Continuous discrete type rare earth permanent magnet high gradient magnetic separator

A high-gradient magnetic separator and rare earth permanent magnet technology, applied in high-gradient magnetic separators and other directions, can solve the problems of low effective recovery rate of fine-grained magnetic minerals, high operating costs, and large equipment investment, saving equipment investment. and production cost, large processing capacity, small volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

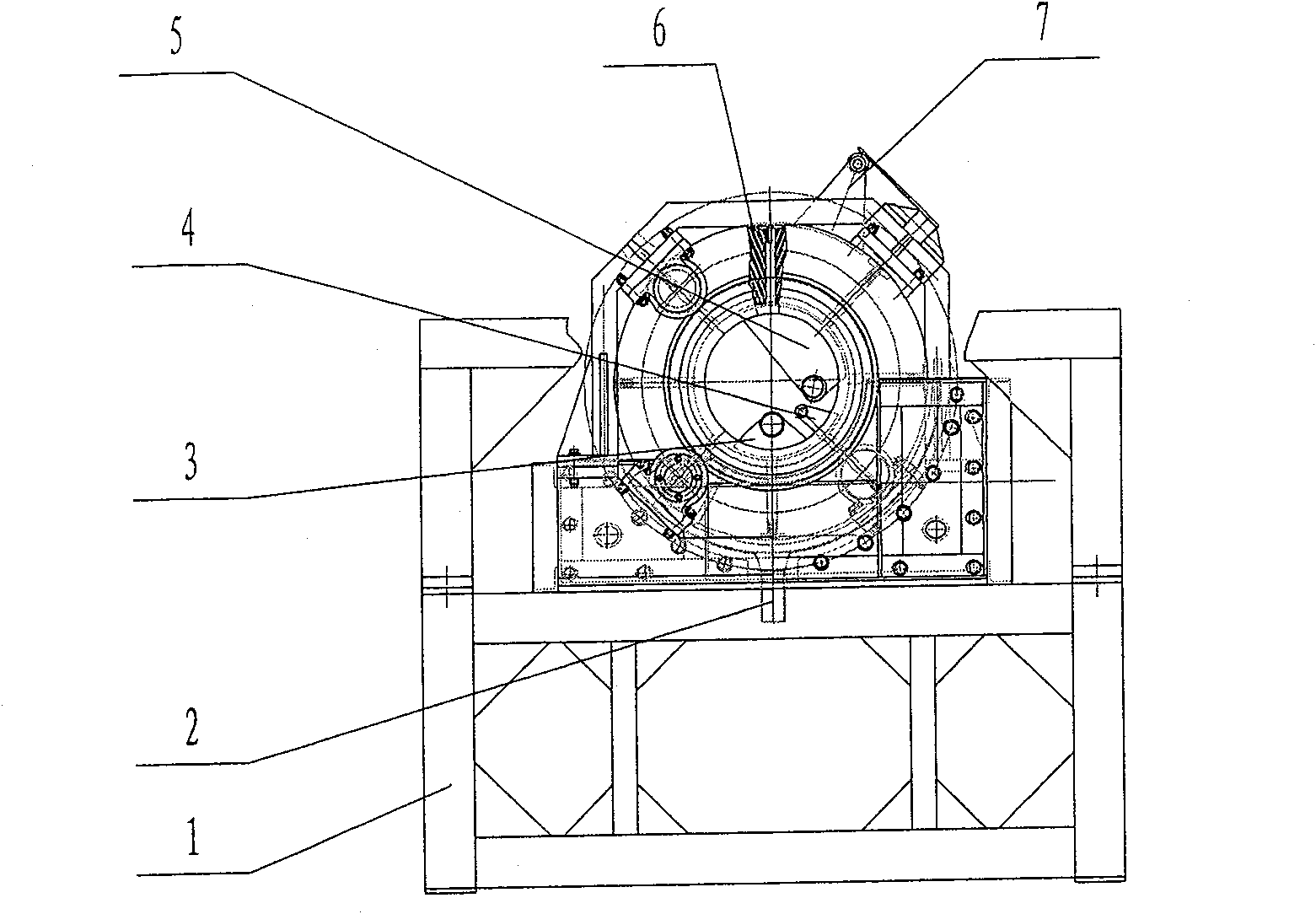

