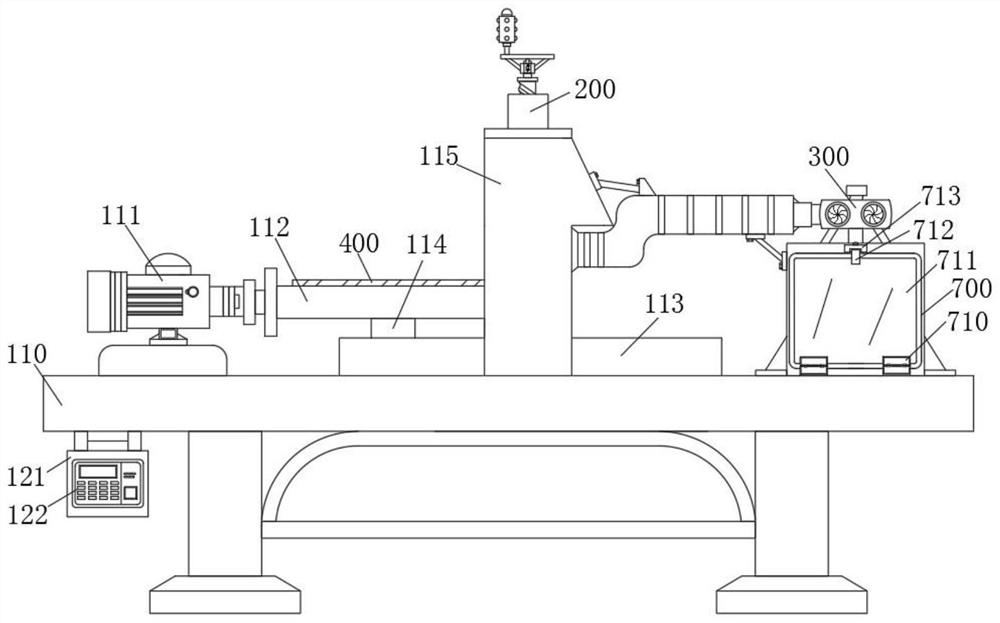

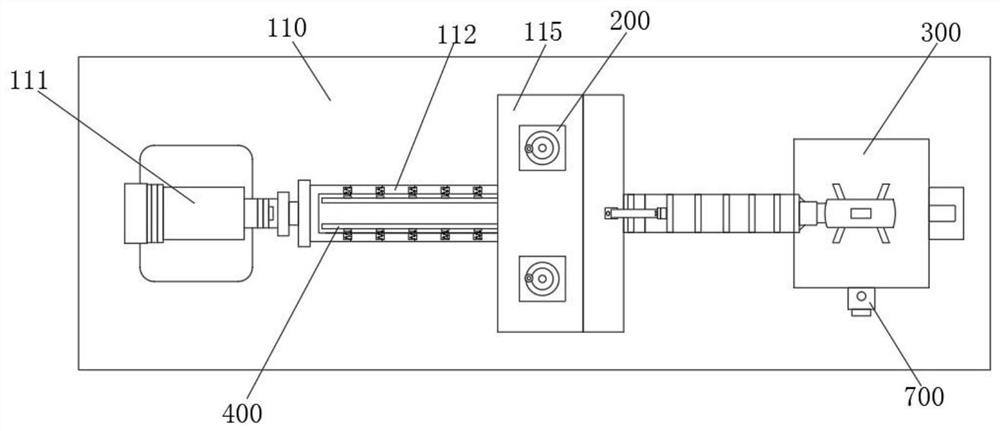

Power cable peeling device with wire and sheath winding and recycling functions

ActiveCN109347004AAvoid misalignmentFacilitates peeling operationsApparatus for removing/armouring cablesEngineeringConductor Coil

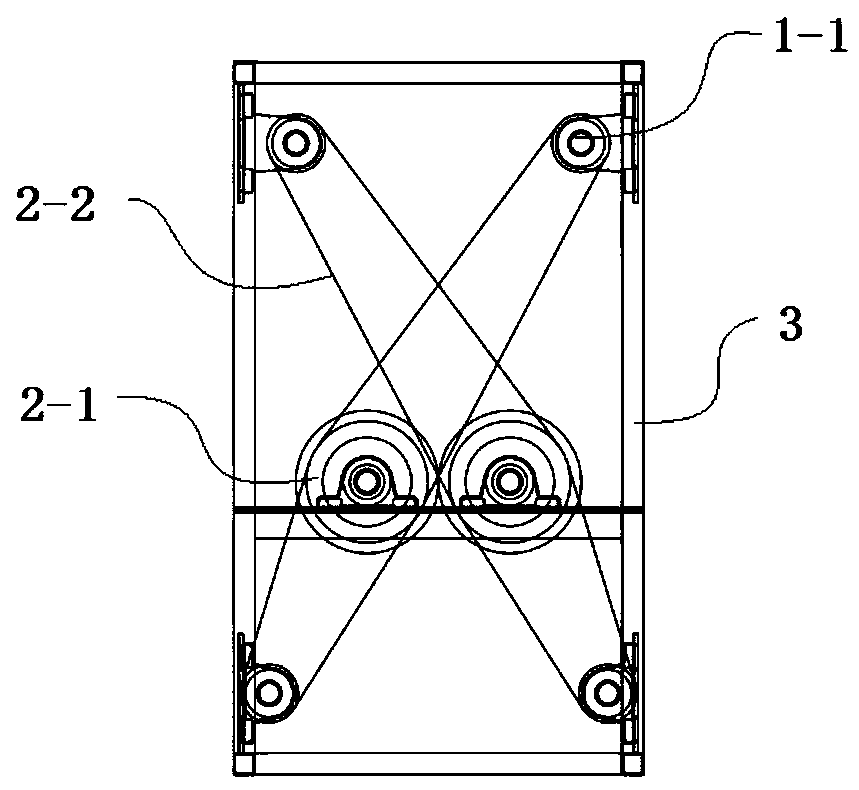

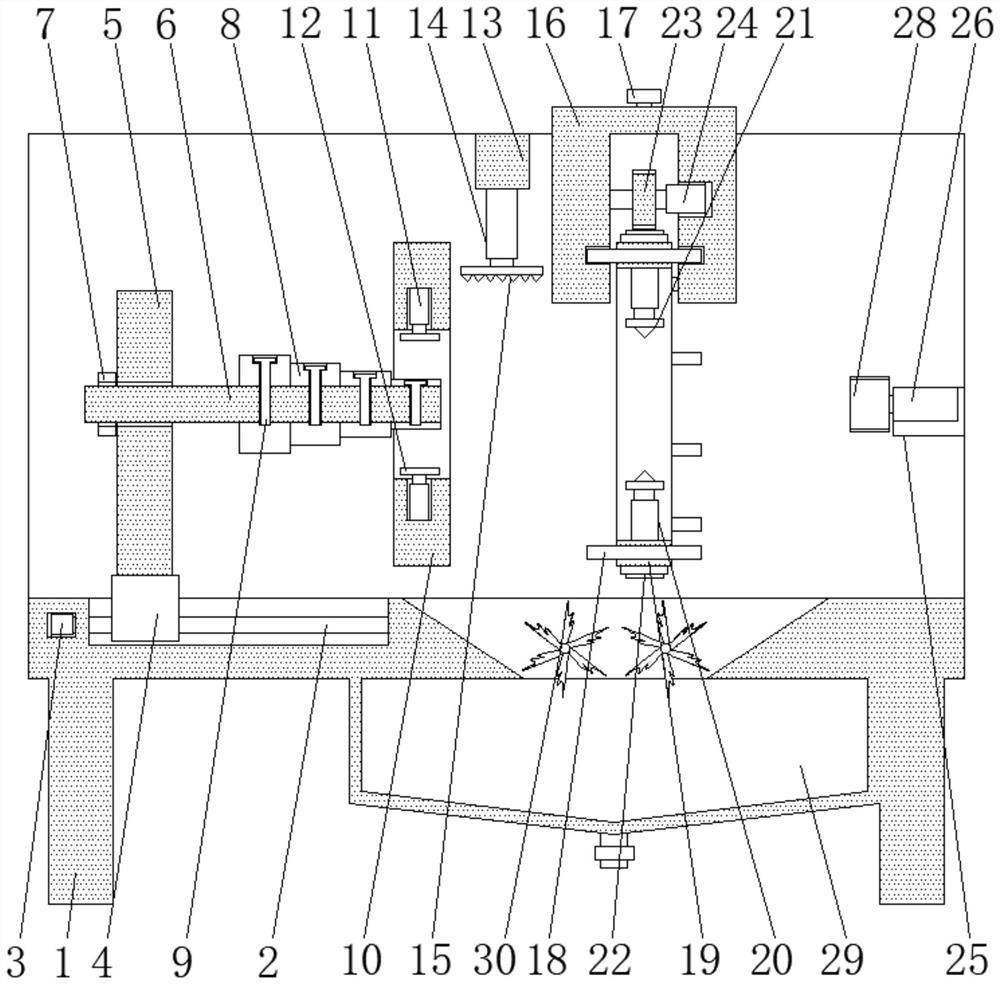

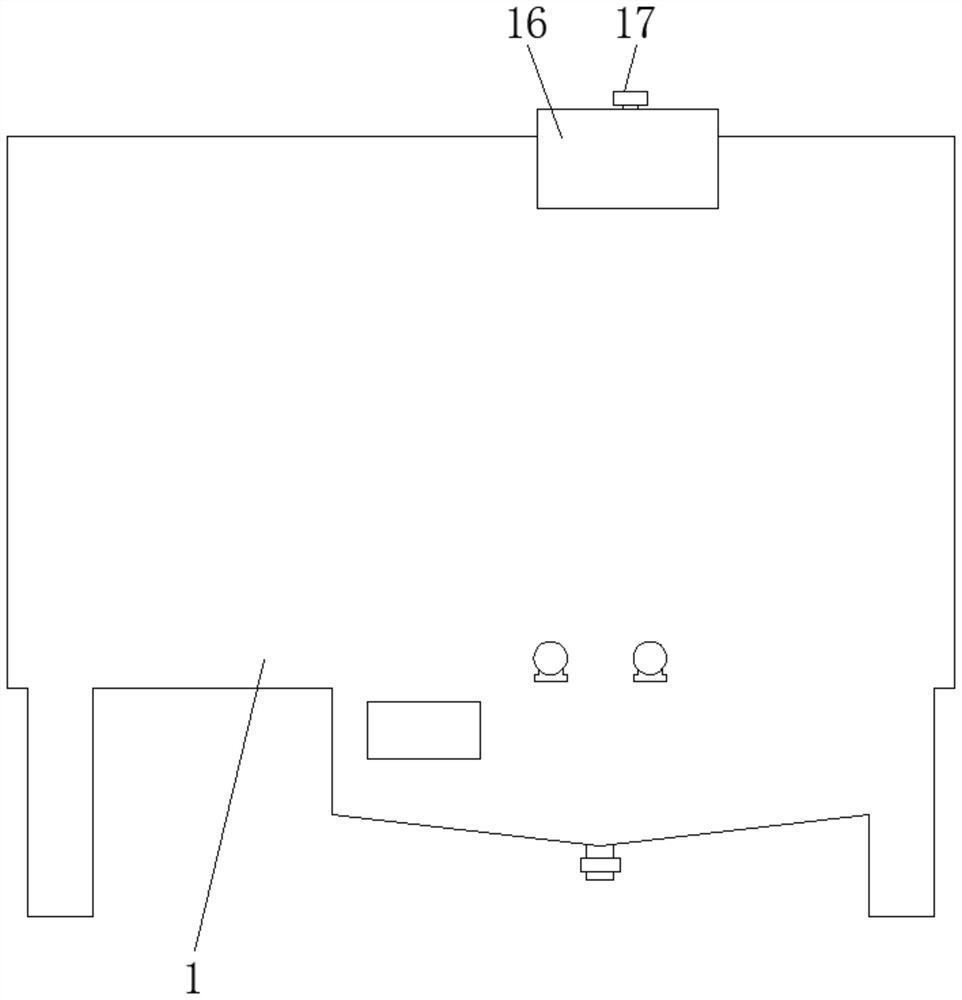

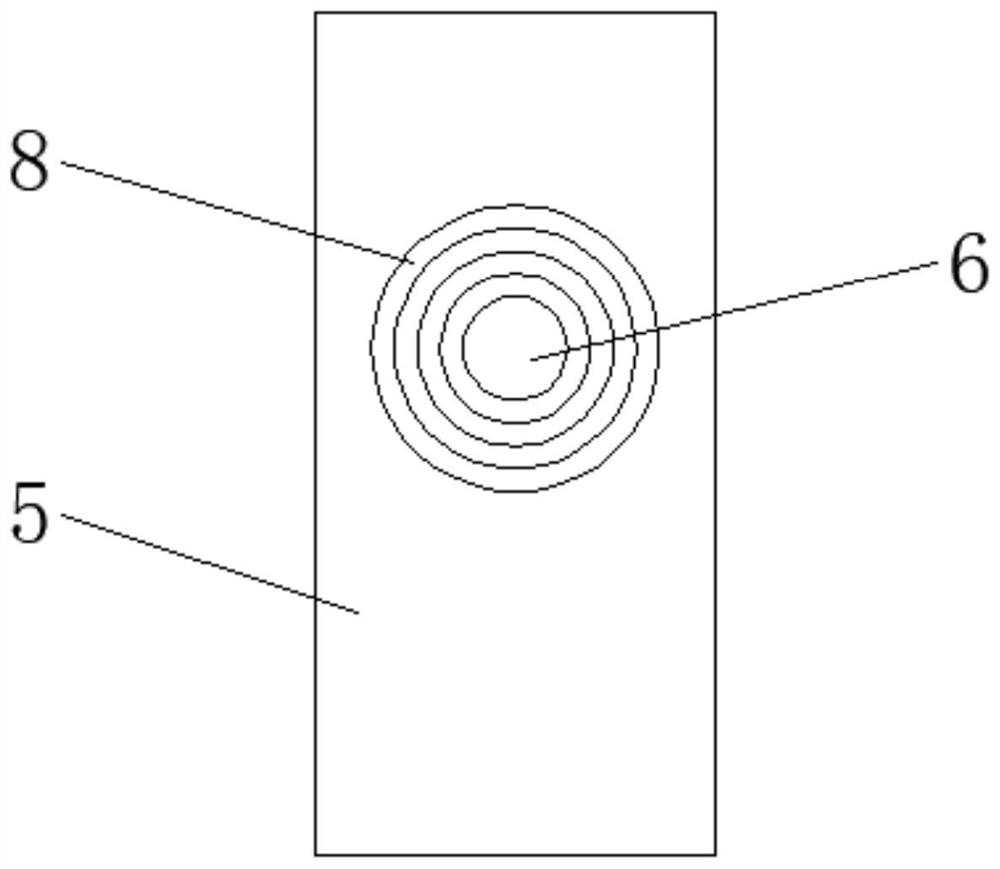

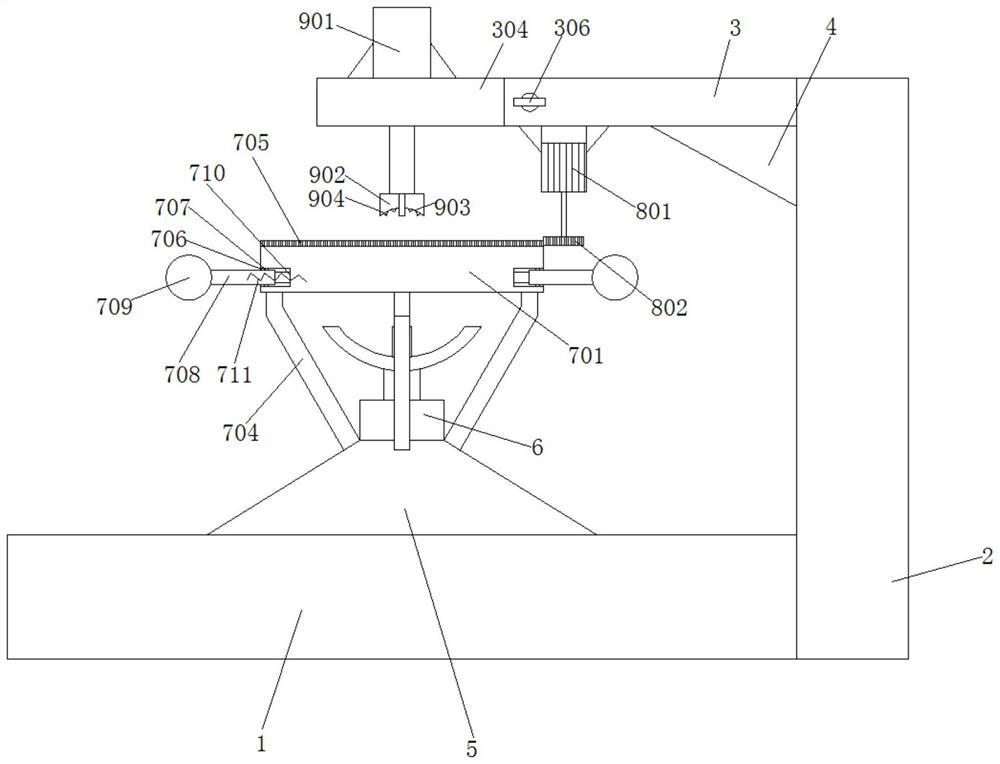

The invention discloses the power cable peeling device with wire and sheath winding and recycling functions. The power cable peeling device comprises a power cable and a peeling and winding device, wherein the power cable is movably connected with the peeling and winding device; compared with the prior art, the device has the advantages that the device can be applied to power cables with differentdiameters, the phenomenon that the power cable is deflected is effectively avoided, the two sides of the cable can be cut, the bare wire and the cable sheath do not need to be separated manually, andthe peeling time is short; a condition that one end of the cable is grasped and dragged forcefully to move manually is not needed; instead, the cable is cut and peeled by taking the cable sheath andbare wire as a movable part and by taking a peeling knife as a static part, so that an operator does not make contact with the power cable, and the hand cannot be scratched by the relatively thin cable; and meanwhile, the cable sheath and the bare wire which are subjected to cutting and peeling can be wound and recycled, and manual winding and recycling by the operator is not needed, so that the workload of operator is greatly reduced, and the working efficiency is greatly improved.

Owner:南通通城电力设备制造有限公司

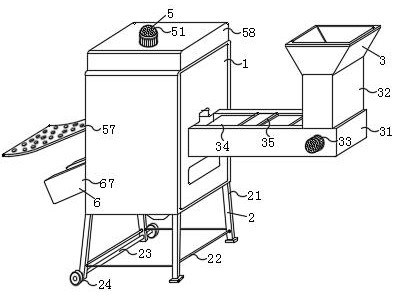

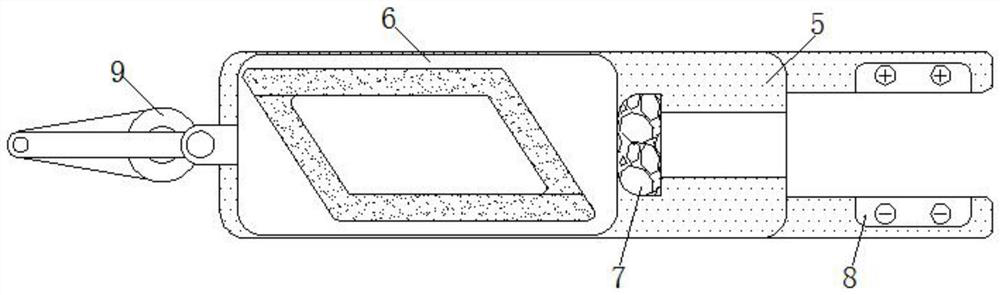

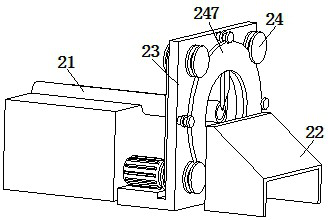

Peeling device for single-core cable

InactiveCN107768043AEasy peeling operationEasy to follow upBasic electric elementsElectronic waste recyclingEngineeringSingle-core

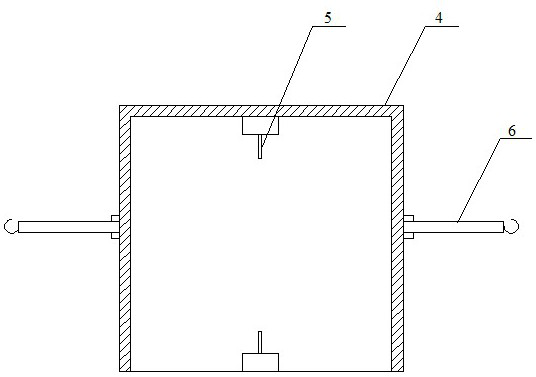

The invention discloses a peeling device for a single-core cable, and the device comprises a device body. The interior of a container is sequentially provided with a heating box, an extruding plate, asectioning apparatus and a peeling apparatus from the left to the right. The right side of the device body is fixedly connected with a collection box. The invention relates to the technical field ofcables, and the device enables the material incoming and outgoing to be very convenient, separates the cable and the sheath, facilitates the processing, improves the stability, is simple in structure,and is high in practicality.

