Pile forming operation method for bi-directional stirring piles

A technology of two-way mixing and operation method, which is applied in the direction of sheet pile wall, building, foundation structure engineering, etc., can solve the problems of low work efficiency, leakage of slurry, and affecting the quality of piles, so as to ensure the quality of the pile body, expand the application range, and ensure The effect of pile quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

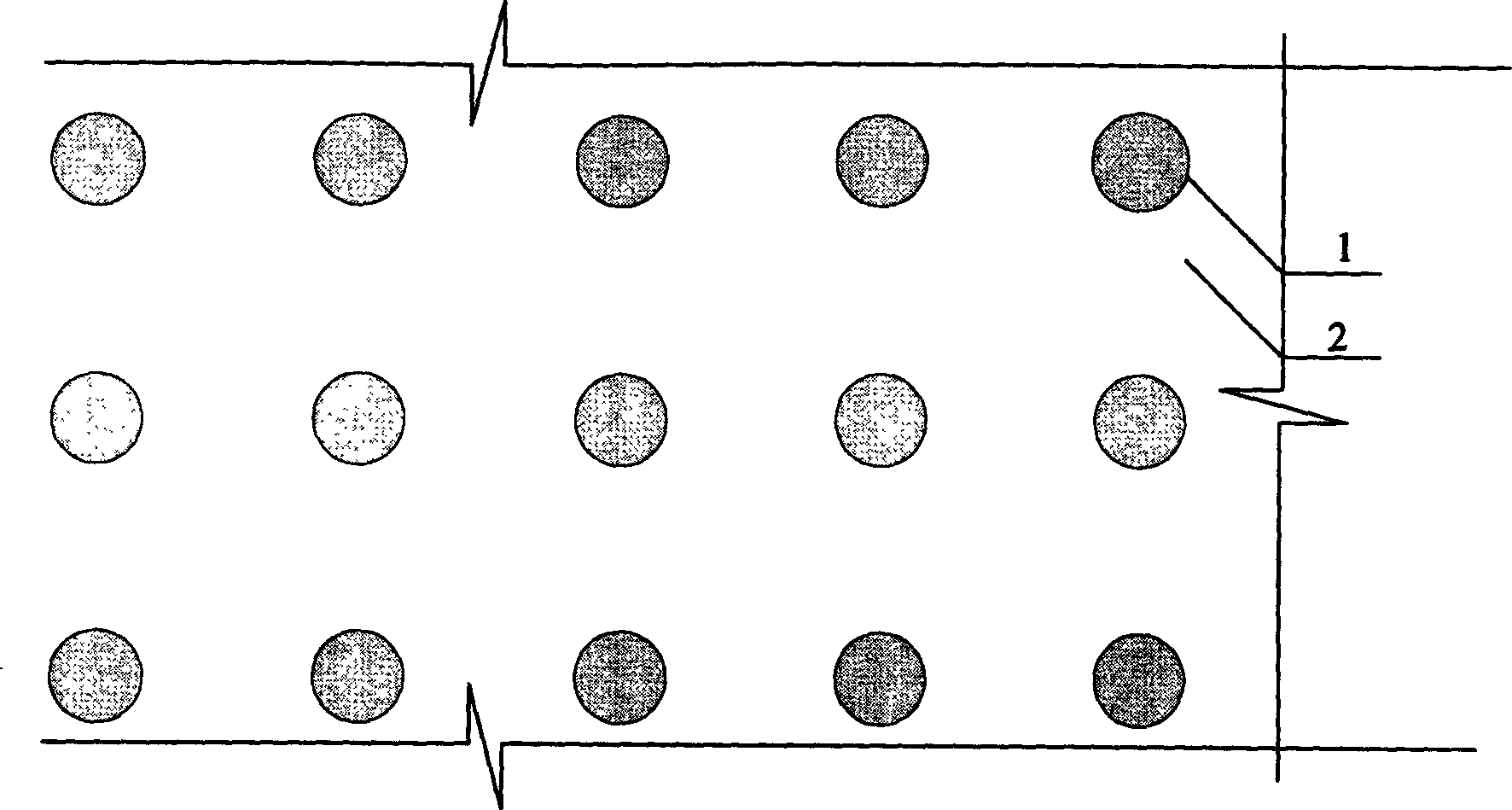

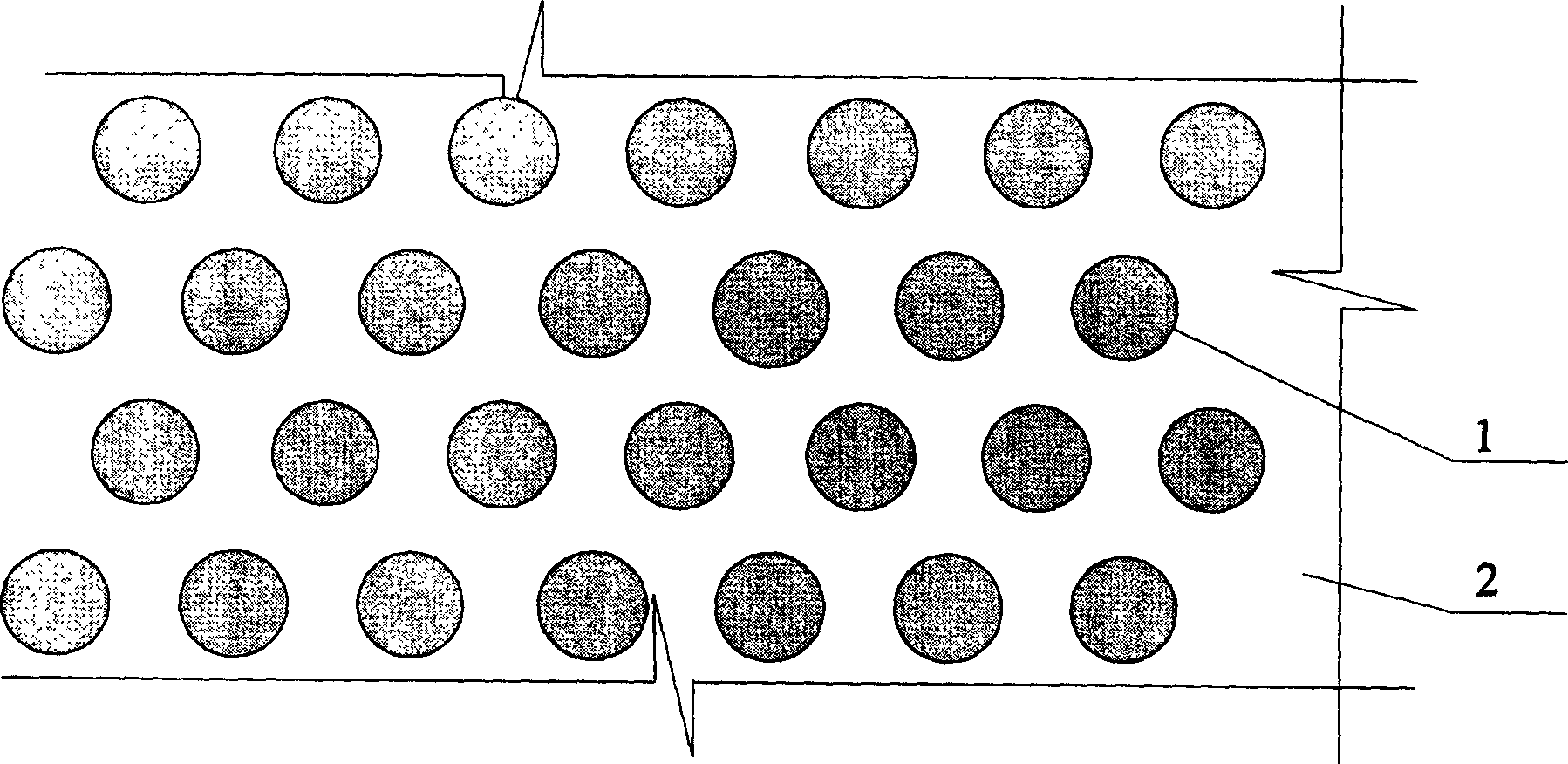