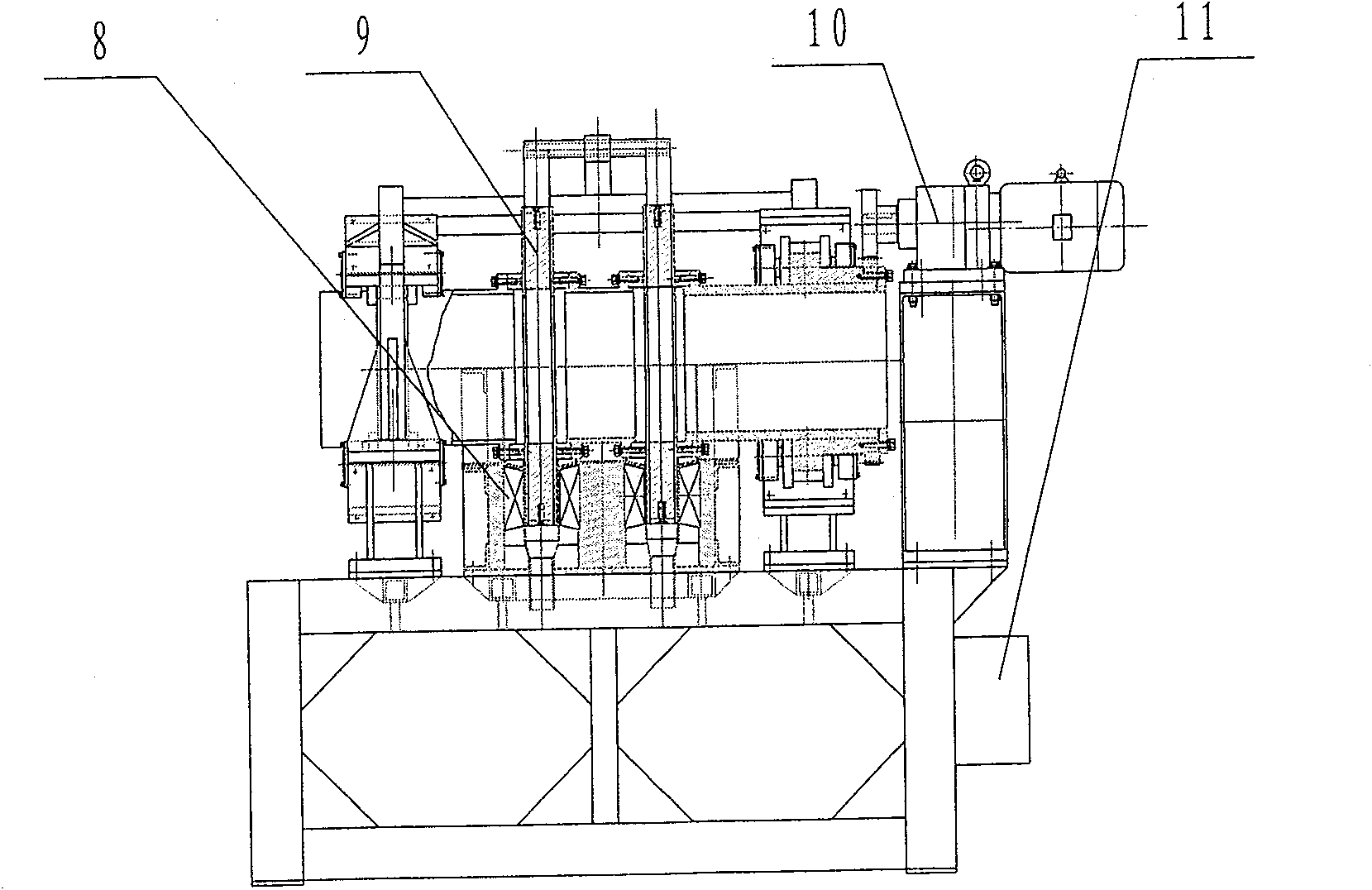

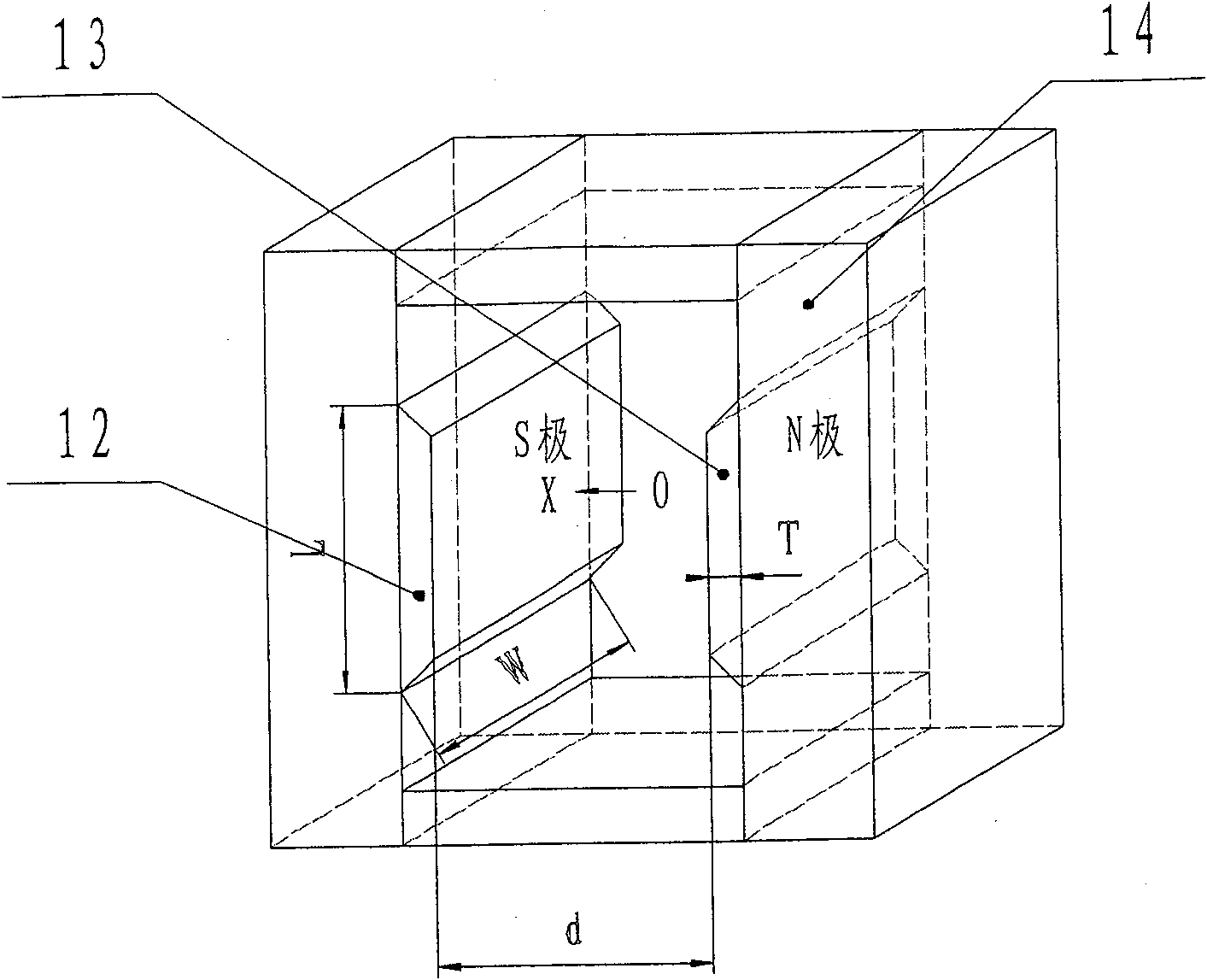

[0014] Embodiment: As shown in the accompanying drawing, the continuous discrete type rare earth permanent magnet high gradient magnetic separator consists of a frame 1, a sorting combination part (sorting box 2, sorting disc 9, rare earth permanent magnet 8), and an ore feeder 3 , cleaning device 4, magnetic product receiving tank 5, sorting medium stack 6, flushing device 7, driving device 10, frequency conversion speed control electric control box 11 and other main components. The two ends of the inner diameter of the sorting disc 9 are respectively fixed with the large diameter hollow shaft to form an integral rotating part, which is driven by the drive device 10 and controlled by the frequency conversion speed control electric control box 11, and rotates around the hollow shaft. The fan-shaped stainless steel medium heap 6 that can be easily disassembled is housed in the periphery of the sorting disc 9 . Rare earth permanent magnet 8 is composed of S pole 12, N pole 13 an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com