Regional control multi-stage turbulent fluidization reaction furnace

A fluidized reaction and zone control technology, applied in furnace control devices, furnaces, furnace components, etc., can solve the problems of short residence reaction time, large circulation equipment structure, and inability to quickly separate and react, and achieve good product quality and occupation. The effect of small floor area and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

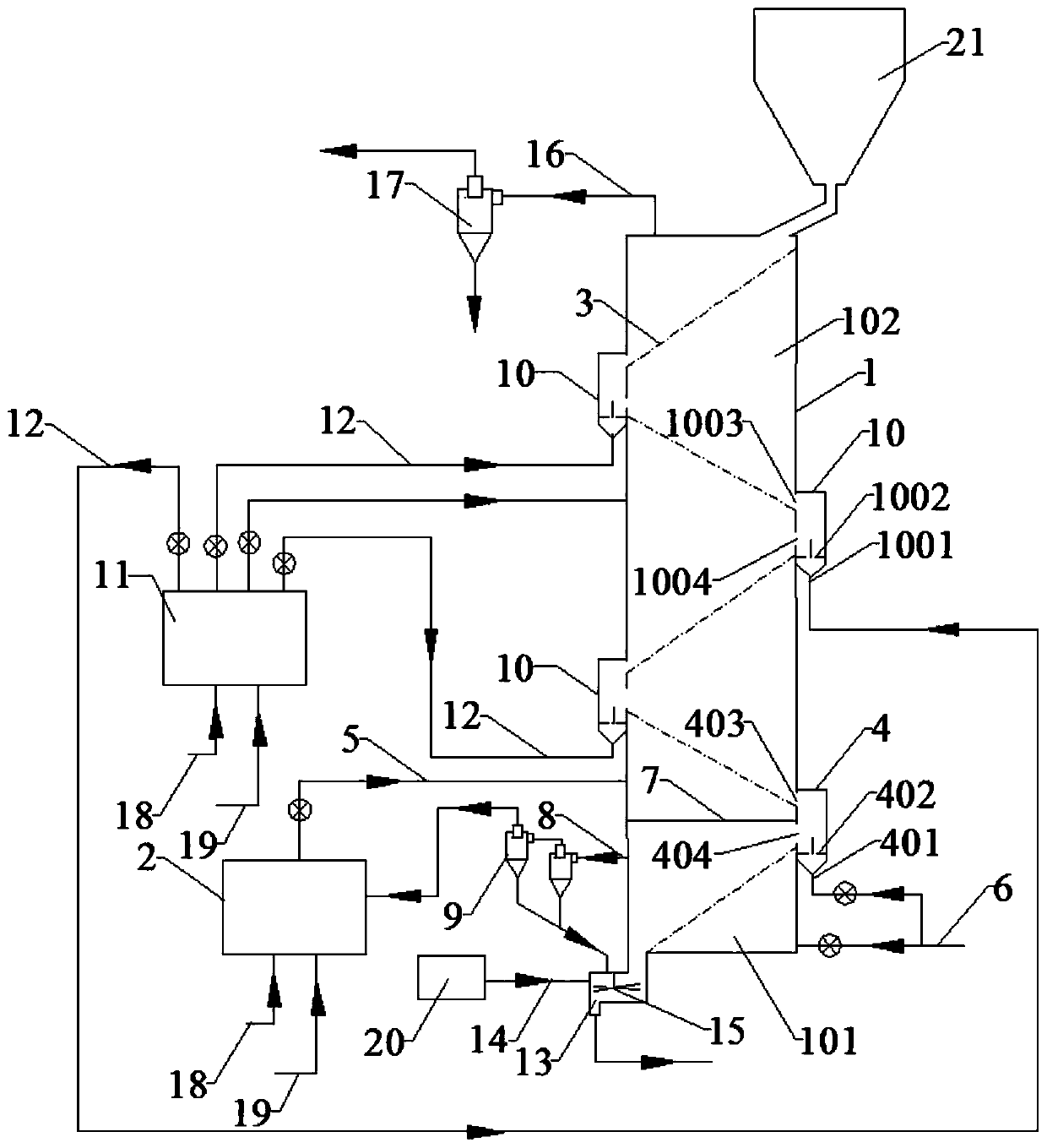

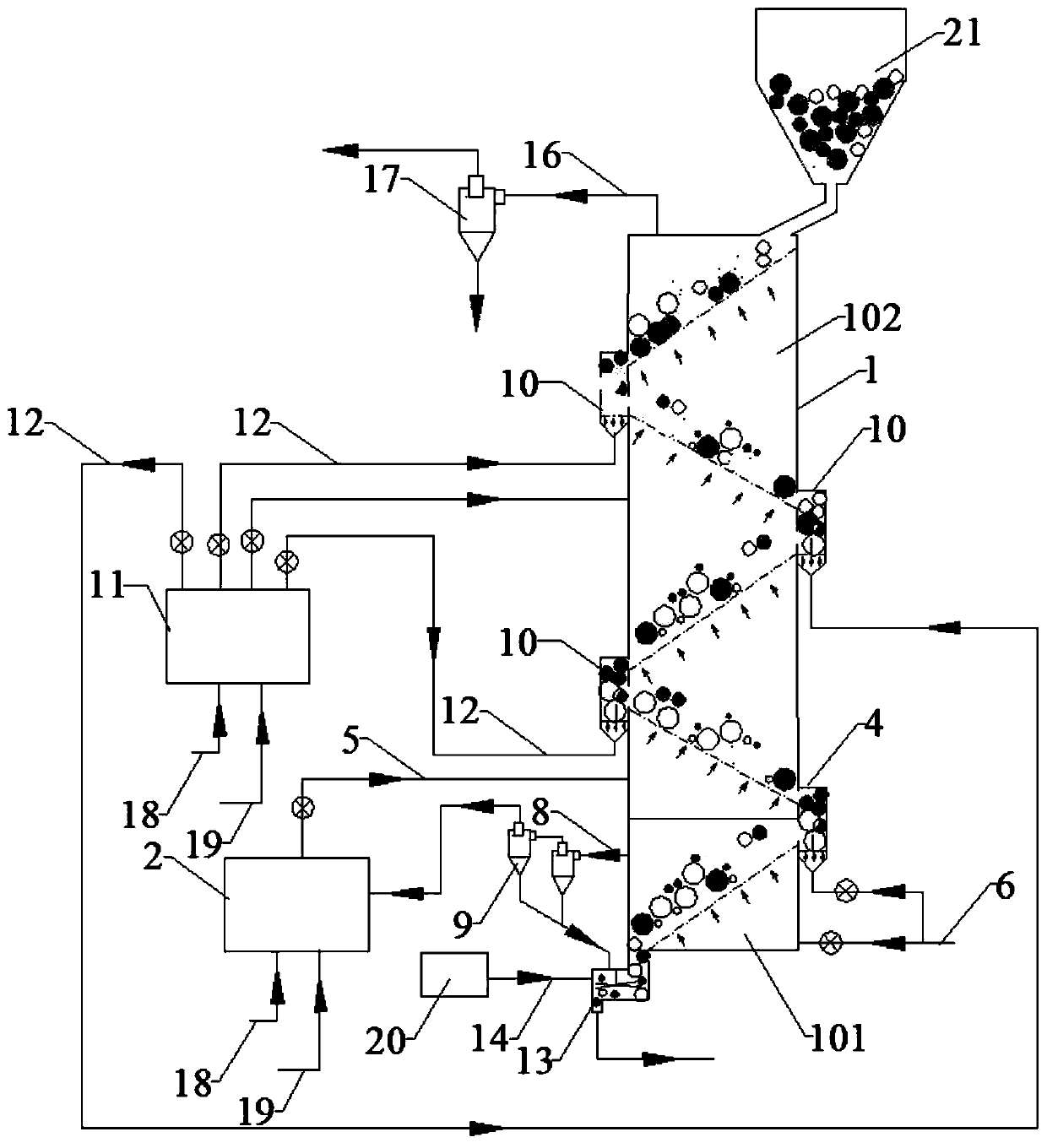

[0032] Such as figure 1 with figure 2 As shown, the zone-controlled multi-stage turbulent fluidized reaction furnace in this embodiment includes a furnace body 1 and a main combustion furnace 2 . The body of furnace 1 comprises a reaction zone 101 and at least one preheating zone 102 ( figure 1 , figure 2 In order to show four preheating zones 102, which are respectively Zone I, Zone II, Zone III and Zone IV, and the four preheating zones 102 are independent of each other), the preheating zone 102 is arranged on the top of the reaction zone 101, and the reaction zone 101 and The preheating zone 102 is provided with perforated gas distribution plates 3 arranged obliquely. The preheating zone 102 and the reaction zone 101 are separated into independent cavities by a separator 7. The material outlet of the preheating zone 102 is connected to the reaction zone. The material inlet of 101 is connected through a reaction zone sealing valve 4 (L-shaped valve), and the material ou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com