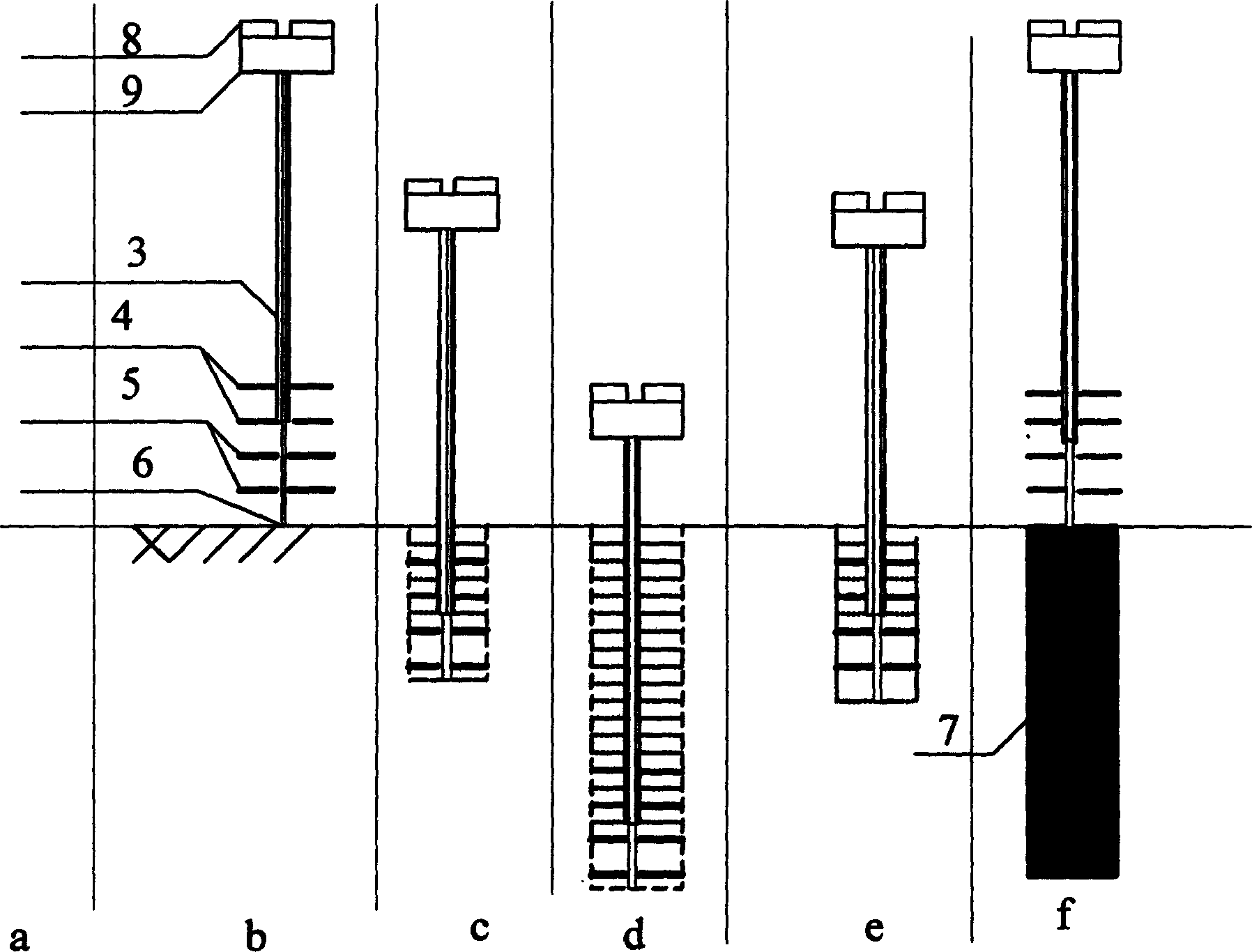

[0030] In the present invention, the drill pipes of the cement-soil mixing piles are designed as biaxial concentric drill pipes, forwardly rotating blades are installed on the inner drill pipes, and reversely rotating blades are installed on the outer drill pipes. Utilize the grouting effect of the forward and reverse rotation of the two sets of blades to control the cement slurry between the forward and reverse rotation of the two sets of blades, so that the cement slurry will not go up the drill pipe to the ground, and the cement slurry will not be lost. In this way, the mixing amount of cement slurry in the pile body and the uniform distribution of cement slurry in the pile body can be ensured; due to the forward and reverse rotation of the drill pipe, the two sets of blades are driven to rotate forward and reverse at the same time, so that the mixing of cement and soil is more sufficient and uniform .

[0031] The test site is located in a certain construction section. Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com