Production line quality evaluation method based on cosmetics and production data processing center

A technology for producing data and cosmetics, applied in the field of cosmetic production and big data processing, can solve the problems of complex production process and many production nodes in cosmetic production lines, and achieve the effect of ensuring quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

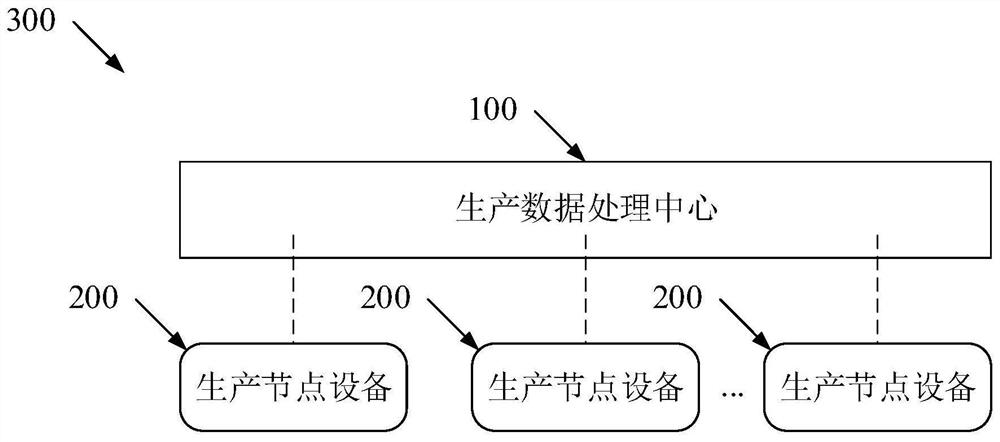

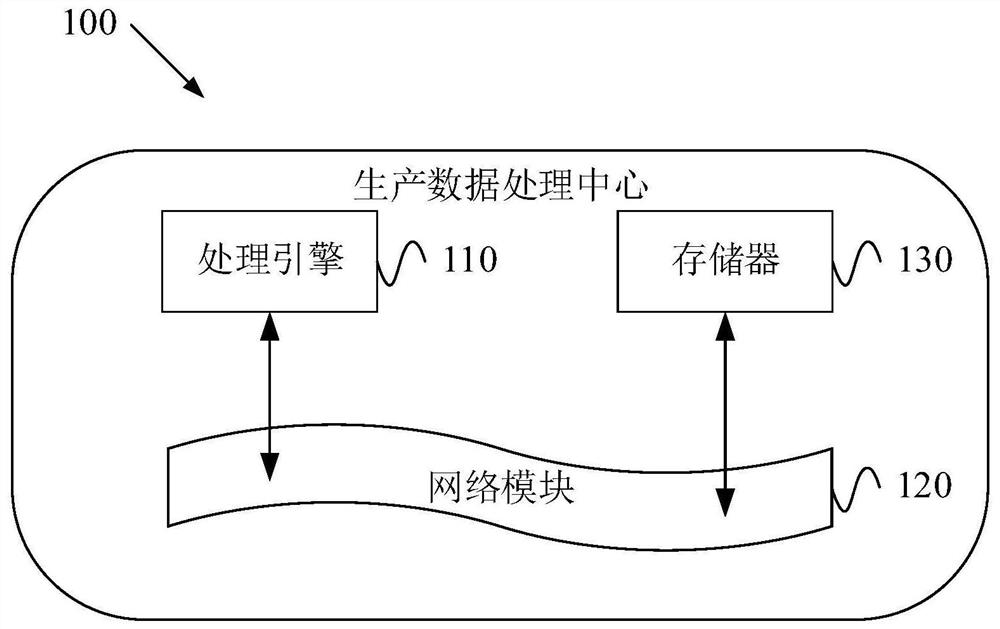

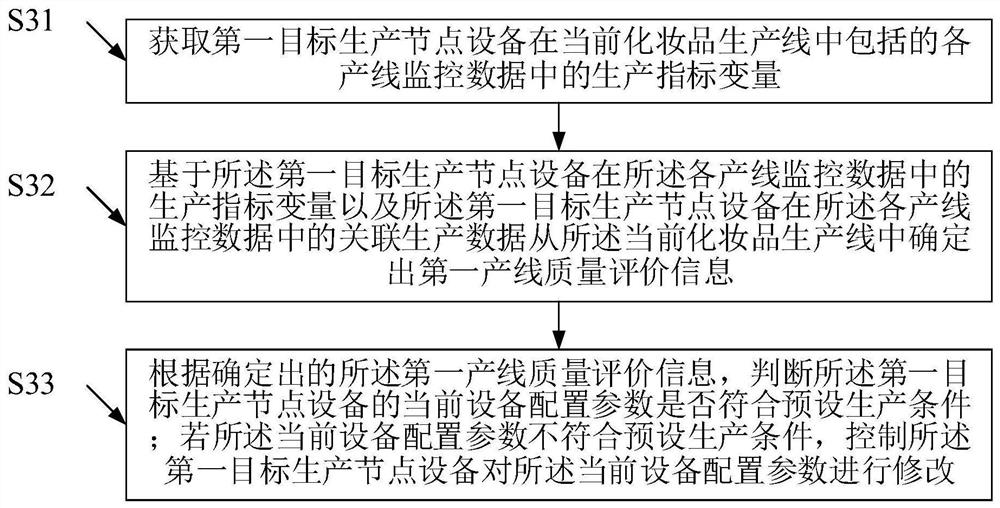

[0055] After studying and analyzing common cosmetic production lines, the inventor found that the key to determining the production quality of cosmetic production lines is whether the production equipment meets the production indicators. Based on this, the inventor innovatively found that if the production indicators are monitored for each production equipment, It can effectively monitor the production quality of the cosmetics production line, so as to ensure the quality of the cosmetics produced. In order to achieve the above purpose, the embodiments of the present invention provide a cosmetics-based production line quality evaluation method and a production data processing center.

[0056] In order to better understand the above technical solutions, the technical solutions of the present invention will be described in detail below through the accompanying drawings and specific examples. It should be understood that the embodiments of the present invention and the specific fea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com