A kind of low temperature resistant zinc oxide ore flotation composite agent and its preparation method and application

A technology of zinc oxide ore and composite reagents, applied in chemical instruments and methods, flotation, wet separation, etc., can solve the problems of inability to completely eliminate the interference of ore slime, the difficulty of accurately controlling the amount of desliming, and the impossibility of flotation operations, etc. problem, to achieve the effect of improving the low temperature flotation environment, increasing the recovery rate of ore dressing, and increasing the flotation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

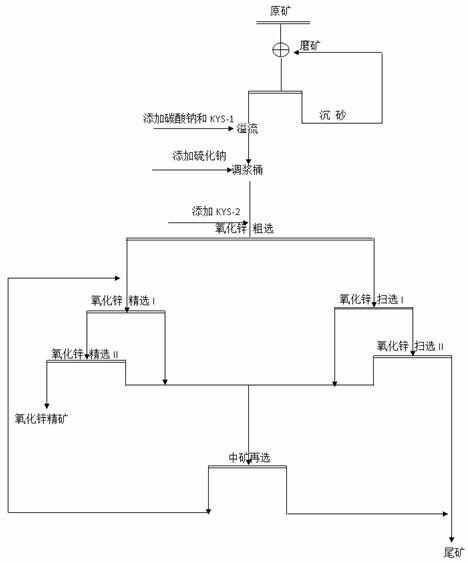

Image

Examples

Embodiment 1

[0027] The low-temperature-resistant zinc oxide ore flotation composite agent in this embodiment includes a composite regulator and a composite collector, wherein the composite regulator is mixed with sodium hexametaphosphate, starch, and sodium humate in a weight ratio of 5:3:1 The composite collector is composed of octadecylamine, glacial acetic acid, sodium benzyl hydroxamate and waste oil in a weight ratio of 8:5:2:1.

[0028] The preparation method of the low temperature resistant zinc oxide ore flotation composite agent of the present embodiment is carried out as follows:

[0029] Mix sodium hexametaphosphate, starch, and sodium humate in a weight ratio of 5:3:1, stir in a high-speed mixer for 10 minutes, and take out the mixture as a compound regulator, denoted as KYS-1.

[0030] According to the weight ratio, first heat 8 parts of octadecylamine and 5 parts of glacial acetic acid to dissolve; then add 2 parts of waste oil to the dissolving solution, stir and emulsify b...

Embodiment 2

[0037] The low-temperature-resistant zinc oxide ore flotation composite agent of the present embodiment includes a composite regulator and a composite collector, wherein the composite regulator is mixed by sodium hexametaphosphate, starch, and sodium humate in a weight ratio of 6:6:3 The composite collector is composed of octadecylamine, glacial acetic acid, sodium benzyl hydroxamate and waste oil in a weight ratio of 8:8:2:2.

[0038] The preparation method of the low temperature resistant zinc oxide ore flotation composite agent of the present embodiment is carried out as follows:

[0039] Mix sodium hexametaphosphate, starch, and sodium humate in a weight ratio of 6:6:3, stir in a high-speed mixer for 10 minutes, and take out the mixture as a compound regulator, denoted as KYS-1.

[0040] According to the weight ratio, first heat 8 parts of octadecylamine and 8 parts of glacial acetic acid to dissolve; then add 2 parts of waste engine oil to the dissolving solution, ultraso...

Embodiment 3

[0047]The low-temperature-resistant zinc oxide ore flotation composite agent in this embodiment includes a composite regulator and a composite collector, wherein the composite regulator is mixed with sodium hexametaphosphate, starch, and sodium humate in a weight ratio of 7:6:3 The composite collector is composed of octadecylamine, glacial acetic acid, sodium benzyl hydroxamate and waste oil in a weight ratio of 5:5:1:1.

[0048] The preparation method of the low temperature resistant zinc oxide ore flotation composite agent of the present embodiment is carried out as follows:

[0049] Mix sodium hexametaphosphate, starch, and sodium humate in a weight ratio of 7:6:3, stir in a high-speed mixer for 10 minutes, and take out the mixture as a compound regulator, denoted as KYS-1.

[0050] According to the weight ratio, first heat 5 parts of octadecylamine and 5 parts of glacial acetic acid to dissolve; then add 1 part of waste engine oil to the dissolving solution, ultrasonically...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com