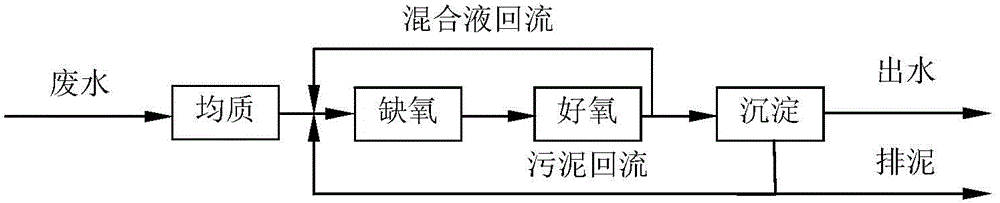

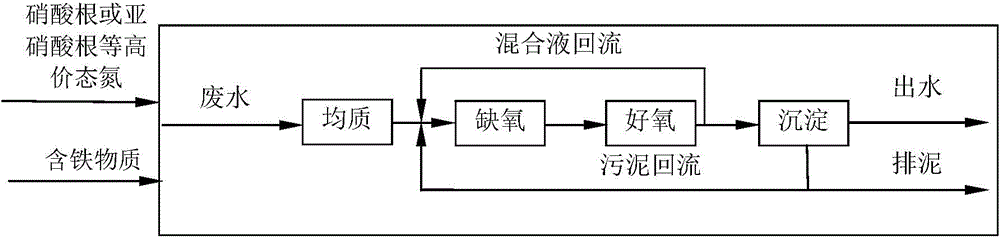

Method for rapidly starting denitrification-nitrification biochemical treatment system

A biochemical treatment and quick start-up technology, applied in the field of biochemical treatment, can solve the problems of low proportion of nitrifying bacteria, easy loss of nitrifying bacteria, slow system start-up, etc., and achieve the goal of increasing the effluent compliance rate, curbing the poor return of sludge and speeding up the start-up Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0096] The technical scheme of the present invention is used to treat about 20t / h of wastewater discharged from a cyclohexanone production device, about 80t / h of wastewater discharged from a coal gasification device, and about 200t / h of urban sewage, and the COD of wastewater discharged from a cyclohexanone production device is about 1500mg / L. COD of wastewater discharged from the coal gasification unit is about 1000mg / L, ammonia nitrogen is about 700mg / L, urban sewage COD is about 300mg / L, ammonia nitrogen is about 30mg / L; the total volume of facultative tank and aeration tank is 8000m 3 ; 3 strands of wastewater are mixed into the anoxic unit in the homogeneous tank, the COD of wastewater is 400-700mg / L, NH 3 -N is 100~250mg / L, B / C is 0.5~0.7; effluent requires COD≤60mg / L, NH 3 -N≤15mg / L; the seed sludge is the residual sludge of the municipal sewage treatment plant; the time to increase the flow rate of wastewater entering the structure of the homogeneous pool or to increas...

Embodiment 2

[0105] The technical scheme of the present invention is used to treat about 10L / d of wastewater discharged from a cyclohexanone production device, about 40L / d of wastewater discharged from a coal gasification device, about 5L / d of wastewater discharged from a rubber antioxidant RD production device, and about 100L / d of circulating cooling water wastewater. d. The COD of the wastewater discharged from the cyclohexanone production unit is about 1500mg / L, the COD of the wastewater discharged from the coal gasification unit is about 1000mg / L, the ammonia nitrogen is about 500-700mg / L, and the COD of the wastewater discharged from the rubber antioxidant RD production unit is about 9000~ 15000mg / L, the COD of circulating cooling water sewage is about 80mg / ; the total effective volume of the anoxic unit and the aerobic unit is 250L; the 4 strands of wastewater are mixed into the anoxic unit in the homogeneous tank, and the COD of the wastewater is 550-1000mg / L, NH 3 -N is 100~200mg / L,...

Embodiment 3

[0114] The technical scheme of the present invention is used to treat about 10L / d of wastewater discharged from coal gasification devices and about 100L / d of urban sewage, COD of wastewater discharged from coal gasification devices is about 1000mg / L, ammonia nitrogen is about 700mg / L, and urban sewage COD is about 300mg / L L, ammonia nitrogen is about 30mg / L; the total volume of the facultative tank and the aeration tank is 60L; the two streams of wastewater are mixed into the anoxic unit in the homogeneous tank, and the COD of the wastewater is 300-400mg / L, NH 3 -N is 60~120mg / L, B / C is 0.6~0.9; effluent requires COD≤60mg / L, NH 3 -N≤15mg / L; the seed sludge is the sludge from the digestion tank of the municipal sewage treatment plant; the time to increase the flow of wastewater entering the structure of the homogeneous pool or increase the type of wastewater entering the structure of the homogeneous pool is when the concentration of COD in the effluent of the sedimentation unit ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com