Owner:陈杨平

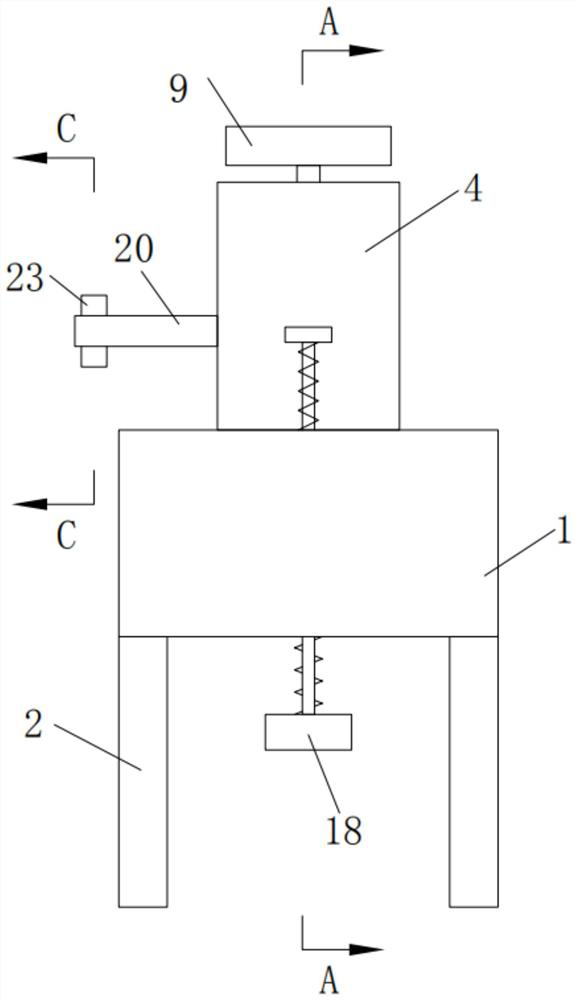

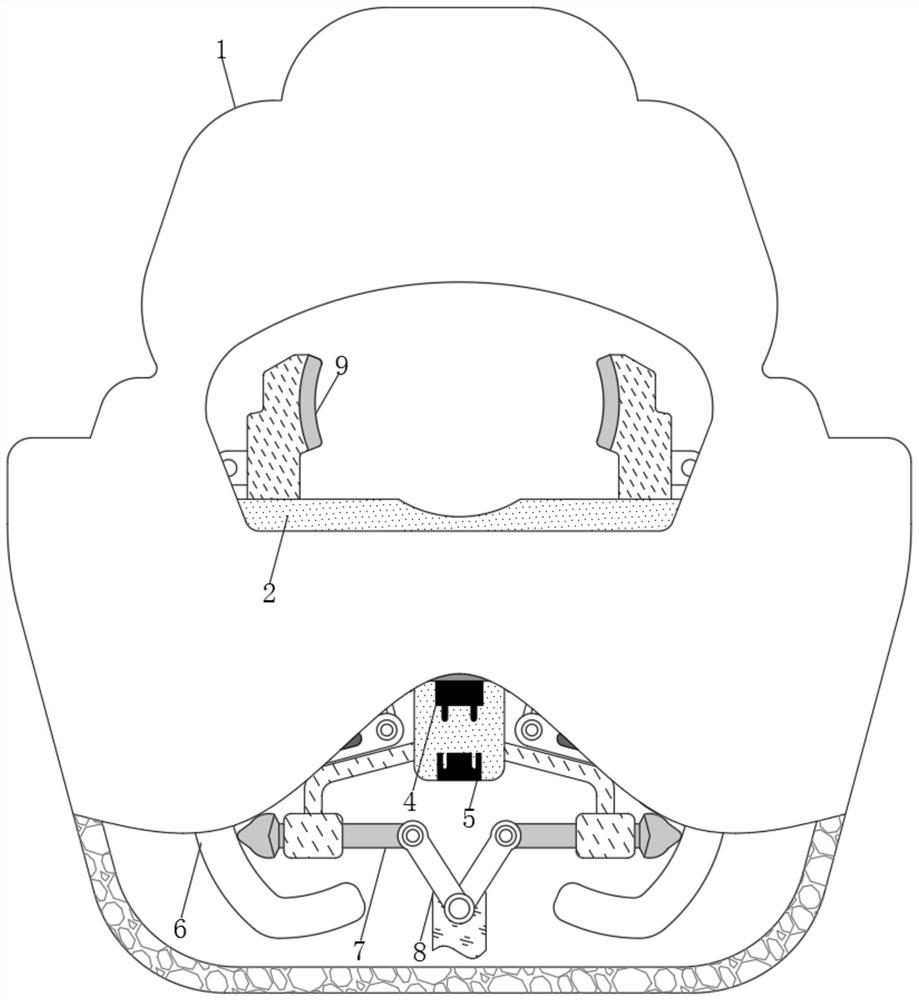

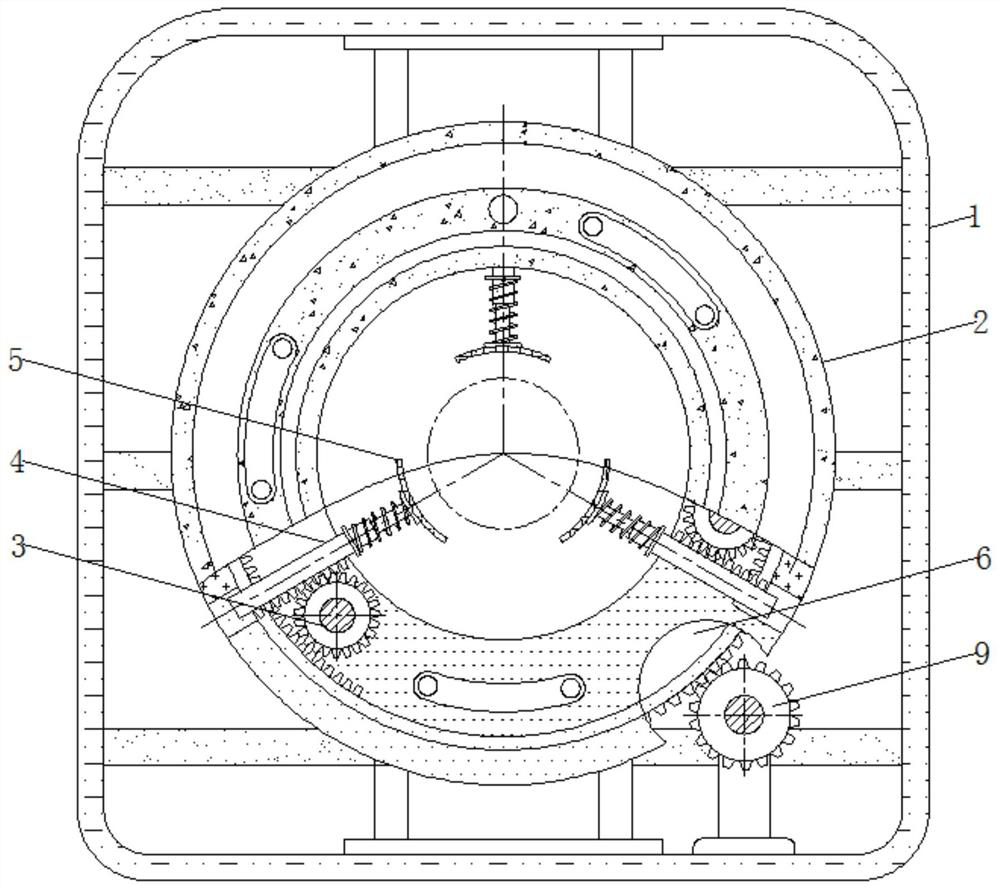

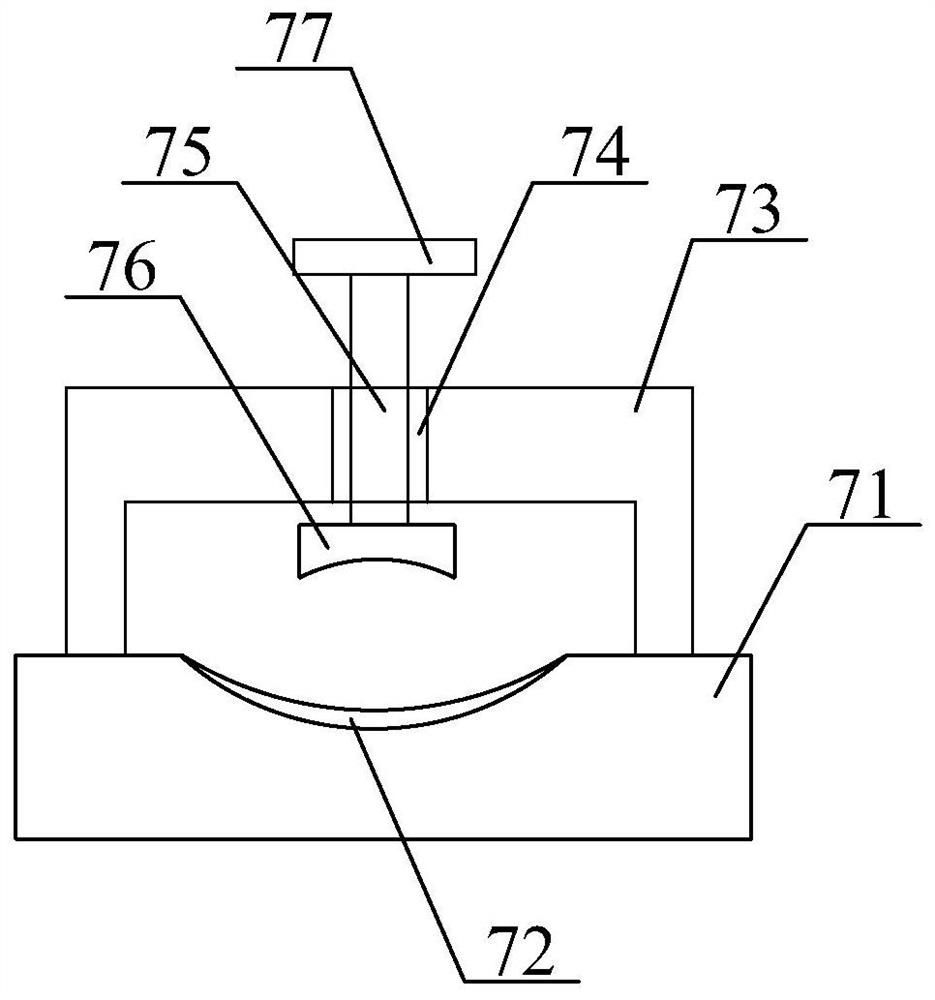

Peeling and gourd ladle taking integrated device for pumpkin processing

ActiveCN111642967ANot easy to dropTo achieve the effect of peelingPeelersAgricultural engineeringStructural engineering

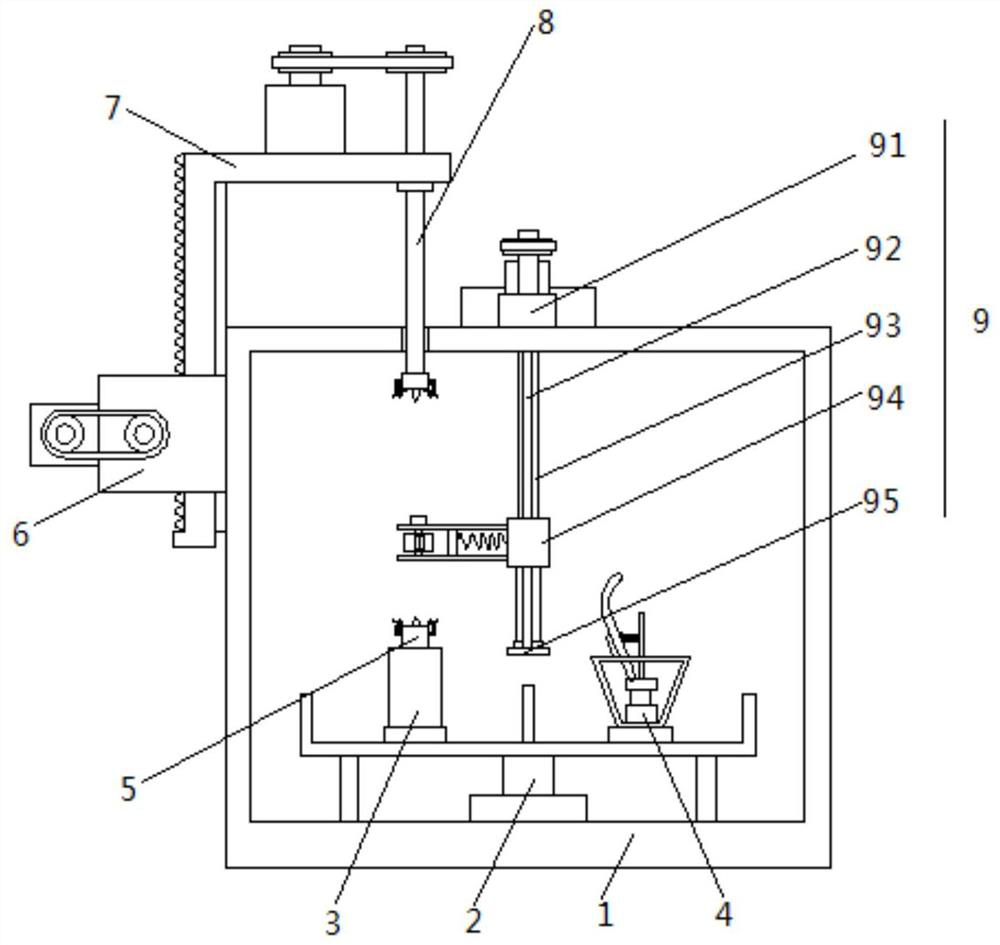

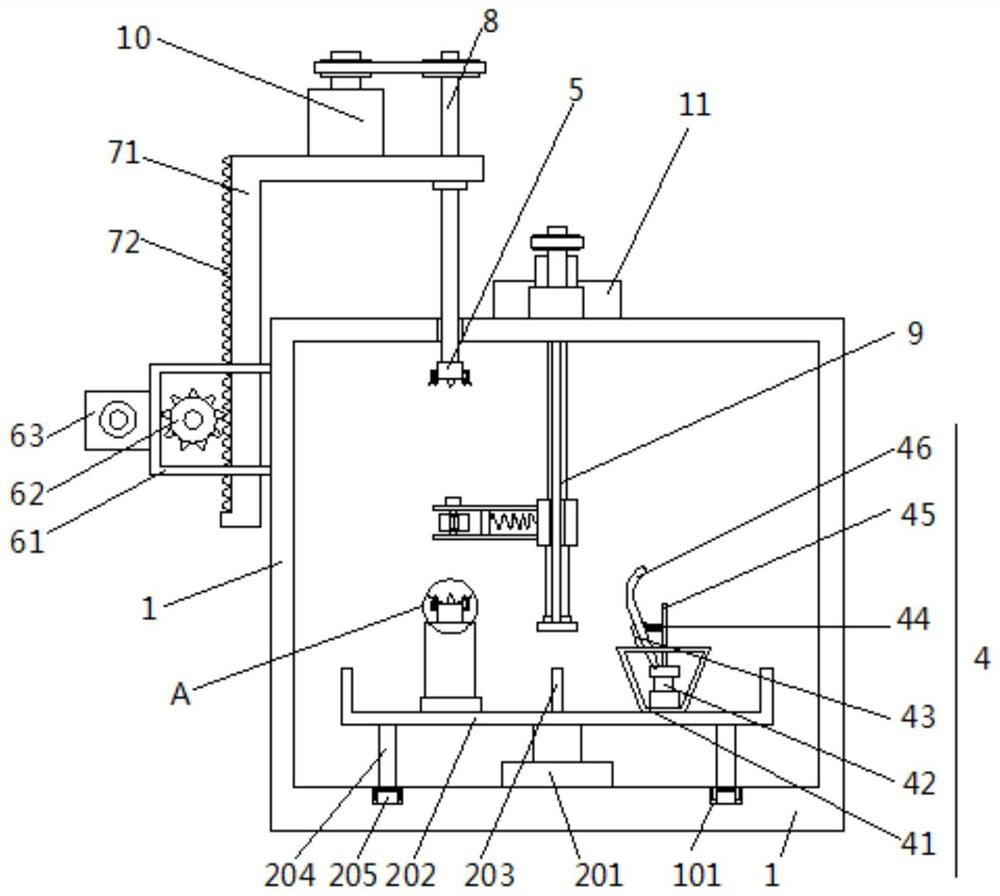

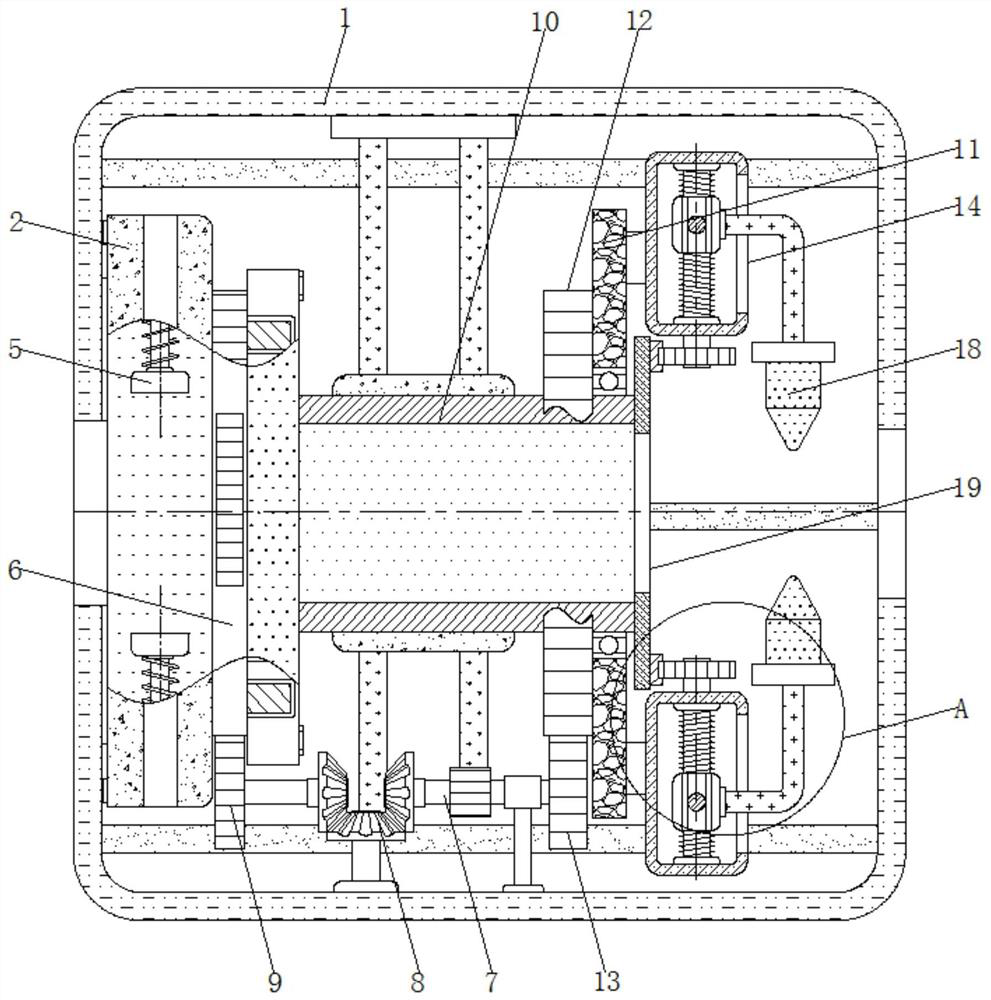

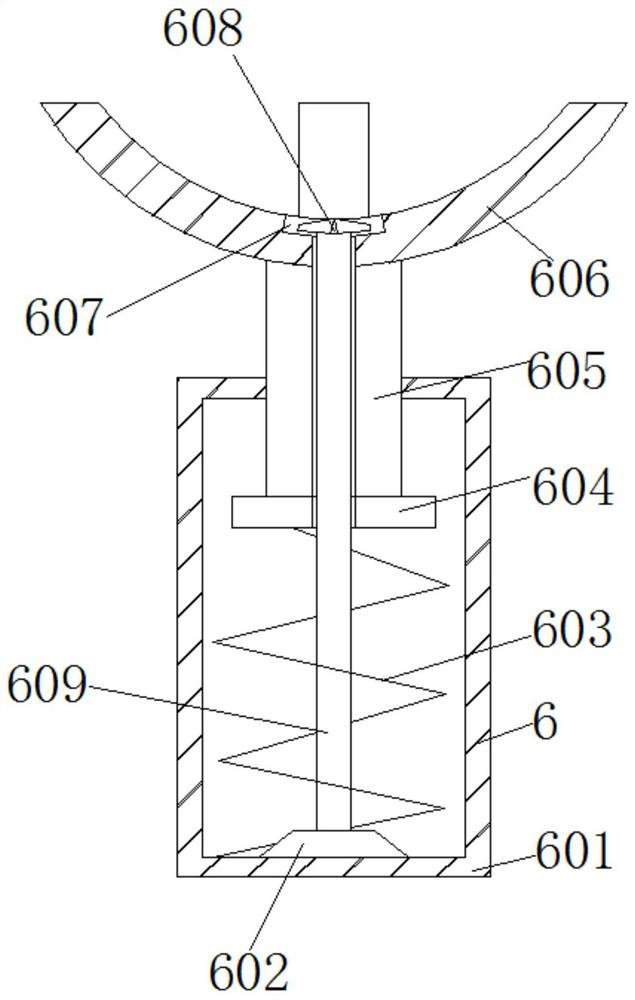

The invention provides a peeling and gourd ladle taking integrated device for pumpkin processing. The device comprises a box body in a front and back side penetrating arrangement, an annular chute isformed in the outer side of the bottom center of the box body; a rotary collecting device is horizontally and rotationally connected to the center of the bottom of the box; a supporting shaft and a ladle removing device are horizontally and rotationally connected to the two sides of the center of the top of a horizontal collecting device correspondingly; a servo motor is fixedly mounted at the topof a lifting assembly; a rotating shaft is vertically and rotationally connected to the side, close to the center of the box, of the lifting assembly; a notch groove is longitudinally formed in the center of the top of the box, rolling grooves are formed in the left and right sides of the notch groove; a lifting device is mounted at the upper end of the notch groove; and a vertical plate is fixedly connected to the position, located on the rear side of the notch groove, of the top of the box body, a first electric push rod is fixedly connected to the side, close to the center of the box body,of the vertical plate, and the other end of the first electric push rod is fixedly connected with the lifting device. The invention provides the peeling and gourd ladle taking integrated device for pumpkin processing to solve the problem of low efficiency of peeling and gourd ladle taking of the pumpkin processing.

