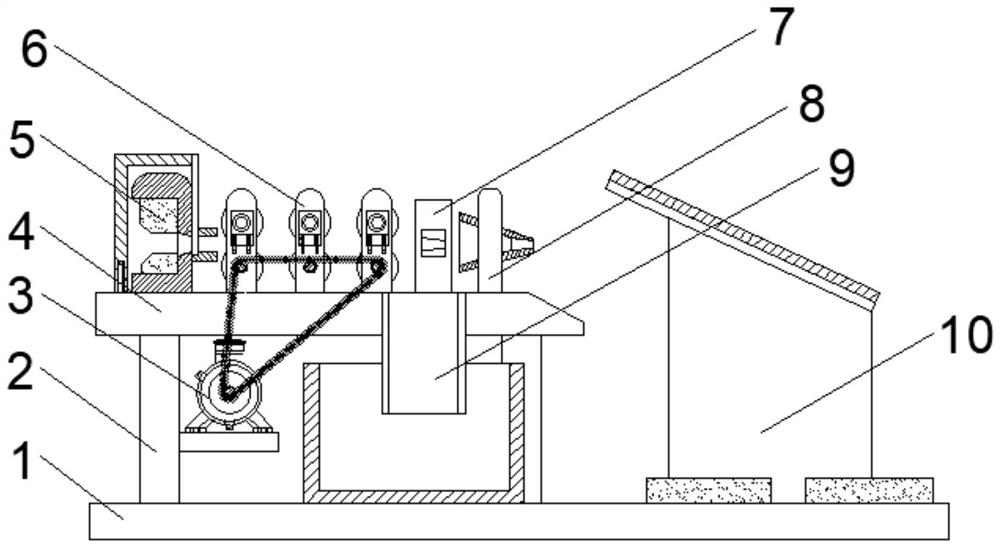

Wicker peeling processing equipment for intelligently producing willow products

A technology of processing equipment and willow products, applied in the field of wicker peeling processing equipment, can solve the problems of wicker extrusion damage, transmission mechanism pinching fingers, operator damage, etc., to improve the use effect, reduce the frequency of regular sponge replacement, reduce damage effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

