Extrusion pin mechanism

A technology of extrusion pin and extrusion hole, applied in the field of extrusion pin, can solve the problems of difficult mass production, easy to get stuck, easy to stick to aluminum die and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

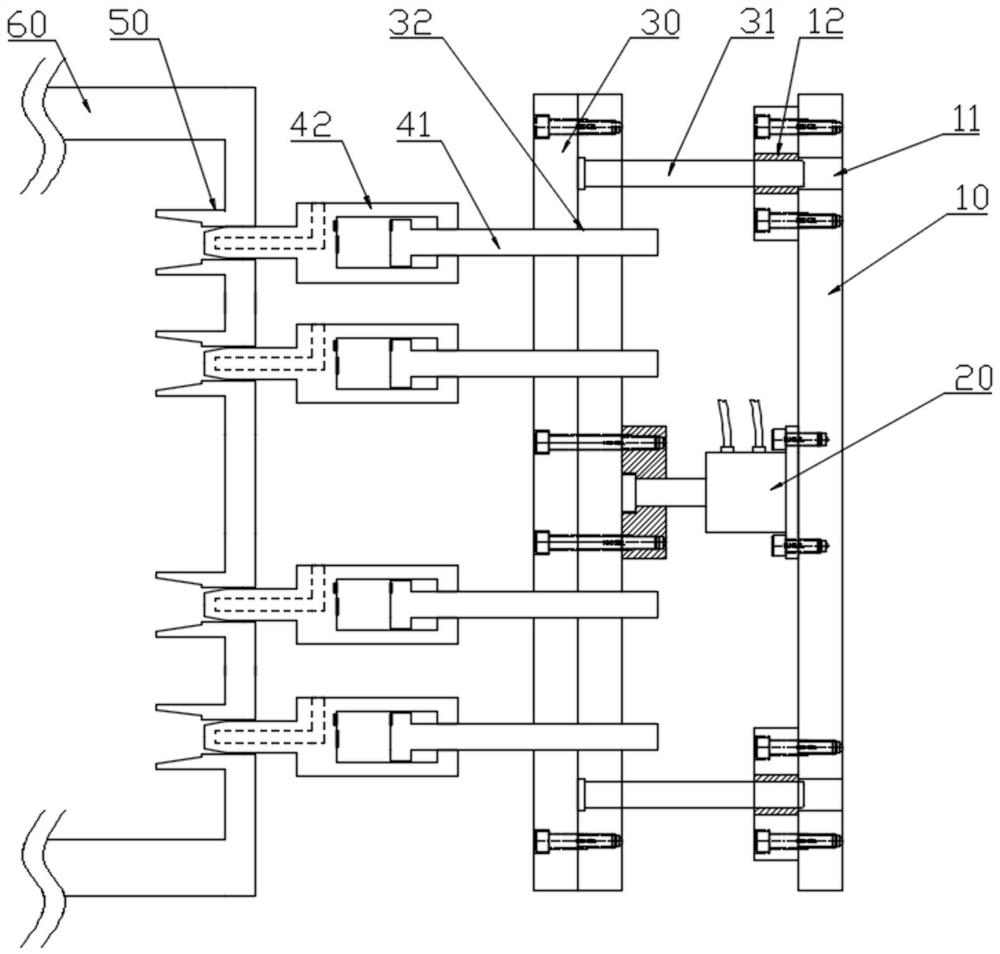

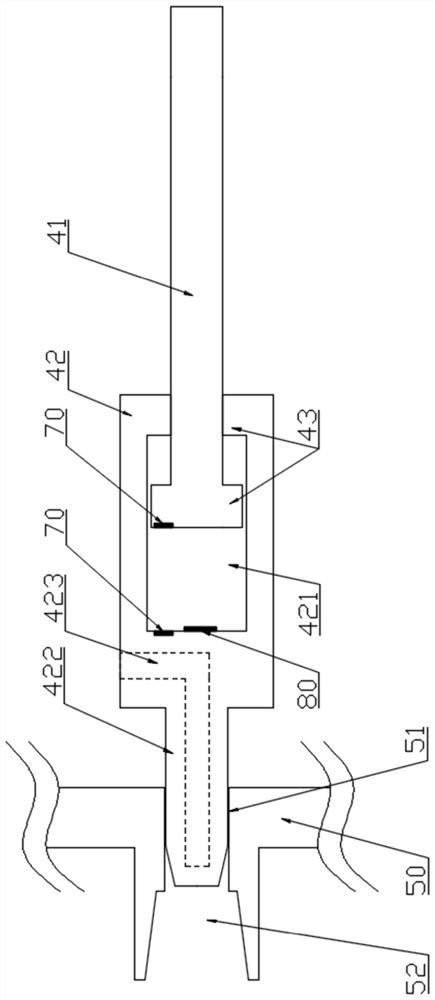

[0034] see figure 1 and figure 2 , an extrusion pin mechanism of the present embodiment, comprising a fixed plate 10, an oil cylinder 20, a needle insert plate 30, a plurality of extrusion pins, a number of needle sleeves 50 consistent with the extrusion pins, and a mold 60;

[0035] Specifically, the oil cylinder 20 is arranged on the fixed plate 10;

[0036] Specifically, the needle-set plate 30 is slidably arranged with the fixed plate 10; the output end of the oil cylinder 20 is connected with the first end surface of the needle-set plate 30, and drives the needle-set plate 30 to move relative to the fixed plate 10;

[0037] More specifically, a plurality of guide posts 31 are provided on the first end surface of the needle-set plate 30, and a plurality of guide holes 11 are provided on the fixed plate 10, and each guide hole 11 is correspondingly provided with each guide post 31, each guide post 31 is slidably arranged in the corresponding guide hole 11;

[0038] More...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com