Owner:新疆海川三新食品有限公司

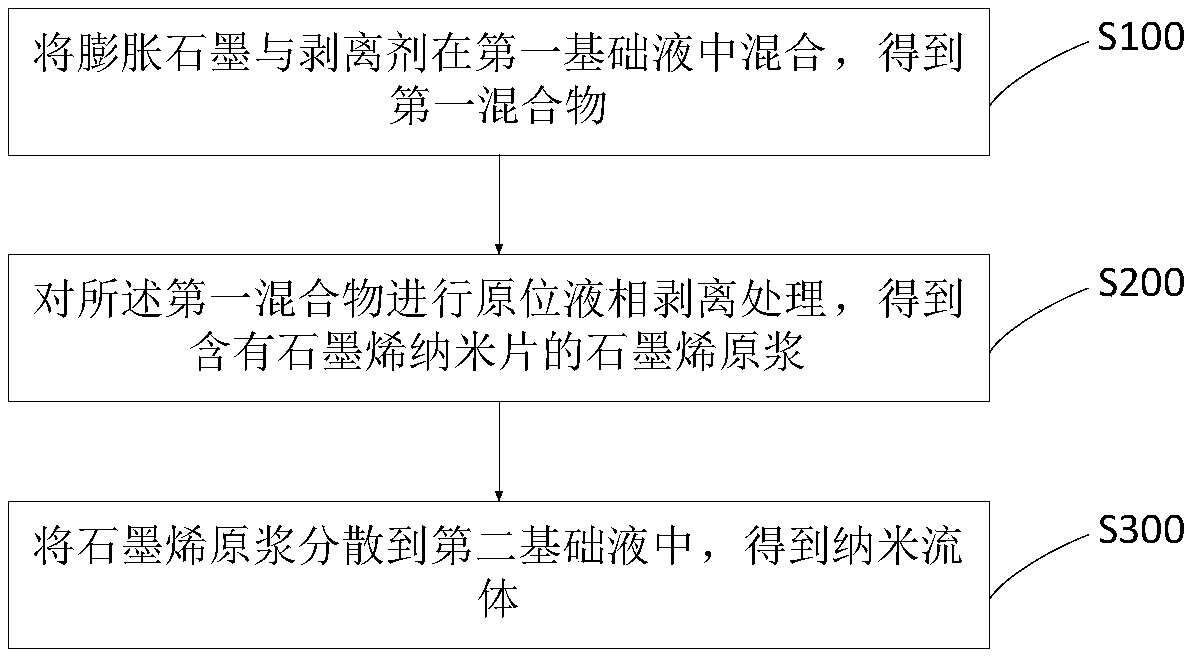

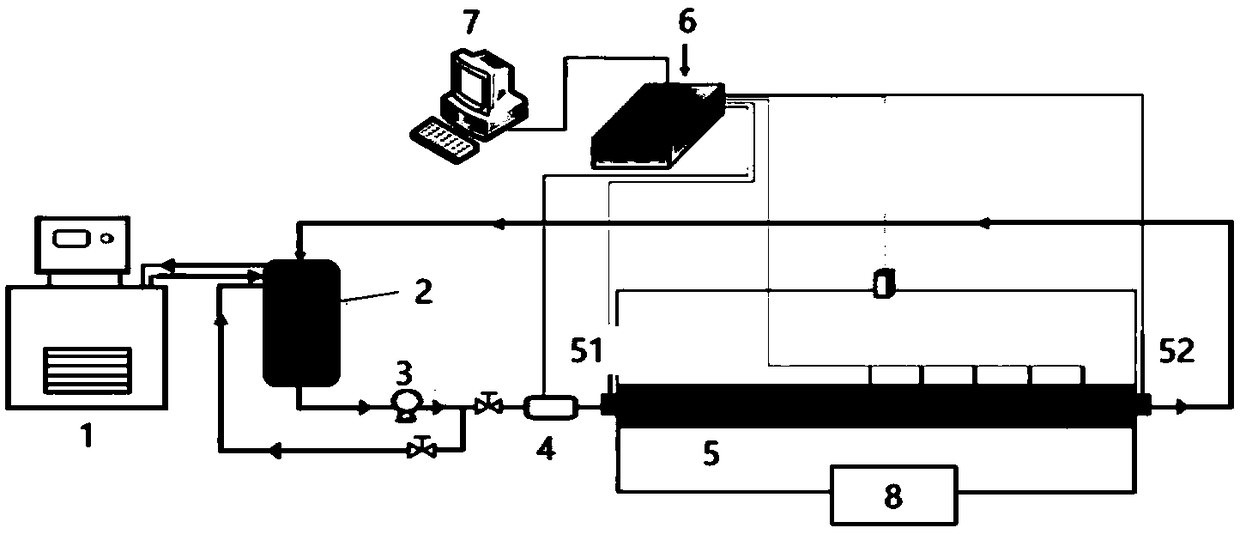

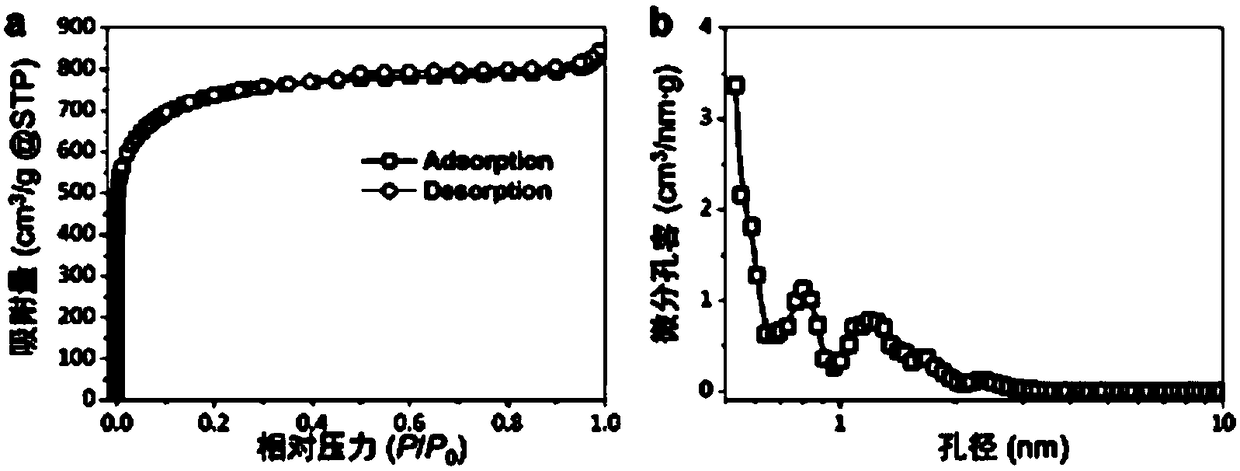

Nano-fluid for efficient heat transfer fluid, preparation method thereof and heat exchange device

The invention provides a nano-fluid, a preparation method thereof and a heat exchange device. The preparation method of the nano-fluid comprises the following steps: mixing expanded graphite with a stripping agent in a first base fluid to obtain a first mixture, and performing in-situ liquid phase stripping treatment on the first mixture to obtain a raw graphene stock containing graphene nano-sheets; and uniformly dispersing the raw graphene stock into a second base fluid to obtain the nano-fluid. The inventors have found that the method is simple and convenient to operate, facilitates large-scale production, is safe and environment-friendly, and can obtain the nano-fluid with high heat transfer coefficient, high thermal conductivity, low flow resistance and long-term stable dispersion.