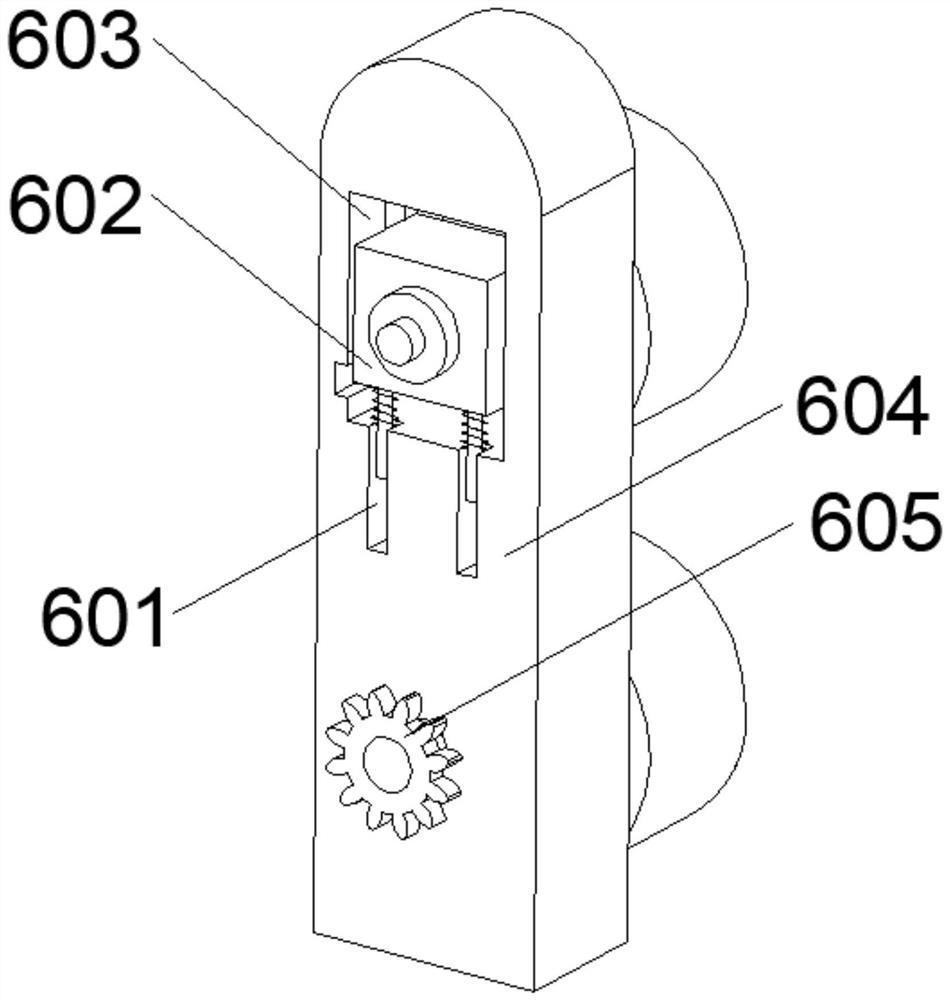

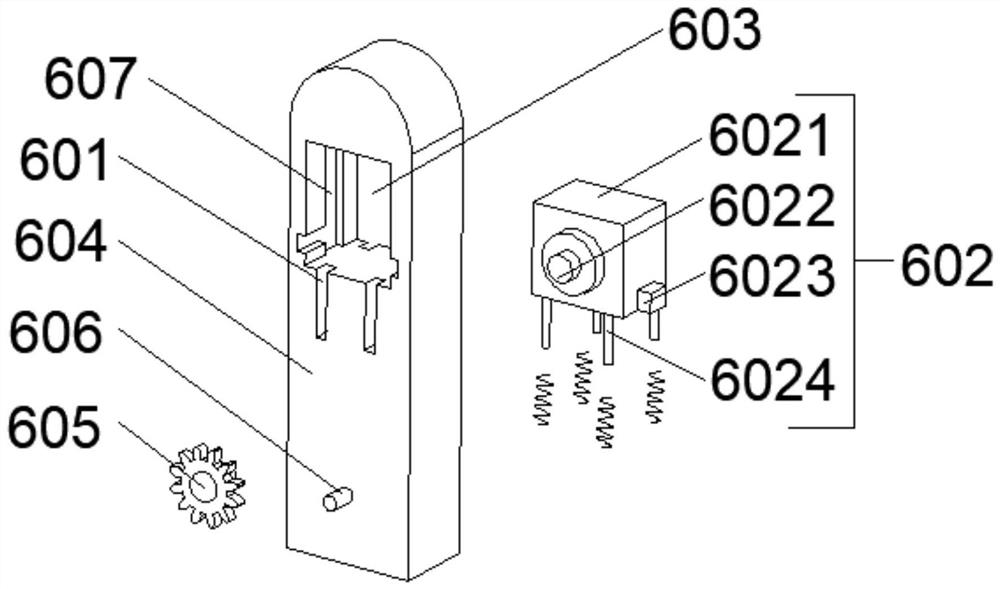

[0031] see figure 2 As shown, the above-mentioned transmission mechanism 6 includes a mounting seat 604 fixedly connected to the support plate 4, and the top of the mounting seat 604 is provided with a mounting groove 603, and both sides of the mounting groove 603 are provided with a slide groove 607, and the mounting groove 603 The bottom of the groove wall is provided with four limiting grooves 601, the interior of the mounting groove 603 is provided with a shock absorbing mechanism 602, the bottom of the mounting seat 604 is provided with a first rotating shaft 606, and one end of the first rotating shaft 606 is fixedly connected with a gear 605, which 605 is transmission-connected with the output end of the drive motor 3 through a chain, and the other end of the first rotating shaft 606 runs through the mounting seat 604 movably.

[0032] see image 3 As shown, the above-mentioned cushioning mechanism 602 includes a bearing seat 6021 located in the installation groove 60...

Embodiment 2

[0035] see Figure 4 with Figure 5As shown, the above-mentioned protection mechanism 5 includes a protection block 501 fixedly connected to the support plate 4. A protection groove is opened on a side of the protection block 501 away from the mounting seat 604. Two sponge pads 505 are arranged inside the protection groove. The protection block 501 There is a through hole facing one side of the mounting base 604, and both sides of the through hole are fixedly connected with the limiting plate 506, the front and rear ends of the mounting base 604 are provided with guide grooves, and the outer side of the protective block 501 is provided with a protective cover 502. The two side inner walls of the protective cover 502 are fixedly connected with the limit strips 507, and the two limit strips 507 are respectively slidably connected with the corresponding guide grooves. The top side of the protective cover 502 is fixedly connected with a shielding plate 504, and the bottom of the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com