Water recycle system of beneficiation

A water reuse and main system technology, applied in the pipeline system, gas/liquid distribution and storage, mechanical equipment, etc., can solve the problems that affect the production index of ore dressing and the instability of the beneficiation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

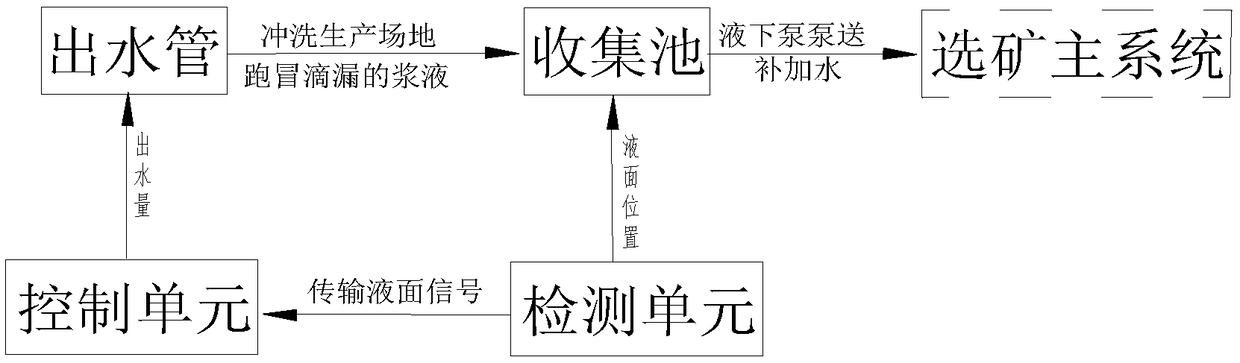

[0011] Such as figure 1 As shown, a recycling water system for beneficiation includes:

[0012] The collection pool is used to collect the slurry that escapes, emits, drips, and leaks during the production process of the main beneficiation system;

[0013] Outlet pipe, the inlet is connected to the water source, and the outlet water washes the slurry that runs, drips, and leaks into the collection tank;

[0014] A submerged pump is installed in the pool of the collecting tank, and the submerged pump pumps the slurry in the collecting tank to a certain water point of the main beneficiation system in the form of additional water in a balanced manner.

[0015] The main mineral processing production system needs to continuously add water due to the continuous output of slurry. While clearing the production site, the materials that run, emit, drip, and leak from the system are recovered and returned to the system; and the submerged pump always transports the collected liquid to t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com