Owner:ENN GRAPHENE TECH CO LTD

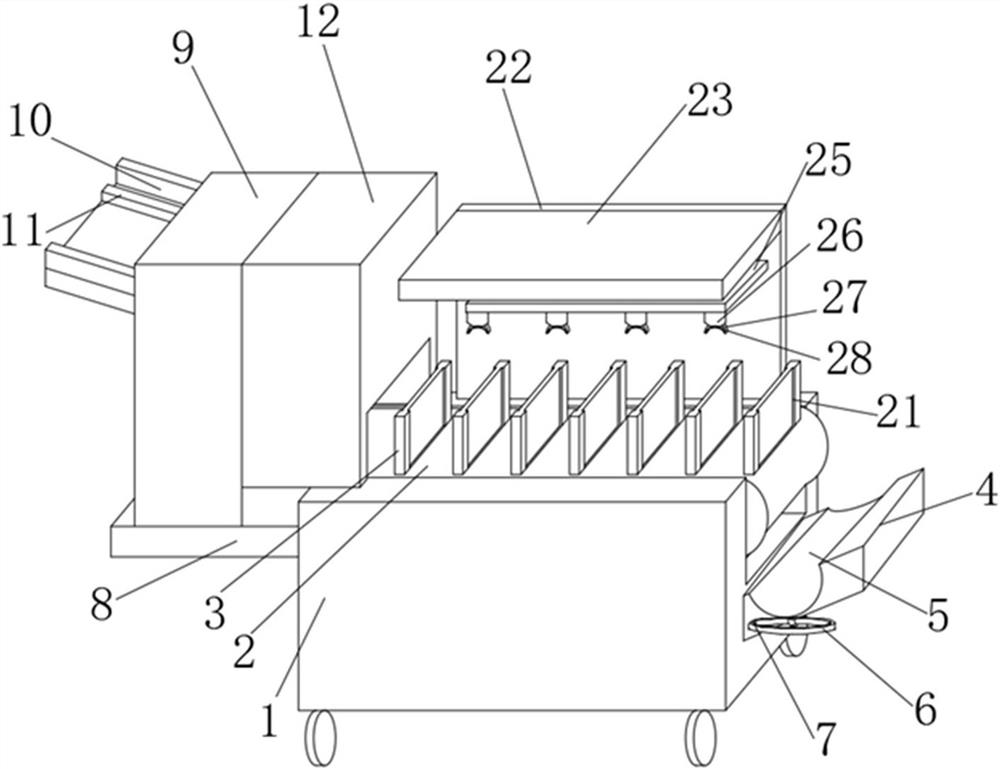

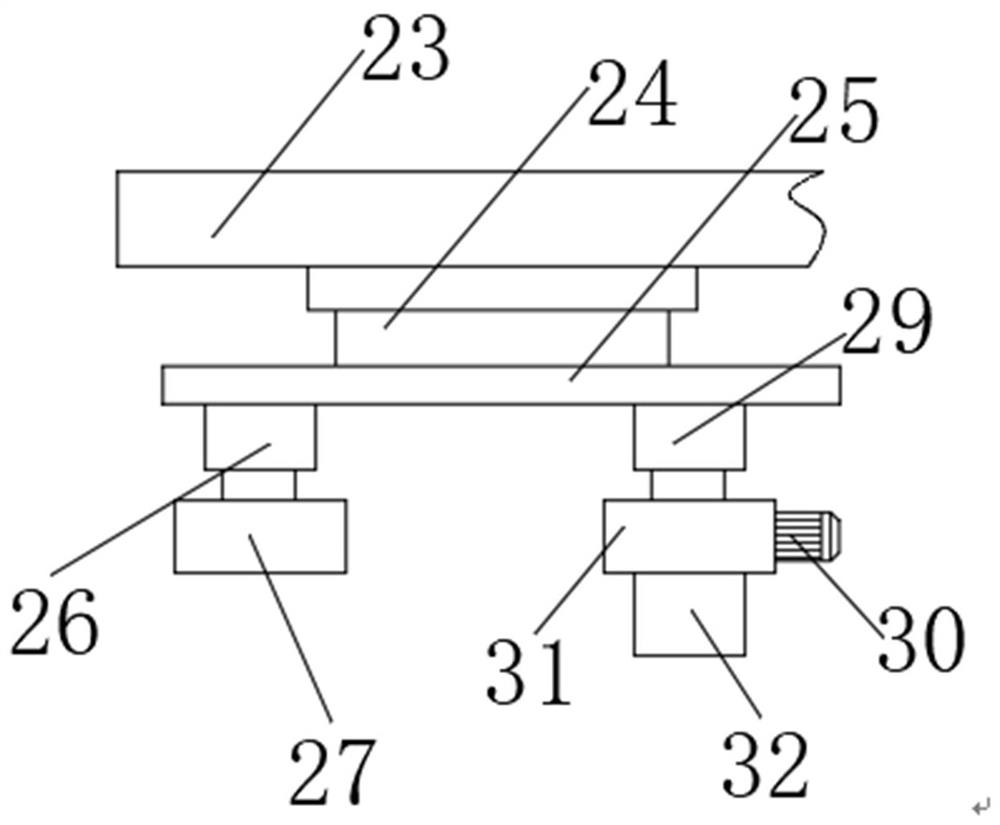

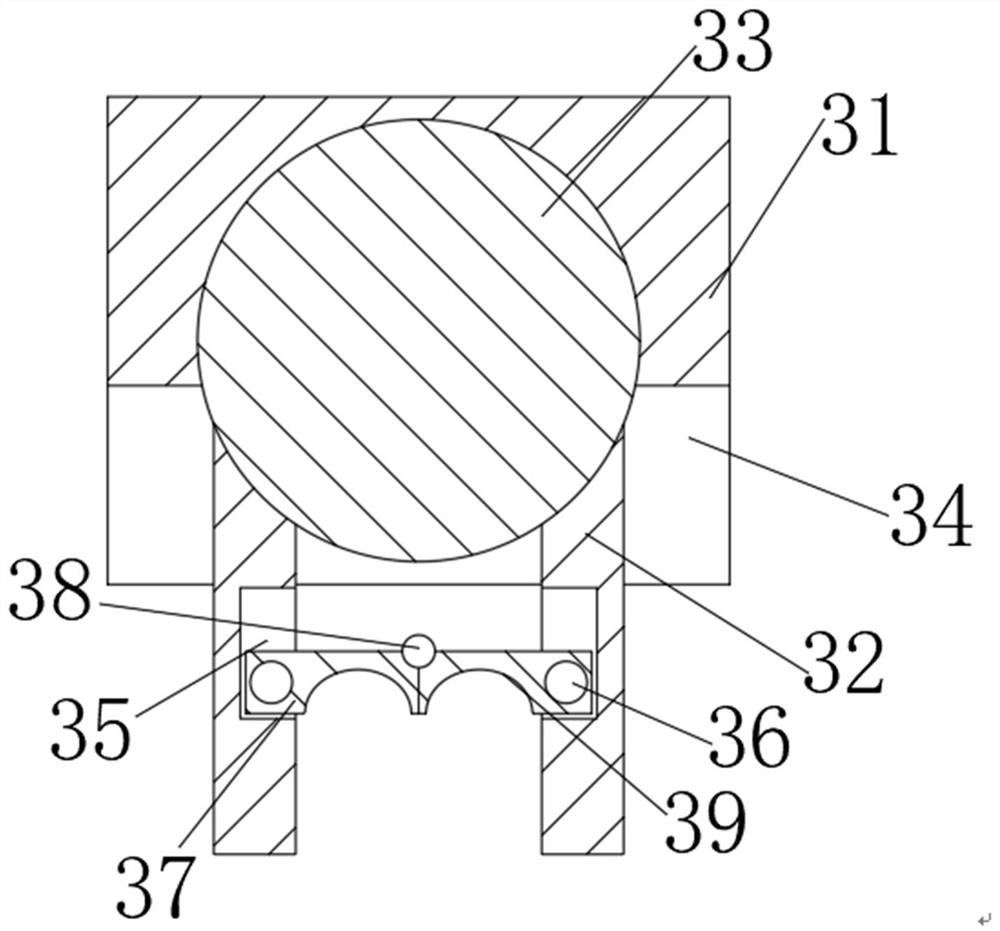

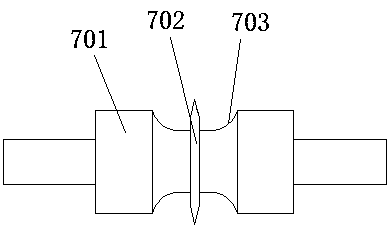

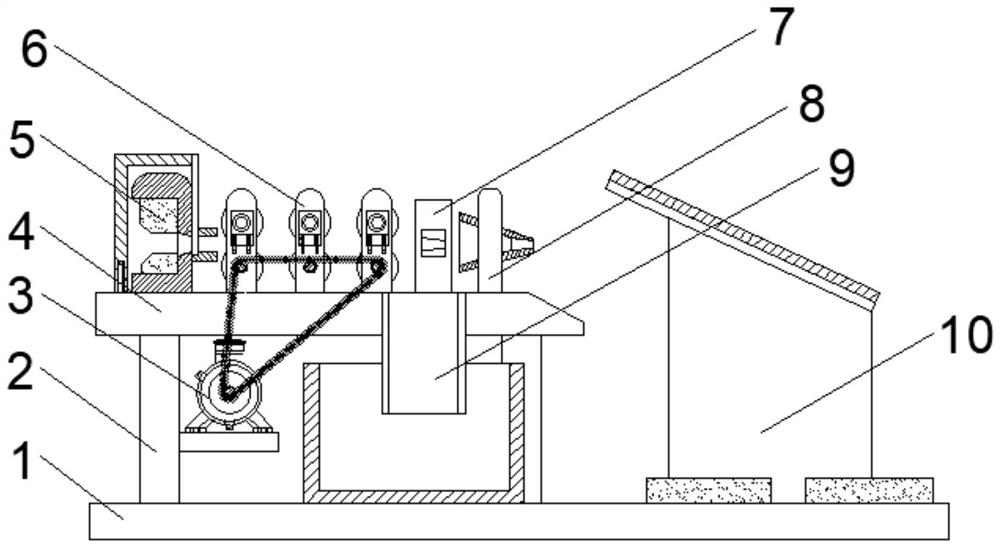

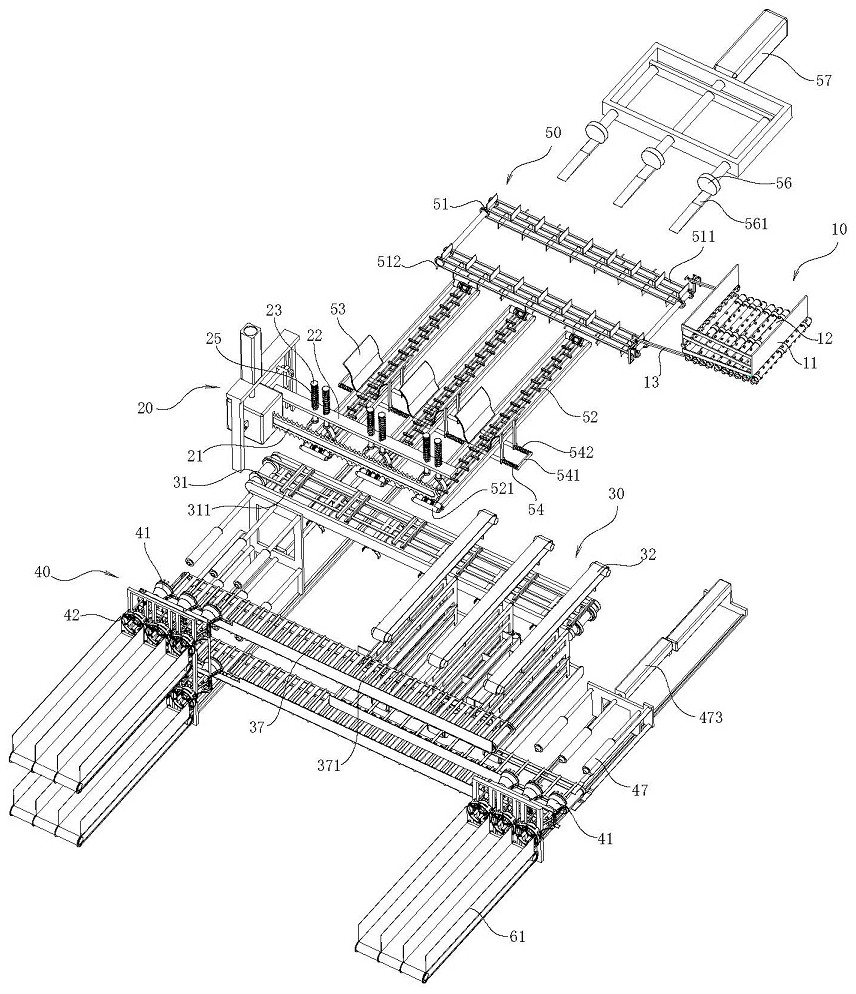

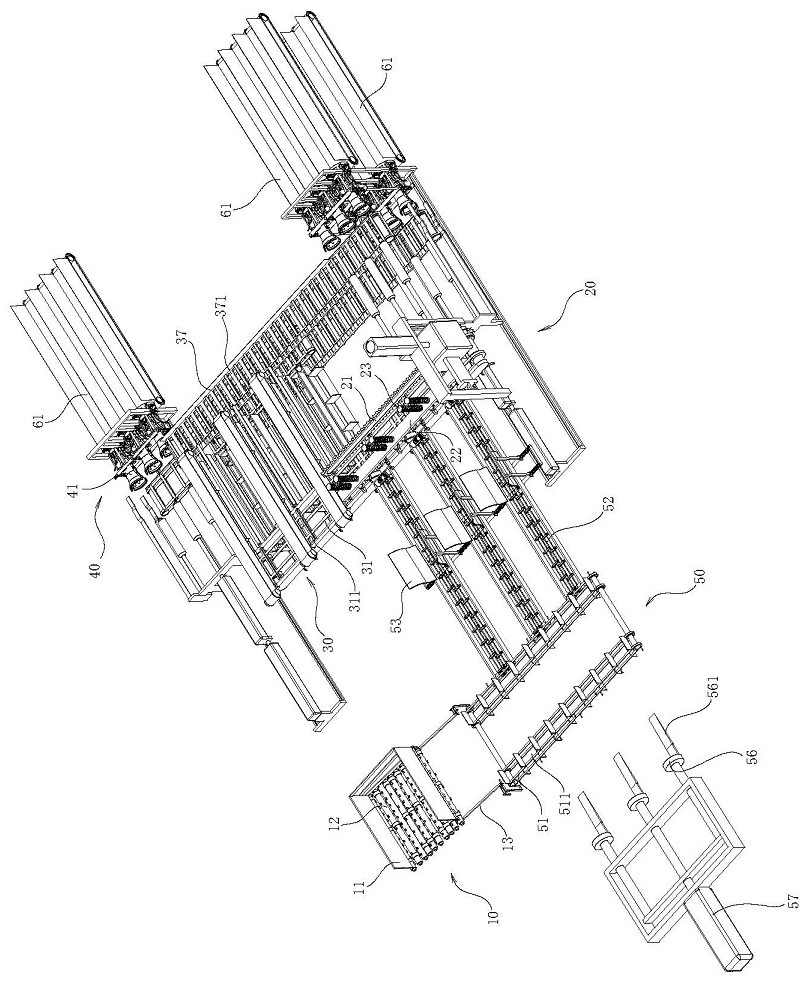

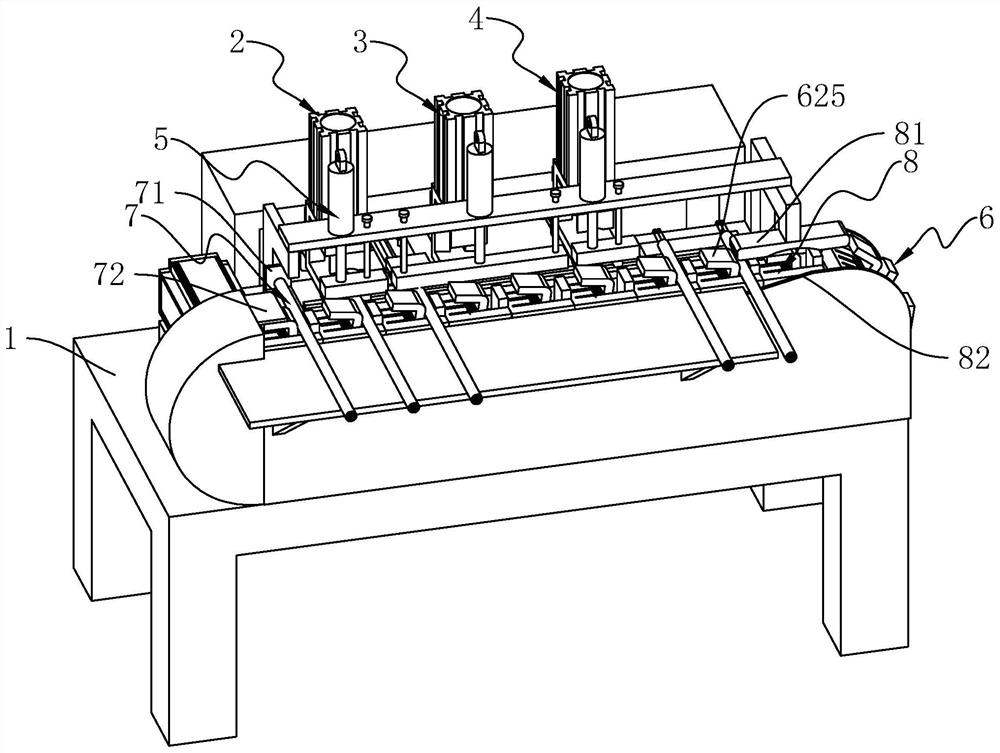

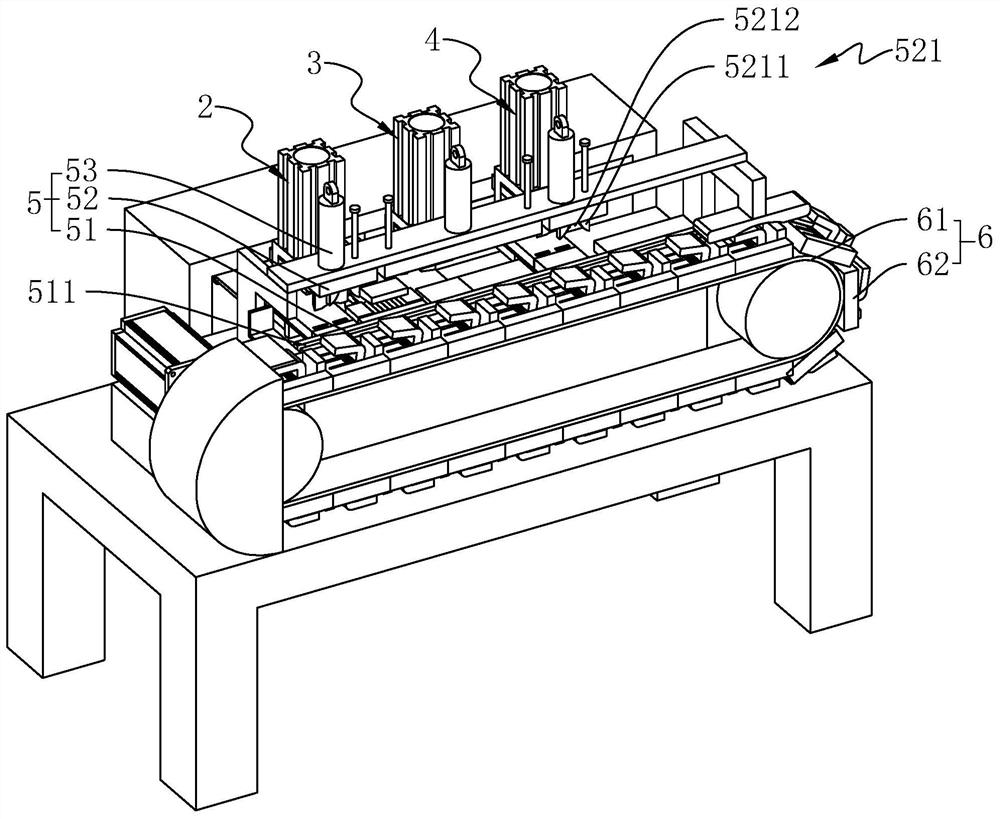

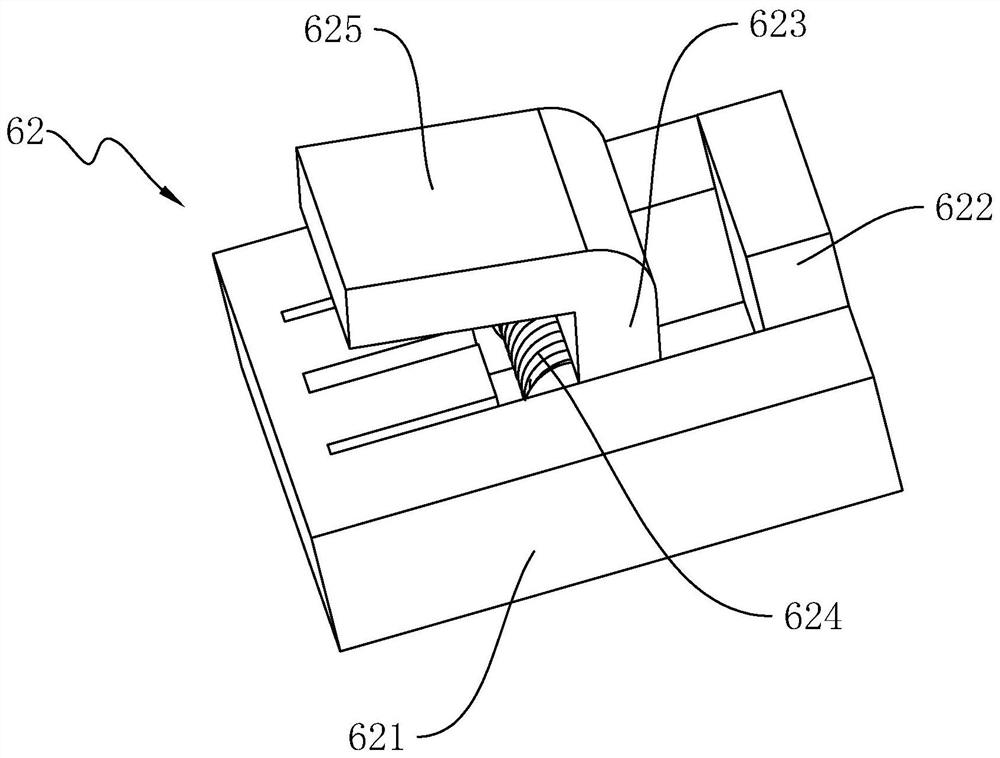

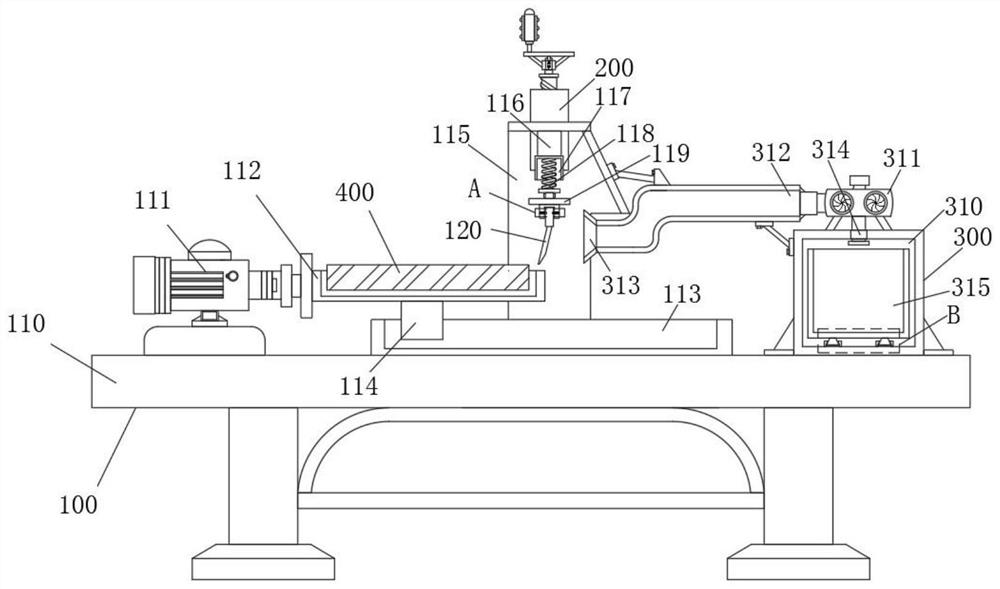

Cable peeling equipment

ActiveCN112838463AAutomate operationEasy peeling operationLine/current collector detailsApparatus for removing/armouring cablesStructural engineeringMechanical engineering

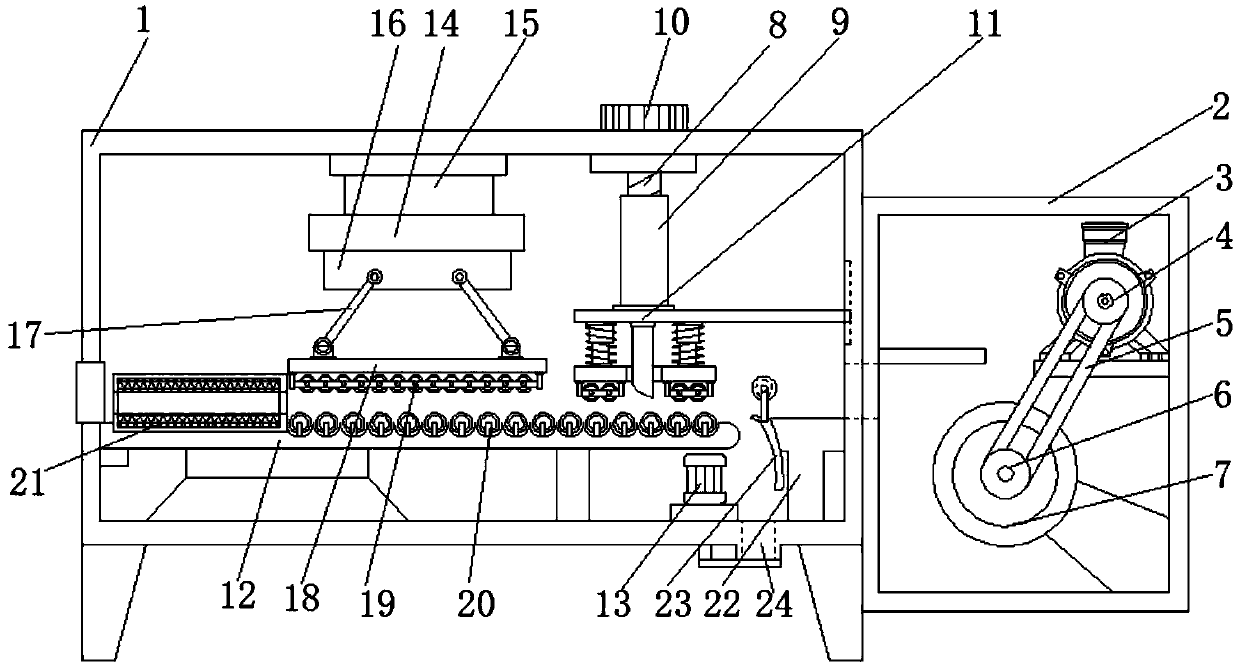

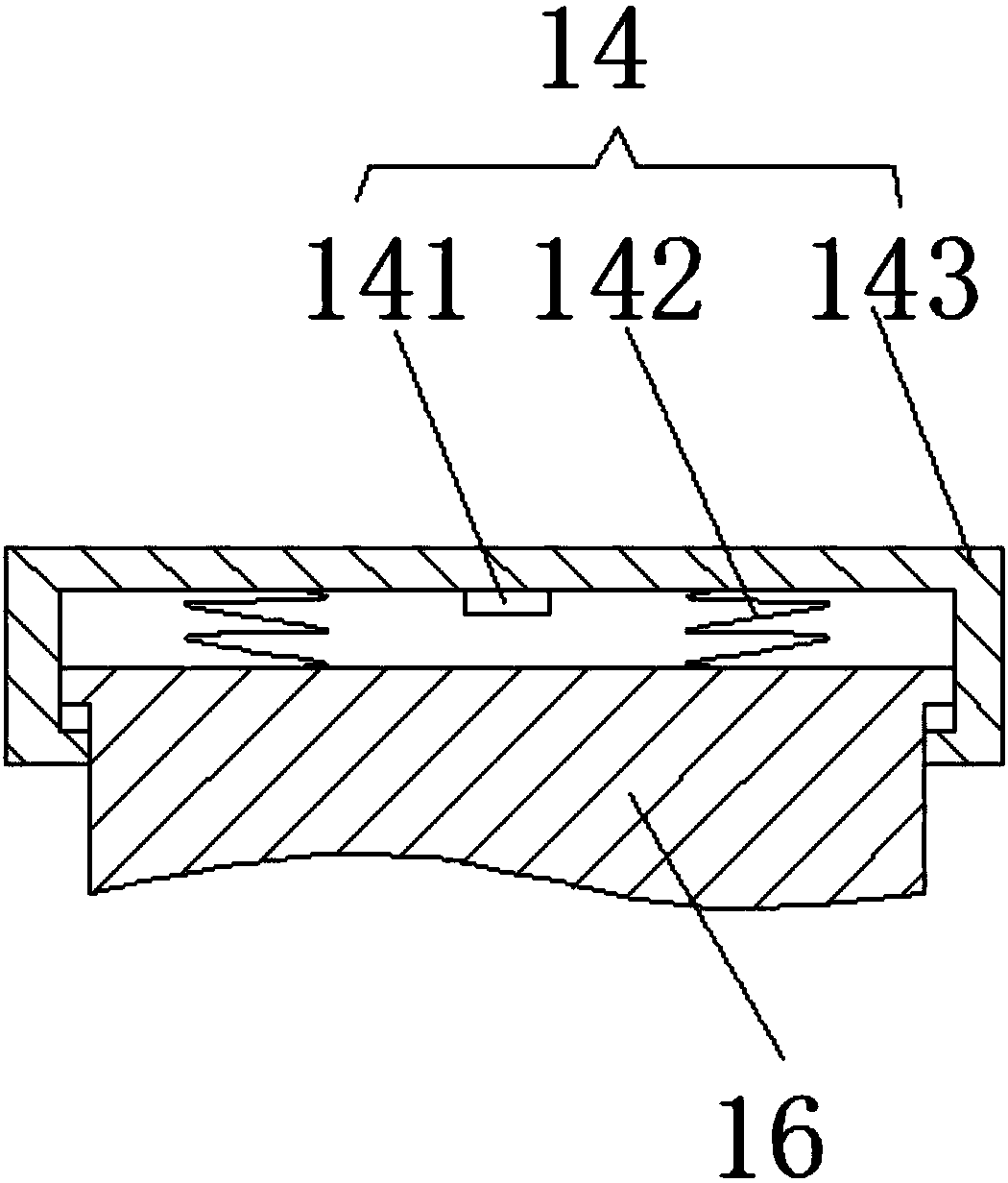

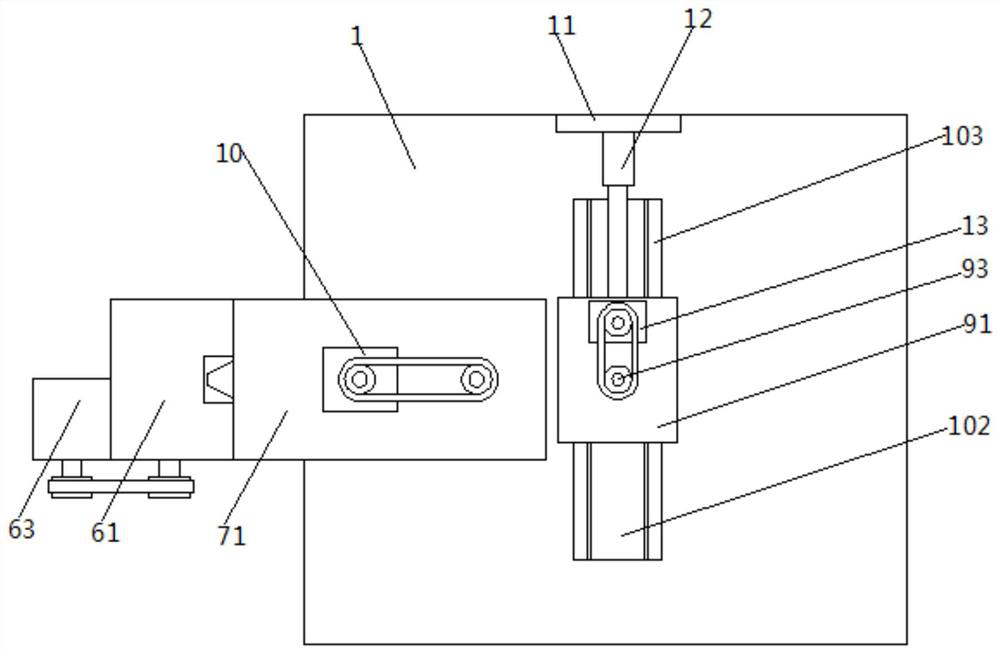

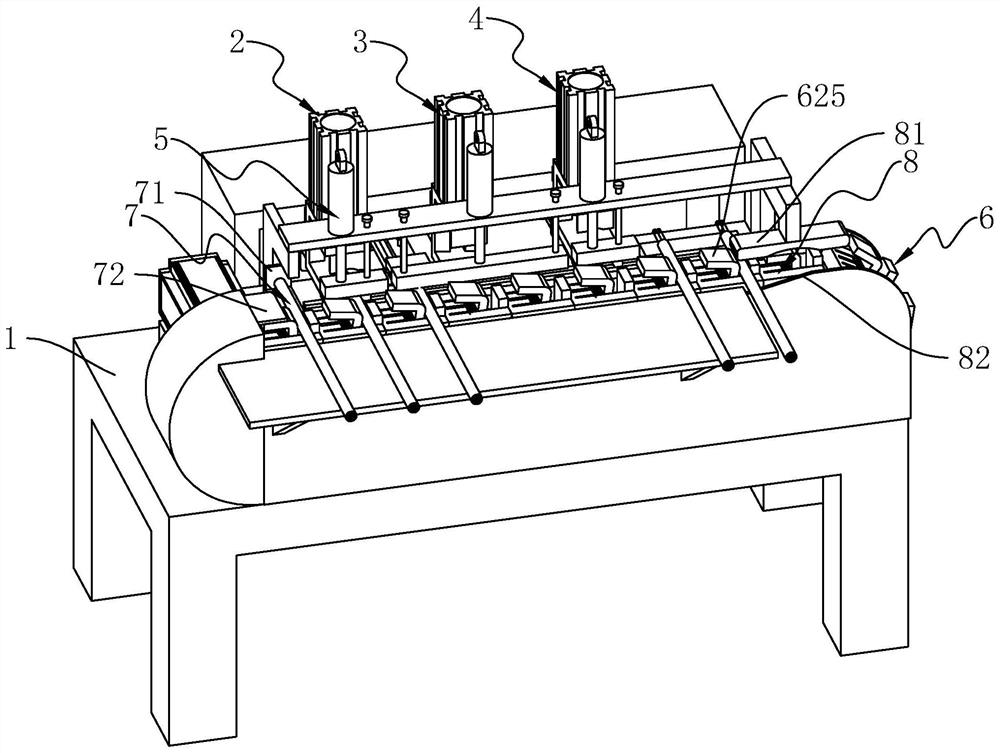

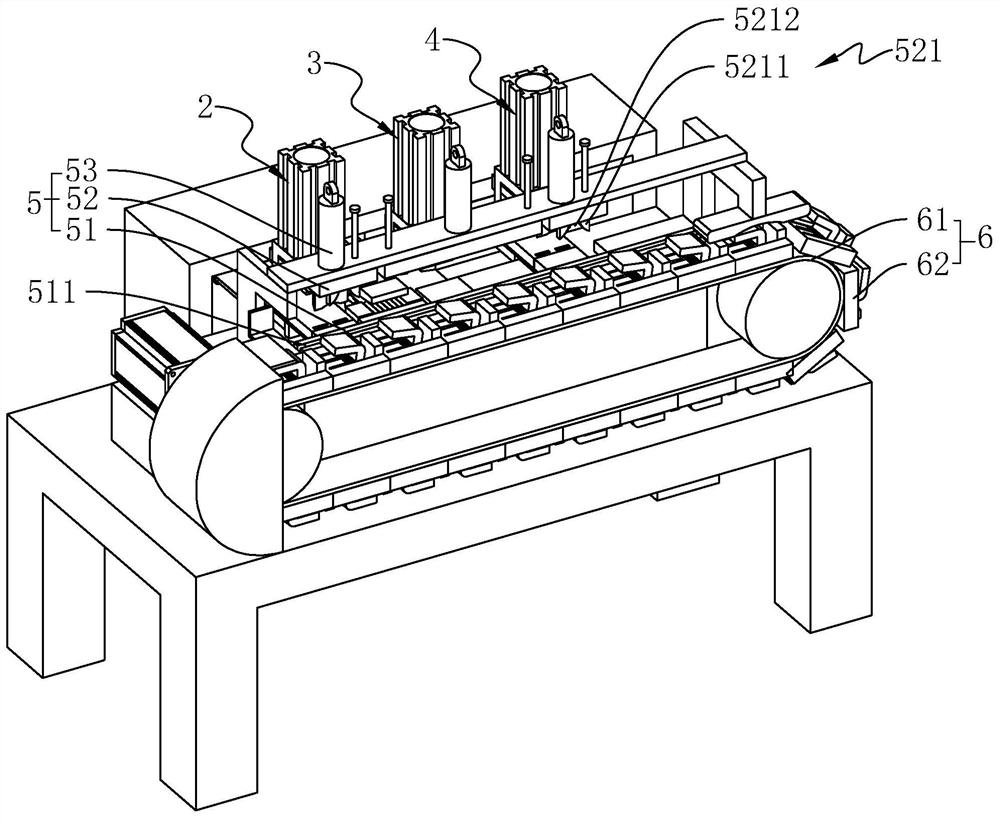

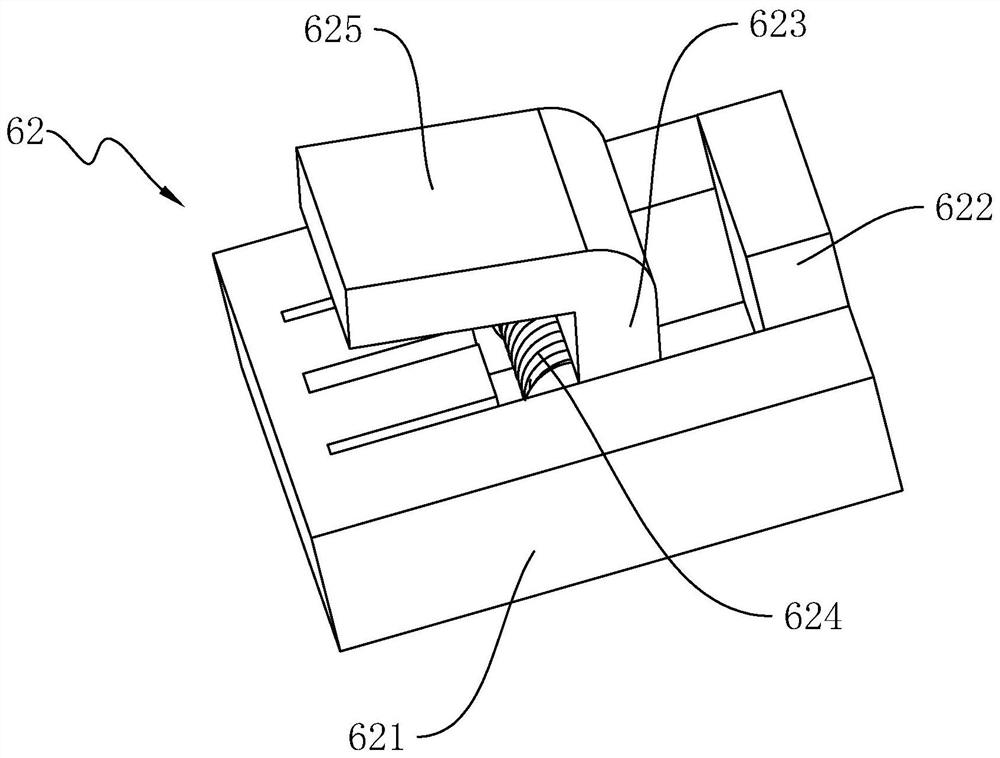

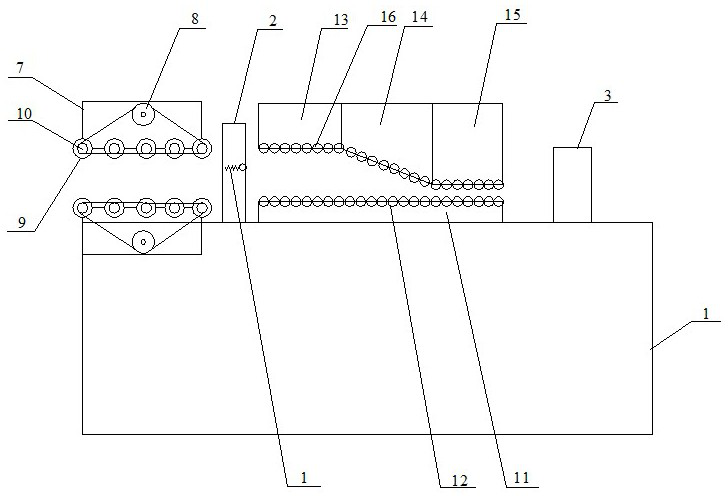

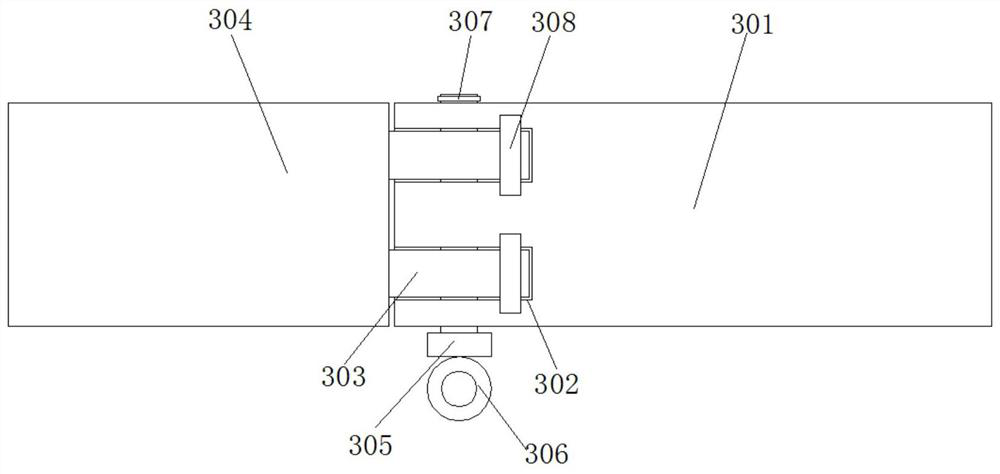

The invention discloses cable peeling equipment, and relates to the field of cable processing, and the cable peeling equipment comprises a rack, the rack is provided with a pressing device, two peeling devices and a conveying device, the two peeling devices are the first peeling device and the second peeling device respectively, the conveying device is used for enabling a cable to sequentially pass through the first peeling device and the second peeling device, and the conveying device is used for conveying the cable to the first peeling device and the second peeling device. The first stripping device is used for stripping an outer ring sheath of a cable, and the second stripping device is used for stripping a sub-wire of the cable; each peeling device comprises a sliding seat connected to the rack in a sliding manner, a peeling assembly arranged on the sliding seat and a driving part for driving the sliding seat to slide; and the sliding base slides in the direction away from the pressing device, and the peeling assembly comprises a peeling tool apron connected to the sliding base in a sliding mode and a driving air cylinder driving the peeling tool apron to slide. By arranging the pressing device, the two peeling devices and the conveying device, the cable peeling operation is more automatic, and the cable peeling operation is more convenient.

