Oxygen-enriched side-blowing smelting method of impurity-poor high-silicon copper concentrate

A copper concentrate and high-silicon technology, applied in the direction of improving process efficiency, can solve problems such as rising smelting costs, frequent fluctuations in furnace conditions, and nodules in the flue, so as to increase processing fee income, maximize processing capacity, and increase production The effect of index stabilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0167] An oxygen-enriched side blowing smelting method for impurity-poor high-silicon copper concentrate, comprising the following steps:

[0168] Step 1, mixing ore:

[0169] Take impurity-poor high-silicon low-copper copper concentrate and impurity-poor high-silicon low-sulfur copper concentrate, add copper-rich high-sulfur ore and slag concentrate to them, and mix them evenly to obtain a composite ore. The composite ore includes components and mass percentages The content is: 64% of high-silicon and low-sulfur copper concentrate, 32% of copper-rich high-sulfur ore and 4% of slag concentrate; and CaO is added to the composite ore, and the CaO mass ratio is 3.09% of the composite ore, wherein:

[0170] The elements and mass percentages of impurity-poor high-silicon and low-sulfur copper concentrate, impurity-poor high-silicon and low-copper copper concentrate, copper-rich high-sulfur ore and slag concentrate are shown in Table 1.

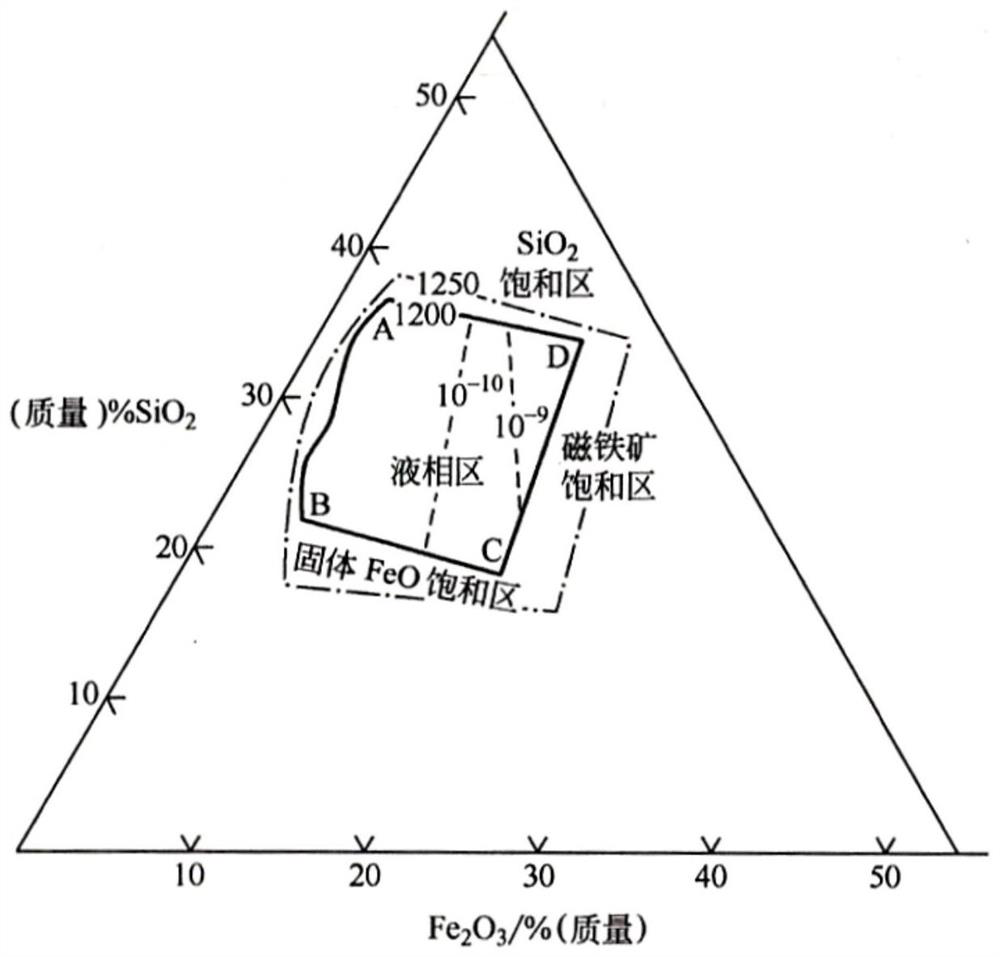

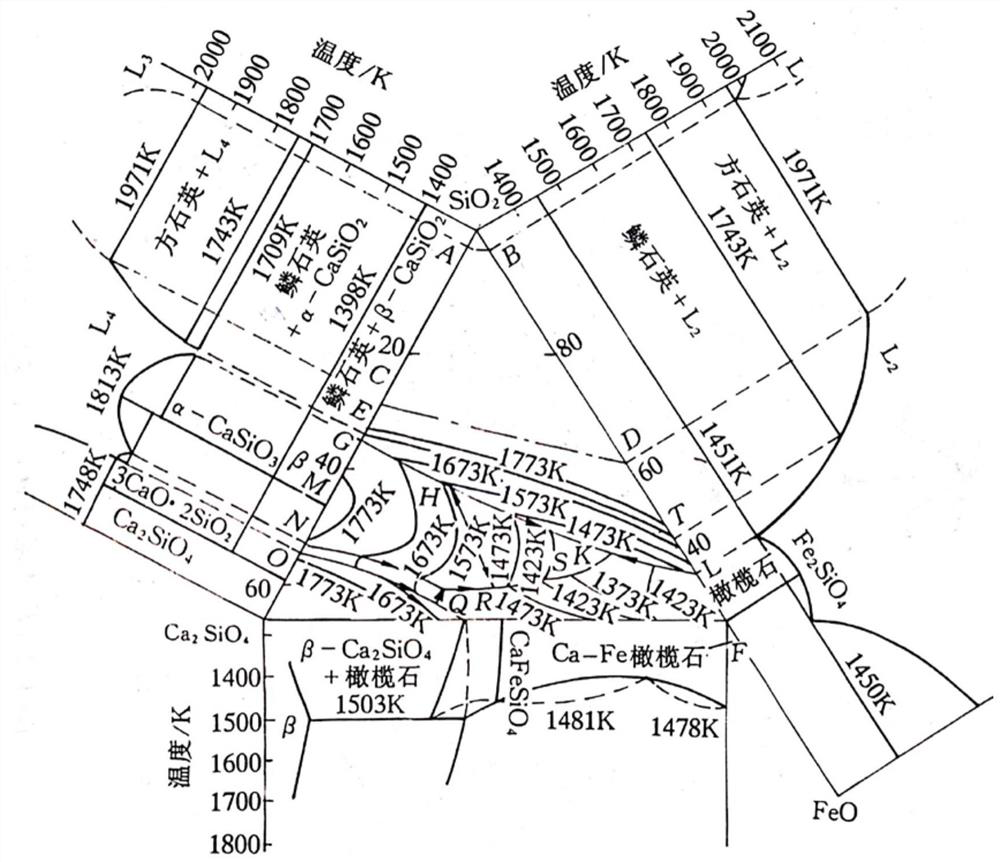

[0171] Get Composite Ore SiO 2 Content, Al...

Embodiment 2

[0179] An oxygen-enriched side blowing smelting method for impurity-poor high-silicon copper concentrate, comprising the following steps:

[0180] Step 1, mixing ore:

[0181] Take impurity-poor high-silicon low-copper copper concentrate and impurity-poor high-silicon low-sulfur copper concentrate, add copper-rich high-sulfur ore and slag concentrate to them, and mix them evenly to obtain a composite ore. The composite ore includes components and mass percentages The content is: 54% of high-silicon and low-sulfur copper concentrate, 10% of high-silicon and low-copper copper concentrate, 32% of copper-rich high-sulfur ore and 4% of slag concentrate; The ratio is 2.78% of the composite ore, of which:

[0182] The elements and mass percentages of impurity-poor high-silicon and low-sulfur copper concentrate, impurity-poor high-silicon and low-copper copper concentrate, copper-rich high-sulfur ore and slag concentrate are shown in Table 1.

[0183] Get Composite Ore SiO 2 Conten...

Embodiment 3

[0189] An oxygen-enriched side blowing smelting method for impurity-poor high-silicon copper concentrate, comprising the following steps:

[0190] Step 1, mixing ore:

[0191] Take impurity-poor high-silicon low-copper copper concentrate and impurity-poor high-silicon low-sulfur copper concentrate, add copper-rich high-sulfur ore and slag concentrate to them, and mix them evenly to obtain a composite ore. The composite ore includes components and mass percentages The content is: 36% of high-silicon and low-sulfur copper concentrate, 28% of high-silicon and low-copper copper concentrate, 32% of copper-rich high-sulfur ore and 4% of slag concentrate; and CaO is added to the compound ore, and the quality of CaO accounts for The ratio is 2.15% of the composite ore, of which:

[0192] The elements and mass percentages of impurity-poor high-silicon and low-sulfur copper concentrate, impurity-poor high-silicon and low-copper copper concentrate, copper-rich high-sulfur ore and slag c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com