Lightweight overhead wire automatic stripping device based on the principle of four-bar linkage mechanism

A four-bar linkage, lightweight technology, applied in the directions of cable installation, cable installation device, connection, etc., can solve the problems of complicated operation, inconvenient peeling process, low peeling efficiency, etc., and achieve the effect of improving efficiency and convenient peeling operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

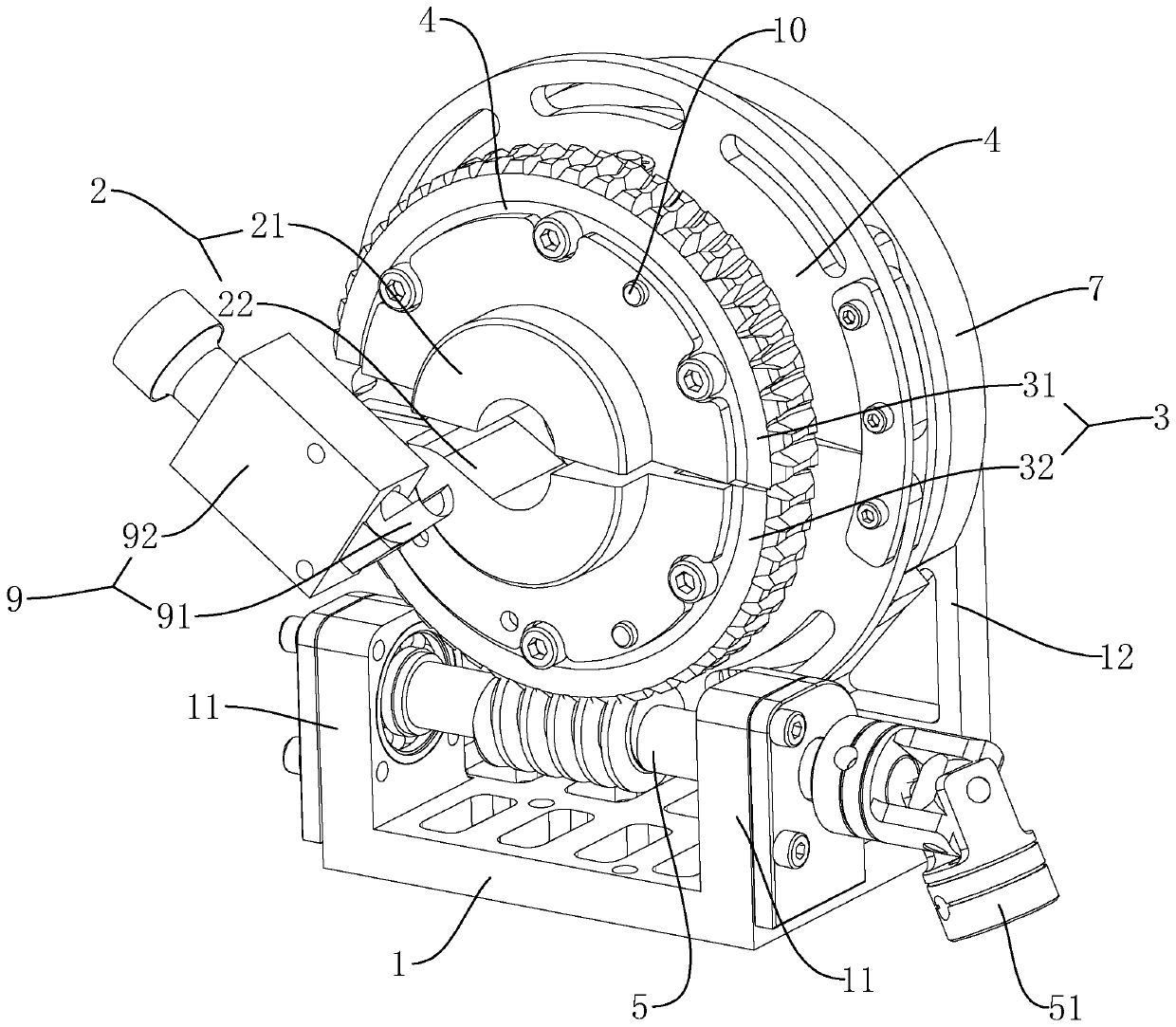

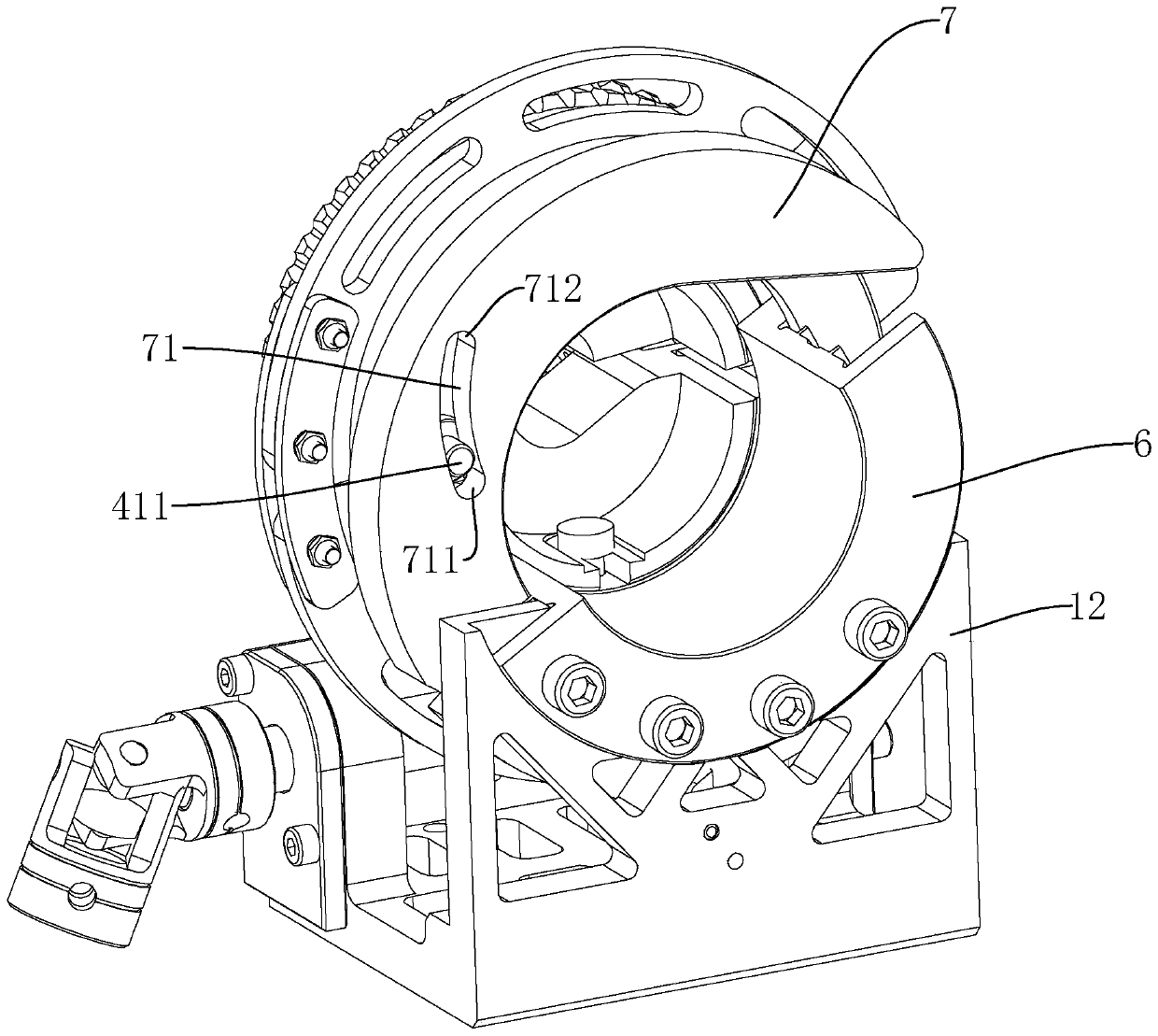