Owner:台州腾标电子有限公司

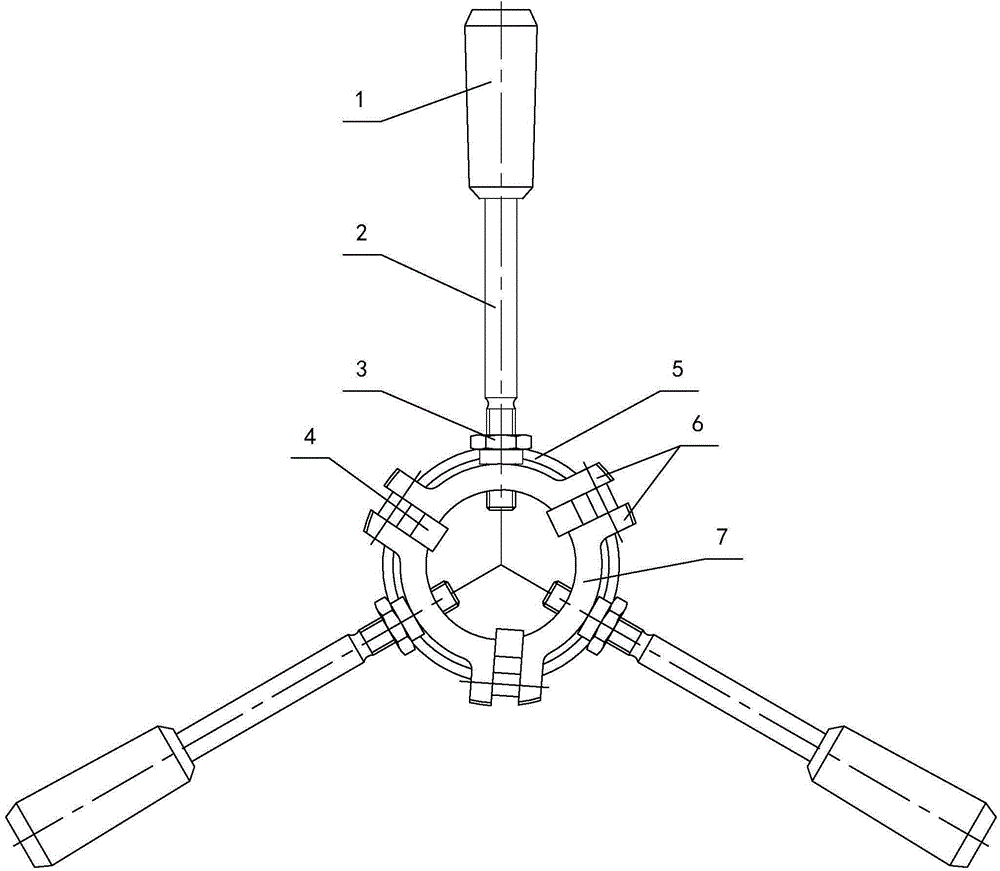

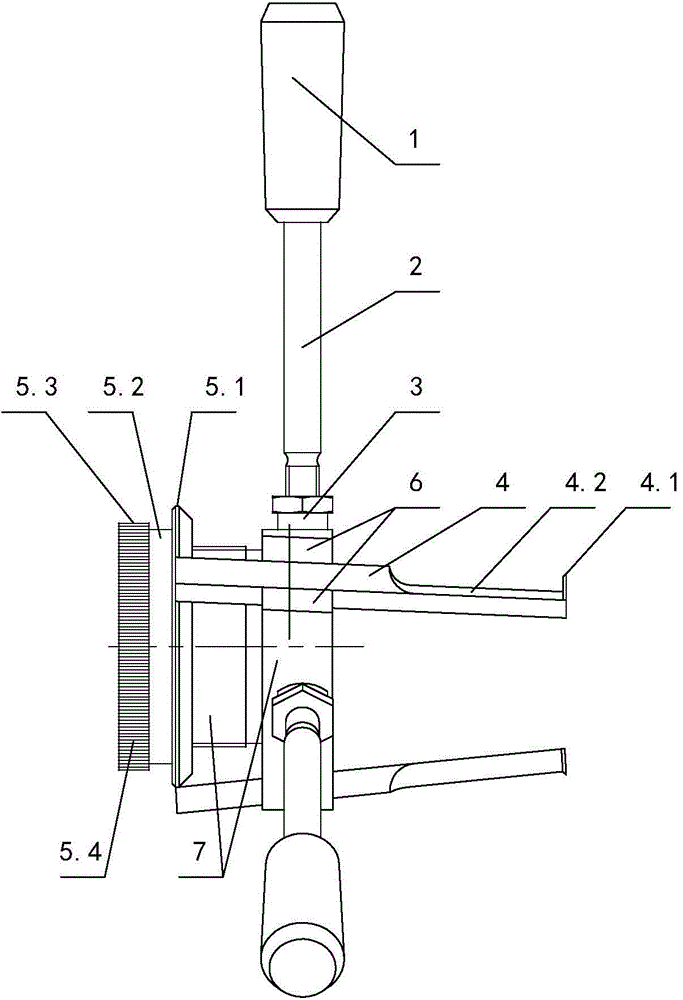

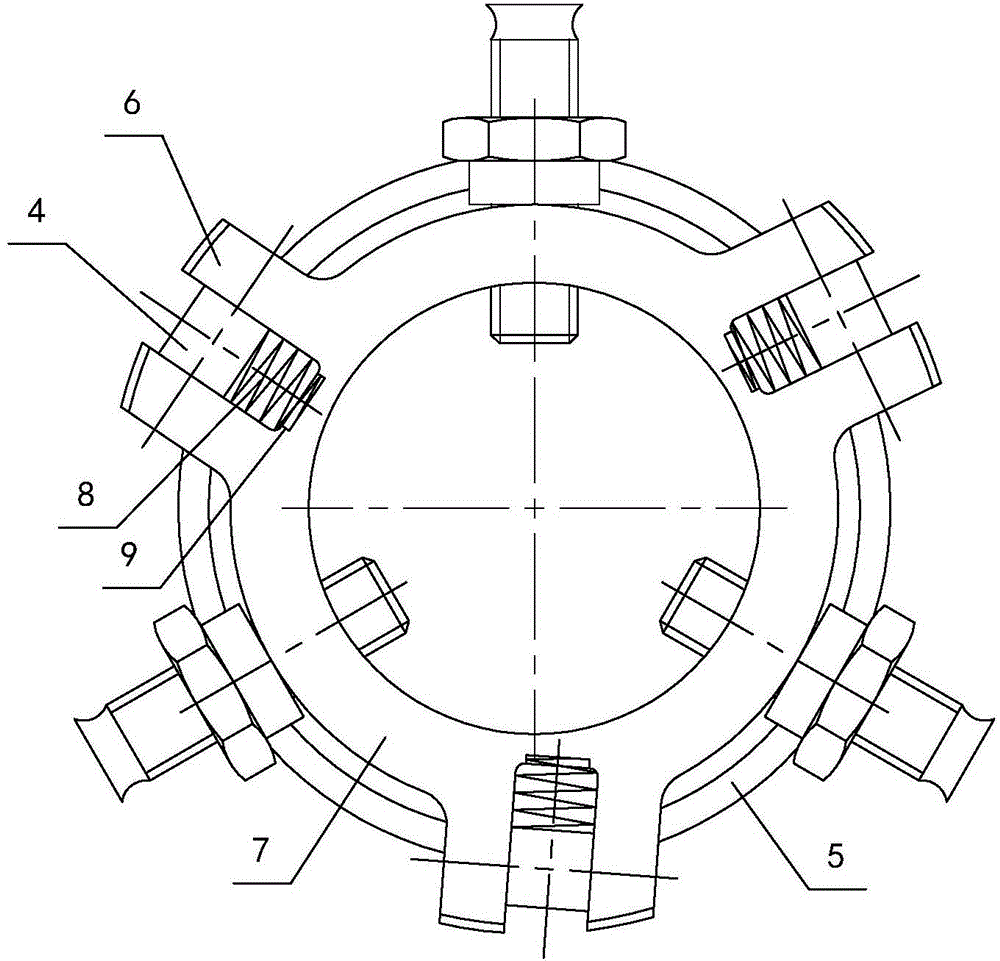

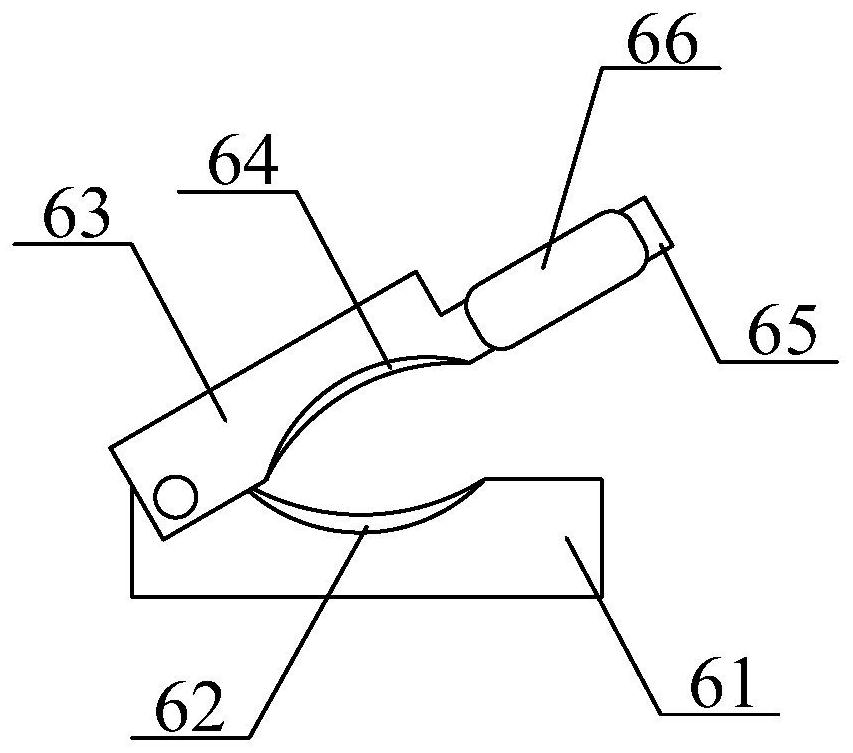

Cable peeler

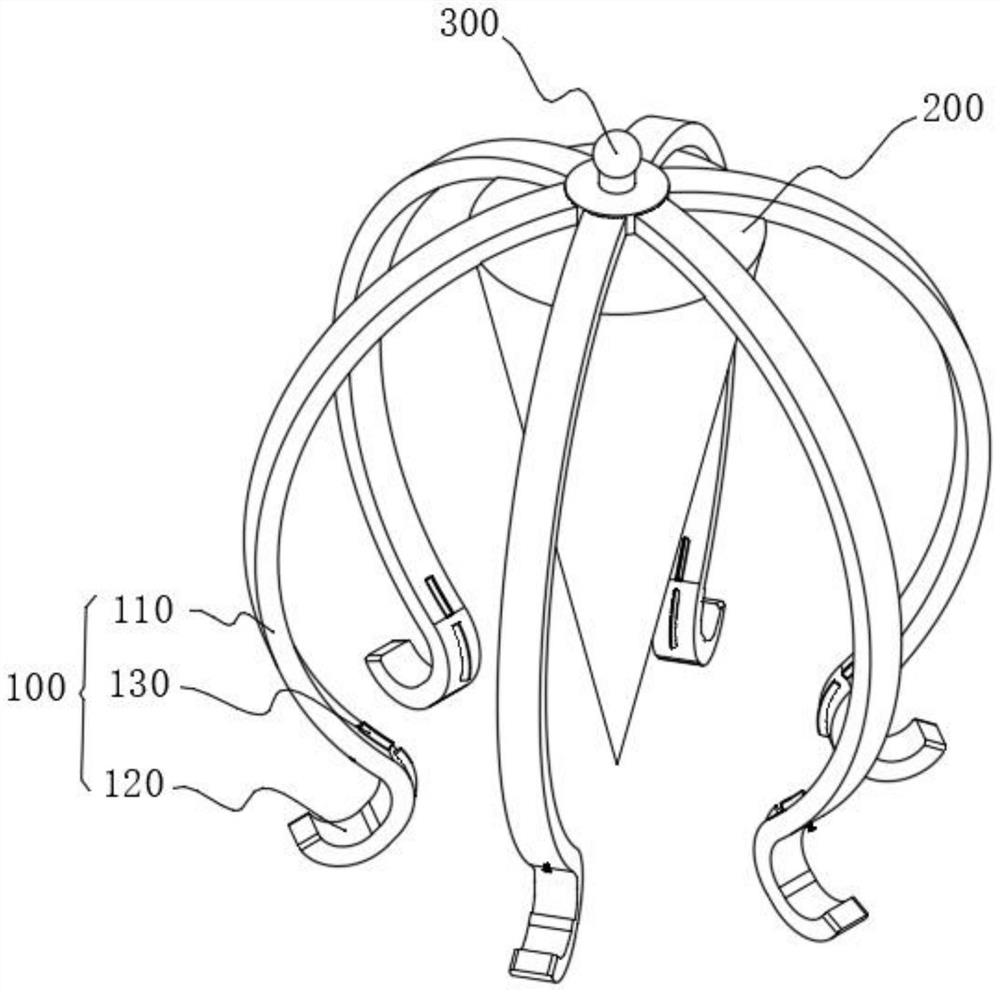

The invention discloses a cable peeler, comprising handles, a cable fixing sleeve, cable clamping units and cutter head assemblies, wherein the cable clamping units and the cutter head assemblies are all connected on the cable fixing sleeve. The three cable clamping units are uniformly distributed on the side wall of the cable fixing sleeve along the circumference. The three cutter head assemblies are hinged on the side wall of the cable fixing sleeve along the circumference. The three cable clamping units and the three cutter head assemblies are distributed in an alternate manner. The three handles are respectively connected to end portions of the cable clamping units. The cable peeler also comprises a cutter-head angle adjuster, which is screwed to one end of the cable fixing sleeve and is connected with the cutter head assemblies. By adopting such a structure, the cut-in angle and the cut-in depth of a cutter head can be randomly controlled, therefore making it very convenient to peel a cable and improving the production efficiency. In addition, a cable sheath is helically peeled off while the cutter head is screwed to conduct the cut-in operation, so that the cable sheath can be completely peeled off.

Owner:象山石浦浦江工具厂 +1

Sugarcane field leaf peeling machine

PendingCN111480456ATo achieve the purpose of peeling leavesReduce manual labor intensityHarvestersAgricultural lifting devicesEngineering

The invention discloses a sugarcane field leaf peeling machine. The sugarcane field leaf peeling machine comprises a machine body; a walking device which is mounted at the bottom of the machine body;a leaf peeling device which comprises a leaf peeling frame, wherein the front side of the leaf peeling frame is installed on the rear side of the machine body in a lifting mode, and the leaf peeling frame is driven by a lifting mechanism to ascend and descend; a plurality of leaf peeling rollers, wherein the axis of each leaf peeling roller is distributed in the front-back direction, and a plurality of leaf peeling ropes are arranged on each leaf peeling roller at intervals in the axis direction of the leaf peeling roller; wherein the front end of each leaf peeling roller is connected with therear side of the leaf peeling frame in a rotatable and detachable mode, and all the leaf peeling rollers are driven by a rotating mechanism to rotate. The leaf peeling frame can ascend and descend soas to be suitable for sugarcanes of different heights; the leaf peeling rope on the leaf peeling roller can rotate and knock off sugarcane leaves to achieve the purpose of leaf peeling, and the walking device on the machine body can drive the leaf peeling machine to walk between sugarcane rows to peel leaves, so that the labor intensity of workers is reduced, and the working efficiency is improved.

