Flotation machine middle box anti-ore-settling device and working method

A technology of intermediate box and flotation machine, applied in flotation, solid separation, etc., can solve the problems of frequent abnormal parking, fast settling speed of large particles, serious ore sinking in the middle box of flotation tank, etc. Mine, reduce the frequency of abnormal parking, and prevent the effect of sinking the middle box

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

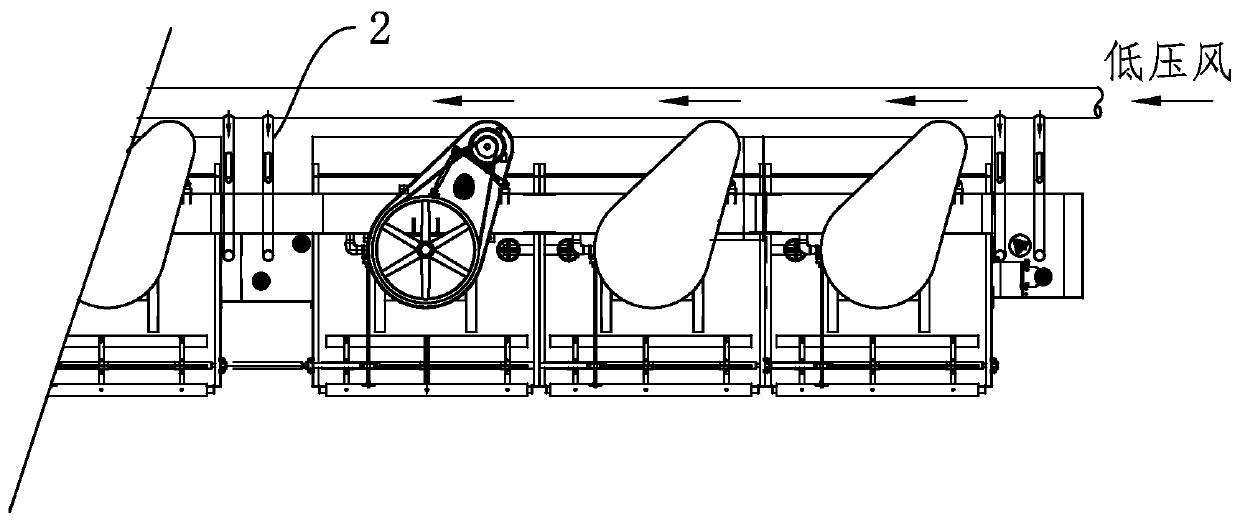

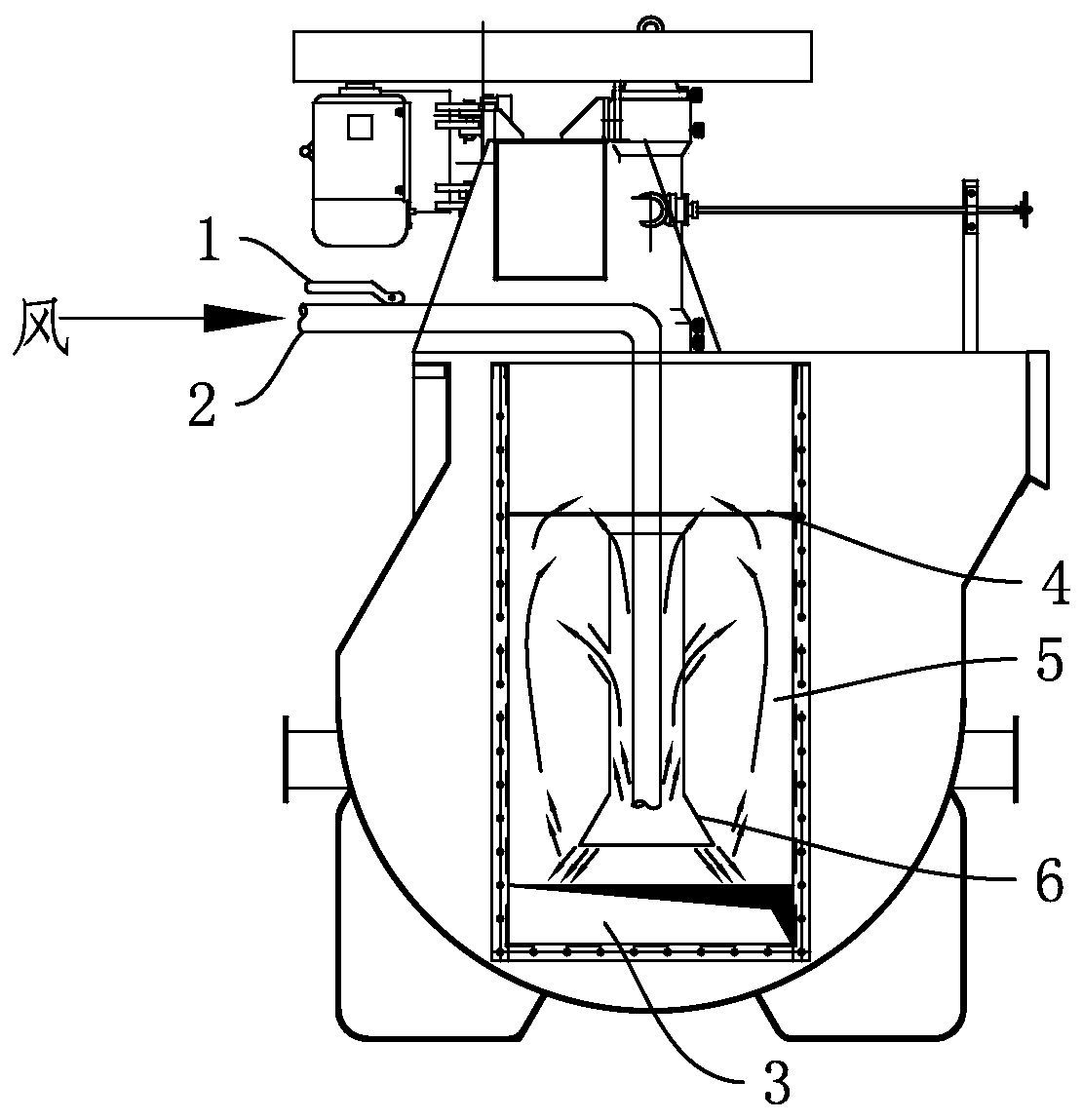

[0016] like Figure 1-2 As shown, a kind of anti-settling device for the middle box of a flotation machine has an air pipe 2 drawn from the main road of the air supply system, and the air pipe 2 is inserted into the middle box 5 of the flotation machine, and the air pipe 2 in the middle box 5 A flashboard 4 is arranged at the middle and upper part, and a circulation bucket 6 is arranged inside the middle box 5 , and the circulation bucket 6 is in the shape of an inverted funnel, and a coarse sand channel 3 is arranged at the bottom of the middle box 5 .

[0017] The air pipe 2 is inserted into the circulation barrel 6 through the shutter 4 . The air duct 2 is provided with a low pressure air switch 1 . The side wall of the circulation barrel 6 is provided with several air inlets with openings obliquely upward.

[0018] The working method of the anti-sedimentation device of the middle box of the flotation machine: firstly, the low-pressure air switch 1 is turned on, and the l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com