A method for purifying phosphogypsum based on a flotation column with a filler and a gravity column

A phosphogypsum and flotation column technology, applied in flotation, chemical instruments and methods, wet separation, etc., can solve the problems of less than 30% comprehensive utilization rate, unclear removal of radioactive elements, heavy burden on production enterprises, etc. The effect of low labor intensity of workers, saving pharmaceutical dosage, and reducing short circuit phenomenon

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

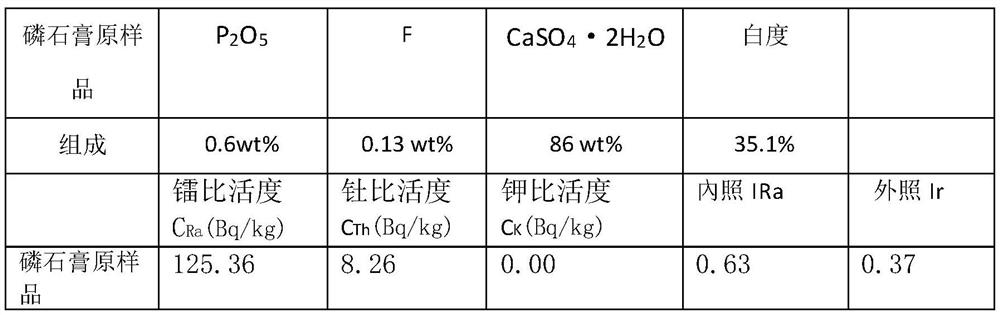

[0019] The phosphite raw material used in the examples of the present invention is a phospantine in the production process of Sichuan, and the phosphite of the pneumon is shown in the table:

[0020] Table 1 Nature of phospantine raw materials

[0021]

[0022] The radioactive detection of the sample in Table 1 is the test conducted by the Wuhan Mineral Resources Supervision and Testing Center of the Ministry of Land and Resources of the People's Republic of China.

[0023] The phosphite raw material also contains SiO 2 , Alumina, iron oxide, magnesium oxide, acid insoluble organic matter, etc.

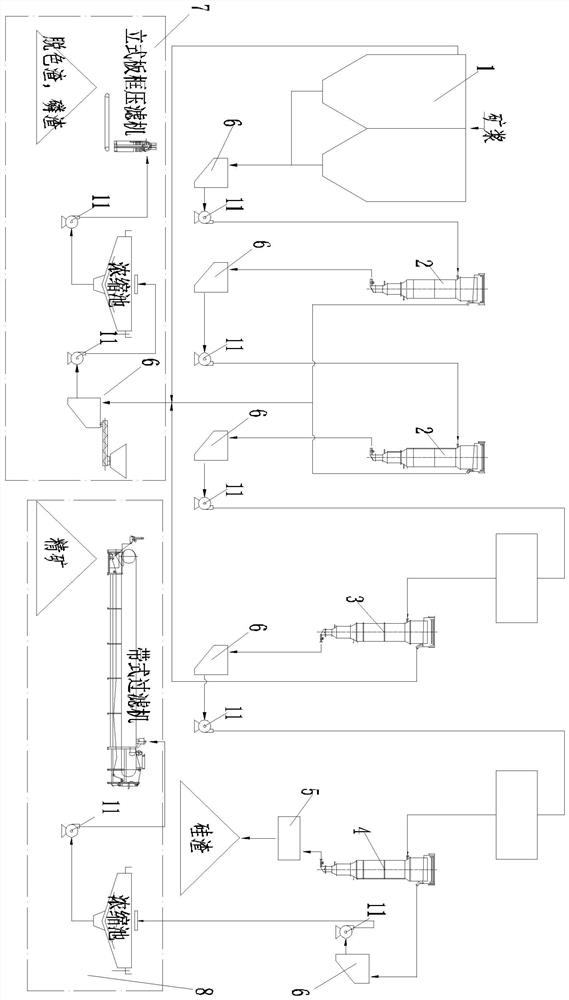

[0024] In this embodiment, a method of purifying a plotted column and an alternative column on a pluggable form, including the following steps:

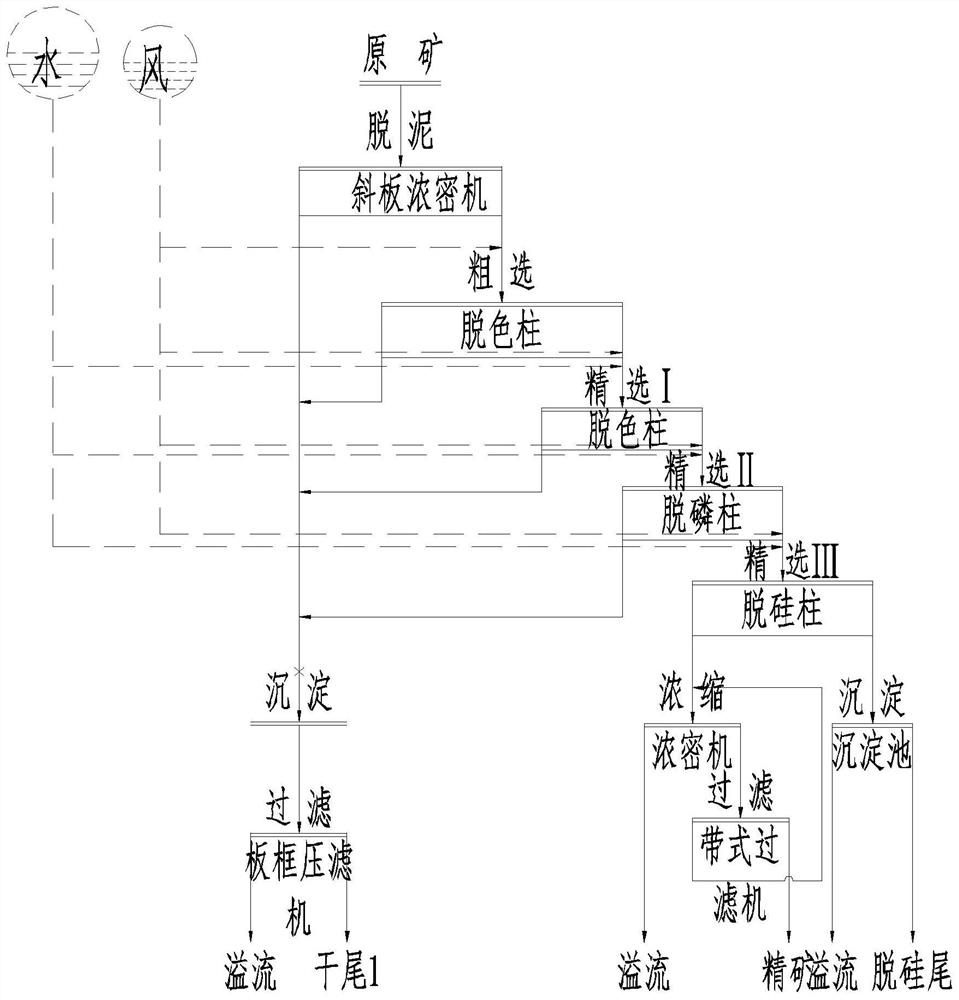

[0025] like figure 1 Due to the 333.36 tons of phosphite mass in the factory production project, only 12.5%, a water containing 291.69 tons, and the Kunming Metallurgical Research Institute is concentrated in patented CN101569868B, and the top...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com