Owner:广西双高农机有限公司

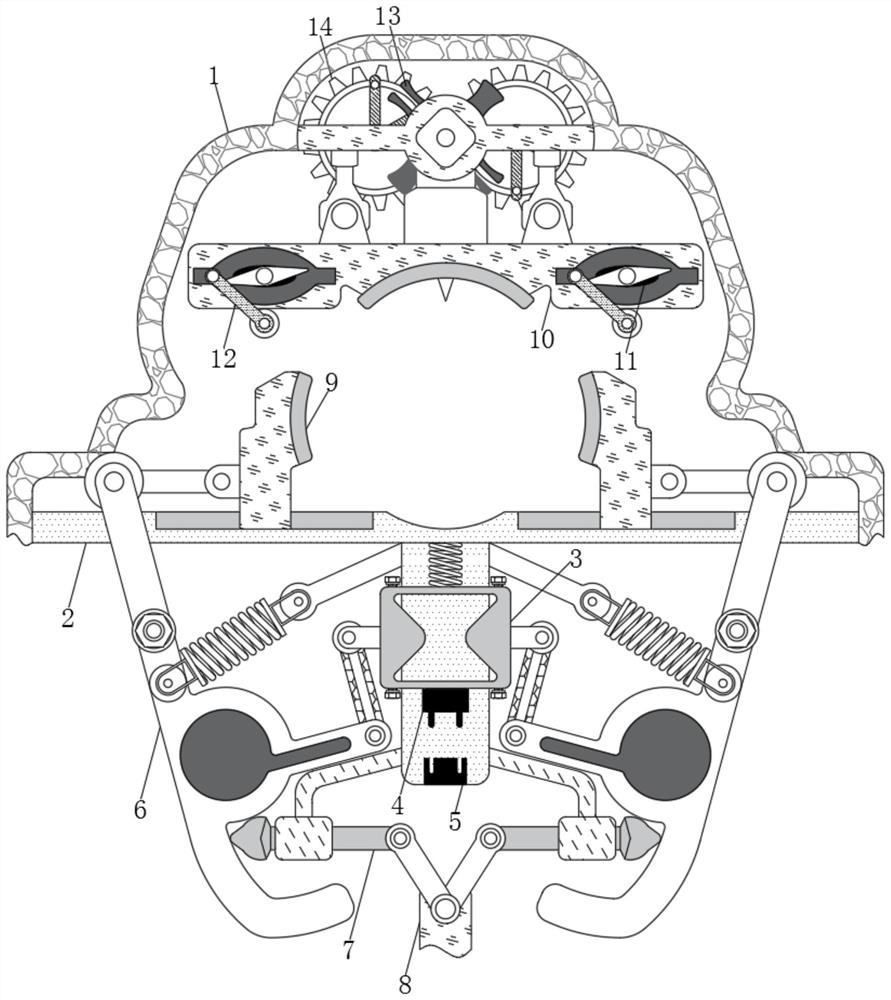

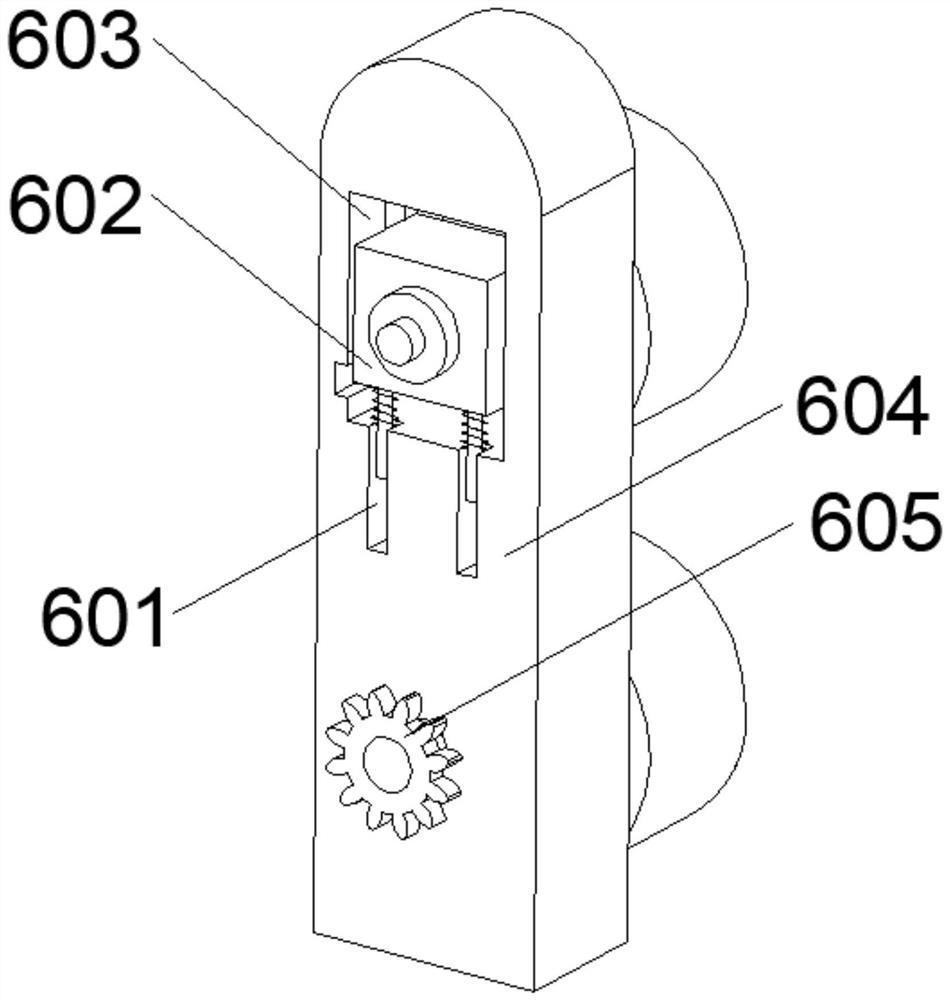

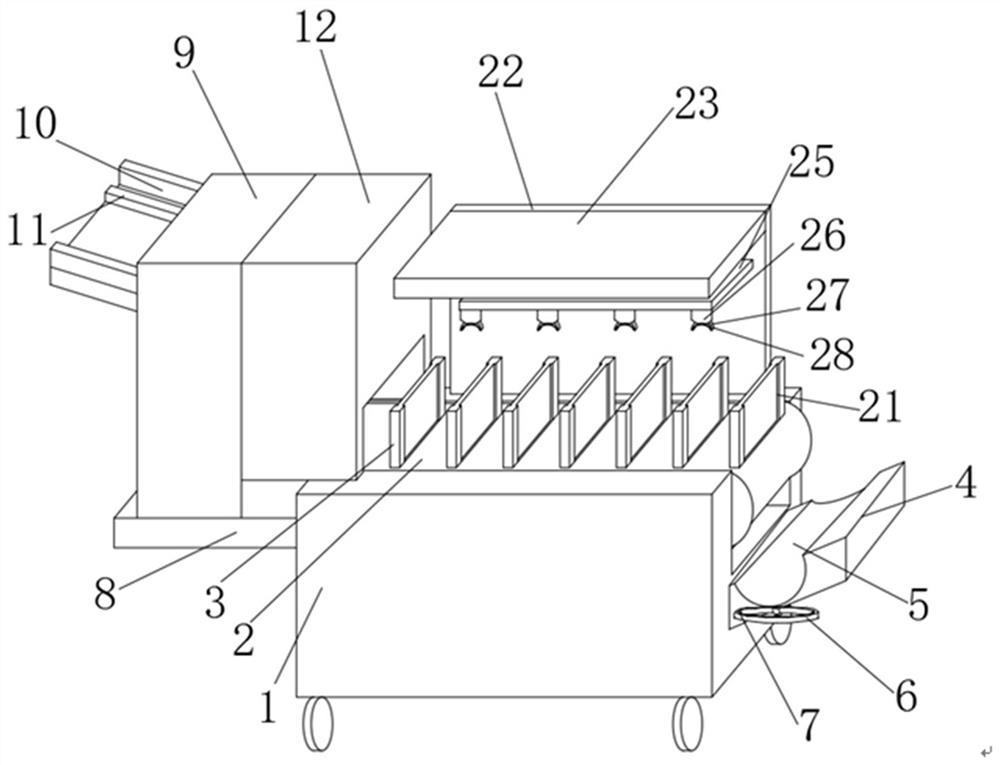

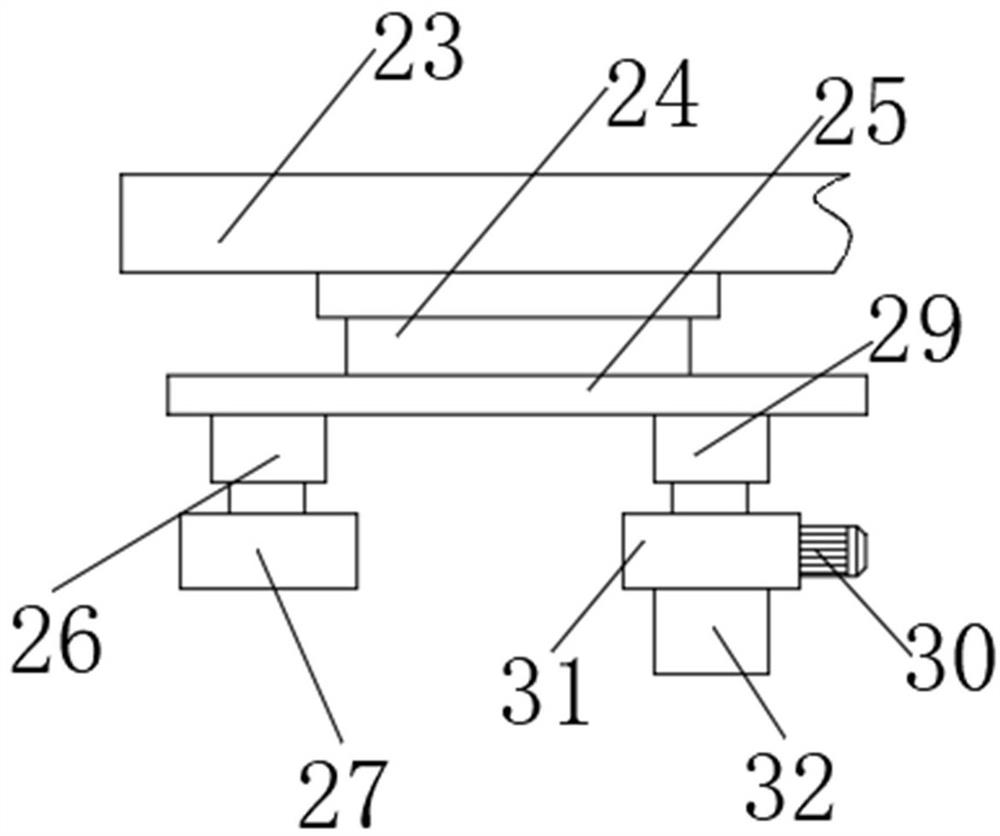

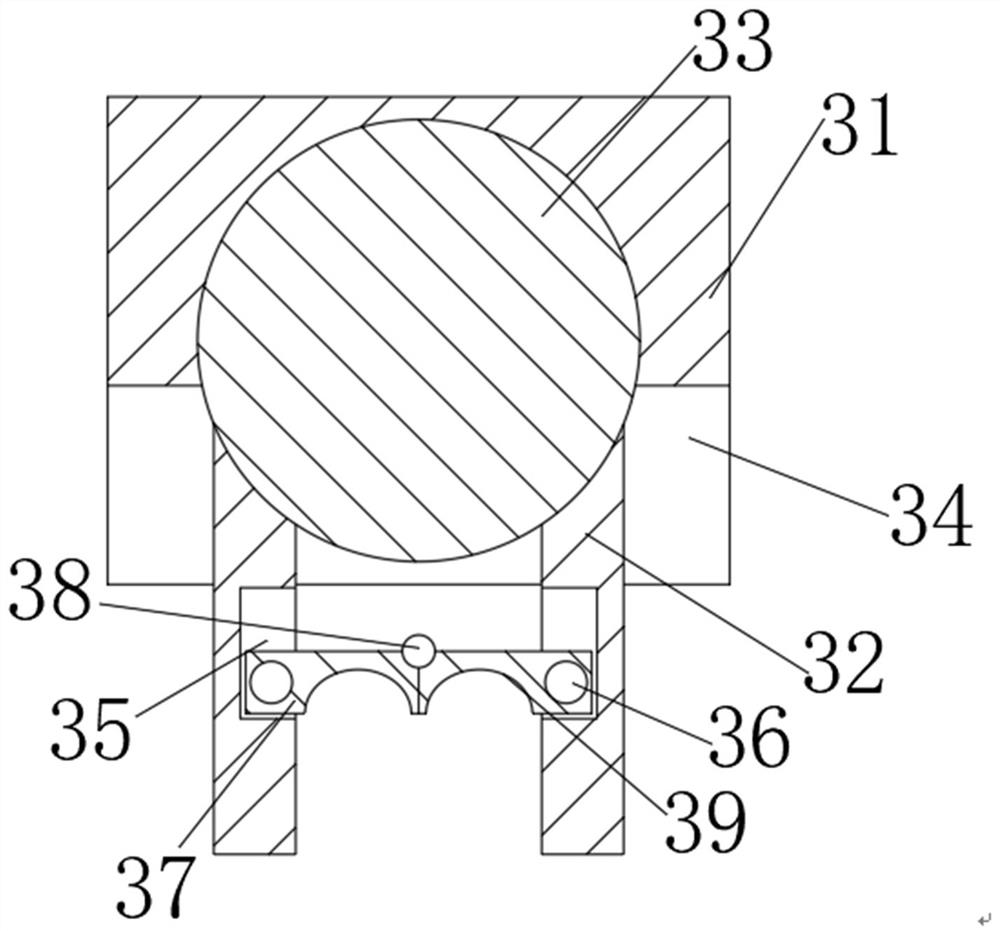

Cable peeling device for high-voltage cable connection

ActiveCN111952899AHigh degree of automationSave human effortLine/current collector detailsApparatus for removing/armouring cablesHigh-voltage cableDrive wheel

The invention discloses a cable peeling device for high-voltage cable connection, which belongs to the technical field of cable peeling, and comprises a bearing platform, a conveying mechanism arranged on the bearing platform, a first peeling mechanism for removing the sheath of a cable, a dispersing mechanism and a second peeling mechanism for removing the insulating layer of each cable, the first peeling mechanism comprises an n-shaped support, cutters and drag hooks, the n-shaped support is arranged on the bearing platform, the drag hooks are hinged to the left side and the right side of the n-shaped support respectively, the cutters are arranged on the upper side of the n-shaped support and the bearing platform respectively, the conveying mechanism comprises two conveying modules whichare symmetrically arranged up and down, and each conveying module comprises a frame body. The driving wheel and the driven wheels are arranged on the frame body, gears are arranged on the outer sidesof the driven wheels, and the gears are in transmission connection with the driving wheel through chains. Cable sheaths and insulating layers of all strands of wires can be sequentially removed, theautomation degree is high, manpower is saved, and the working efficiency is improved.

Owner:NANYANG POWER SUPPLY COMPANY OF STATE GRID HENAN ELECTRIC POWER

Cable stripping equipment and using method thereof

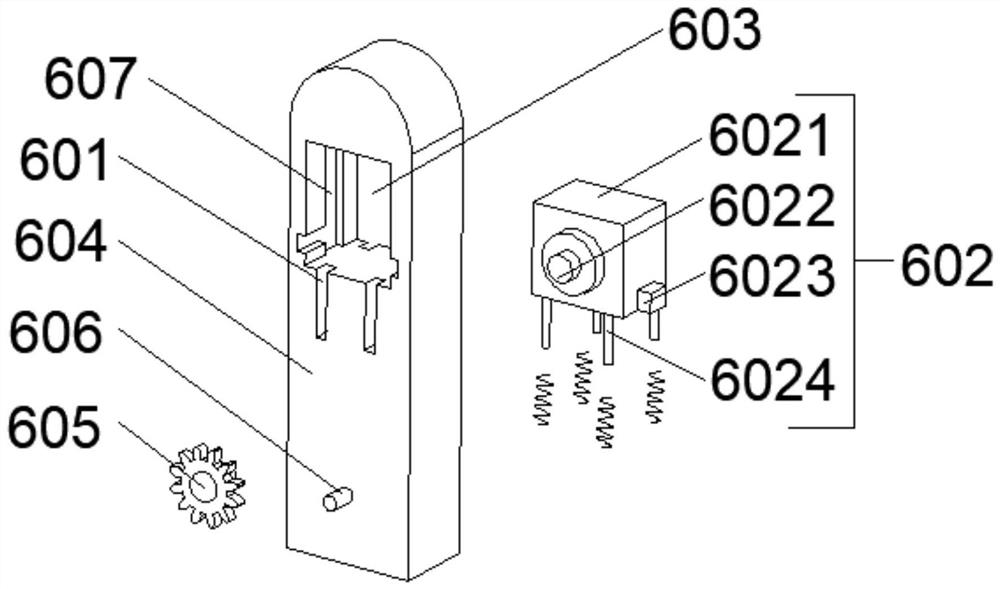

ActiveCN113161928AAvoid damageEasy to collectApparatus for removing/armouring cablesElectronic waste recyclingGear wheelElectric machinery

The invention relates to the technical field of power equipment, and discloses cable stripping equipment and a using method thereof. The cable stripping equipment comprises a base, supporting legs are fixedly installed at the four corners of the bottom of the base, a sliding groove is formed in the top of the base, and two sliding frames are slidably installed in the sliding groove; the bottom ends of rotating shafts are rotationally installed on the inner walls of the bottoms of the two sliding frames correspondingly, conveying rollers are fixedly installed on the outer sides of the two rotating shafts correspondingly, a motor is fixedly installed on the rear side of the sliding frame located on the rear side in the two sliding frames, and a first gear is fixedly installed on an output shaft of the motor. The top ends of the two rotating shafts extend to the position above the sliding frame and are fixedly provided with second gears. The cable stripping equipment is reasonable in structural design, simple to operate, time-saving and labor-saving, facilitates stripping operation of a cable, can divide a cable sheath into two complete half sheaths, is convenient to collect, and can avoid damage to a copper core during stripping through joint cooperation of a roller and a third spring.

Owner:广州电力工程监理有限公司

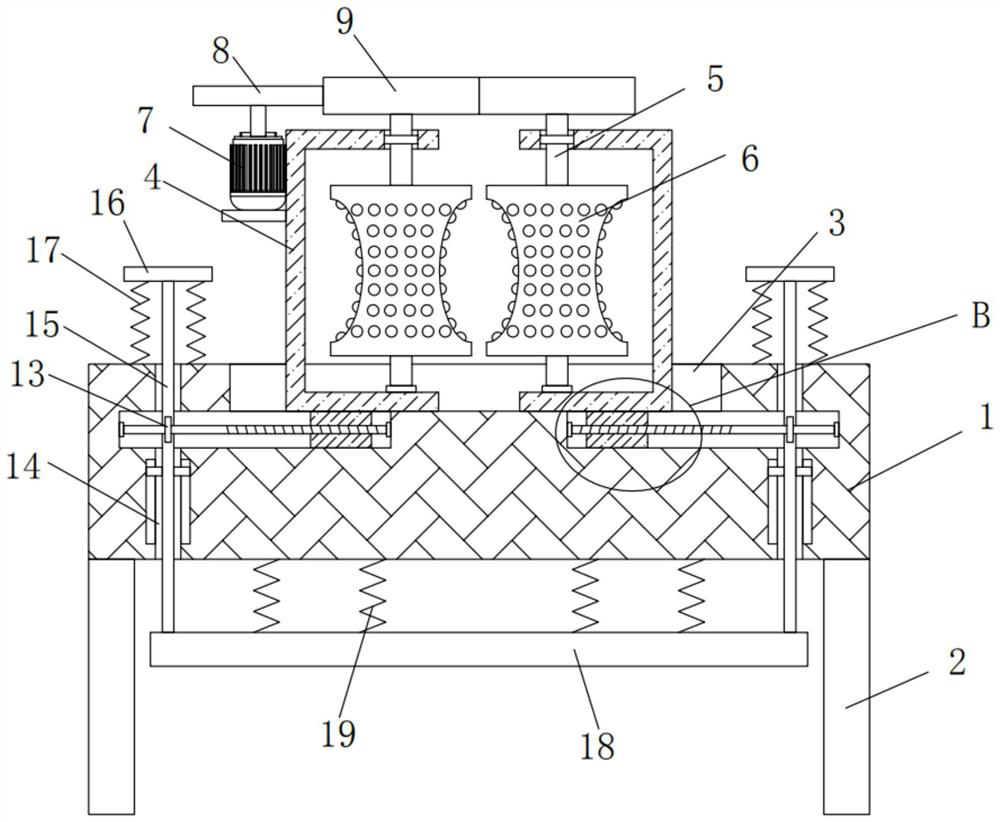

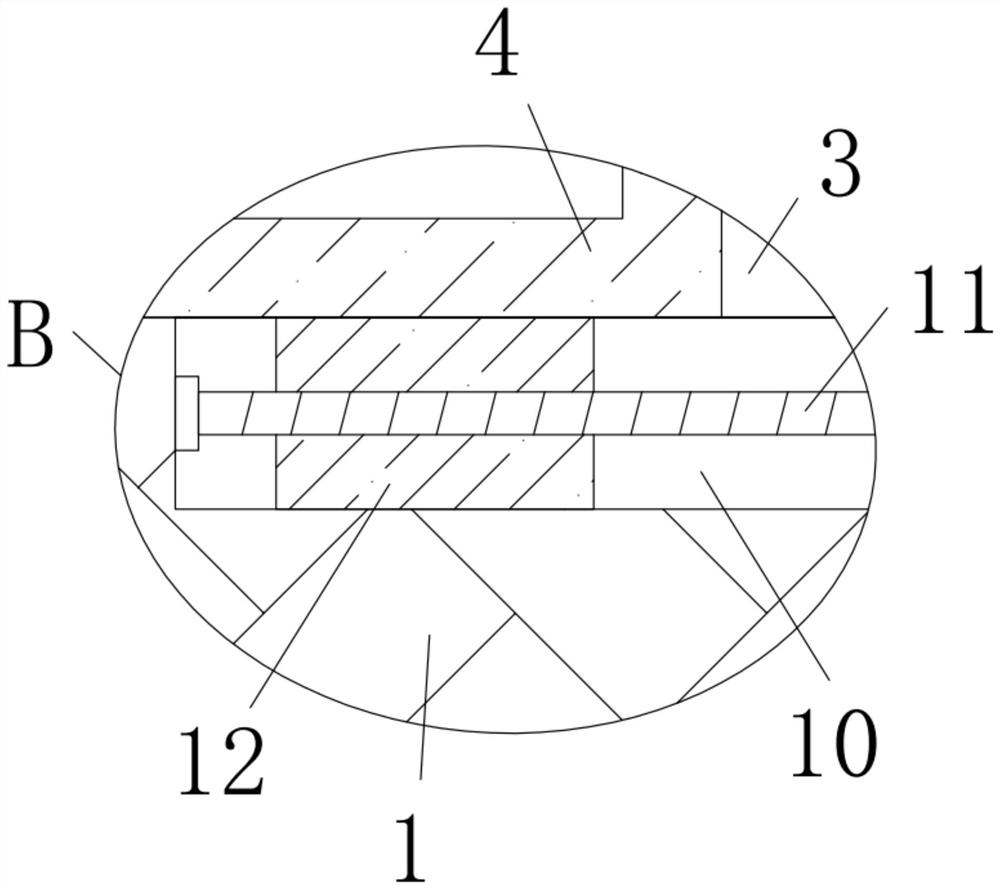

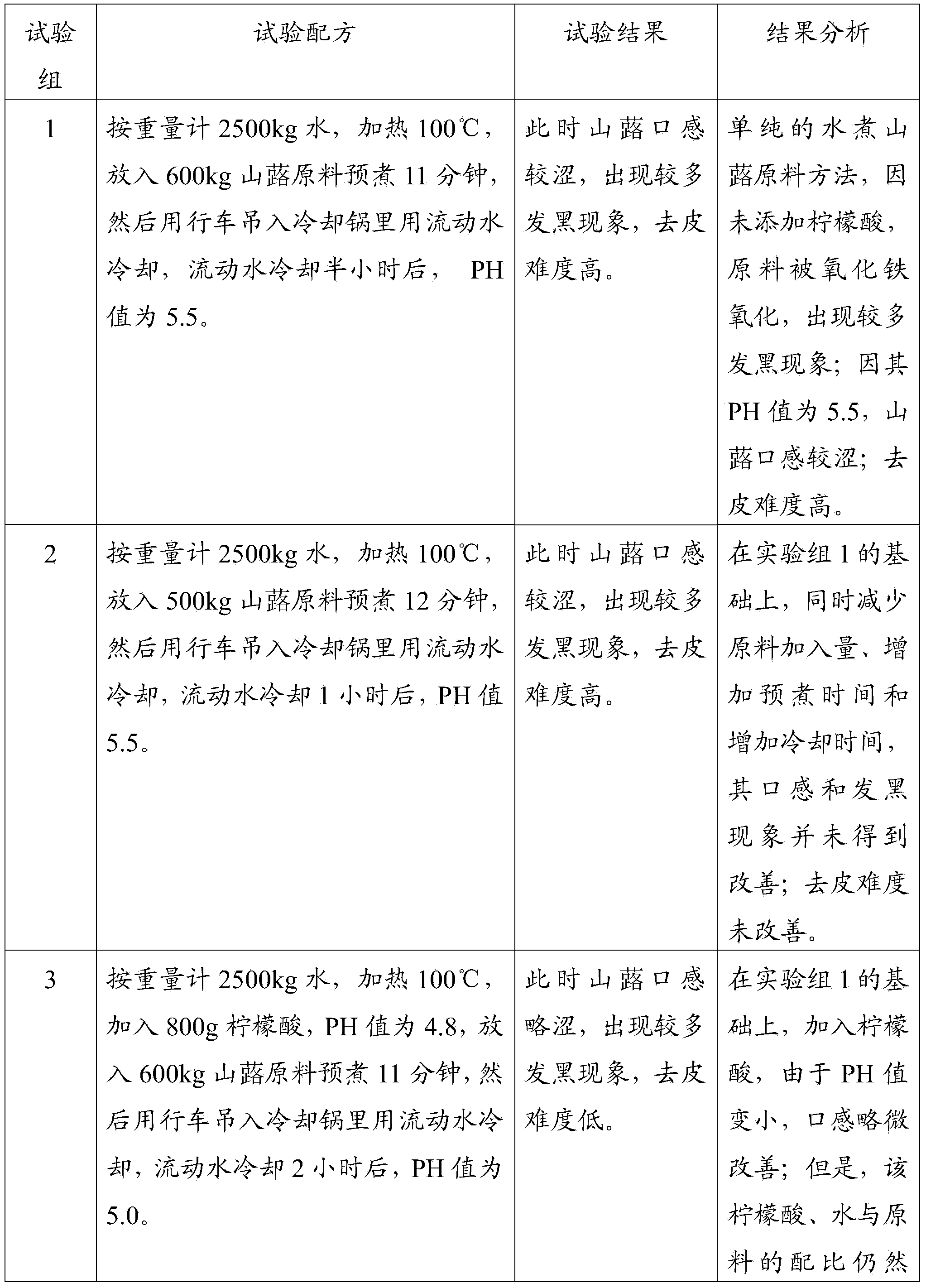

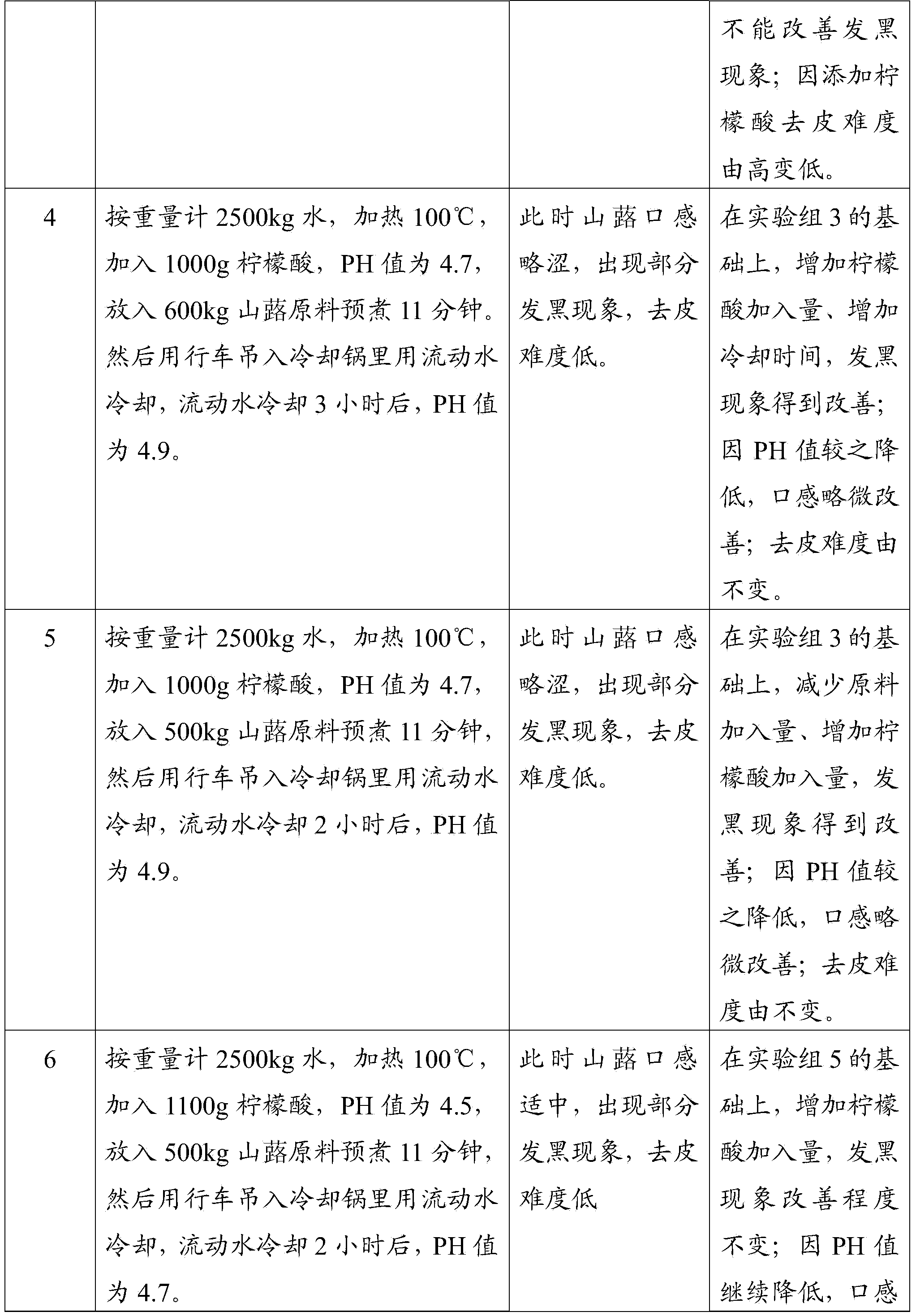

Processing method of boiled petasites tatewakianus

ActiveCN103976307AReduce iron oxide contentImprove darkeningFood ingredientsFood preparationCitric acidChemistry

The invention relates to a processing method of boiled petasites tatewakianus. The processing method comprises the step of adding petasites tatewakianus raw materials into a citric acid solution for sufficiently precooking for 7-12min, wherein the citric acid solution is prepared by adding 520-560g of citric acid into every 1000kg of water, the mass ratio of the petasites tatewakianus raw materials to the water in the citric acid solution is 1:5, the temperature of the citric acid solution is 95-100 DEG C, and the pH value is 3.9-4.3. The canned boiled petasites tatewakianu prepared by using the processing method of the boiled petasites tatewakianu, provided by the invention, has the advantages of petasites tatewakianus raw material blackening phenomenon improvement, petasites tatewakianus taste improvement, low petasites tatewakianus skin viscidity, high toughness as well as simplicity and easiness for peeling.

