Anti-ultraviolet polyester fabric processing method

A technology of anti-ultraviolet rays and processing methods, which is applied in the field of polyester fabrics, can solve the problems of manual cutting of polyester fabrics, achieve the effect of smooth cutting, improve the use effect, and ensure the stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

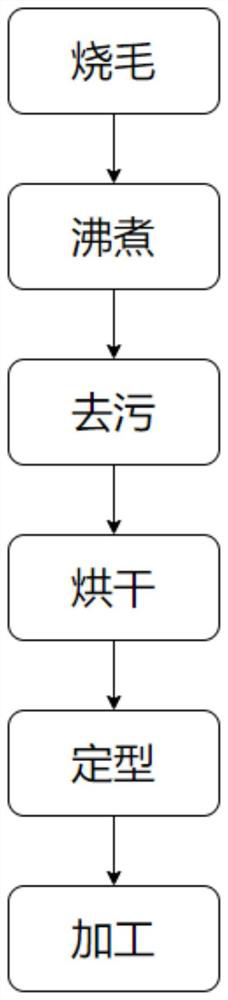

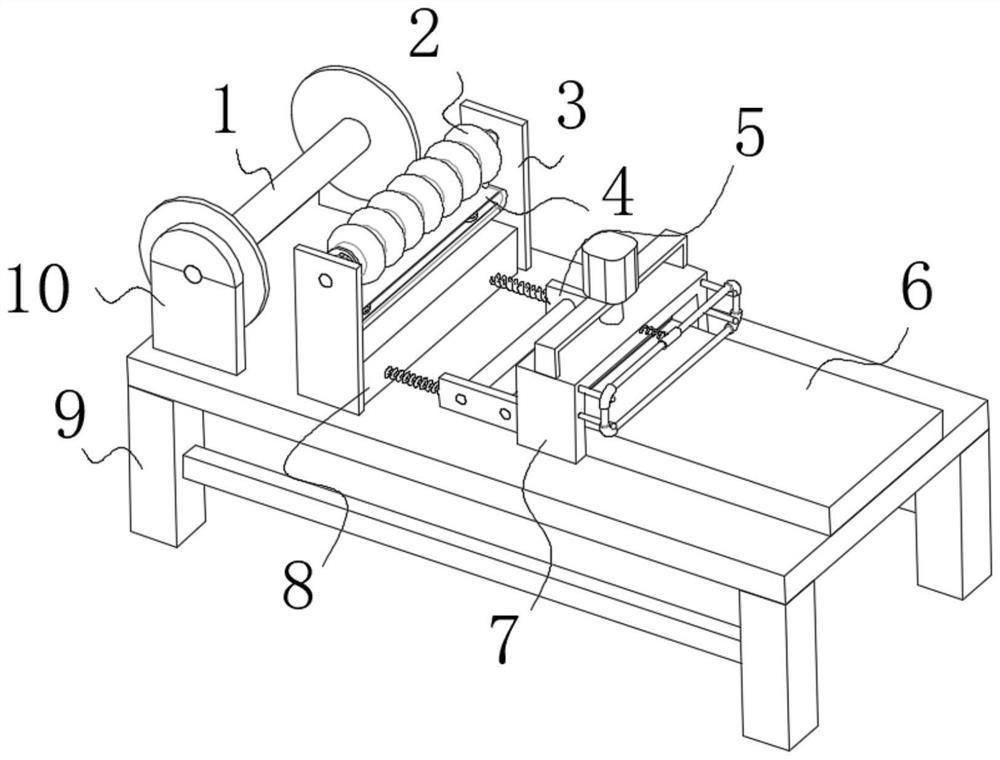

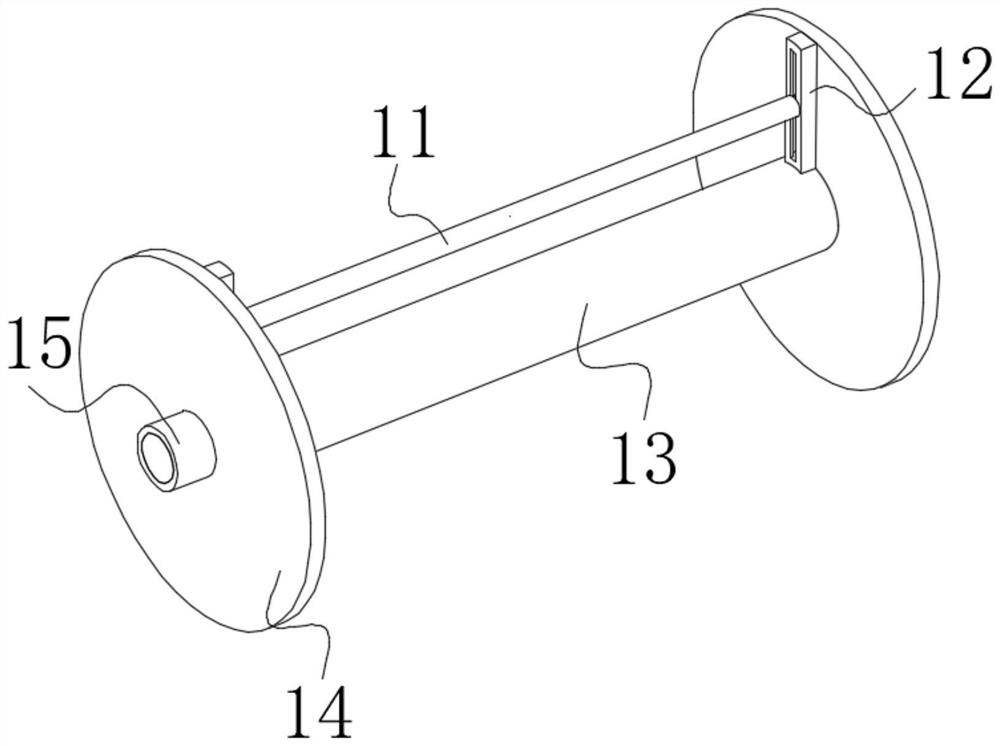

[0037] use Figure 1-Figure 7 A method for processing an anti-ultraviolet polyester fabric according to an embodiment of the present invention is described as follows.

[0038] Such as Figure 1-Figure 7 Shown, a kind of anti-ultraviolet polyester fabric processing method of the present invention comprises the following steps:

[0039] S1: Singeing the fabric that needs to be prepared with anti-ultraviolet rays, and burning off the surface yarn hairiness, some knots and weaving defects of the fabric;

[0040] S2: putting the singeed fabric into clean water at a temperature of 100°C and boiling for 8-10 minutes;

[0041] S3: Invade the fabric after the first boiling into the decontamination solution, soak in the decontamination solution at 35-40°C for 20-30 minutes, and then scrub the fabric in the decontamination solution to remove free substances on the fabric, Remove impurities such as grease and dyeing attachments, and finally rinse with clean water several times to remo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com