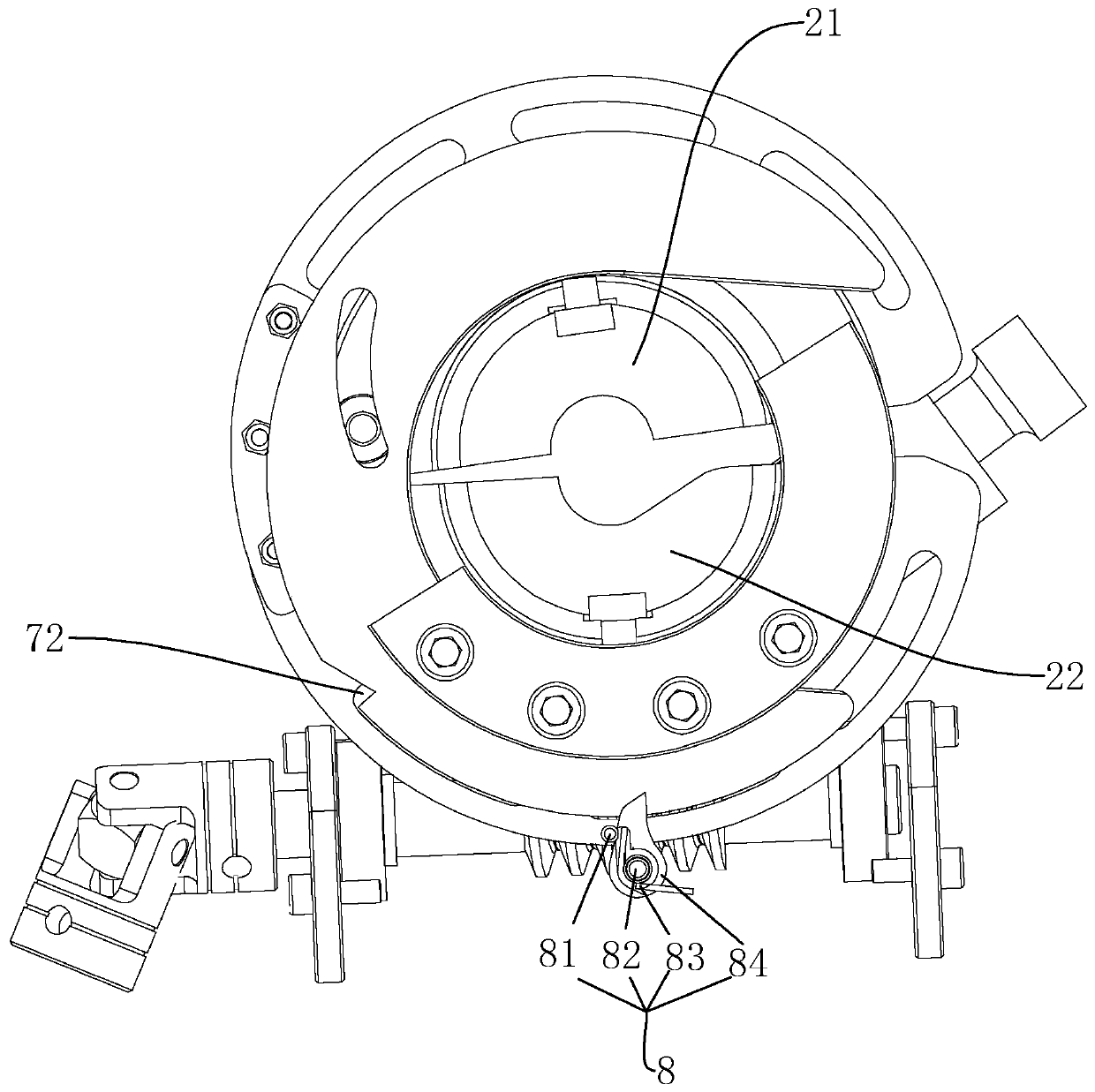

[0040] combine Figure 1 to Figure 8 The light-weight trolley wire automatic stripping device based on the principle of the four-bar linkage mechanism of the present invention will be further described.

[0041] A light-weight overhead wire automatic stripping device based on the principle of a four-bar linkage mechanism is characterized in that it includes:

[0042] The base 1, the base 1 includes a base plate and a transmission shaft fixing plate 11 and a mounting plate fixing plate 12 located on the base plate.

[0043] Drive worm 5, said drive worm 5 is erected on the two drive shaft fixing plates 11 of base 1 through bearings, so as to realize the rotatable setting of drive worm 5; at the same time, one end of drive worm 5 is connected with shaft coupling 51, through which The shaft coupling 51 can facilitate the connection between the transmission worm 5 and the external drive components, that is, facilitate the rotation of the transmission worm 5 .

[0044] The bushin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com