Owner:FUJIAN SANXIN FOOD STUFFS

Mature coconut peeling equipment and use method

The invention provides mature coconut peeling equipment and a use method, and relates to the field of food processing. The mature coconut peeling equipment comprises a fixed base, a supporting block is welded and fixed to the right side of the fixed base, the left side of the supporting block is located above the fixed base and connected with a connecting device, a fixed seat is fixedly connected to the top of the fixed base, and a coconut placing device is arranged in the fixed seat; and a peeling device is connected to the fixing seat, a transmission device is arranged on the connecting device, and a pressing device is connected to the connecting device. According to the mature coconut peeling equipment, a driving gear is meshed with an annular tooth groove, a driving motor can drive a circular ring to rotate in the rotating process, the rotation of the circular ring can drive a centrifugal hammer to conduct centrifugal movement, and peeling teeth can make contact with coconut peels through the centrifugal movement of the centrifugal hammer; and along with the rotation of the circular ring, the coconut can be conveniently peeled.

Owner:刘庆连

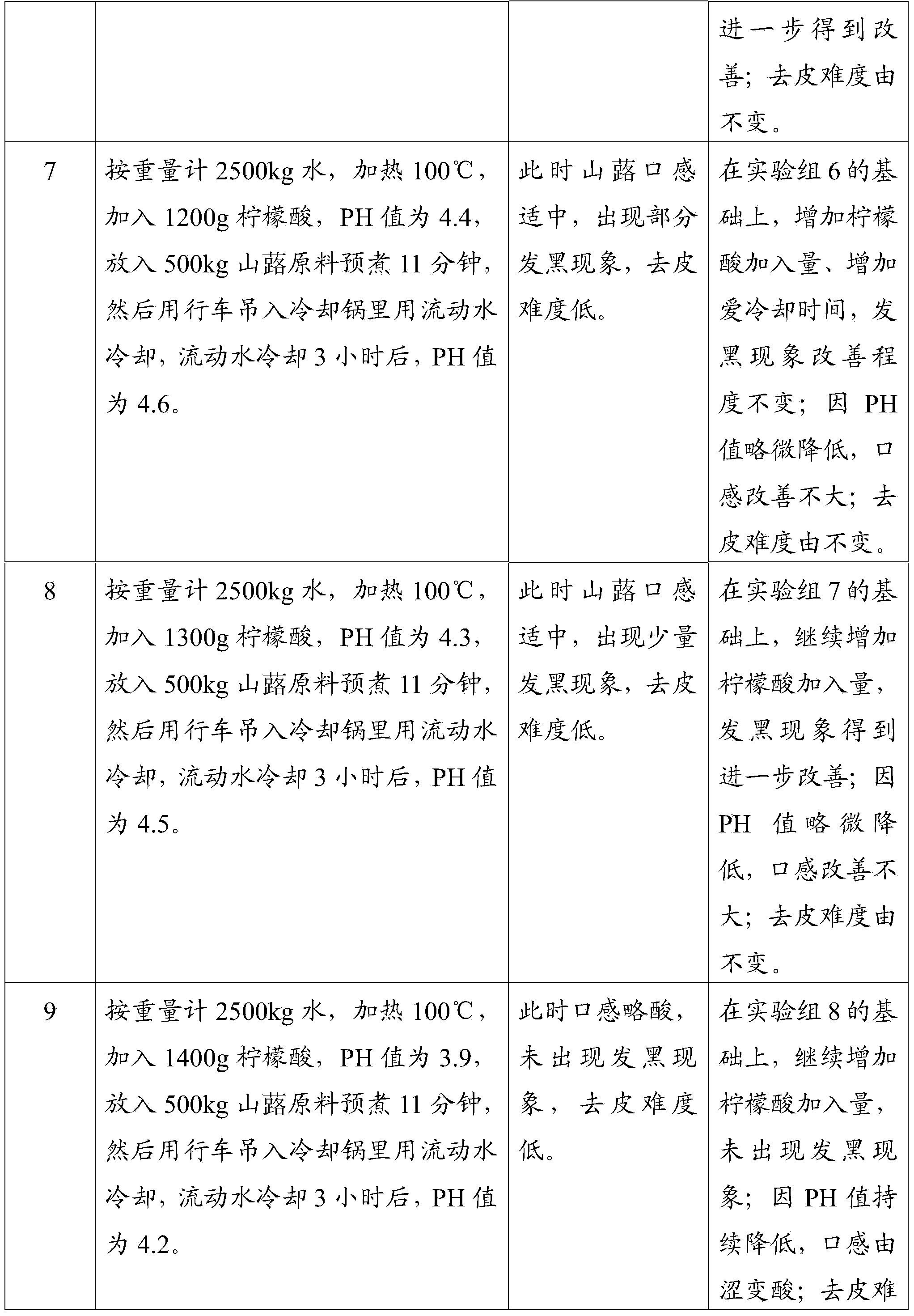

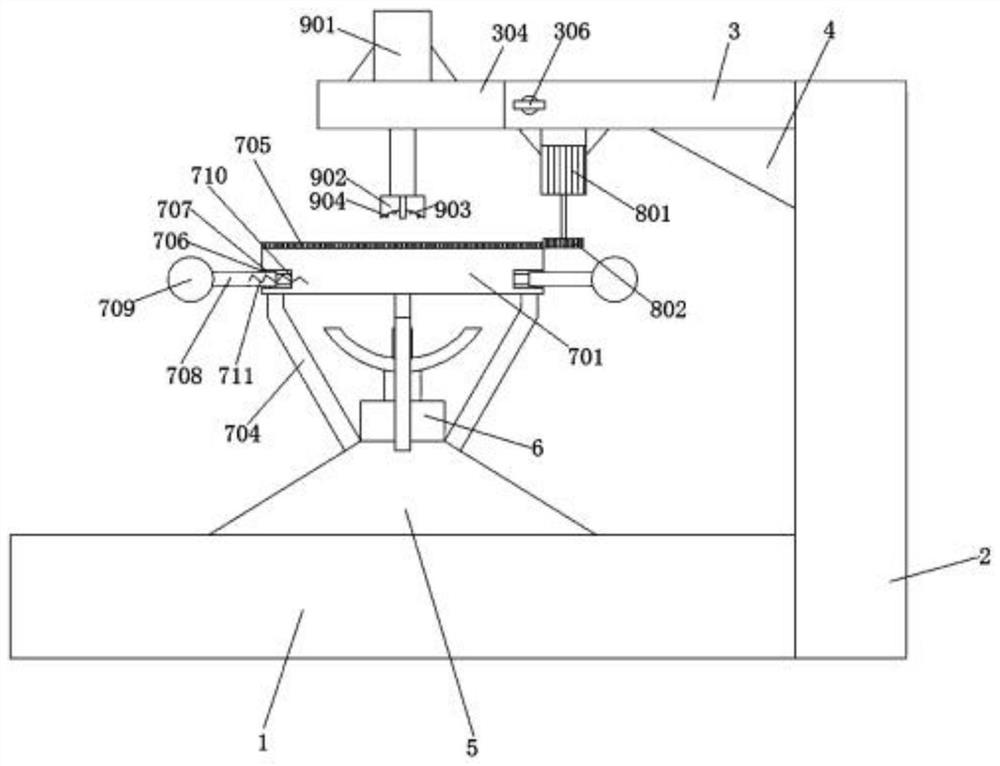

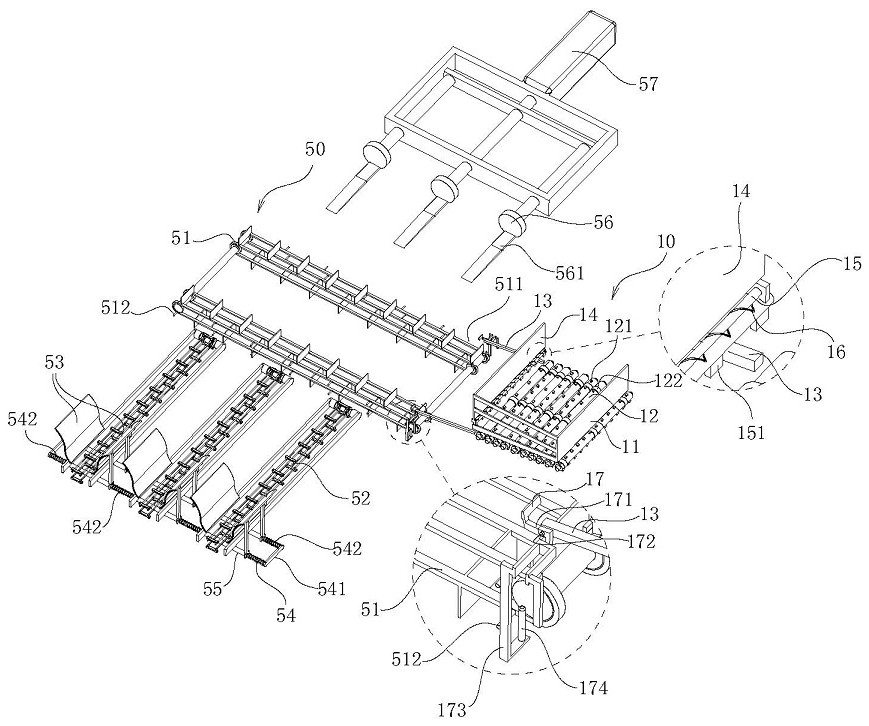

A power cable stripping device with the function of simultaneously rewinding and recovering wire and sheath

ActiveCN109347004BAvoid misalignmentEasy peeling operationApparatus for removing/armouring cablesPower cableControl theory

The invention discloses the power cable peeling device with wire and sheath winding and recycling functions. The power cable peeling device comprises a power cable and a peeling and winding device, wherein the power cable is movably connected with the peeling and winding device; compared with the prior art, the device has the advantages that the device can be applied to power cables with differentdiameters, the phenomenon that the power cable is deflected is effectively avoided, the two sides of the cable can be cut, the bare wire and the cable sheath do not need to be separated manually, andthe peeling time is short; a condition that one end of the cable is grasped and dragged forcefully to move manually is not needed; instead, the cable is cut and peeled by taking the cable sheath andbare wire as a movable part and by taking a peeling knife as a static part, so that an operator does not make contact with the power cable, and the hand cannot be scratched by the relatively thin cable; and meanwhile, the cable sheath and the bare wire which are subjected to cutting and peeling can be wound and recycled, and manual winding and recycling by the operator is not needed, so that the workload of operator is greatly reduced, and the working efficiency is greatly improved.

Owner:南通通城电力设备制造有限公司

High-efficiency and safe peeling device for waste gas optical fiber recovery

InactiveCN112630908AImprove efficiencyIncrease linkageFibre mechanical structuresFiberOperation safety

The invention relates to the technical field of optical fibers, and discloses a high-efficiency and safe peeling device for waste gas optical fiber recovery. The device comprises a housing, and the interior of the housing is fixedly connected with a placing table; through the combined action of a placing table, a sleeve block, a plug, a socket, a rotating rod, a push rod, an ejector rod and a clamp, an optical fiber is automatically clamped and fixed, the peeling operation is facilitated, the subsequent peeling operation is triggered by utilizing the operation condition of the fixing operation, the linkage between structures is increased, the operation is convenient, the automation degree is relatively high, the automatic cutting knife cuts into the insulating layer of the optical fiber and extrudes and fixes the cutting surface of the optical fiber, the cutting stability is improved, after the cutting knife is inserted, the insulating layer is linearly moved and cut, human intervention is reduced, the operation safety is higher, and compared with a traditional peeling method, the situation that fibers in the optical fiber are damaged is effectively avoided. The working efficiency is higher, and the use requirements are met.

Owner:何玉博

Corn threshing processing equipment

The invention relates to the technical field of corn processing, in particular to corn threshing processing equipment. The equipment comprises an equipment body, a supporting mechanism, a feeding mechanism, a dredging mechanism, a threshing mechanism and a discharging mechanism. When the equipment is used, the threshing mechanism is arranged in the equipment body, and corns entering the equipmentbody can be conveniently and automatically threshed through the driving of a motor and a corresponding gear chain transmission assembly, so that the manual operation is avoided, the injury to human hands is reduced, and meanwhile, the working efficiency is improved; and the discharging mechanism is arranged in the equipment body, through a corresponding screening and filtering assembly and the transmission assembly similar to a cam, primarily husked corn kernels can be screened and filtered conveniently, the situation that impurities such as corncobs and corn leaves are doped in the obtained corn kernels is avoided, the product quality is guaranteed, meanwhile, secondary machining is avoided, and the working efficiency is further improved.

Owner:余杏花

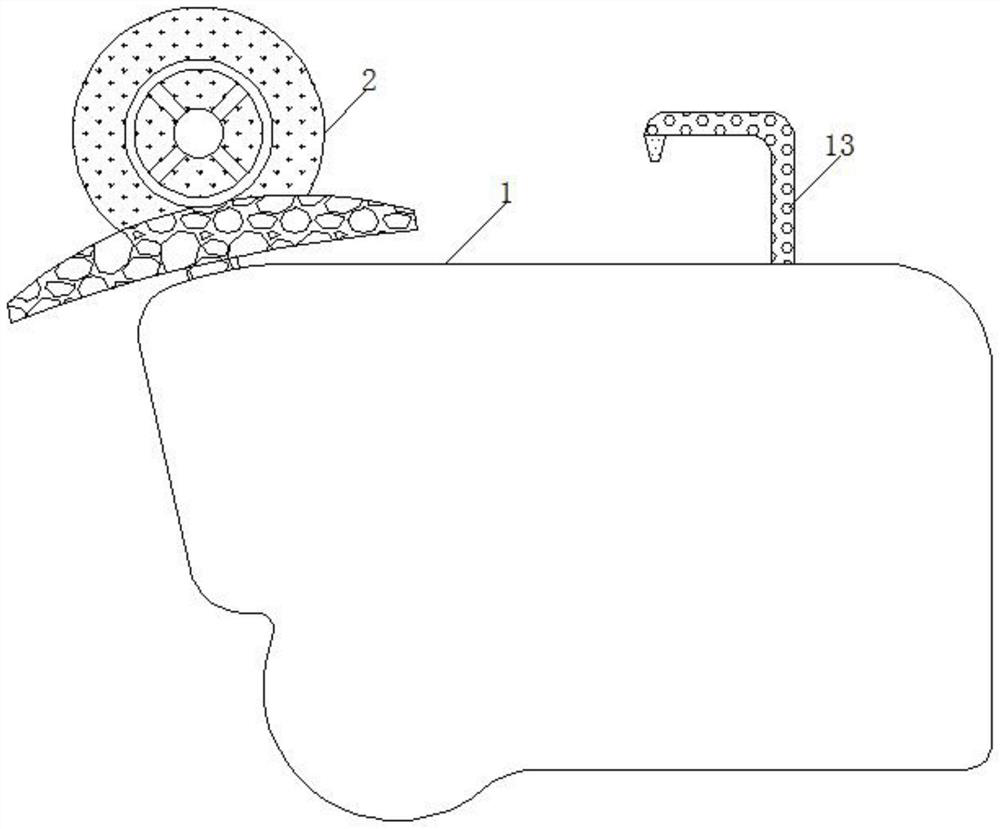

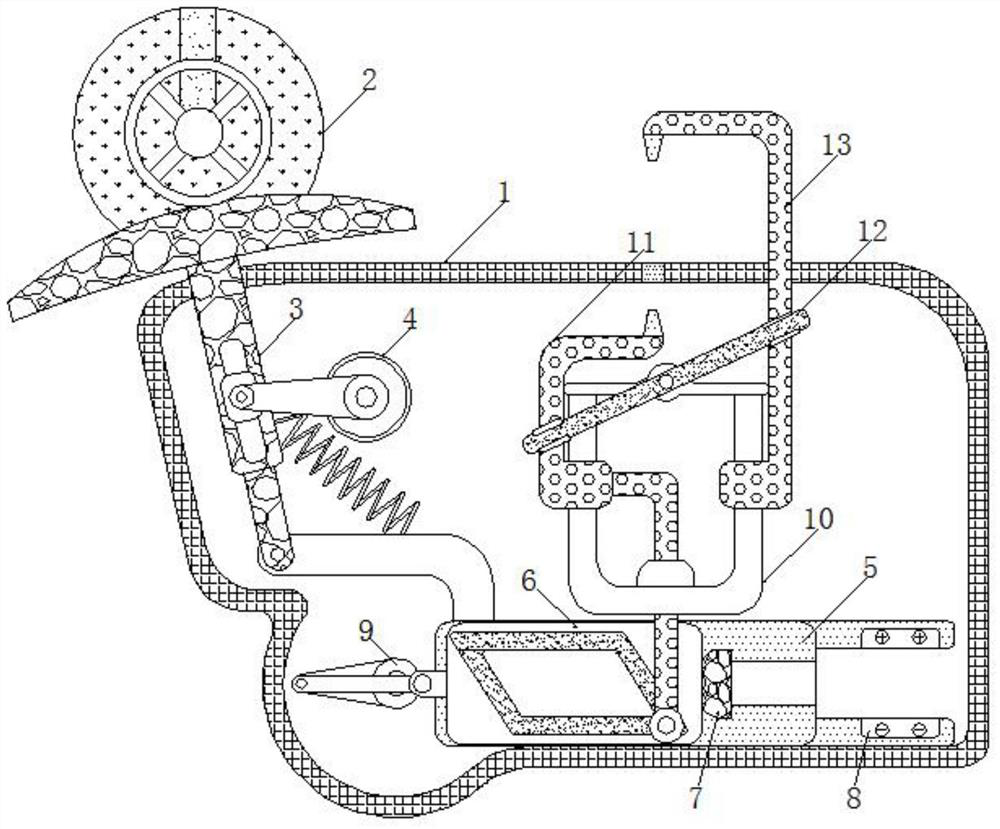

Cable peeling device for cable installation

InactiveCN112736779AImprove cut qualityIncrease linkageApparatus for removing/armouring cablesHand partsCapacitance

The invention relates to the technical field of cables, and discloses a cable peeling device for cable installation, and the device comprises a housing, the top of the housing is movably connected with a reel, and the outer side of the reel is movably connected with a T-shaped rod; through the combined action of a sliding plate, a dielectric plate, a pole plate group, a rotating plate, a fixed frame, a lower cutting rod, a rotating rod and an upper cutting rod, the sheath of the cable is automatically and annularly cut, both hands are liberated, the damage to a cable core caused by difficult control of cutting force is avoided, the cutting quality is effectively improved, and the cutting device is clamped at the cutting position of the sheath and is beneficial to peeling operation. Meanwhile, the capacitance principle is used for triggering the cable stretching operation, the linkage between structures is improved, operation is more convenient, the cable is automatically wound and stretched through the combined action of the reel, the T-shaped rod and the rotary disc, a cable core of the cable is separated from the sheath, the hand burden is relieved, the peeling operation difficulty is reduced, and higher work efficiency is achieved.

Owner:胡伟

Corn peeling device for agriculture

ActiveCN112119769AShorten the timeEasy peeling operationThreshersAgricultural engineeringAgriculture

The invention discloses a corn peeling device for agriculture. The corn peeling device comprises a workbench, wherein a supporting plate is arranged on the upper portion of the side face of the workbench, and a box body is arranged on the upper surface of the supporting plate; and a placement groove is formed inside the box body, a first hydraulic telescopic rod is arranged at the bottom end of the placement groove, a movable frame is arranged at the upper end of the first hydraulic telescopic rod, and a rotating frame is arranged on the upper portion of the interior of the movable frame. According to the corn peeling device, corns opposite to a corn stalk fixing device on the device can fall into the placement groove through convex blocks above the placement groove, and the corns are turned over by utilizing the rotating frame in the placement groove, so that the peeling operation on the corns is facilitated; and the corns apply one upward force to rotating plates under the extensionof fourth hydraulic telescopic rods, with the extension of the fourth hydraulic telescopic rods, corn stalks are broken off from roots, corn husks are removed, and v-shaped bulges are arranged in a sliding groove, so that the corn husks are cleared again, and the corn husks are completely removed.

