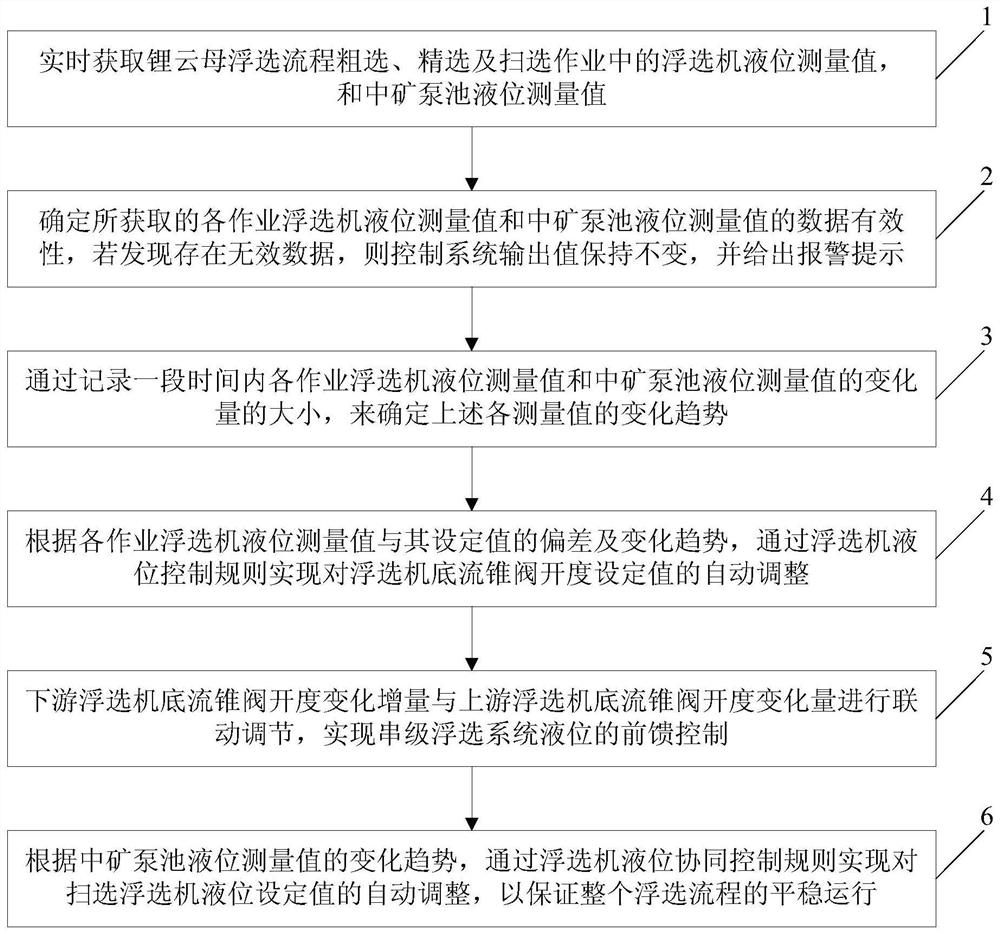

Intelligent control method for liquid level of lepidolite flotation system

An intelligent control, lepidolite technology, applied in flotation, liquid level indicator, engine lubrication, etc., can solve the problems of affecting flotation product quality, flotation liquid level shock, poor control stability, etc., and achieve stable production indicators , to ensure stable operation and maintain the effect of stable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

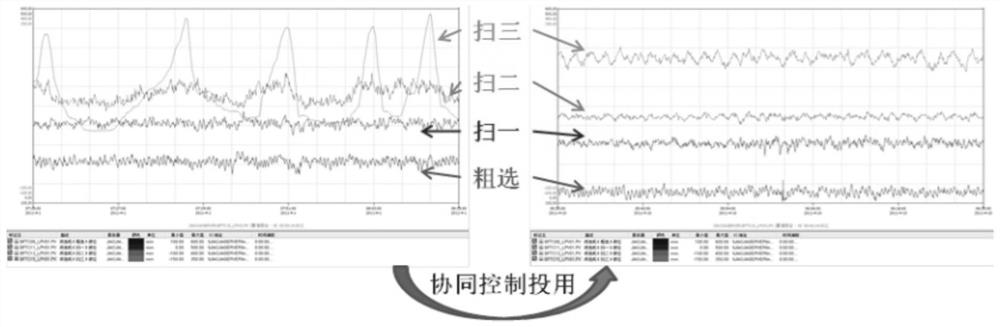

[0090] In order to further illustrate the intelligent control symbol of the present invention, the implementation of the intelligent control of the above-mentioned flotation process flow level is described in detail by taking the sweeping operation of a lepidolite flotation as a specific example:

[0091] Step 1. First read the online data;

[0092] Read the liquid level measurement value of lepidolite sweeping flotation machine at the current moment through OPC mode, the measured value of flotation machine liquid level is 180mm, the liquid level measurement value of flotation machine for rough selection operation is 175mm, the liquid level measurement value of flotation machine for fine selection operation is 170mm, the middle The measured value of the mine pump pool liquid level is 1.35m;

[0093] Step 2, judging the data validity of the liquid level measurement value of the flotation machine for sweeping, roughing, and selection operations and the liquid level measurement v...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com