Owner:新疆先锋伟业种子有限公司

A peeling device for data cable processing that automatically cuts and pulls peeling

ActiveCN111463644BEasy to operateEnsure consistencyLine/current collector detailsEngineeringCutting force

The invention relates to the technical field of data processing, and discloses a stripping device for data line processing that automatically cuts and pulls off the strips. The second movable block is close to each other to cut the outer skin of the data line to ensure the consistency of the cutting degree and avoid the situation of poor cutting effect due to the difference in cutting force. It is fixed to facilitate the peeling operation. The rotation of the arc disc makes the rotary plate rotate intermittently by 180 degrees, and the data line in the rotary plate rotates and stretches, so that the outer skin of the data line moves outside the core, reducing the outer skin wrapping line. The tightness of the core, the core and the sheath are partially separated, the end of the core is protected, the storage of the core is convenient, the difficulty of peeling is also reduced, the burden on the hands is reduced, and the work efficiency is effectively improved.

Owner:深圳市凯宝电线有限公司

Cable joint peeling device for communication technology equipment

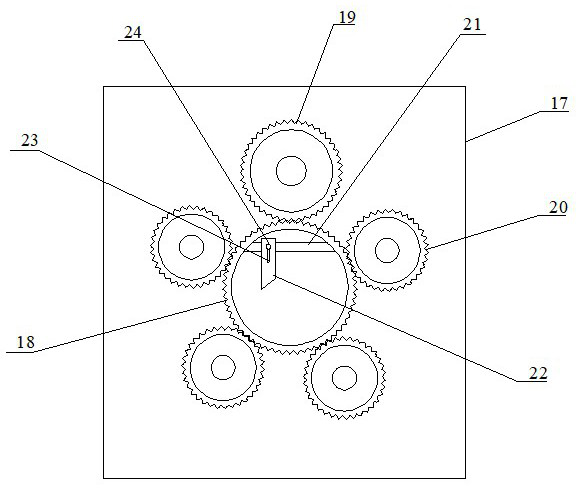

InactiveCN112993876AEasy peeling operationEasy to operateLine/current collector detailsApparatus for removing/armouring cablesDrive shaftEngineering

The invention relates to the technical field of communication technical equipment and discloses a cable joint peeling device for communication technical equipment. The device comprises a shell, wherein a base is arranged in the shell, a first gear is arranged on an inner surface of the base, a toothed bar is arranged on a surface of the first gear, and a clamping block is arranged at one end, away from the first gear, of the toothed bar; a surface of the base is movably connected with a toothed disc, and an inner part of the shell is provided with a transmission shaft. According to the cable connector peeling device for the communication technology equipment, through cooperative use of a transmission shaft and a second gear, cooperative use of a second toothed disc and a rotary disc, cooperative use of a toothed ring and the second gear, cooperative use of a lead screw and a sliding base and cooperation between cutting heads, a skin layer on a surface of the cable connector can be peeled, cable surface peeling operation is convenient, the peeling effect is good, meanwhile, cables of different specifications can be peeled, and the cable application range is wide.

Owner:白荣益

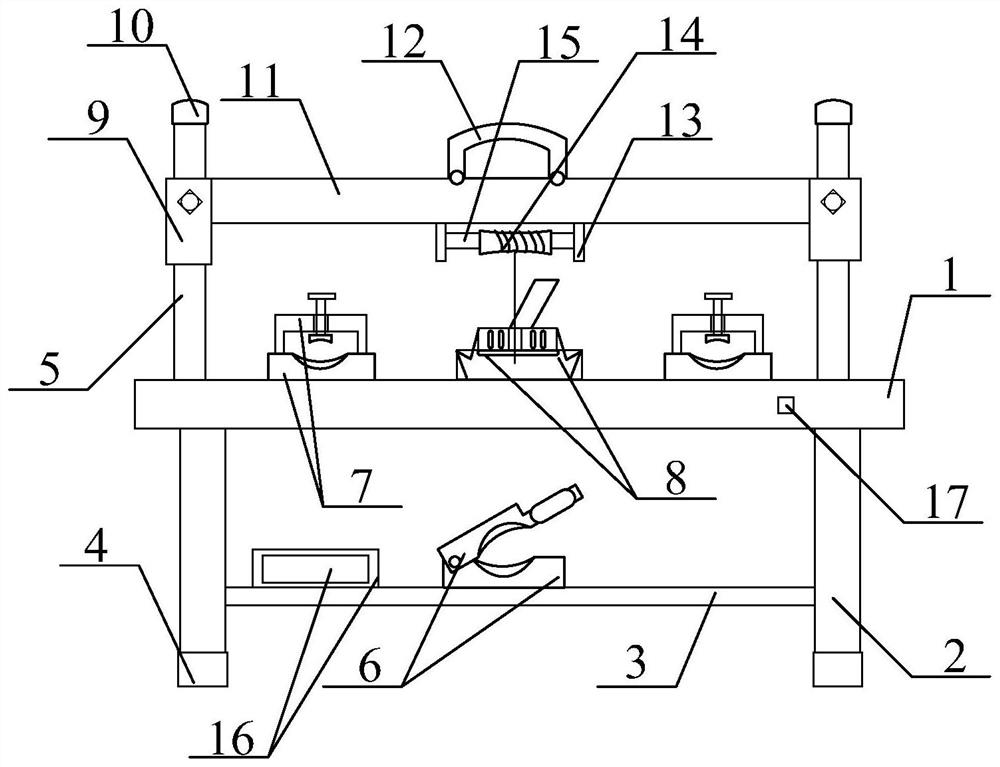

A multifunctional power cable connection device

ActiveCN109103819BEasy peeling operationImprove labor efficiencyLine/current collector detailsApparatus for removing/armouring cablesPower cableControl switch

The invention provides a multifunctional power cable connection device, which includes a cable connection workbench, a support column, a horizontal plate for storage, an anti-slip sleeve, a longitudinal slide bar, a cable stripping knife structure, an adjustable cable fixing seat structure, and a cable welding box. Structure, adjustment sliding sleeve, limit cap, protective plate, handle, suspender, solder wire shaft, rotating shaft, power supply box and control switch, the support columns are respectively bolted to the four corners of the lower surface of the cable connection workbench; The transverse screw of the storage horizontal plate is connected between the support column and the inner lower part of the support column. The setting of the lower blade, the lower pressing plate and the upper blade of the present invention is conducive to the peeling operation of the cables that need to be connected, which improves the labor efficiency; Adjust and compress differently to meet the needs of cable fixing and facilitate the wiring operation.

Owner:广西智光电力建设有限公司

Waste cable recovery device

InactiveCN111489867AEasy to recycleImprove efficiencyBasic electric elementsElectronic waste recyclingBlade plateScrew thread

The invention discloses a waste cable recovery device, and relates to the technical field of waste cable recovery. The problems that the plastic skin outside a cable is difficult to peel off and the recycling value of the waste cable is reduced are solved. The device specifically comprises a base; a door-shaped frame is fixedly installed at the top end of the base; a turnover box is fixedly installed at the top of the base; a guide mechanism is fixedly installed on one side of the interior of the door-shaped frame; a lower shearing mechanism is rotatably installed in the middle of the door-shaped frame; and two threaded rods are connected with the top end of the door-shaped frame in a threaded mode. According to the invention, the end part of the cable is arranged between an upper shearingmechanism and the lower shearing mechanism; the skin is cut into two parts; the cable skin and the core wire are separated through the skin guide mechanism, then a conductor in the middle of the waste cable is stripped and recycled, and the separated skin enters the position between a cutting knife plate and the lower shearing mechanism through the skin guide mechanism to be sheared into small sections; recycling treatment is facilitated; and the waste cable recycling efficiency and quality are improved.

Owner:张建新

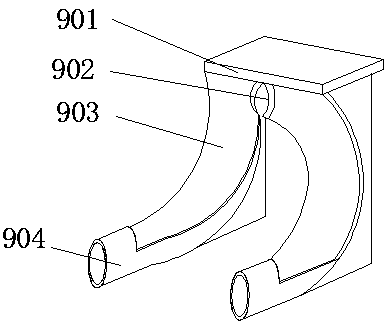

Peeling machine capable of machining hydraulic pipes with different pipe diameters

InactiveCN114434518AEasy to crushReduce volume rangeGrain treatmentsMetal working apparatusTool bitGear wheel

The invention discloses a peeling machine capable of processing hydraulic pipes with different pipe diameters, which comprises a base, one side of the bottom in the base is connected with a vertical plate through a moving mechanism, one end of a sleeve rod is provided with a nut, the top of the base is connected with a clamping plate through a second fastener, and the inner side of the clamping plate is connected with a second circular ring through a sliding rod. The inner side of the second circular ring is connected with a tool bit through a third electric telescopic rod, and the outer side of the second circular ring is engaged with a gear through a rack. According to the peeling machine capable of machining the hydraulic pipes with the different pipe diameters, a gear can be driven to rotate by starting a motor, a tool bit on the inner side of a second circular ring can be driven to rotate through meshing connection of the gear and a rack, peeling operation on the outer surfaces of the hydraulic pipes can be completed conveniently, and compared with cutting peeling conducted through extrusion of two tool bits, the peeling efficiency is improved; according to the peeling machine, the inner side part of the hydraulic pipe cannot be damaged, and the third electric telescopic rod drives the cutter head to move, so that peeling operation can be conveniently performed on hydraulic pipes with different pipe diameters.

Owner:徐州恒和机械科技有限公司

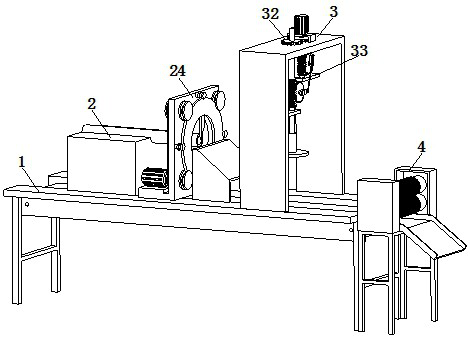

Data cable peeling equipment

InactiveCN113102066AEasy peeling operationEasy to crushGrain treatmentsApparatus for removing/armouring cablesEngineeringMechanical engineering

The invention discloses data cable peeling equipment, and belongs to the technical field of data cable processing. The data cable peeling equipment comprises a moving device, a peeling device, a core collecting device and a crushing device. The moving device is horizontally arranged on the ground, the peeling device is vertically arranged on the top of the moving device, and the core collecting device is vertically arranged on the top of the moving device. The crushing device is vertically arranged at the discharging end of the moving device. According to the data cable peeling equipment, the core collecting device is used for collecting the peeled data cable cores, and the crushing device is used for processing the peeled data cable skins.

Owner:朱立梅

Wicker peeling processing equipment for intelligently producing willow products

PendingCN113954132AAdjust the extrusion effectEasy peeling operationMetal working apparatusAgricultural engineeringElectric machinery

The invention relates to wicker peeling processing equipment for intelligently producing willow products. The wicker peeling processing equipment for intelligently producing the willow products comprises a bottom plate; one side of the top of the bottom plate is fixedly provided with a supporting plate through a supporting frame; one side of the top of the supporting plate is provided with a protection mechanism used for preventing hands of an operator from being injured and three transmission mechanisms used for conveying wickers; a driving motor is fixedly installed in the middle of the supporting frame; and a limiting mechanism is arranged on the other side of the top of the bottom plate. The wicker is conveyed through rotation of rollers; tension is provided for a bearing seat through a tension spring, so that the bearing seat provides buffering for a second rotating shaft, and therefore the extrusion effect of the two rollers on the wicker is adjusted, and the wicker can be conveniently and better peeled; and meanwhile, the bearing seat can be conveniently taken down for maintenance and cleaning, the interior of a mounting groove can be effectively cleaned, and the situation that the bearing seat and the mounting groove are blocked is prevented.

Owner:ANHUI XINDA HOME FURNISHING CO LTD

A corn peeling device for agriculture

ActiveCN112119769BShorten the timeEasy peeling operationThreshersAgricultural scienceAgricultural engineering

The invention discloses an agricultural corn peeling device, which comprises a workbench, a support plate is arranged above the side of the workbench, a box is arranged on the upper surface of the support plate, and a box is arranged inside the box. There is a placement slot, the bottom end of the placement slot is provided with a first hydraulic telescopic rod, the upper end of the first hydraulic telescopic rod is provided with a movable frame, and the upper end of the movable frame is provided with a rotating frame. In the corn peeling device of the present invention, the protrusion above the placement groove can drop the corn opposite to the corn stalk fixing device on the device into the placement groove, and use the rotating frame in the placement groove to turn the corn over, which is convenient for corn stalks The peeling operation, under the extension of the fourth hydraulic telescopic rod, makes the corn exert an upward force on the rotating plate, and with the extension of the fourth hydraulic telescopic rod, the corn stalk is broken off at the root, so as to remove the corn husk. And the chute is provided with a V-shaped protrusion, which is cleaned again to completely remove the corn husks.

Owner:新疆先锋伟业种子有限公司

A mature coconut peeling equipment

The invention provides a mature coconut peeling device, which relates to the field of food processing. The mature coconut peeling equipment includes a fixed base, the right side of the fixed base is welded and fixed with a support block, the left side of the support block is connected to the connecting device at the top of the fixed base, and the top of the fixed base is fixedly connected with a Fixed seat, the inside of the fixed seat is provided with a coconut placement device, the fixed seat is connected with a peeling device, the connecting device is provided with a transmission device, and the connecting device is connected with a pressing device. The mature coconut peeling equipment, through the meshing of the driving gear and the annular tooth groove, can make the driving motor drive the circular ring to rotate during the rotation process, and the rotation of the circular ring can drive the centrifugal hammer to perform centrifugal activities. The peeling teeth can be brought into contact with the coconut skin, and the coconut peeling operation can be conveniently performed along with the rotation of the circular ring.

Owner:海南欧椰生态农业股份有限公司

Flexible peeling assisting device with sectioning function and for canned orange processing

ActiveCN114027529AEasy peeling operationPlay the role of auxiliary peelingVegetable peelingMetal working apparatus'Orange peel' skinAnnular array

The invention relates to a peeling assisting device, and concretely relates to a flexible peeling assisting device with a sectioning function and for canned orange processing. The device comprises a cutting mechanism and a sectioning piece arranged in the cutting mechanism, the cutting mechanism comprises a plurality of arc-shaped flexible plates, the flexible plates are arranged in an annular array with the sectioning piece as the axis, a containing cavity is formed in the flexible plates, and an opening is formed in the bottom of the containing cavity. The cutting assembly can cut orange peels of oranges, so that peeling operation in the later period is facilitated, and the effect of assisting peeling is achieved; and meanwhile, the sectioning piece can extrude the oranges to expand the oranges, then the expanded oranges are limited by the containing cavity, orange sections are expanded, and the sectioning purpose is achieved.

Owner:湖南芝麻官农业科技有限公司

Distribution device

ActiveCN108972806BEasy peeling operationMake sure to removeTree debarkingMulti-purpose machinesAgricultural engineeringStructural engineering

The invention relates to a material dividing device. A material receiving continuous track is included, and the length direction of the material receiving continuous track is horizontal and perpendicular to the conveying direction of a guiding and conveying chain; the material receiving continuous track is provided with material receiving grooves at equal intervals in the peripheral direction; thematerial receiving grooves are parallel with the conveying direction of the guiding and conveying chain; the guide-out end of the material receiving continuous track is provided with a material chasing mechanism; the material chasing mechanism is used for pushing pine segments in the material receiving grooves into a classifying mechanism; the classifying mechanism classifies pine according to the diameter of the pine; an outlet of the classifying mechanism is connected with a feeding port of a peel planing device; the pine segments in the material receiving grooves are pushed into the classifying mechanism through the material chasing mechanism, so that the segments can be classified according to the diameter size, and therefore peel planing operation of the peel planing device subsequently carried out on the segments is facilitated, and it is guaranteed that segment bark and a part of wooden core can be removed in a planing manner.

Owner:南京三禾防腐设备有限公司

A kind of cable peeling equipment

ActiveCN112838463BAutomate operationEasy peeling operationLine/current collector detailsApparatus for removing/armouring cablesStructural engineeringMechanical engineering

The application discloses a cable stripping device, which relates to the field of cable processing, and includes a frame, which is provided with a pressing device, two stripping devices and a conveying device, and the two stripping devices are stripping device one and stripping device two , the conveying device is used to pass the cable through the stripping device one and the stripping device two successively, the stripping device one is used to strip the outer sheath of the cable, and the stripping device two is used to strip the sub-wire of the cable; each stripping device The devices all include a sliding seat that is slidably connected to the frame, a peeling assembly arranged on the sliding seat, and a driver that drives the sliding seat to slide; the sliding seat slides in a direction away from the pressing device, and the peeling assembly includes a sliding The peeling knife seat connected to the sliding seat and the drive cylinder that drives the skidding of the peeling knife seat. By arranging the pressing device, the two stripping devices and the conveying device, the cable peeling operation is more automated, and the cable peeling operation is more convenient.

Owner:台州腾标电子有限公司

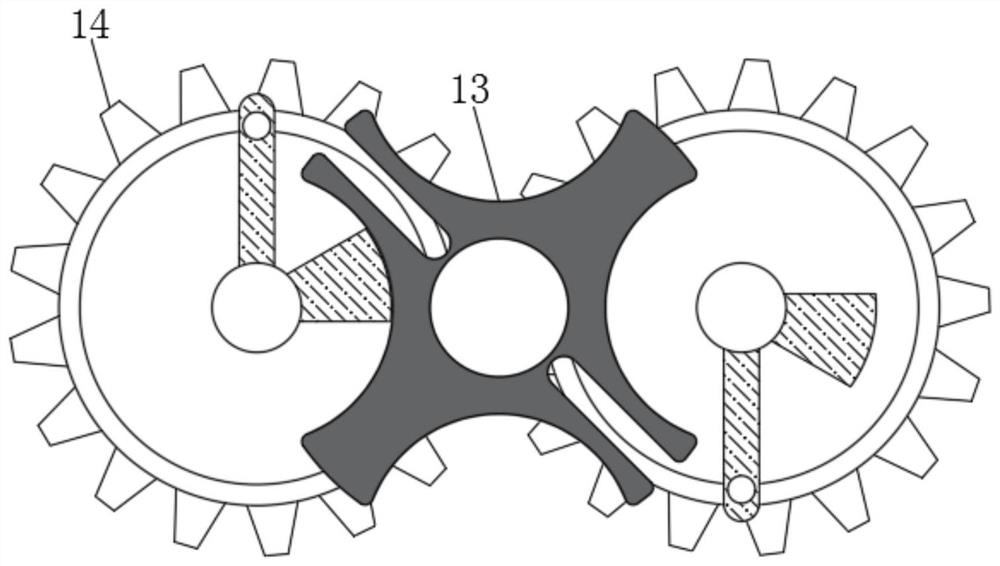

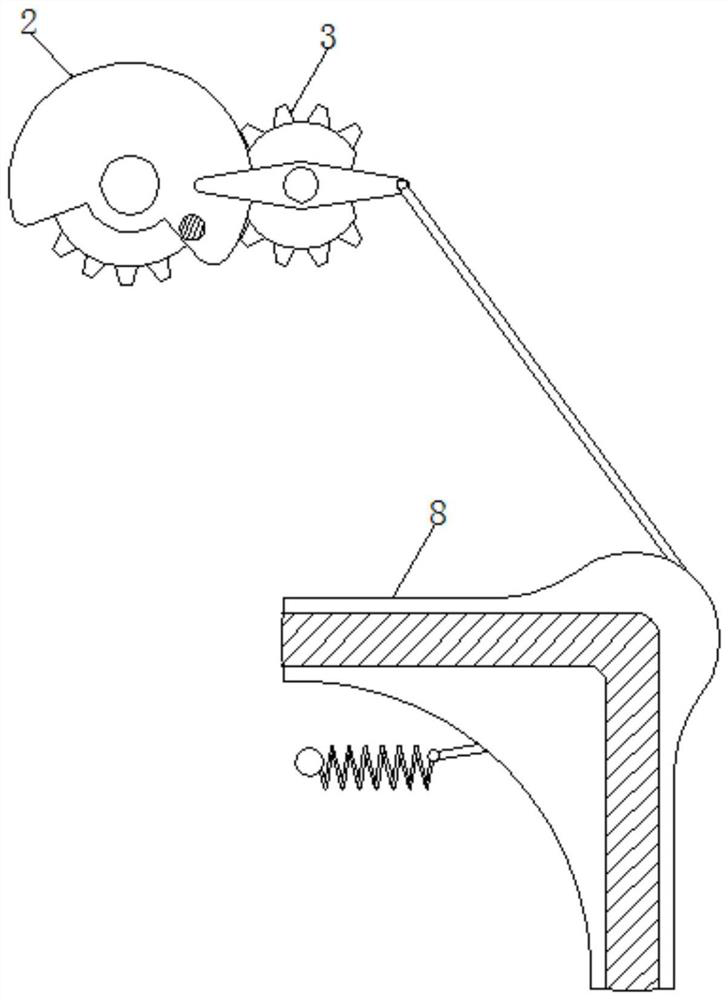

Lightweight overhead wire automatic stripping device based on the principle of four-bar linkage mechanism

ActiveCN110601093BEasy to put inEasy peeling operationLine/current collector detailsApparatus for removing/armouring cablesRatchetKnife blades

The invention discloses a lightweight automatic overhead line peeling device based on a four-link mechanism principle. The device includes a base and a transmission worm mounted on the base; a bushingformed by hinging a upper half sleeve to a lower half sleeve; a worm gear consisting of a worm gear upper half ring and a worm gear lower half ring which are fixed to the upper half sleeve and the lower half sleeve respectively; a backplane fitted into the back side of the bushing and having a guide groove, wherein the upper half sleeve has a guide shaft pin fitted in the guide groove, when the bushing and the backplane are relatively rotated, the guide shaft pin moves in the guide groove and the upper half sleeve rotates relative to the lower half sleeve; a mounting plate fixed on the base,wherein the bushing is fitted into the mounting plate; a ratchet assembly matching a slot on the backplane; a peeling component fixed to the front end surface of the bushing and having a blade corresponding to the central hole of the bushing. The lightweight automatic overhead line peeling device not only facilitates the peeling operation of the overhead line by workers, but also improves the peeling efficiency.

Owner:YANGTZE DELTA REGION INST OF TSINGHUA UNIV ZHEJIANG +1

Fresh orange dried ballonflower peeling device with angle convenient to adjust

PendingCN112352969ARemove comprehensivelyImprove practicalityVegetable peelingEngineeringStructural engineering

The invention relates to the technical field of dried ballonflower processing, in particular to a fresh orange dried ballonflower peeling device with an angle convenient to adjust, comprising a devicebody, the device body comprises a support table, a hydraulic telescopic rod is fixedly mounted at the top end of the support table, and a placement groove is fixedly mounted at one end of the hydraulic telescopic rod; a first sliding rail is fixedly installed at one end of the supporting table. By arranging the fixing frame, the transmission lead screw, the adjusting rotating wheel, the transmission block, the connecting rod and the first connecting shaft, the two adjusting mechanisms are arranged in the arch-shaped frame and connected with the fixing plate, and the transmission lead screw isrotated so that the transmission block can drive the connecting rod to lift the first connecting shaft; the first connecting shaft is used for adjusting the lifting of the fixing plate, after the twoends of the fixing plate are adjusted to different heights, the angle of the mounting plate can be adjusted, the peeling blades can remove the skin of dried ballonflowers more comprehensively, and the practicability of the device is improved.

Owner:安徽省义门苔干有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com